You might be wondering, how does a hand saw work? Well, I’ve got the scoop for you!

Imagine you’re trying to cut through a piece of wood or metal. A hand saw is a simple yet mighty tool that can make this task a breeze.

With its sharp teeth and ergonomic handle, a hand saw allows you to slice through materials with precision and ease. So, let’s dive in and explore the inner workings of this handy tool!

How Does a Hand Saw Work? An Expert Guide to Unlocking the Secrets of Cutting Tools

Introduction:

Using a hand saw may seem like a straightforward task, but have you ever wondered how this simple tool actually works? In this expert guide, we will explore the inner workings of a hand saw, revealing the mechanics behind its slicing power. From the teeth to the handle, every component plays a vital role in creating clean and precise cuts. Whether you’re a seasoned carpenter or a DIY enthusiast, understanding how a hand saw works will not only enhance your woodworking skills but also deepen your appreciation for this timeless tool.

The Anatomy of a Hand Saw

Introduction:

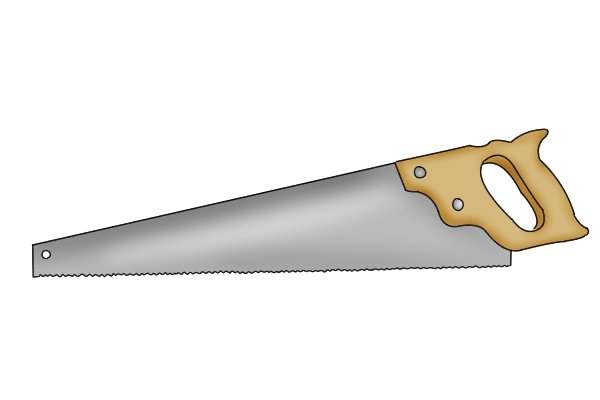

Before diving into the mechanics of a hand saw, it’s important to familiarize ourselves with its unique anatomy. A hand saw is typically composed of three main components: the blade, the handle, and the teeth. Each element plays a crucial role in the saw’s functionality, allowing it to effortlessly glide through various materials. Let’s take a closer look at these parts and how they work together to achieve those smooth and precise cuts we all strive for.

The Blade: The Cutting Edge

The blade is the heart and soul of the hand saw, responsible for making the actual cuts. It is typically made of high-quality steel or a combination of steel and other alloys to ensure durability and sharpness. The blade is long and narrow, tapering towards the tip to allow for precise cutting. Its edge is sharpened and features a series of teeth that vary in size, spacing, and shape depending on the intended purpose of the saw.

When using a hand saw, the blade is guided through the material by applying controlled pressure and strokes. As the blade moves back and forth, the teeth engage with the material, effectively cutting it. The cutting action is achieved by the teeth removing small chips of material with each stroke. The number of teeth per inch on the blade, known as the “tooth count,” determines the saw’s cutting speed and the finish of the cut. Higher tooth count blades are suitable for fine cuts, while lower tooth count blades are more suitable for rough cuts.

The Handle: Grip and Control

The handle, also known as the grip, is the part of the hand saw that allows the user to hold and maneuver the tool. It is usually made of wood, plastic, or rubber, providing a comfortable and secure grip. The shape and design of the handle can vary depending on the user’s preference and the type of saw.

The handle plays a crucial role in controlling the saw and directing its cutting path. By gripping the handle firmly, the user can maintain stability and control throughout the cutting process. The handle also helps in absorbing some of the vibrations generated during the sawing motion, reducing fatigue and discomfort. It is important to choose a handle that feels comfortable and ergonomic to ensure optimal performance and safety.

The Teeth: Slicing with Precision

The teeth are the star of the show when it comes to the cutting action of a hand saw. They are the small, jagged edges along the edge of the blade that bite into the material, creating the necessary friction to cut through it. The shape, spacing, and orientation of the teeth determine the type and quality of the cut.

Hand saws feature different types of teeth, each designed for specific cutting tasks. Some teeth are designed for cross-cutting, where the blade cuts across the wood grain, while others are more suitable for ripping, where the blade cuts parallel to the grain. The varying shapes of the teeth, such as rip teeth, crosscut teeth, and combination teeth, are optimized for efficient cutting in different scenarios.

The teeth’s orientation, commonly referred to as the “set,” is another critical factor in a hand saw’s cutting performance. The set is the slight angle at which each tooth is bent away from the blade, allowing for clearance and preventing the blade from getting stuck in the cut. The set also creates a wider kerf, which is the width of the cut, further reducing friction and facilitating smoother cuts.

In conclusion, a hand saw is a well-engineered tool with each component meticulously designed to enable efficient cutting. From the blade’s teeth to the handle’s grip, there is a harmony of elements that contribute to the saw’s functionality. Understanding the mechanics behind the hand saw allows users to make informed decisions when choosing the right tool for the task at hand. So the next time you pick up a hand saw, remember that it’s not just about the physical effort but also about harnessing the science behind its cutting prowess.

Key Takeaways: How Does a Hand Saw Work?

- A hand saw has a sharp, toothed blade that cuts through materials when you move it back and forth.

- The teeth on the blade are designed to remove material with each stroke, creating a cutting action.

- By applying pressure and maintaining a steady motion, the saw cuts through wood or other materials.

- Hand saws can have different types of teeth, such as crosscut teeth for cutting across the wood grain or rip teeth for cutting with the grain.

- It’s important to choose the right hand saw for the job and use proper technique to ensure accurate and efficient cutting.

Frequently Asked Questions

1. How does a hand saw work to cut through wood?

A hand saw works by utilizing a sharp blade with teeth that are specifically designed for cutting through wood. When you apply force and push or pull the saw across the wood, the saw teeth come into contact with the material, creating a cutting action. The teeth of the hand saw are set in a way that allows them to remove small chips of wood as they cut through the material. This cutting and chipping action continues as you move the saw back and forth, resulting in a clean cut.

The type and size of the teeth on a hand saw will vary depending on the desired application. Some hand saws have larger teeth for rough cuts, while others have smaller teeth for more precise cuts. Additionally, the angle of the teeth can also vary, which affects the way the saw cuts through the wood. It’s important to choose the right hand saw with the appropriate tooth configuration for the specific woodworking task at hand.

2. What is the proper way to use a hand saw?

To use a hand saw properly, start by selecting the appropriate saw for the task. Ensure your workpiece is securely clamped in place to prevent it from moving while cutting. Hold the hand saw firmly with one hand on the handle and the other hand gripping the blade close to the handle for improved control. Position the saw at a slight angle to the wood, with the teeth pointing away from you.

Apply gentle downward pressure on the saw and start the cutting motion by pushing or pulling the saw back and forth. Use long and smooth strokes, letting the blade do the work rather than forcing it. Maintain a steady pace and keep the saw perpendicular to the wood to ensure an accurate cut. You can use a marking tool to guide the saw along a straight line, especially for precision cuts.

Always prioritize safety by wearing protective eyewear and keeping your fingers away from the path of the saw. It’s also crucial to work in a well-lit area and maintain a stable footing for better control while cutting.

3. Can a hand saw be used for cutting other materials besides wood?

While hand saws are primarily designed for cutting wood, there are specialized saws available for cutting various materials such as metal, plastic, and even concrete. These saws have blades with different tooth configurations and cutting edges that are specifically designed to handle the unique properties of these materials.

It’s important to choose the right hand saw for the intended material to ensure efficient and precise cutting. Attempting to use a hand saw designed for wood on other materials may result in damage to the saw or unsatisfactory cutting performance. Always consult the manufacturer’s recommendations and select the appropriate hand saw for the specific material you are working with.

4. How do you maintain a hand saw to ensure optimal performance?

To maintain a hand saw and keep it performing at its best, there are a few key steps you can take. Firstly, it’s important to keep the saw clean and free of debris. After each use, remove any sawdust or wood chips from the blade and handle using a soft brush. This prevents buildup that can hinder the saw’s cutting ability.

Regularly inspect the teeth of the saw for any signs of damage or dullness. If there are any chips or broken teeth, it’s best to replace the blade or have it professionally sharpened. Dull teeth can significantly affect the saw’s performance and make cutting more difficult and time-consuming.

When storing the hand saw, ensure it is protected from moisture and kept in a dry place. Moisture can cause rust or corrosion, which can damage the blade and compromise its cutting ability. Consider using a protective cover or sheath to keep the saw safe and prolong its lifespan.

5. Are there different types of hand saws available for specific woodworking tasks?

Yes, there are various types of hand saws available, each designed for different woodworking tasks. Here are a few examples:

– Crosscut Saw: This type of hand saw is designed for cutting across the grain of the wood and produces smooth, accurate cuts.

– Rip Saw: Rip saws have fewer teeth per inch compared to a crosscut saw. They are better suited for cutting along the grain of the wood.

– Backsaw: Backsaws have a stiffened spine, which helps to keep the blade straight during cutting. They are commonly used for precise joinery work.

– Coping Saw: A coping saw has a thin, flexible blade that is ideal for intricate and curved cuts. It’s commonly used in woodworking and other crafts.

– Dovetail Saw: Dovetail saws have a fine-toothed blade, making them suitable for cutting dovetail joints and other precise joinery work.

These are just a few examples, and there are many more specialized hand saws available to cater to specific woodworking needs. Choosing the right hand saw for the task at hand will ensure better results and a more enjoyable woodworking experience.

Summary

So, that’s how a hand saw works! When you push and pull it back and forth, the teeth on the blade cut through the wood. The shape of the teeth and the direction they point help make the cuts smooth and accurate. Remember to be careful and always use a hand saw safely!

In conclusion, a hand saw is a handy tool that uses metal teeth to cut through wood. By understanding how it works, you can use it effectively for all your woodworking projects. Happy sawing!