Do you ever wonder how things are made? Well, let’s take a closer look at planers and how they work. Planers are amazing machines that help smooth out rough surfaces and create precise thickness. So, if you’re curious to know how do planers work, you’ve come to the right place!

Imagine you have a piece of wood with uneven bumps and rough edges. A planer is like a superhero that comes to the rescue! It has a spinning cutter head with sharp blades that shave off a thin layer of wood as the piece moves through. This action helps to flatten the surface and make it smooth.

But wait, there’s more to it! Planers also have adjustable tables that allow you to control the thickness of the wood. These tables can be lowered or raised, determining the amount of wood removed with each pass. So whether you need a thin board for a cabinet door or a chunky plank for a workbench, the planer has got you covered.

So there you have it, a brief introduction to how planers work. They may seem like magic, but they’re actually intricate machines that bring precision and smoothness to woodworking projects. Now that you have a taste of what planers are all about, let’s dive deeper into how they work their magic!

How Do Planers Work? Exploring the Mechanics Behind Woodworking’s Essential Tool

Welcome to the world of woodworking! If you’re new to this craft, you may find yourself intrigued by the assortment of tools available to help you shape and smooth your creations. One tool that stands out is the planer. In this article, we’ll take a deep dive into the inner workings of planers and explore how they transform rough lumber into perfectly flat and smooth boards.

The Anatomy of a Planer: Breaking Down the Components

Before we delve into the actual process, let’s familiarize ourselves with the key components of a planer. Typically, a planer consists of the following parts:

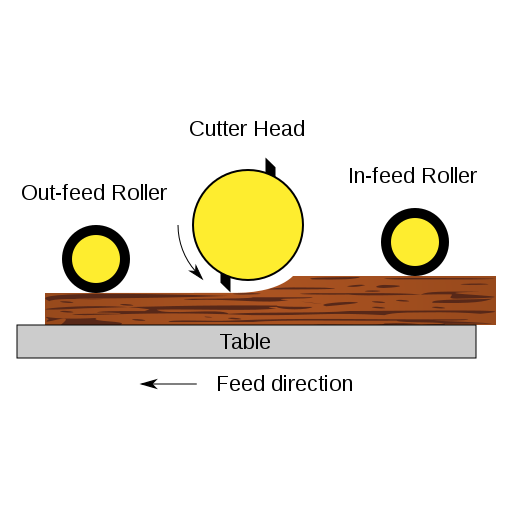

- Infeed Table: This is where you slide your rough lumber into the planer for processing.

- Cutterhead: The heart of a planer, the cutterhead houses multiple cutting blades or knives that remove material from the surface of the wood.

- Feed Rollers: These rubber or metal rollers help propel the wood through the planer at a consistent speed, ensuring an even cut.

- Outfeed Table: Once the wood has been processed by the cutterhead, it exits the planer onto the outfeed table.

- Dust Collection System: Woodworking can produce a lot of dust, so most planers come equipped with a dust collection system to keep your workspace clean.

Now that we have a basic understanding of the planer’s structure, let’s dive into how it actually works!

The Planer in Action: Step-by-Step Process

In order to make rough lumber smooth and flat, a planer goes through several key steps:

Step 1: Setting the Depth of Cut

Before feeding your wood into the planer, you need to determine the desired thickness. This is done by adjusting the depth of cut on the planer. By setting the depth of cut, you determine how much material the cutterhead will remove with each pass.

It’s important to note that planers have a minimum and maximum depth of cut, so be sure to check your planer’s specifications and set the depth accordingly.

Step 2: Feeding the Wood

With the depth of cut set, it’s time to feed your wood into the planer. Start with the infeed table and carefully slide your piece of lumber between the feed rollers. Make sure the wood is flat against the infeed table to ensure an even result.

It’s crucial to maintain a steady and consistent feed rate to ensure a smooth finish. Pushing the wood too quickly can lead to tear-out and an uneven surface, while feeding it too slowly can cause burn marks or snipe (a slight depression at the beginning or end of the board).

Step 3: Material Removal

As the wood passes through the planer, the cutterhead spins rapidly, removing material from the top surface of the board. The cutting knives on the cutterhead slice away small shavings, leaving behind a smoother, more even surface.

Most planers are equipped with a system that allows you to adjust the speed of the cutterhead, giving you more control over the final result. Fine-tuning the speed can help minimize tear-out and achieve a flawless finish.

Step 4: Exiting the Planer

Once the wood has been processed by the cutterhead, it continues to move forward and exits the planer onto the outfeed table. At this point, it should be noticeably smoother and flatter compared to its initial rough state.

Remember to support the wood as it exits the planer to prevent any snipe or damage to the finished surface.

The Benefits of Using a Planer

Now that you have a better understanding of how planers work, let’s explore some of the benefits they offer:

- Efficient Material Removal: Planers can quickly and easily remove material from the surface of the wood, saving you time and effort.

- Consistent Thickness: By setting the depth of cut, you can ensure that all your boards are the same thickness, making them easier to work with during assembly.

- Smooth Finish: Planers leave behind a smooth and even surface, eliminating the need for extensive sanding.

- Enhanced Control: Many planers allow you to adjust various settings, giving you greater control over the final result.

Tips for Using a Planer Safely and Effectively

Now that you’re well-acquainted with the mechanisms behind planers, let’s discuss some tips to ensure safe and effective usage:

Tip 1: Wear Proper Safety Gear

Wear safety glasses, hearing protection, and a dust mask to protect yourself from flying debris and excessive noise and dust.

Tip 2: Use a Push Stick

When your wood becomes too thin to safely guide through the planer manually, use a push stick to keep your hands safely away from the cutterhead.

Tip 3: Take Light Passes

It’s best to take light passes instead of trying to remove too much material at once. This helps prevent tear-out and ensures a smoother finish.

Tip 4: Check for Snipe

Inspect your boards for snipe, especially at the beginning and end of each piece. Adjusting the infeed and outfeed tables can help minimize snipe.

Tip 5: Clean Regularly

Regularly clean your planer, removing debris and dust buildup. This helps maintain its performance and extends its lifespan.

Choosing the Right Planer for Your Needs

When it comes to planers, there are various types and sizes available, each catering to different woodworking tasks. Here are a few options to consider:

Portable Planers

If you’re a hobbyist or have limited space, portable planers are a great choice. They are lightweight, easy to transport, and can handle smaller projects.

Benchtop Planers

Benchtop planers are larger and more powerful than portable ones. They are designed to be mounted on a workbench and can handle larger boards and more demanding woodworking tasks.

Thickness Planers

If your focus is on achieving consistent thickness across your boards, a thickness planer is the way to go. These machines excel at removing material from one side of the wood to achieve a uniform thickness.

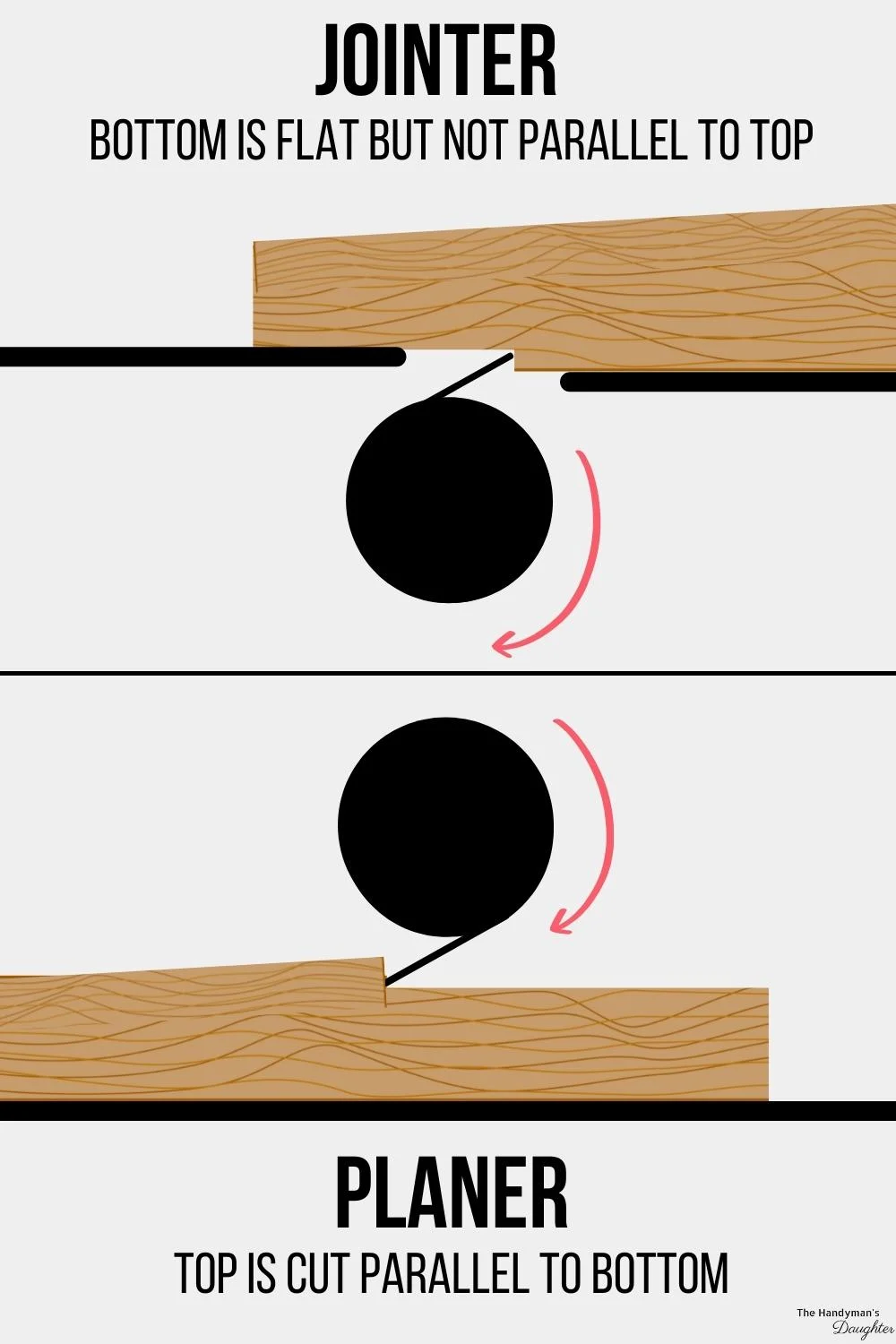

Joint Planers

Joint planers are specifically designed to flatten one face of a board and create a straight edge. They are commonly used in conjunction with thickness planers to produce flat and square boards for joinery work.

When selecting a planer, consider factors such as the size of your projects, the type of wood you work with, and your budget. This will help you choose the right planer to meet your specific needs.

Mastering the Planer: Practice Makes Perfect

As with any woodworking tool, mastering the planer takes practice and patience. Experiment with different settings and techniques to achieve the desired results. Before long, you’ll be transforming rough lumber into beautifully finished boards that are ready for your next woodworking project!

Key Takeaways: How Do Planers Work?

- A planer is a powerful woodworking tool used to smoothen and level wooden boards or planks.

- It works by having a rotating cutterhead fitted with blades that remove thin layers of wood with each pass.

- Planers have adjustable tables and depth settings to control the amount of wood being removed.

- The boards are fed through the planer using rollers or other feeding mechanisms.

- Planers can be used to remove imperfections, create uniform thickness, and prepare wood for various woodworking projects.

Frequently Asked Questions

Welcome to the Frequently Asked Questions section where we’ll answer all your queries about how planers work!

1. How can planers create smooth surfaces on wood?

Planers are equipped with a set of rotating blades that spin at high speeds. As you pass a piece of wood through a planer, the blades remove thin layers of material, resulting in a smoother surface. This process is known as “cutting” or “planing.” By repeating the pass several times, the planer gradually shaves off imperfections and leaves behind a polished, even surface.

Additionally, planers often have an adjustable height feature, allowing you to control the depth of cut. By adjusting this setting, you can determine the thickness of the material being removed, which helps achieve the desired smoothness.

2. What are the different types of planers available in the market?

There are several types of planers available, each with its own unique features and functionalities. Some common planer types are:

– Handheld Planers: These portable planers are perfect for smaller projects and offer more control over the planing process.

– Benchtop Planers: These larger planers rest on a workbench and are ideal for medium to large woodworking projects.

– Thickness Planers: Also known as “surface planers,” these specialized tools focus on removing material to achieve a consistent thickness across the entire piece of wood.

– Jointer Planers: These versatile machines combine the functionality of a jointer and a planer to flatten both faces and square the edges of a piece of wood.

3. Are planers suitable for both hard and softwoods?

Yes, planers are designed to work with both hard and softwoods. The rotating blades in a planer are typically made of high-speed steel, which can easily handle the density of hard or softwood materials. However, it’s important to note that dense hardwoods might require slower feed rates to prevent tear-out and ensure a smooth finish.

Before using a planer on a specific type of wood, it’s always a good idea to check the manufacturer’s recommendations regarding feed rates and blade sharpening to optimize the performance and achieve the best results.

4. Can planers be used to flatten warped or twisted boards?

Absolutely! Planers can be incredibly useful for flattening warped or twisted boards. By repeatedly feeding the board through the planer, a small amount of material is removed with each pass. This process gradually reduces the warping or twisting until the board becomes flatter and more usable. However, it’s important to note that severe warping may require additional techniques, such as jointing, to achieve the desired flatness.

It’s also worth mentioning that when flattening boards, it’s important to alternate the grain orientation during each pass to prevent tear-out and ensure an even surface. Taking light passes and making adjustments to the planer depth can help achieve the best results.

5. What safety precautions should be taken when using a planer?

When using a planer, it’s crucial to prioritize safety. Here are some important precautions to keep in mind:

– Always wear safety goggles to protect your eyes from flying wood chips and debris.

– Use a push block or push stick to guide the wood through the planer, keeping your hands safe from the blades.

– Make sure the planer is properly secured or clamped to prevent any movement or instability during operation.

– Never remove dust or debris from the planer while it’s running. Always turn off the machine and unplug it before performing any maintenance or cleaning.

– Read and follow the manufacturer’s instructions and guidelines for safe operation and maintenance of the planer.

Summary

Planers are tools that smooth and shape wood by removing thin layers from its surface. They have a rotating cutterhead with blades that cut away wood as it is fed through the machine. The feed rollers hold the wood securely in place and move it through the planer. By adjusting the depth of cut and feed speed, planers can create different thicknesses and smooth finishes on wood.

Planers have different types based on their size and purpose. Benchtop planers are small and portable, suitable for hobbyists and small woodworking projects. Thickness planers are larger and more powerful, capable of handling thicker and wider boards. Jointer planers combine the functions of both a planer and a jointer, allowing for precise edge jointing and thickness planing.

In conclusion, planers are versatile tools that help shape and smooth wood for various woodworking projects. Understanding how they work, their types, and their capabilities can aid in selecting the right planer for the job at hand. So, next time you see a planer in action, you’ll know how it’s turning rough wood into a beautifully finished piece!