Hey there! Are you curious about how a hollow chisel mortiser works? Well, you’re in the right place because we’re about to dive into the fascinating world of this woodworking tool!

Now, you might be wondering, what on earth is a hollow chisel mortiser? Simply put, it’s a machine that helps create precise and clean holes in wood. It’s like a supercharged drill press that specializes in cutting square or rectangular holes for things like mortise and tenon joints.

You might be thinking, “But how does it actually work?” Don’t worry, we’ll break it down for you in the simplest way possible. A hollow chisel mortiser consists of three main components: the chisel, the bit, and the drill press. When you lower the chisel into the wood, it hollows out a perfectly shaped hole, while the drill press provides the power and control. It’s like a woodworking superhero that makes precise cuts effortlessly!

So, if you’re a woodworking enthusiast or just someone who loves to learn about cool tools, stick around because we’re going to explore the wonderful world of the hollow chisel mortiser in more detail. Get ready to be amazed by the ingenuity of this handy machine!

A hollow chisel mortiser is a woodworking tool used to create square or rectangular holes, also known as mortises. Here’s a step-by-step guide on how it works:

1. Secure the workpiece and align the mortise location.

2. Adjust the depth and width of the chisel.

3. Start the machine and lower the chisel into the workpiece.

4. Move the workpiece back and forth to create the mortise.

5. Remove the chisel and clean up the mortise.

With its powerful motor and chisel design, the hollow chisel mortiser efficiently and accurately creates mortises for various woodworking projects.

How Does a Hollow Chisel Mortiser Work?

A hollow chisel mortiser is a versatile tool used in woodworking to create mortises, which are square or rectangular holes in wood pieces to accommodate tenons for joinery. This specialized machine is designed to make this process faster, more accurate, and easier for woodworkers. By understanding how a hollow chisel mortiser works, you can enhance your woodworking skills and improve the quality of your projects.

1. The Anatomy of a Hollow Chisel Mortiser

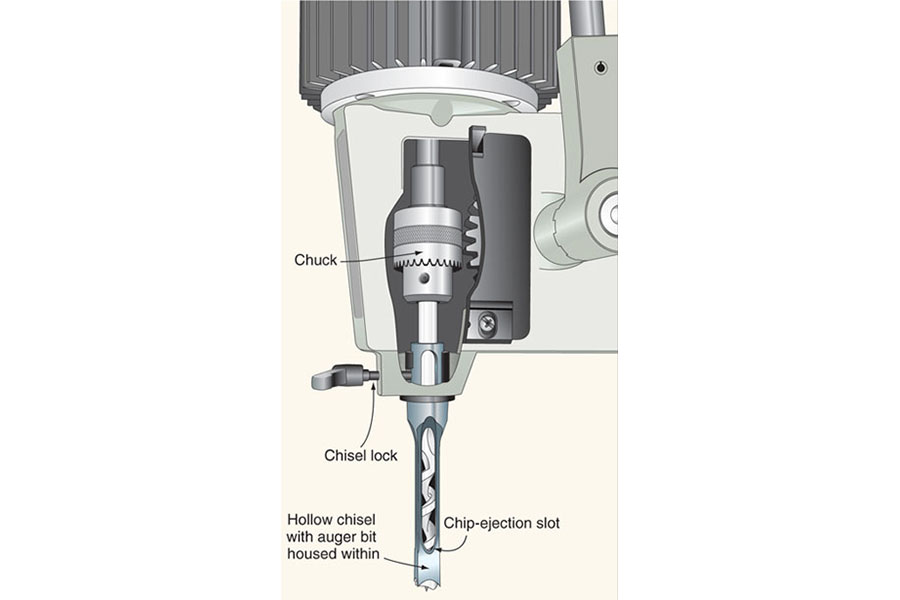

A hollow chisel mortiser consists of several key components. First, there is a base or table that provides stability and supports the workpiece. The chisel, which is the central component of the mortiser, is held in place by the headstock or main body of the machine. The headstock is attached to an arm that moves vertically, allowing the chisel to plunge into the wood. The arm is often operated by a handle or a lever. To hold the workpiece securely, there is usually a clamp or a hold-down mechanism.

Between the chisel and the headstock, there is a drill bit known as the auger. The auger is responsible for removing most of the waste material from the mortise, providing space for the chisel to follow and cut the remaining wood fibers. The chisel itself has a hollow body with sharp edges, allowing it to plunge through the wood and remove the material within the marked-out boundaries of the mortise.

Additionally, many hollow chisel mortisers have adjustable features, such as depth stops, to control the depth of the mortise, and fences or guides to ensure accurate and parallel cuts. Some advanced models may also have additional features like oscillation to reduce friction and enhance chip removal.

2. The Mortising Process

The process of using a hollow chisel mortiser begins with marking out the location and dimensions of the mortise on the workpiece. This can be done with the help of a template, a marking gauge, or other measuring tools. Once the layout is complete, the workpiece is securely clamped to the mortiser’s table, ensuring stability during the cutting process.

With the workpiece in place, the operator adjusts the height and the position of the chisel according to the marked lines. The depth of the mortise can be set using the depth stops or by adjusting the plunge depth of the chisel manually. It is crucial to ensure that the chisel is aligned parallel to the edges of the workpiece to achieve accurate results.

Once everything is correctly set up, the operator activates the machine to start the cutting process. The motor drives the auger, which removes the majority of the waste material, clearing a path for the chisel. Simultaneously, the operator lowers the chisel into the wood by operating the handle or lever. The sharp edges of the chisel cut and shape the remaining wood fibers, creating the precise shape and depth of the mortise. The resulting mortise is clean, accurately sized, and ready to receive a tenon for joinery purposes.

3. Benefits of Using a Hollow Chisel Mortiser

Using a hollow chisel mortiser offers several advantages for woodworkers. Firstly, it allows for precise and consistent mortise cuts, reducing the risk of human error that may occur when making mortises by hand. This results in tighter joints and improved overall craftsmanship.

Secondly, hollow chisel mortisers are designed to remove waste material efficiently, minimizing the amount of cleanup required. The combination of the auger and chisel removes wood fibers as chips, effectively clearing the mortise during the cutting process. This saves time and effort, especially when compared to manual chisel and mallet methods.

Lastly, a hollow chisel mortiser provides a safer alternative to traditional mortising techniques. The use of a machine eliminates the need for excessive manual force and reduces the chance of accidents or injuries. The controlled and precise movements of the machine ensure a safer working environment.

Types of Hollow Chisel Mortisers

While the basic principles of how a hollow chisel mortiser works remain the same, there are different types of mortisers available in the market. Each type has its own unique features and functionalities, catering to the diverse needs of woodworkers. Let’s explore three common types of hollow chisel mortisers.

1. Benchtop Hollow Chisel Mortiser

The benchtop hollow chisel mortiser is a compact and portable option suitable for small woodworking workshops or hobbyists. It is designed to be placed on a workbench or a sturdy table. Benchtop mortisers often come with a smaller motor and a limited cutting capacity, making them ideal for lighter woodworking projects. This type of mortiser is more budget-friendly and easy to store when not in use.

2. Floor Standing Hollow Chisel Mortiser

The floor-standing hollow chisel mortiser is a heavier and more robust option, suitable for professional woodworking shops or enthusiasts working on larger projects. It features a more powerful motor and a larger work area, allowing for increased capacity and versatility. Floor standing mortisers often have additional features such as tilting tables, integration with drill presses, and more precise adjustability options.

3. Combination Mortiser

A combination mortiser is a versatile option that integrates a hollow chisel mortiser with other woodworking machines like drill presses and bench grinders. This type of mortiser is designed for space-saving and increased functionality. Combination mortisers provide woodworkers with the ability to perform multiple tasks without the need for separate machines, making them suitable for compact workspaces or those with limited budgets.

Tips for Using a Hollow Chisel Mortiser

Using a hollow chisel mortiser effectively requires attention to detail and proper technique. Here are some tips to keep in mind:

1. Secure workpiece properly:

Ensure the workpiece is securely clamped to the mortiser’s table to prevent any movement or vibration during the cutting process. This will result in cleaner and more accurate mortises.

2. Use sharp chisels:

Regularly sharpen and maintain the sharpness of the chisels. Dull chisels can lead to tear-out, compromised accuracy, and increased strain on the machine’s motor.

3. Practice on scrap wood:

If you are new to using a hollow chisel mortiser, practice on scrap wood before working on your actual project. This will help you become familiar with the machine and refine your technique.

4. Take breaks during extended use:

If you are using the mortiser for an extended period, take breaks to prevent the machine from overheating. This will prolong its lifespan and ensure optimal performance.

5. Clean the machine after each use:

Remove any debris, dust, or chips from the machine after each use. This will prevent them from affecting the accuracy and performance of the mortiser in the future.

6. Wear appropriate safety gear:

Always wear safety goggles, ear protection, and appropriate clothing when operating a hollow chisel mortiser. Protecting your eyes, ears, and body will ensure a safer woodworking experience.

Common Mistakes to Avoid

While using a hollow chisel mortiser, it is important to avoid these common mistakes:

1. Rushing the process:

Take your time and ensure that all the settings, including depth and alignment, are properly adjusted before making any cuts. Rushing may lead to inaccuracies and compromised results.

2. Neglecting chisel maintenance:

Regularly sharpen and maintain the chisels. Neglecting chisel maintenance can result in poor-quality cuts, damaged workpieces, and increased strain on the motor.

3. Failing to mark-out mortise boundaries accurately:

Accurate marking-out is crucial for precise mortises. Failing to mark the boundaries properly may result in misaligned or incorrect-sized mortises.

4. Overloading the machine:

Avoid forcing the machine to cut through materials that exceed its recommended capacity. Overloading the machine can result in motor burnout, shortened lifespan, and subpar performance.

5. Using excessive force:

Let the machine do the work for you. Excessive force or downward pressure may lead to the chisel getting stuck, damaged workpieces, or even injury to yourself.

6. Not properly clearing waste:

Ensure the waste material is effectively cleared from the mortise during the cutting process. Accumulated waste can cause the chisel to bind or result in irregular mortises.

In Summary

A hollow chisel mortiser is an invaluable tool in the woodworking arsenal, allowing for precise and efficient mortise cutting. Understanding its anatomy, the mortising process, and following the proper techniques and tips will help you get the most out of this machine. By avoiding common mistakes and practicing safe operation, you can create flawless mortises for your woodworking projects and achieve professional-level craftsmanship.

Key Takeaways: How Does a Hollow Chisel Mortiser Work?

- A hollow chisel mortiser is a woodworking machine used to create a square or rectangular hole known as a mortise.

- It consists of a motor, chisel, and drill bit that work together to remove wood and create the mortise.

- The chisel and drill bit are hollow, allowing chips and debris to be extracted through a connected dust collection system.

- When the machine is turned on, the chisel and drill bit are lowered into the wood, removing material and forming the mortise.

- Once the desired depth and size of the mortise is achieved, the chisel and drill bit are retracted, and the process is repeated for each mortise needed.

Frequently Asked Questions

In this section, we’ll explore some commonly asked questions about how a hollow chisel mortiser works and provide detailed answers to help you understand the process.

1. What is a hollow chisel mortiser and how does it work?

A hollow chisel mortiser is a woodworking tool used to create square or rectangular holes, known as mortises, in wood for joinery purposes. It consists of a motor that drives a chisel and a drill bit.

When you operate a hollow chisel mortiser, the drill bit removes the majority of the material from the mortise area, while the chisel squares off the walls of the hole, resulting in a clean and precise mortise.

2. Can you explain the components of a hollow chisel mortiser?

A hollow chisel mortiser has four primary components: the motor, the chisel, the drill bit, and the fence. The motor provides the power needed to drive the chisel and drill bit.

The chisel is the cutting tool that squares off the walls of the mortise, while the drill bit removes the majority of the material. The fence helps to guide the wood and ensures accurate placement of the mortise.

3. How do you set up and use a hollow chisel mortiser?

To set up a hollow chisel mortiser, secure it to a stable workbench or stand. Adjust the height and position of the fence according to your desired mortise size and placement.

When using the tool, align the wood with the fence and hold it firmly in place. Activate the motor, lower the chisel and drill bit into the wood, and apply gentle pressure. Slowly move the chisel and drill bit through the wood until the desired depth is achieved.

4. What are the advantages of using a hollow chisel mortiser?

One of the key advantages of a hollow chisel mortiser is its ability to create precise and clean mortises, making it an ideal tool for joinery work. The square shape of the mortise ensures a tight and secure fit between the joined pieces of wood.

Additionally, a hollow chisel mortiser saves time and effort compared to traditional methods like chisel and mallet. It allows for efficient and accurate production of mortises, enhancing the overall productivity of woodworking projects.

5. Are there any safety precautions to consider when using a hollow chisel mortiser?

Absolutely! Safety should always be a top priority. When using a hollow chisel mortiser, wear safety goggles to protect your eyes from wood chips or debris. Avoid loose clothing or long hair that could get caught in the tool.

Always follow the manufacturer’s instructions and guidelines for safe operation. Keep your hands away from the rotating chisel and drill bit, and never force the tool through the wood. If you’re new to using a hollow chisel mortiser, it’s wise to practice on scrap wood before working on your actual project.

Summary

So, to sum it up, a hollow chisel mortiser is a powerful machine used to create square holes. It works by drilling out the waste material from the hole, using a chisel with a hollowed-out center. This chisel fits into a drill press and cuts a clean and precise hole. Unlike other methods, it eliminates the need for manual chiseling and produces professional results in less time. Just remember to follow safety precautions and enjoy creating your woodworking projects with this handy tool!