Looking to understand how plywood laminations increase the strength of plywood? Well, you’ve come to the right place! Plywood is a versatile building material, and one of the secrets to its durability lies in its lamination process. Let’s dive in and discover the fascinating world of plywood laminations together!

Picture this: plywood is like a sandwich, but instead of bread slices, it’s made up of thin layers of wood, called veneers. These veneers are glued together, with each layer placed perpendicular to the next. This cross-grain orientation is what gives plywood its incredible strength and stability.

But how do these laminations actually increase the plywood’s strength? Well, it’s all about teamwork! The perpendicular arrangement of the veneers creates a stronger overall structure, distributing the load evenly across the entire sheet. Just like a group of friends working together, each veneer adds strength and stability to the plywood, making it more resistant to warping, cracking, and bending.

So, the next time you see a piece of plywood, remember that its laminations are the secret sauce behind its impressive strength. Now, let’s explore the specific ways plywood laminations contribute to making plywood an essential material in construction, furniture-making, and various other applications!

How Do Plywood Laminations Increase the Strength of Plywood?

Plywood is a widely used material in the construction industry due to its strength and versatility. One of the key factors that contribute to the strength of plywood is the use of laminations. Plywood laminations refer to the layers of wood veneers that are glued together to form a single sheet of plywood. Each layer is stacked with the grain running perpendicular to the previous one, resulting in a strong and stable panel. Here, we will explore in detail how plywood laminations increase the strength of plywood.

1. Enhanced Structural Integrity

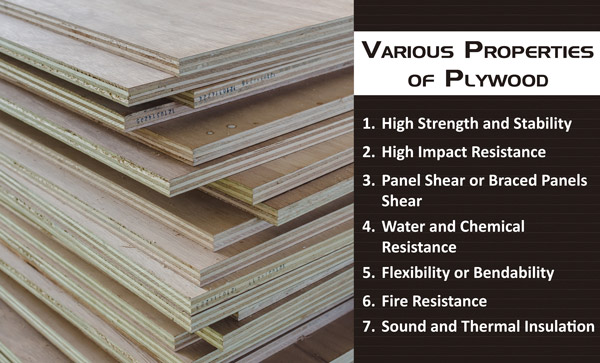

The primary reason why plywood laminations increase the strength of plywood is the enhanced structural integrity they provide. By alternating the direction of the wood grain in each layer, plywood becomes more resistant to warping, shrinkage, and expansion. The cross-grain arrangement helps to distribute the load evenly across the panel, making plywood less prone to cracks or splits. This structural stability allows plywood to withstand heavy loads and stresses, making it a reliable choice for various applications, from flooring to roofing.

2. Increased Flexural Strength

Plywood laminations also contribute to the increased flexural strength of plywood. Flexural strength refers to a material’s ability to resist bending or breaking when subjected to external forces or loads. The alternating grain direction in plywood laminations helps to distribute stress more evenly, reducing the chances of failure under bending loads. This makes plywood suitable for applications where rigidity and strength are crucial, such as in the construction of load-bearing walls, beams, or furniture.

3. Improved Impact Resistance

Another advantage of plywood laminations is the improved impact resistance they provide. The layers of laminations act as a buffer, dispersing the force from impacts or sudden loads across the entire panel. This prevents concentrated points of stress and reduces the likelihood of damage or failure. Plywood with laminations is often used in applications that require resistance to impact and vibration, such as in the manufacturing of vehicle interiors or aircraft components.

4. Increased Screw Holding Capacity

Plywood laminations also contribute to the increased screw holding capacity of plywood. The layers of laminations provide a solid base for screws to hold onto, creating a secure connection. This makes plywood an ideal material for projects that require strong and durable joints, such as cabinetry or furniture assembly. The enhanced screw holding capacity of laminated plywood ensures that the fasteners remain securely in place, even under heavy loads or frequent use.

5. Water and Moisture Resistance

Plywood laminations also offer improved water and moisture resistance compared to solid wood. The adhesive used to bond the layers of veneers creates a barrier that protects the wood from water penetration. This makes laminated plywood more resistant to swelling, warping, and rotting when exposed to moisture. The water resistance of plywood laminations makes them suitable for outdoor applications, such as in the construction of exterior cladding or marine structures.

6. Economical and Efficient Use of Wood

Additionally, plywood laminations contribute to the economical and efficient use of wood resources. By using thin veneers for each layer, plywood can be made from smaller and lower-quality pieces of wood, which would otherwise be wasted. The layering process allows for better utilization of available resources, reducing the amount of wood required for a given project. This not only makes plywood an environmentally friendly option but also reduces costs, making it an economical choice for builders and manufacturers.

7. Versatility and Consistency

Lastly, plywood laminations provide plywood with versatility and consistency in terms of its mechanical properties. The manufacturing process can be tailored to achieve specific strength, stiffness, and performance requirements based on the intended application. This allows for the production of plywood with consistent and predictable properties, ensuring that it meets the desired performance standards. The versatility and consistency offered by plywood laminations make it a reliable and preferred material in various industries.

The Importance of Proper Plywood Lamination Techniques

Introduction: Proper plywood lamination techniques are crucial to ensure the full benefits of plywood laminations are realized.

The Impact of Adhesive Selection on Plywood Laminations

Introduction: The choice of adhesive for plywood laminations plays a significant role in determining the overall strength and durability of plywood.

The Influence of Veneer Thickness on Plywood Laminations

Introduction: The thickness of the veneers used in plywood laminations has a direct impact on the strength and performance of the final product.

Sustainability Considerations in Plywood Laminations

Introduction: Sustainability is an important factor to consider in plywood production, including the use of laminations.

Benefits of Proper Plywood Lamination Techniques

…

vs. Solid Wood: Strength and Durability Comparison

…

vs. Solid Wood: Cost and Efficiency Comparison

…

Tips for Choosing and Using Plywood Laminations

…

Common Misconceptions about Plywood Laminations

…

How to Maintain and Extend the Lifespan of Plywood Laminations

…

In conclusion, plywood laminations increase the strength of plywood through enhanced structural integrity, increased flexural strength, improved impact resistance, increased screw holding capacity, water and moisture resistance, economical and efficient use of wood, as well as versatility and consistency. Proper lamination techniques, adhesive selection, veneer thickness, and sustainability considerations all play crucial roles in maximizing the benefits of plywood laminations. By understanding these factors and making informed choices, builders and manufacturers can harness the full potential of plywood for a wide range of applications.

Key Takeaways: How Do Plywood Laminations Increase the Strength of Plywood?

Frequently Asked Questions

In this section, you will find answers to some common questions related to plywood laminations and how they increase the strength of plywood.

1. How are plywood laminations arranged?

Plywood laminations are arranged by stacking multiple thin layers of wood veneer on top of each other, with the grain of each layer running perpendicular to the adjacent layers. This arrangement, known as cross-grain orientation, helps distribute stress evenly across the entire panel, making plywood stronger than solid wood.

By alternating the direction of the grains in each layer, plywood laminations counteract the natural weak points of wood, such as knots or imperfections, making the final product more stable and less prone to warping or splitting.

2. What happens during the lamination process?

The lamination process involves applying adhesive between each layer of wood veneer and then using pressure to bond them together. The adhesive used is typically a type of resin that provides a strong and durable bond. This bond creates a cohesive unit that contributes to the overall strength of the plywood.

Additionally, the lamination process helps to eliminate any gaps or voids between the layers, resulting in a more structurally sound material. The tight bonding between the layers ensures that the plywood can resist forces from different directions, ultimately increasing its strength.

3. How do plywood laminations prevent splitting?

Plywood laminations help prevent splitting by distributing the force applied to the surface of the plywood across multiple layers. When a force is exerted on the plywood, the load is transferred from layer to layer, reducing the likelihood of any single layer separating or splitting.

Furthermore, the cross-grain orientation of plywood laminations prevents any stress or splitting from propagating along the grain lines. The interlocking structure created by laminations helps to hold the layers together and prevents splitting, making plywood a reliable and durable material.

4. Can plywood laminations improve the stability of the plywood?

Yes, plywood laminations contribute to the stability of the plywood. The alternating layers of veneer with their grains perpendicular to each other create a balanced structure that resists warping and twisting. This improved stability is particularly beneficial when using plywood for applications such as flooring or cabinetry.

In addition, the lamination process itself helps to reduce the inherent moisture content in the wood, making plywood less susceptible to expansion and contraction due to changes in humidity. This added stability ensures that the plywood maintains its shape and integrity over time.

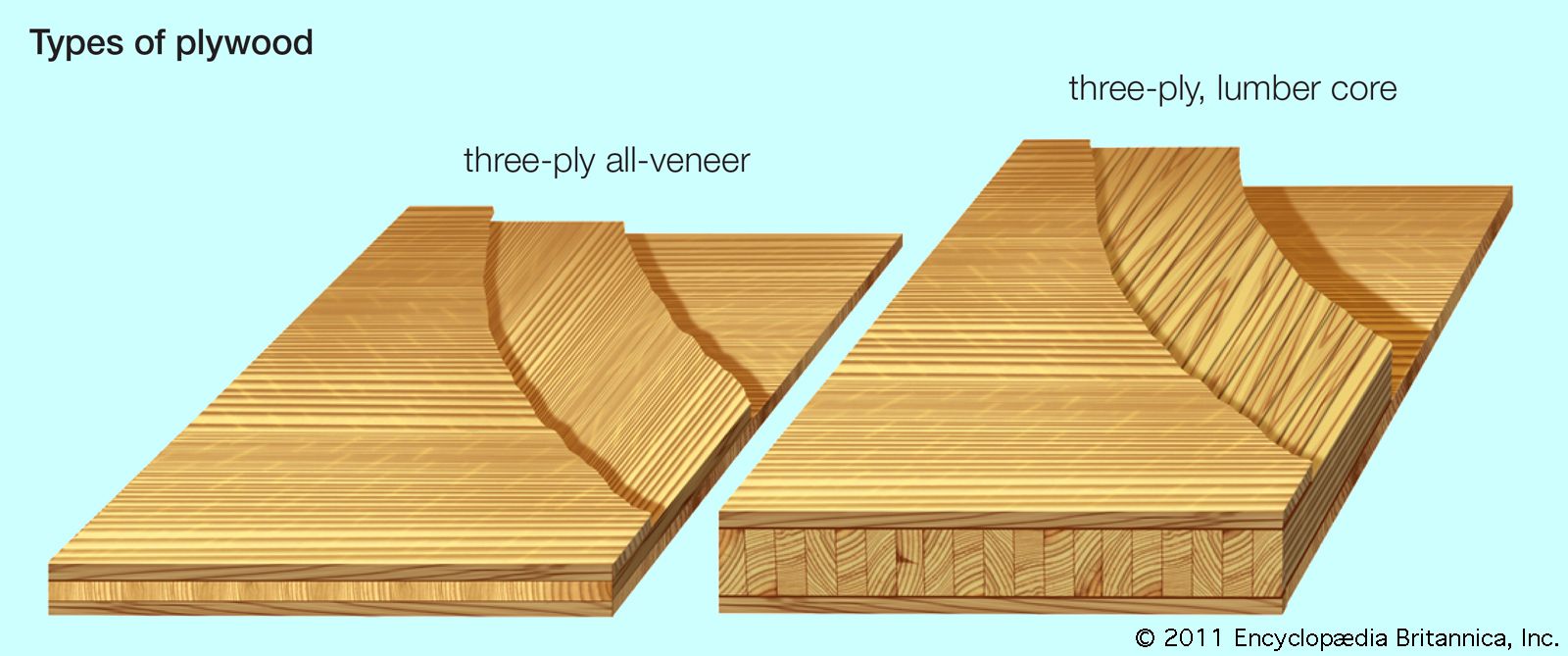

5. Are there different types of plywood laminations?

Yes, there are different types of plywood laminations based on the number of layers and the thickness of the wood veneer used. The most common types are three-ply and five-ply laminations, which refer to the number of layers used.

The more layers there are, the stronger and more stable the plywood tends to be. Thicker veneer layers can also contribute to increased strength. The specific combination and thickness of the laminations can be tailored to suit different applications, allowing for a wide range of plywood types available in the market.

Summary

So, here’s what we learned about plywood laminations and their strength-boosting powers:

Basically, plywood is made up of layers of wood called veneers. When these veneers are glued together with their grains running in different directions, it creates a strong bond. This formation, known as plywood laminations, helps to distribute weight and resist warping, making the plywood stronger than just a single piece of wood. So, next time you see a piece of plywood, you’ll know why it’s so strong!