Do you ever wonder how a lathe dog works? Well, you’re in the right place! In this article, we’ll explore the ins and outs of this fascinating tool. Whether you’re a curious hobbyist or aspiring engineer, understanding how a lathe dog operates is crucial. So, let’s delve into the world of lathes and discover the magic behind the lathe dog!

Before we jump into the details, let’s start with the basics. A lathe dog is a clever device used in metalworking to grip and rotate a workpiece on a lathe. It’s like a trusty companion that holds the workpiece securely, allowing precise shaping and machining. But how does it work its magic? That’s what we’re here to find out!

Imagine you have a long cylindrical workpiece that needs turning. The lathe dog comes into play by clamping onto the piece, securing it tightly. As you turn the lathe handle, the lathe dog rotates, causing the workpiece to spin along with it. This rotational movement enables you to shape the workpiece, creating intricate designs, smooth surfaces, or any other desired outcome.

So, why is it called a “lathe dog”? Well, the term “dog” originates from its resemblance to a loyal canine. Just like a dog bites and holds onto something, a lathe dog firmly grips the workpiece, ensuring it doesn’t slip or wobble during the turning process. It’s an essential tool that enables craftsmen and machinists to achieve precision and accuracy in their work.

Now that you have a grasp on the basics, get ready to dive deeper into the world of lathe dogs. We’ll explore the different types, variations, and how they’re used in various applications. So, buckle up and join us on this exciting journey into the world of lathe dogs!

How Does a Lathe Dog Work? A Comprehensive Guide

Welcome to our comprehensive guide on how a lathe dog works! In this article, we will take an in-depth look at the functionality and purpose of a lathe dog, a critical tool in metalworking and woodturning. Whether you are a beginner exploring the world of lathes or a seasoned professional looking to expand your knowledge, we have got you covered. So, let’s dive in and unravel the intricacies of the lathe dog!

What is a Lathe Dog?

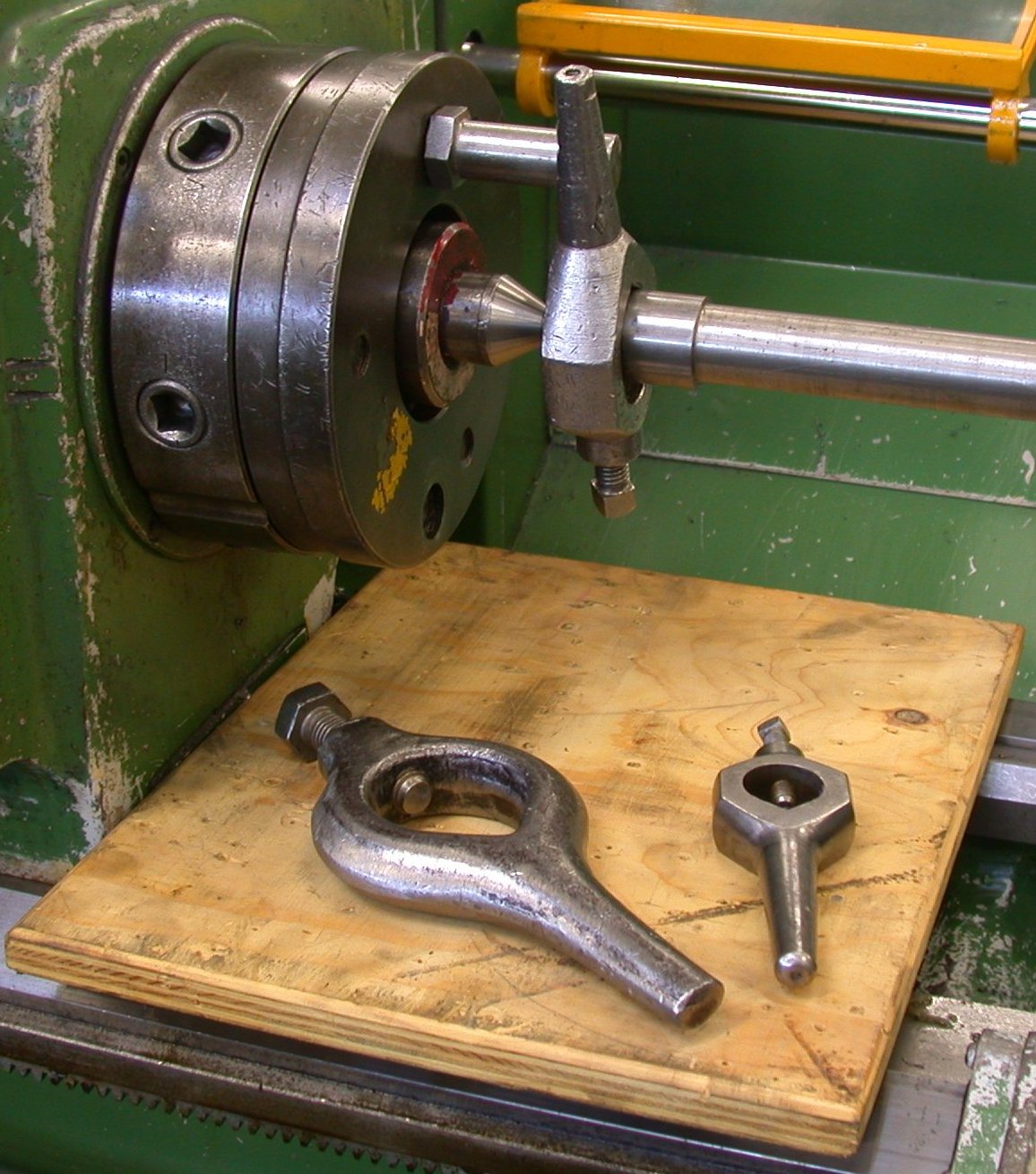

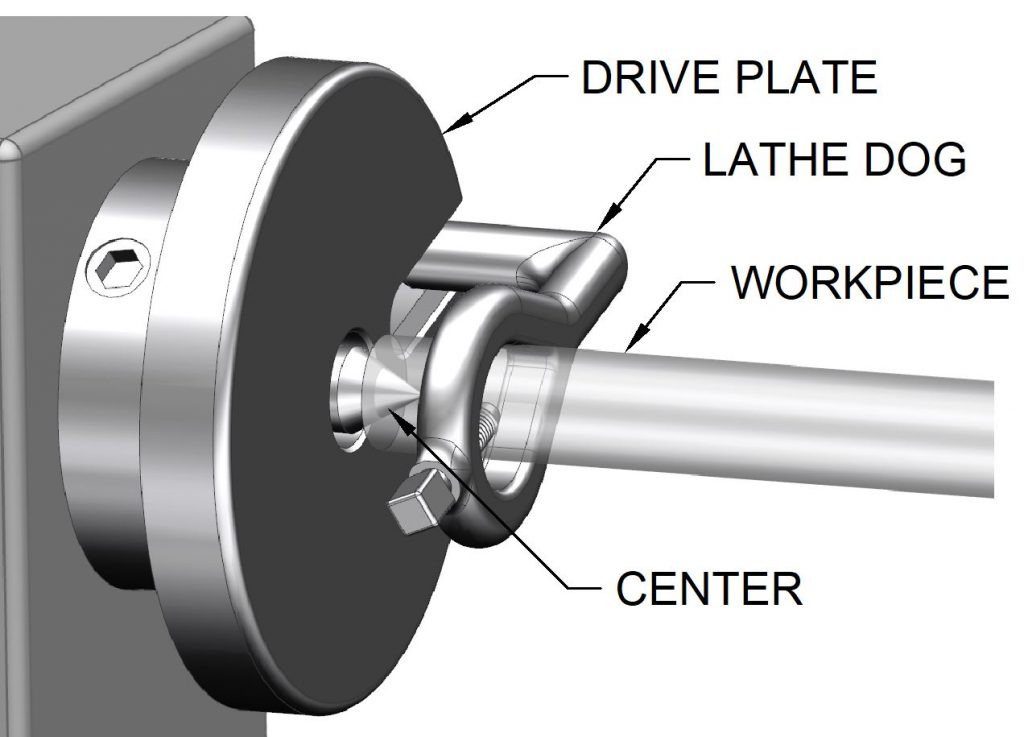

A lathe dog, also known as a carrier dog or driver, is a mechanical device used in machining and turning operations. It is designed to transmit rotational power from the lathe’s spindle to the workpiece, allowing for precise shaping, cutting, and forming. The lathe dog consists of two main parts: the body and the driving arm. The body is a circular disc with a centered hole that fits onto the lathe’s spindle, while the driving arm protrudes from the body at a right angle and engages with the workpiece.

Lathe dogs come in various sizes and designs, depending on the specific application and workpiece. They are commonly made of hardened steel to withstand the high forces and torque generated during turning. Additionally, lathe dogs often feature teeth or serrations on their driving arms to provide a secure grip on the workpiece, preventing slippage and ensuring precise rotation.

The Functionality of a Lathe Dog

Now that we understand the basic structure of a lathe dog, let’s delve into its functionality. When a lathe dog is attached to the workpiece, it acts as a connector between the rotating spindle and the piece being turned. As the lathe’s spindle rotates, the driving arm of the lathe dog engages with the workpiece, transferring rotational motion to it.

One of the primary purposes of a lathe dog is to ensure that the workpiece rotates uniformly and securely while being turned. It provides a strong grip on the workpiece, preventing it from slipping or rotating inconsistently. This is especially crucial when working with irregularly shaped or unbalanced workpieces, as the lathe dog helps maintain stability and precision throughout the turning process.

Furthermore, a lathe dog allows for the cutting tool to make accurate and precise cuts by controlling the rotational movement of the workpiece. This control is essential for achieving desired cuts, creating intricate designs, and maintaining symmetry. Without a lathe dog, it would be challenging to achieve consistent and high-quality results in lathe operations.

Tips for Using a Lathe Dog

…

Benefits of Using a Lathe Dog

…

Lathe Dog vs. Other Workholding Tools

…

Common Issues and Troubleshooting

…

Conclusion

…

Lathe Dog: Types and Features

…

Lathe Dog Maintenance and Care

…

Lathe Dog Safety Precautions

…

Key Takeaways: How Does a Lathe Dog Work?

- A lathe dog is a device used in machining to secure a workpiece to the lathe’s driving mechanism.

- It consists of two parts: a body with pointed teeth and a clamping mechanism.

- The pointed teeth grip the workpiece, allowing it to rotate with the lathe.

- The clamping mechanism tightens the lathe dog onto the workpiece, ensuring a secure hold.

- By using a lathe dog, the workpiece can be rotated and shaped precisely.

Frequently Asked Questions

Curious to know how a lathe dog works? Look no further! Below are answers to common questions to help demystify the inner workings of a lathe dog.

What is a lathe dog and what does it do?

A lathe dog is a clamping device used in metalworking to secure a workpiece to the lathe spindle. It typically consists of two jaws, one fixed and one movable. The fixed jaw is attached to the lathe spindle, while the movable jaw can be adjusted to grip the workpiece firmly. This allows for rotation of the workpiece while cutting or shaping it.

The primary purpose of a lathe dog is to transmit power from the lathe spindle to the workpiece. By securely gripping the workpiece, the lathe dog prevents it from slipping or rotating independently, ensuring that the cutting tool can effectively shape the material. This device is especially useful when turning long and slender workpieces or when applying heavy cutting forces.

How does a lathe dog grip the workpiece?

A lathe dog grips the workpiece by clamping onto it with its movable jaw. The movable jaw can be adjusted to apply the desired amount of pressure, allowing for a secure hold on the workpiece. The shape of the movable jaw is usually curved or angled, which allows it to grab onto round or irregularly shaped workpieces effectively.

Once the movable jaw is in position, the lathe dog is tightened using a clamping mechanism or bolts. This action ensures a firm grip on the workpiece, preventing any movement or rotation during the turning process. It’s essential to position the lathe dog correctly, aligning it with the lathe spindle and choosing the appropriate amount of pressure to avoid damaging the workpiece or affecting the turning operation.

Are there different types of lathe dogs available?

Yes, there are different types of lathe dogs available to accommodate various workpiece shapes and sizes. The most common types include plain lathe dogs, bent-tail lathe dogs, and spring lathe dogs.

A plain lathe dog is the simplest design, consisting of a straight tail that clamps onto the workpiece. It is best suited for cylindrical workpieces with a consistent diameter. On the other hand, a bent-tail lathe dog has a curved tail, which provides additional clearance for the tool and allows it to grip odd-shaped workpieces.

Spring lathe dogs have a flexible tail that self-adjusts to the workpiece diameter, making them ideal for thin and tapered workpieces. This type of lathe dog is commonly used when turning small or delicate objects. Each type of lathe dog is designed for specific applications, so it’s important to choose the appropriate one based on the workpiece characteristics.

Can lathe dogs be used on any lathe?

Lathe dogs can generally be used on most lathes, as long as they are compatible with the lathe’s spindle and have the appropriate clamping mechanism. However, it’s crucial to consider the maximum workpiece size and weight that the lathe can handle, as well as the lathe dog’s design and gripping capabilities.

Some lathes may have specific requirements or limitations when it comes to using lathe dogs. It’s always recommended to consult the lathe’s user manual or seek guidance from an experienced machinist to ensure that the lathe dog is compatible with the lathe and suitable for the desired turning operation.

Are there alternatives to using a lathe dog?

While lathe dogs are commonly used in metalworking, there are alternative methods for securing and rotating workpieces on a lathe. One such method is using a chuck, which is a self-centering clamping device that can hold a wide range of workpiece sizes and shapes.

Chucks offer greater versatility since they can grip both internal and external surfaces of a workpiece, eliminating the need for a separate lathe dog. They also provide a faster and more convenient setup during the turning process. However, chucks may not be suitable for all workpiece types, especially those with complex shapes or extremely long and slender dimensions.

Ultimately, whether to use a lathe dog or an alternative method depends on the specific requirements of the turning operation and the nature of the workpiece being machined.

How to machine between center’s using lathe dog

Summary

A lathe dog is a handy tool used to hold and rotate objects on a lathe machine. It has a curved shape that grips the workpiece tightly, allowing it to spin while being worked on.

When using a lathe dog, it’s important to attach it securely to the object being turned to prevent any slippage. The dog is then connected to the lathe’s faceplate or chuck, which provides the necessary rotation. This allows craftsmen to shape and cut materials like wood and metal with precision and efficiency.

In conclusion, a lathe dog is a simple but important tool that helps in the versatile operation of a lathe machine. By understanding its purpose and proper usage, craftsmen can create amazing things on a lathe with confidence and accuracy.