When it comes to building materials, two popular options often come up: LVL veneers and plywood. But how do they differ? Let’s dive in and explore the unique characteristics of these materials.

LVL stands for Laminated Veneer Lumber, while plywood is made by layering thin sheets of wood together. So, what sets them apart?

Firstly, LVL veneers are engineered wood products made by bonding thin layers of wood veneers together, resulting in a strong and durable material. On the other hand, plywood consists of multiple layers of wood glued together, making it versatile and cost-effective.

So, as we delve deeper into the world of construction materials, let’s uncover the fascinating differences between LVL veneers and plywood.”

When comparing LVL (Laminated Veneer Lumber) veneers and plywood, there are a few key distinctions to consider. LVL veneers are made from multiple layers of thin wood veneers, offering enhanced strength and durability. Plywood, on the other hand, is made from layers of wood veneers stacked together. LVL veneers are known for their uniformity and resistance to warping, making them ideal for construction projects. Plywood is more versatile and cost-effective, making it suitable for various applications. Overall, the choice between the two depends on your specific needs and project requirements.

How Do LVL Veneers Differ from Plywood?

In the world of construction and woodworking, there are various materials used to create sturdy structures and attractive finishes. Two commonly used materials are LVL (Laminated Veneer Lumber) veneers and plywood. While they may appear similar at first glance, there are some key differences between the two. In this article, we will delve into the specifics of LVL veneers and plywood, exploring their composition, properties, applications, and advantages.

The Composition and Structure of LVL Veneers

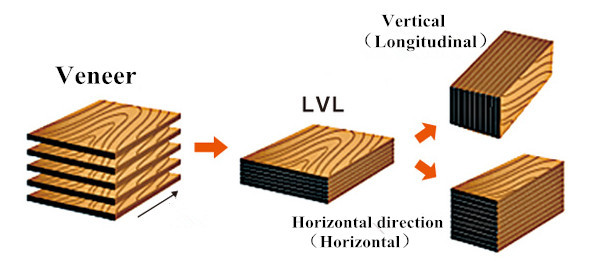

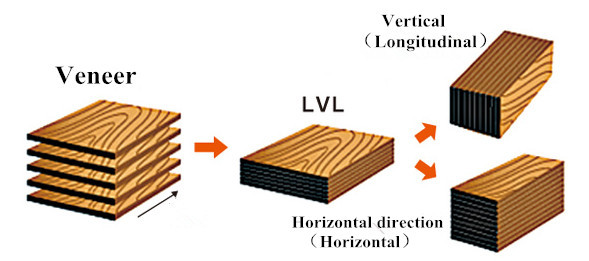

LVL veneers are constructed by bonding thin layers of wood veneers together with adhesives. These veneers are typically made from softwood species such as pine or fir. The layers are arranged in a parallel pattern, with the grain direction running in the same direction in each layer. This results in a strong and durable material.

The adhesive used in LVL veneers is usually a water-resistant resin, which enhances the material’s resistance to moisture and other environmental factors. LVL veneers are also treated with preservatives to protect against decay, rot, and insect infestation.

The thickness of LVL veneers can vary depending on the intended use. They are available in different sizes and can be specially ordered to meet specific project requirements.

The Applications of LVL Veneers

LVL veneers have a wide range of applications in the construction industry. Due to their strength and load-bearing capabilities, they are commonly used in structural elements such as beams, columns, and joists. LVL veneers are especially useful in applications that require long, continuous spans, as they can provide the necessary support.

Additionally, LVL veneers can be used in the manufacturing of doors, frames, and window components, thanks to their stability and resistance to warping or twisting. They are also used in the production of furniture, cabinets, and other interior finishes where a strong and durable material is required.

Furthermore, LVL veneers can be used for decorative purposes, such as cladding or paneling, adding a natural and textured appearance to surfaces.

The Composition and Structure of Plywood

Plywood, like LVL veneers, is composed of thin layers of wood veneers bonded together with adhesives. However, the key difference lies in the arrangement of these layers. In plywood, the grains of adjacent layers are rotated 90 degrees to each other, creating a cross-grain pattern.

This unique layering pattern gives plywood its strength and stability. The adhesive used in plywood can vary depending on the intended application, with phenolic or melamine-based adhesives being commonly used for exterior-grade plywood due to their resistance to moisture and weathering.

The Applications of Plywood

Plywood is a versatile material widely used in the construction and woodworking industries. It is commonly used for sheathing roofs, walls, and floors, providing a stable and uniform surface for other finishing materials to be applied.

Additionally, plywood is often used in the manufacturing of furniture, cabinets, and shelves, thanks to its strength and durability. The cross-grain pattern of plywood also makes it less susceptible to warping or splitting, making it an ideal choice for these applications.

Moreover, plywood is popular in DIY projects, as it is easier to work with compared to solid wood. It can be easily cut, shaped, and joined, making it a versatile material for various craft and construction endeavors.

The Benefits of LVL Veneers and Plywood

Both LVL veneers and plywood offer unique advantages that make them suitable for different applications. Here are some of the benefits of each material:

Benefits of LVL Veneers:

- High strength and load-bearing capacity

- Resistance to warping and twisting

- Durable and long-lasting

- Can be custom ordered for specific project requirements

- Provides excellent support for long spans in structural applications

Benefits of Plywood:

- Strong and stable due to cross-grain layering pattern

- Resistance to warping, splitting, and twisting

- Can be used for a wide range of applications

- Available in different grades, thicknesses, and sizes

- Easier to work with compared to solid wood

Conclusion:

When it comes to choosing between LVL veneers and plywood, it ultimately depends on the specific requirements of your project. Consider the structural needs, desired aesthetics, and budget constraints. LVL veneers are ideal for applications that require exceptional strength and load-bearing capacity, while plywood offers versatility and stability for a wide range of construction and woodworking projects. Take the time to evaluate your needs and consult with professionals to make the best choice for your project.

Key Takeaways: How do LVL Veneers Differ from Plywood?

- LVL veneers and plywood are both types of engineered wood products.

- LVL veneers are made by stacking thin layers of wood together and bonding them with adhesive.

- Plywood is made by gluing together several thin layers of wood veneers.

- LVL veneers are typically stronger and more dimensionally stable than plywood.

- Plywood is more readily available and often used in construction for its affordability.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about the differences between LVL veneers and plywood. Read on to learn more!

What are LVL veneers and plywood?

LVL (Laminated Veneer Lumber) veneers and plywood are both popular building materials used for various construction projects. LVL veneers are made by gluing together thin layers of wood veneers under high pressure, creating a strong and durable material. Plywood, on the other hand, is made by bonding multiple layers of thin wooden sheets together, with the grain alternating between each layer.

While both materials are made from wood veneers, they have some notable differences in terms of composition, strength, and usage.

How do LVL veneers differ from plywood?

One key difference between LVL veneers and plywood lies in their composition. LVL veneers are usually made from high-quality hardwood species, such as oak or Douglas fir, which are carefully selected to ensure strength and stability. Plywood, on the other hand, can be made from a variety of wood species, including softwoods like pine.

In terms of strength, LVL veneers have a higher structural capacity compared to plywood. The manufacturing process of LVL veneers aligns the grain of the wood layers, resulting in a material that is more resistant to bending and sagging. Plywood, on the other hand, has less structural integrity due to the alternating grain direction between layers.

Which material is more suitable for load-bearing applications?

When it comes to load-bearing applications, LVL veneers are generally considered to be the better choice. The construction of LVL veneers gives them a high load-carrying capacity, making them ideal for projects that require structural strength. Whether you’re building beams, trusses, or columns, LVL veneers can handle heavy loads and provide long-term stability.

Plywood, on the other hand, is better suited for non-structural applications or projects that don’t require significant load-bearing capabilities. It is commonly used for sheathing, flooring, and interior applications where strength is not the primary concern.

Which material offers better dimensional stability?

When it comes to dimensional stability, both LVL veneers and plywood have their advantages. LVL veneers are known for their exceptional dimensional stability, as the manufacturing process minimizes warping, twisting, and shrinking. This makes LVL veneers a reliable choice for applications where maintaining consistent dimensions over time is crucial.

On the other hand, plywood also offers decent dimensional stability, especially when properly sealed or treated. However, plywood may be more susceptible to warping or swelling if exposed to severe moisture or temperature fluctuations. As such, it’s important to consider the specific environmental conditions when choosing between LVL veneers and plywood for your project.

Which material is more cost-effective?

When it comes to cost-effectiveness, plywood tends to be the more budget-friendly option compared to LVL veneers. Plywood is widely available and produced in large quantities, making it more affordable for various construction projects. It offers a good combination of strength and versatility at a lower price point.

While LVL veneers may be more expensive than plywood, they offer enhanced structural capabilities and durability. If your project requires a high load-bearing capacity or if you need a material that can withstand heavy use, the added cost of LVL veneers may be justified by the long-term performance and stability they provide.

Summary

So, to sum it up: LVL veneers and plywood are both used in construction, but they have some differences. LVL veneers are stronger and more stable because they are made by gluing thin layers of wood together. Plywood, on the other hand, is made by gluing together multiple layers of wood veneers. Overall, LVL veneers are a great choice for projects that require strength and stability, while plywood is more versatile and commonly used in a variety of applications.