Have you ever wondered how do tool box locks work? Well, let me satisfy your curiosity. You see, tool box locks are essential for keeping your tools safe and secure.

Here’s the deal:

Tool box locks function by employing a mechanism that prevents unauthorized access. When you turn the key or enter a combination, the lock engages a series of pins or tumblers inside the lock cylinder.

So, let’s dive deeper into the mechanics of it, shall we?

When you turn the key, it aligns the pins at just the right height, allowing the lock cylinder to rotate and granting you access to the tool box. It’s like a puzzle that only the right key or combination can solve.

Now that you have a basic understanding of how tool box locks work, you’ll appreciate the peace of mind they provide when it comes to safeguarding your valuable tools. So, let’s unlock the mysteries of tool box locks together!

How Do Tool Box Locks Work?

Tool box locks are an essential feature for anyone who wants to keep their tools and equipment safe and secure. These locks provide peace of mind by preventing unauthorized access to your tool box. But have you ever wondered how these locks actually work? In this article, we will delve into the details of tool box locks, exploring their mechanisms, types, and how to choose the right one for your needs.

Types of Tool Box Locks

When it comes to tool box locks, there are several types to choose from. Let’s take a closer look at some of the most common options:

Keyed Locks

Keyed locks are the traditional type of lock that require a physical key to open. These locks use a series of internal pins that align when the correct key is inserted. When the pins align, the lock can be turned and the tool box can be opened. Keyed locks provide a high level of security, as the key needs to match the specific lock in order to gain access.

However, one downside of keyed locks is the risk of losing the key or forgetting it somewhere. In such cases, it can be difficult or even impossible to open the tool box without the key. Additionally, if you share your tool box with others, you may need to provide them with a copy of the key or be present to unlock it for them.

To enhance the security of keyed locks, some manufacturers offer options with unique key codes or pick-resistant mechanisms.

Combination Locks

If you prefer not to deal with keys, combination locks could be the ideal choice for your tool box. Combination locks feature a dial or a keypad that allows you to set a unique combination of numbers or letters. To open the lock, you simply need to input the correct combination.

One of the advantages of combination locks is that you don’t have to worry about losing a key. You also don’t need to carry a key around or remember the code if you opt for a memorable combination. Combination locks are also popular for their ease of use and quick access.

However, it’s important to note that the security level of combination locks can vary. Some lower-quality models may be susceptible to cracking or guessing the combination. To ensure maximum security, choose a high-quality combination lock from a reputable brand.

Electronic Locks

For those who want the latest in lock technology, electronic locks provide a convenient and secure solution. These locks often come with a keypad or a digital display for inputting a code. Some advanced models even offer additional features like biometric fingerprint scanning.

Electronic locks are highly secure, as they typically require a correct code or fingerprint to gain access. They offer ease of use, as you can easily change the code whenever needed, and there’s no risk of losing a physical key. Some electronic locks also have options for remote control or smartphone integration, adding an extra layer of convenience.

However, it’s important to keep in mind that electronic locks may rely on batteries for power, so it’s crucial to ensure they are always charged or have a backup power source. Additionally, some electronic locks can be more expensive than other types, but the added features and convenience may justify the investment.

Choosing the Right Tool Box Lock

When selecting a tool box lock, there are a few key factors to consider:

Security Level

Consider the level of security you require for your tools. If you have valuable or sensitive equipment, investing in a high-security lock is crucial. Look for features like pick-resistance, unique key codes, or advanced biometric technology.

Convenience

Think about how frequently you need to access your tools and how quickly you need to do so. Combination locks and electronic locks offer quick and easy access, while keyed locks can be more time-consuming.

Durability

Choose a lock that is built to withstand the demands of your work environment. Look for locks made from durable materials that can resist corrosion, impact, and harsh weather conditions.

Budget

Consider your budget when selecting a lock. Keyed locks are generally more affordable, while electronic locks tend to be the most expensive. Find the balance between cost and the level of security and convenience you require.

Additional Features

Some locks may offer extra features such as anti-drill plates, tamper-resistant designs, or alarm systems. Assess these additional features and determine if they are necessary for your specific needs.

Maintaining and Troubleshooting Tool Box Locks

Once you have chosen and installed your tool box lock, it’s important to properly maintain it to ensure optimal functionality and longevity. Here are a few maintenance tips to keep in mind:

Regular Lubrication

To prevent rust or sticking, lubricate your lock periodically using a silicone-based or graphite lubricant. Avoid using oil-based lubricants, as they can attract dirt and debris.

Keep Them Clean

Regularly clean the lock mechanism and keyhole area. Use compressed air or a cotton swab to remove any dirt or debris that may have accumulated over time.

Inspect and Repair

Regularly inspect your lock for any signs of wear or damage. If you notice any issues, such as difficulty turning the key or a loose mechanism, consider repairing or replacing the lock to maintain optimal security.

In conclusion, tool box locks are vital for keeping your tools and equipment secure. Whether you opt for a keyed lock, combination lock, or electronic lock, understanding how they work and choosing the right one for your needs is essential. Consider security levels, convenience, durability, and budget when making your selection. Proper maintenance will ensure the longevity and functionality of your lock. With a well-chosen and well-maintained lock, you can have peace of mind knowing that your tools are protected.

Key Takeaways: How Do Tool Box Locks Work?

- Tool box locks secure your tools and prevent unauthorized access.

- Most tool box locks use a key or combination to unlock.

- Some locks require a specific key shape or code for added security.

- Tool box locks often use tumblers or pins that align to open the lock.

- Keyed-alike locks allow multiple tool boxes to be opened with the same key.

Frequently Asked Questions

Curious about how tool box locks work? Explore these common questions:

1. How do tool box locks prevent unauthorized access?

Tool box locks are designed to secure the contents of your toolbox, preventing unauthorized access. These locks typically use a combination of mechanical components, including pins and tumblers or disc detainers, which align when the correct key is inserted. When the key is turned, it moves the locking mechanism into place, securing the lock tightly.

Furthermore, some tool box locks have additional security features, such as anti-drill plates and anti-pick pins. These extra layers of protection make it even more challenging for potential thieves to break into the toolbox. With these mechanisms in place, tool box locks ensure that only individuals with the correct key or combination can access the contents.

2. Can tool box locks be easily picked or bypassed?

While no lock is completely impervious to picking or bypassing, quality tool box locks are designed with security in mind. The complexity of their internal mechanisms and the use of anti-pick pins make them significantly more resistant to picking attempts.

However, it’s important to note that the level of resistance will vary depending on the specific lock. High-quality locks with more complex mechanisms provide greater security. Additionally, using secondary security measures, such as alarm systems or video surveillance, can further deter potential thieves and increase the overall security of your toolbox.

3. Are tool box locks vulnerable to drilling?

Tool box locks that incorporate anti-drill plates are specifically designed to resist drilling attempts. These plates are made of hardened steel and are strategically placed at vulnerable areas of the lock. When a potential thief attempts to drill into the lock, the hardened steel plate resists the drill bit, preventing it from penetrating further.

While it’s true that extremely determined and well-equipped individuals may still be able to drill through some locks, adding an extra layer of protection through the use of anti-drill plates significantly increases the time and effort required to gain entry, ultimately discouraging unauthorized access.

4. Can I rekey my tool box lock if I lose the keys?

Depending on the type of lock, it may be possible to have your tool box lock rekeyed if you’ve lost the keys. Some locks have removable cores or cylinders that can be easily replaced with a new one. In this case, you can contact a locksmith or the manufacturer of the lock to obtain a replacement core or cylinder and have it rekeyed to match your existing keys or a new set.

However, it’s important to note that not all tool box locks can be easily rekeyed. Some locks have fixed cores or cylinders, making rekeying a more complex process. In such cases, you may need to replace the entire lock. It’s always recommended to consult with a professional locksmith to determine the best course of action for your specific lock.

5. How can I maintain the longevity of my tool box lock?

Regular maintenance is key to ensuring the longevity of your tool box lock. Here are a few tips:

First, keep your lock mechanism clean and free of debris by regularly blowing it out with compressed air. This helps prevent any particles from interfering with the functionality of the lock. Secondly, lubricate the lock periodically with a graphite-based lubricant to ensure smooth operation and minimize wear on the internal components. Finally, avoid exposing the lock to excessive moisture or extreme temperatures, as these factors can impact its performance over time. By following these maintenance practices, you can extend the lifespan of your tool box lock and ensure reliable operation.

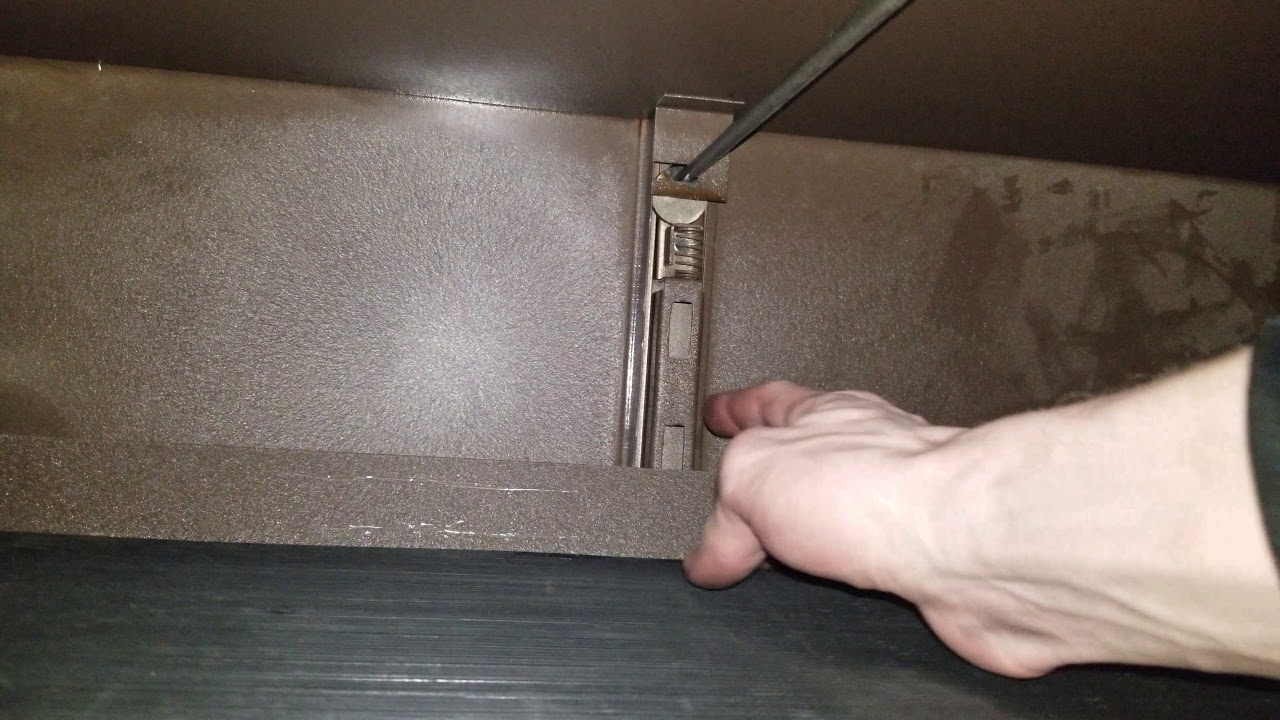

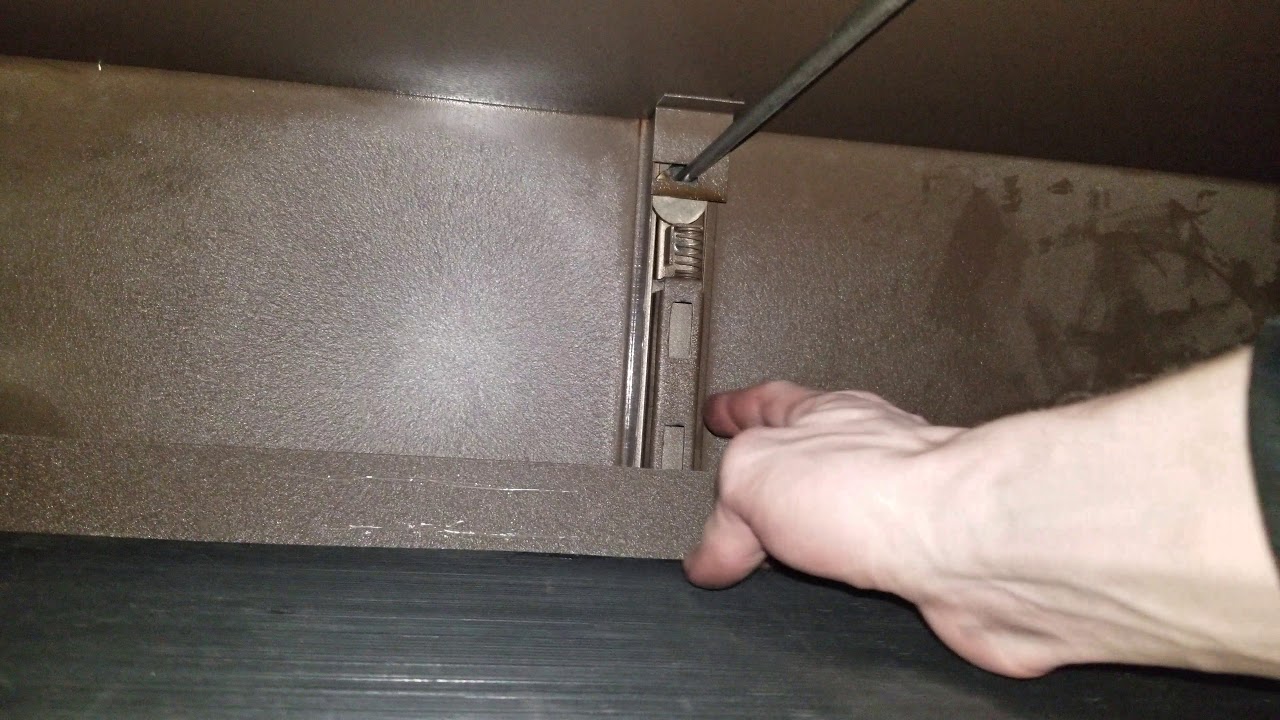

Paper Clip – Craftsman Toolbox Pick

Summary

Toolbox locks are designed to keep your tools safe by preventing unauthorized access. When you lock your toolbox, the lock mechanism engages with a metal latch inside, securing your tools in place. These locks can be opened using a key or a combination code. Some locks even have advanced features like fingerprint recognition for added security.

However, it’s important to keep in mind that no lock is completely foolproof. Skilled individuals can still find ways to bypass these locks. Therefore, it’s a good idea to choose high-quality locks and periodically check for any signs of tampering to ensure the safety of your tools.