Are you curious about how a lathe chuck works? Well, you’ve come to the right place! In this article, we’ll dive into the fascinating world of lathe chucks and uncover the inner workings of these amazing machines. So, buckle up and get ready for a thrilling exploration!

Imagine you have a spinning wheel, and you want to hold a piece of wood securely in place while you shape it. That’s where a lathe chuck comes in. It’s like a superhero’s grip, keeping the workpiece steady and allowing you to work your magic. But how does it accomplish this feat? Let’s find out!

Inside a lathe chuck, there are multiple jaws that can grip the workpiece tightly. These jaws move in and out to adjust their position and securely hold the workpiece. It’s like a group of friends working together, each doing their part to keep things stable. But how exactly do these jaws move? Stay tuned to uncover the secrets of the lathe chuck mechanism!

With this introduction, we’ve set the stage for an exciting journey into the world of lathe chucks. Get ready to uncover the mysteries behind their gripping power and discover the wonders of this essential tool. So, let’s not waste any more time and dive right in!

How Does a Lathe Chuck Work?

1. Introduction to Lathe Chucks

A lathe chuck is an essential component in a lathe machine that is used to securely hold and rotate workpieces. It provides a way to clamp the workpiece, allowing the lathe machine to shape, cut, or drill it with precision. Lathe chucks come in various shapes and sizes, but their fundamental principle of operation remains the same.

The main purpose of a lathe chuck is to grip the workpiece tightly and offer stability during machining operations. It allows for the rotation of the workpiece, enabling the lathe machine to perform tasks such as turning, facing, threading, and knurling. Understanding how a lathe chuck works is crucial for operators and machinists to ensure safe and effective use of the lathe machine.

Let’s delve into the inner workings of a lathe chuck and explore its components and operation in greater detail.

2. Components of a Lathe Chuck

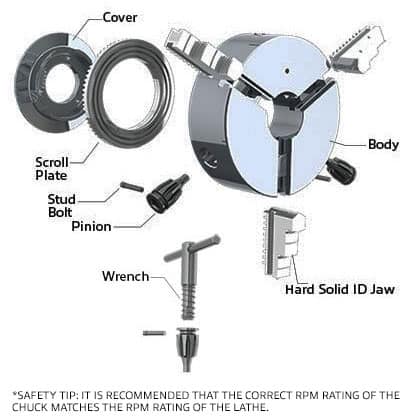

A typical lathe chuck consists of several key components that work together to securely hold the workpiece. These components include:

- Chuck Body: The chuck body is the main housing that holds all the other components and attaches to the lathe spindle.

- Jaws: The jaws are movable components that grip the workpiece. They can be adjusted to accommodate different diameters and shapes.

- Scroll Plate: The scroll plate is a round-shaped component with a spiral groove on its surface. It is connected to the jaws and moves them in or out when rotated.

- Operating Key: The operating key is used to rotate the scroll plate, which in turn moves the jaws.

- Chuck Key: The chuck key is used to tighten or loosen the jaws, allowing for the insertion or removal of the workpiece.

These components work in harmony to provide a secure grip on the workpiece, ensuring stability during machining operations.

3. Operation of a Lathe Chuck

The operation of a lathe chuck involves a series of steps to securely hold the workpiece. Here’s a breakdown of how it works:

- Opening: The chuck jaws are initially in the open position to allow for the insertion of the workpiece.

- Insertion: The workpiece is carefully positioned between the chuck jaws.

- Tightening: The operator inserts the chuck key into the chuck and rotates it clockwise. This action moves the scroll plate, which causes the jaws to move inward, clamping onto the workpiece. The jaws apply a sufficient amount of pressure to ensure a secure grip.

- Testing: Once the workpiece is clamped, the operator ensures that it is securely held by gently applying pressure in different directions. This ensures that the workpiece will not move during machining operations.

- Rotation: With the workpiece securely held in the lathe chuck, the lathe machine can be operated. The chuck allows for smooth and controlled rotation of the workpiece, enabling a wide range of machining operations.

- Release: Once the machining operations are complete, the chuck key is used to rotate the scroll plate counterclockwise, moving the jaws outward and releasing the workpiece.

By following these steps, operators can safely and effectively use a lathe chuck to hold and manipulate workpieces in a lathe machine.

4. Tips for Proper Lathe Chuck Usage

To ensure optimal performance and longevity of a lathe chuck, it is essential to follow these tips:

- Regular Maintenance: Keep the lathe chuck clean and free from debris. Regularly lubricate the moving parts to reduce friction and wear.

- Proper Adjustment: Always adjust the chuck jaws to securely grip the workpiece, but avoid excessive pressure that may damage the workpiece or chuck.

- Use Correct Chuck Keys: Ensure that the chuck keys used are designed for the specific chuck being utilized. Using the wrong key may cause slippage or damage.

- Inspect Chuck Jaws: Regularly inspect the chuck jaws for signs of wear or damage. Replace any worn or damaged jaws promptly to maintain optimal gripping capability.

- Training and Safety: Properly train operators on the safe and correct usage of lathe chucks to prevent accidents or damage to the workpiece and machine.

By adhering to these tips, users can maximize the efficiency and reliability of their lathe chucks, ensuring optimal results in their machining operations.

Benefits of Using a Lathe Chuck

- Securely holds workpieces during machining operations, minimizing the risk of accidents or damage.

- Allows for precise and controlled rotation of the workpiece, enabling accurate shaping, cutting, and drilling.

- Facilitates the use of various cutting tools and attachments for versatile machining capabilities.

- Provides stability and rigidity, resulting in improved machining accuracy and surface finish.

- Enables efficient and expedited workpiece setup and changeover, enhancing productivity.

Lathe Chuck vs. Other Holding Methods

When it comes to holding workpieces during machining, lathe chucks offer several advantages over alternative methods:

- Lathe Chuck vs. Faceplate: While faceplates are suitable for larger or irregularly shaped workpieces, a lathe chuck provides more versatility and convenience for a wide range of workpiece sizes and shapes.

- Lathe Chuck vs. Collet: Collets are ideal for holding small-diameter workpieces with precision. However, lathe chucks offer a greater gripping range and are better suited for larger or irregularly shaped workpieces.

- Lathe Chuck vs. Magnetic Chucks: Magnetic chucks are commonly used for holding ferrous workpieces. However, they may not be suitable for non-magnetic materials or workpieces with intricate shapes. A lathe chuck can securely hold a wider range of materials and shapes.

Taking Care of Your Lathe Chuck: Maintenance Tips

To ensure the longevity and proper functioning of your lathe chuck, follow these maintenance tips:

- Regularly clean the chuck to remove dust, debris, and coolant residue.

- Inspect the chuck jaws and replace any worn or damaged parts.

- Apply a thin film of lubricant to the chuck jaws and scroll plate to reduce friction.

- Ensure that the chuck key is in good condition and operates smoothly.

- Store the chuck in a clean and dry environment to prevent corrosion.

Conclusion

A lathe chuck is a vital component in a lathe machine, enabling the secure gripping and rotation of workpieces. By understanding its inner workings and following proper usage and maintenance techniques, operators can harness the full potential of their lathe chucks. Whether it’s for turning, facing, threading, or knurling, a well-maintained and properly utilized lathe chuck is essential for achieving accurate and precise machining results.

Key Takeaways: How Does a Lathe Chuck Work?

A lathe chuck is a device used to hold and rotate a workpiece in a lathe machine. Here are the key points to understand how it works:

- A lathe chuck consists of jaws that clamp onto the workpiece, holding it securely in place as it spins.

- The jaws can be adjusted to accommodate different sizes and shapes of workpieces.

- By tightening or loosening the chuck’s mechanism, the jaws either grip or release the workpiece.

- As the lathe machine rotates, the chuck spins the workpiece, allowing for precision machining.

- Lathe chucks come in various types, such as self-centering chucks and independent chucks, each suitable for different applications.

Frequently Asked Questions

Here are some common questions about how a lathe chuck works:

1. What is the purpose of a lathe chuck?

A lathe chuck is a device used to securely hold and rotate a workpiece during machining. It provides a stable grip on the workpiece, allowing it to be shaped, cut, or drilled with precision. The chuck’s primary purpose is to hold the workpiece in place, ensuring accuracy and safety during machining operations. Without a chuck, it would be challenging to work on cylindrical or round objects on a lathe.

The chuck typically consists of jaws that can be adjusted to grip different sizes and shapes of workpieces. It is an essential tool for any lathe operator, as it enables the efficient and accurate shaping of various materials, such as wood, metal, or plastic.

2. How does a lathe chuck grip a workpiece?

A lathe chuck grips a workpiece by using adjustable jaws that move inward or outward to clamp onto the workpiece securely. These jaws are typically operated by a chuck key or a lever, which allows the user to tighten or loosen the grip. When tightening the chuck, the jaws move towards the center of the chuck, firmly gripping the workpiece.

Most lathe chucks have three or four jaws that can be adjusted independently. This allows them to hold both cylindrical and irregularly shaped workpieces. By positioning the jaws correctly and tightening the chuck, the workpiece can be held securely in place throughout the machining process, ensuring precise and consistent results.

3. Can a lathe chuck hold different sizes of workpieces?

Yes, a lathe chuck is designed to hold a wide range of workpiece sizes. The jaws of the chuck can be adjusted to accommodate different diameters of workpieces. By moving the jaws closer or farther apart, the chuck can grip both small and large workpieces securely.

Some chucks also have interchangeable jaws that can be swapped out to hold specialized shapes or sizes. This versatility allows the lathe chuck to be utilized for a wide variety of machining projects, making it an indispensable tool for machinists and woodworkers.

4. How does a lathe chuck rotate the workpiece?

A lathe chuck is connected to the lathe spindle, which is driven by a motor. When the lathe is turned on, the chuck spins along with the spindle, causing the workpiece held within the chuck to rotate. This rotation is what allows various machining operations, such as cutting, shaping, or drilling, to be performed on the workpiece.

The speed at which the workpiece rotates can be adjusted using the lathe’s controls, allowing for different cutting speeds and finishes. By controlling the rotational speed and applying appropriate cutting tools, the lathe operator can achieve the desired results on the workpiece.

5. How do you remove a workpiece from a lathe chuck?

To remove a workpiece from a lathe chuck, the user needs to loosen the chuck’s grip on the workpiece. This is typically done by using a chuck key to turn the jaws in a counterclockwise direction, moving them away from the center of the chuck. As the grip on the workpiece is released, it can be safely removed from the chuck.

It is important to exercise caution while removing the workpiece to prevent any accidents or damage. Ensuring that the lathe is turned off and taking proper safety measures, such as wearing gloves or using protective gear, is crucial. Additionally, following the manufacturer’s instructions and guidelines specific to the lathe chuck being used is essential for safe removal of the workpiece.

Summary

So, to recap how a lathe chuck works: it’s like a big clamp that holds your workpiece securely while you shape it. The chuck has jaws that move in and out, gripping the workpiece tightly. You can adjust the jaws to fit different sizes of workpieces, and once it’s in place, you can start using the lathe to shape your material. It’s an essential tool for turning and shaping all sorts of objects, from wooden bowls to metal parts.

In conclusion, a lathe chuck is a vital part of a lathe machine that holds the workpiece securely, allowing you to shape it with precision. By understanding how the chuck’s jaws move and adjust, you can effectively use a lathe for various turning and shaping projects. Happy crafting!