Are you curious about how a lathe foot brake works? Well, let’s dive right in and explore the fascinating mechanics behind it! Picture this: you’re working on a lathe, and suddenly you need to stop the machine quickly and safely. That’s where the foot brake comes in.

You might be wondering, “How does it actually work?” Here’s the deal: the foot brake is a device that allows you to control the speed of the lathe by applying pressure with your foot. It’s like having the power to put the brakes on a speeding train!

Imagine this scenario: you’re using a lathe to shape a piece of wood, and you need to slow down or stop the machine. Instead of fumbling for a button or lever, you simply step on the foot brake and let physics do the rest. Pretty neat, right?

So, in a nutshell, the lathe foot brake gives you the ability to control the speed and stop the lathe with just a tap of your foot. Now that we’ve covered the basics, let’s delve deeper into the mechanics and inner workings of this clever device. Get ready to become a lathe foot brake expert!

How Does a Lathe Foot Brake Work?

Welcome to our comprehensive guide on how a lathe foot brake works. Lathe machines are essential tools in the manufacturing and woodworking industries, and understanding how the foot brake functions is crucial for safe and efficient operation. In this article, we will delve into the inner workings of a lathe foot brake, discussing its components, operation, and safety features. Let’s dive right in!

Component Overview

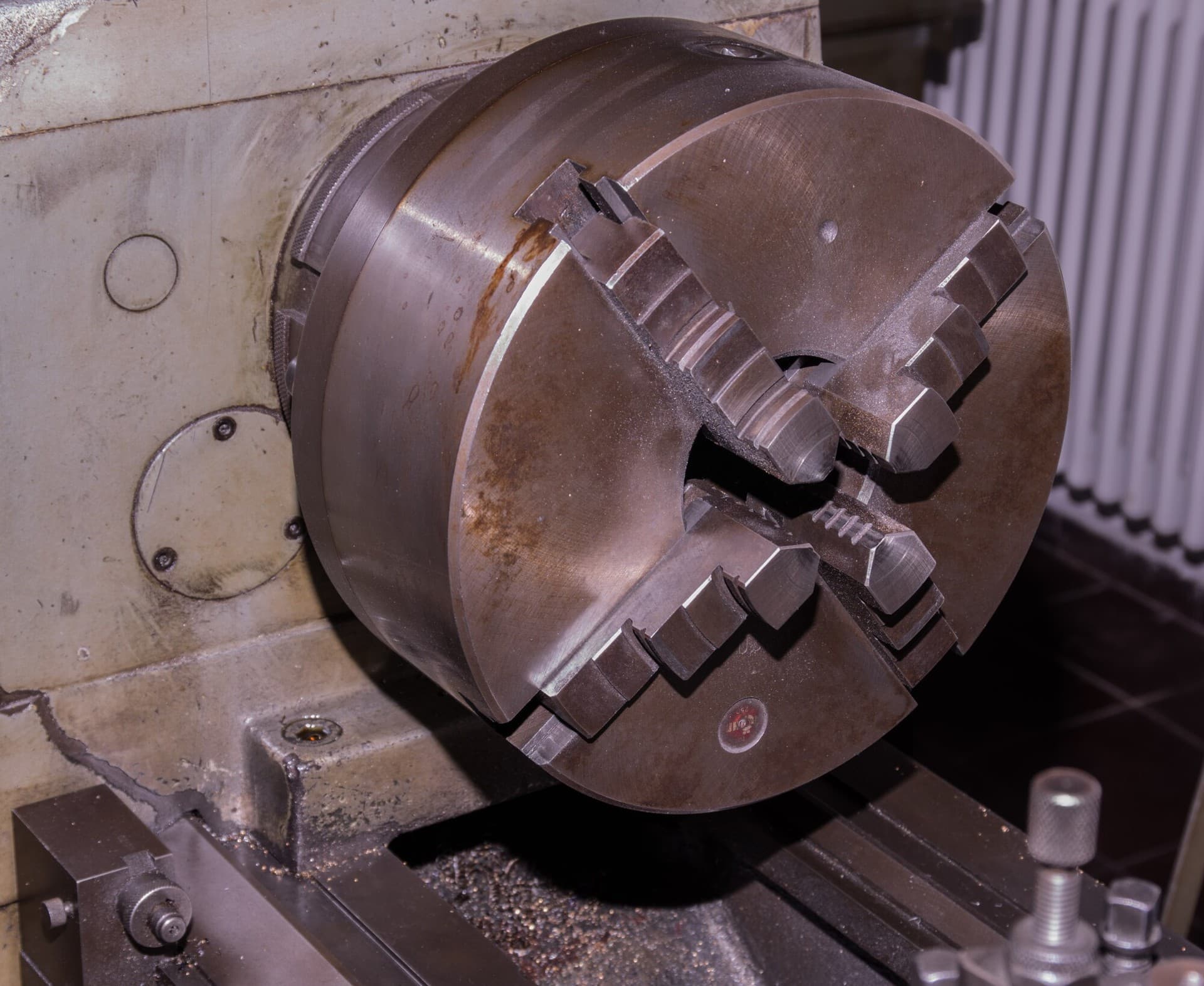

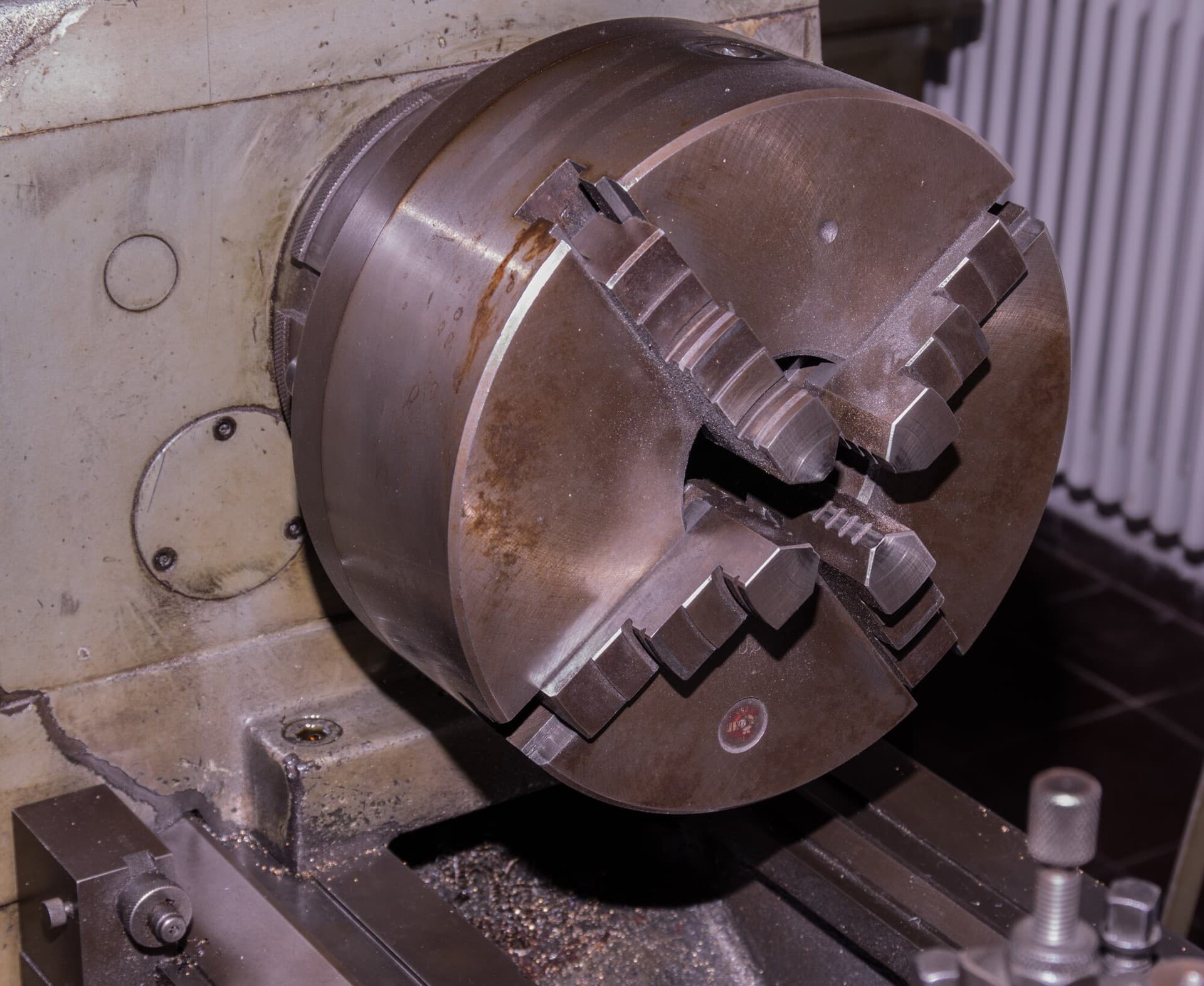

The foot brake of a lathe machine consists of several key components that work together to bring the spinning chuck or spindle to a halt. These components include the foot pedal, linkage system, brake drum, brake shoes, and the clutch. The foot pedal, usually located at the base of the machine, is connected to the linkage system, which transfers the motion to the brake drum. Inside the drum, the brake shoes make contact with the rotating drum surfaces, creating friction and slowing down the spinning motion. The clutch, another important element, disengages the power from the motor, allowing the foot brake to take control.

The functionality of a lathe foot brake relies on the principle of friction. As the foot pedal is depressed, the linkage system moves, causing the brake shoes to engage with the brake drum. The resulting friction between the shoes and drum generates resistance, gradually slowing down the rotational speed of the chuck or spindle. This gradual deceleration ensures a controlled and safe stop, preventing sudden jolts or accidents in the workspace. Additionally, modern lathe foot brakes often feature safety mechanisms, such as microswitches or proximity sensors, that prevent the machine from starting if the foot pedal is depressed.

Operation and Safety Features

Operating a lathe foot brake requires both precision and caution. To bring the machine to a stop, the operator needs to apply gradual pressure on the foot pedal using their foot. The foot pedal is designed to be easily accessible and comfortable to use, often utilizing a large surface area for increased control. When pressure is applied, the linkage system transfers the motion to the brake drum, causing the brake shoes to engage. The friction between the shoes and drum then slows down the rotational motion of the chuck or spindle.

In terms of safety features, lathe foot brakes are equipped with various mechanisms to prevent accidental startups or mishaps. These include emergency stop buttons, which instantly cut off power to the machine, and safety interlock systems that ensure the foot brake is engaged before the lathe can be operated. Some advanced lathe models also incorporate electronic braking systems that provide even greater control and precision during the braking process. It is important for operators to familiarize themselves with these safety features and adhere to proper operating procedures to prevent accidents and ensure the longevity of the machine.

Tips for Using a Lathe Foot Brake

Using a lathe foot brake effectively and safely requires adherence to certain tips and practices. Here are some essential tips to keep in mind:

- Always wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Before operating the lathe, make sure the foot brake is properly adjusted and functioning correctly.

- Use gradual pressure on the foot pedal to bring the machine to a stop, avoiding sudden or jerky movements.

- Never override safety mechanisms or attempt to bypass them.

- Regularly inspect the brake shoes for wear and tear, and replace them as needed.

- Maintain a clean and clutter-free workspace to minimize the risk of accidents or entanglements.

- Seek proper training and familiarize yourself with the specific lathe model’s operating manual.

- Perform regular maintenance and lubrication on the foot brake components to ensure optimal performance.

Advancements in Lathe Foot Brake Technology

Over the years, advancements in technology have led to the development of more sophisticated lathe foot brakes. These advancements aim to enhance safety, improve efficiency, and offer greater control to the operator. Here are three notable advancements in lathe foot brake technology:

Electronic Braking System

Some modern lathes feature electronic braking systems that utilize sensors and electronic controls to regulate the stopping power. These systems offer precise control over the braking process, allowing operators to achieve more accurate and consistent results. Electronic braking systems also reduce the wear and tear on brake components, prolonging their lifespan.

Automatic Brake Adjustment

In traditional lathe foot brakes, manual adjustments are required to maintain optimal performance. However, newer models may incorporate automatic brake adjustment mechanisms. These mechanisms continuously monitor and adjust the brake shoes’ positioning, ensuring consistent contact with the brake drum and optimal braking performance. Automatic brake adjustment minimizes user intervention and reduces the risk of human error.

Integrated Safety Systems

Modern lathe foot brakes often come equipped with integrated safety systems that go beyond the basic safety features. These systems can include advanced sensors that detect irregularities in operation, emergency stop mechanisms that activate upon the detection of a fault, and remote monitoring capabilities for real-time safety monitoring. Integrated safety systems provide an extra layer of protection and peace of mind for both operators and supervisors.

Beyond the Basics: Exploring Advanced Lathe Foot Brake Features

While the fundamental principles of a lathe foot brake remain the same, advanced models come with additional features that enhance the overall functionality and user experience. Let’s explore some of these advanced features:

Variable Speed Control

Some lathe foot brakes offer variable speed control, allowing operators to adjust the braking force and speed according to their specific requirements. The ability to fine-tune the braking process provides greater flexibility and precision, making it easier to work with different materials and achieve desired results.

Programmable Braking Sequences

In high-end lathe foot brakes, programmable braking sequences can be utilized to automate complex stopping procedures. These sequences allow users to set specific speed reduction profiles, time intervals, and other parameters, ensuring consistent and repeatable stopping actions. Programmable braking sequences are especially beneficial for intricate machining processes that require precise control.

Remote Control Operation

For improved convenience and safety, some lathe foot brakes can be operated remotely using dedicated control panels or wireless devices. Remote control operation eliminates the need for physical contact with the foot pedal, reducing the risk of accidents and making the braking process more efficient. This feature is particularly useful when operating heavy or large workpieces.

With these advanced features, lathe foot brakes are becoming more versatile, user-friendly, and safer than ever before. Harnessing these technologies allows operators to optimize their workflow, achieve better results, and ensure a secure working environment.

Conclusion

A lathe foot brake is a vital component of a lathe machine, enabling controlled stopping and ensuring operator safety. By comprehensively understanding how a lathe foot brake works and following proper operating procedures, operators can efficiently and safely use this important tool. With advancements in technology, modern lathe foot brakes offer enhanced features, such as electronic braking systems and automatic adjustments, enabling greater control and precision. Remember to always prioritize safety and adhere to recommended practices when operating a lathe machine.

Key Takeaways: How Does a Lathe Foot Brake Work?

- A lathe foot brake is a safety feature that helps stop the rotation of a lathe machine quickly and safely.

- When you press the foot brake pedal, it activates a brake mechanism that applies pressure to the lathe spindle, slowing it down and eventually stopping it.

- The foot brake is typically connected to a set of brake shoes or bands that clamp down on the spindle or the machine’s flywheel to create friction.

- This friction slows down the rotational energy and converts it into heat, dissipating the energy and stopping the lathe’s movement.

- A properly functioning foot brake is crucial for the operator’s safety, preventing accidents and allowing for quick and precise control over the lathe machine.

Frequently Asked Questions

When it comes to understanding how a lathe foot brake works, you may have a few questions. Let’s dive into some queries that can help you gain a better understanding of this mechanism.

How does the foot brake on a lathe machine function?

The foot brake on a lathe machine is a mechanical stopping device that helps control the rotation of the spindle. When the operator presses the foot pedal, it activates a series of components, including linkages, levers, and a braking mechanism. These parts work together to slow down and eventually stop the spindle’s rotation.

The braking mechanism often consists of brake shoes or pads, which exert friction on a rotating drum attached to the spindle. As the brake shoes press against the drum, the resulting friction generates the necessary force to slow down and stop the spindle.

What are the advantages of using a foot brake on a lathe machine?

Using a foot brake on a lathe machine offers several advantages. One benefit is the operator’s ability to have immediate control over the spindle’s rotation. By using their foot to engage the brake, they can stop the spindle quickly for safety or operational purposes.

Additionally, a foot brake allows for hands-free operation. This becomes particularly useful when the operator needs to make adjustments or perform other tasks while simultaneously stopping the spindle. The convenience of using a foot brake frees up the operator’s hands, providing more flexibility and efficiency in the machining process.

Can I adjust the sensitivity of the foot brake on a lathe machine?

Usually, the sensitivity of the foot brake on a lathe machine can be adjusted based on the operator’s preference or the requirements of the machining task at hand. This adjustment is typically achieved by altering the tension or pressure applied to the brake shoes or pads against the rotating drum.

It’s important to note that adjusting the sensitivity of the foot brake should be done with caution. Proper adjustments should be made according to the manufacturer’s guidelines, ensuring that the brake’s functionality remains optimal and that safety measures are in place.

Do lathe machines only use foot brakes for stopping the spindle?

No, foot brakes are just one type of braking mechanism used on lathe machines. Depending on the specific lathe model, there may be additional braking systems in place. These can include electromagnetic brakes, mechanical brakes, or pneumatic brakes.

Each type of brake serves a particular purpose and may be used in different scenarios. For example, while a foot brake provides immediate stopping power, electromagnetic brakes offer precise control over the spindle’s speed and can be engaged or disengaged electronically.

What safety precautions should I take when using the foot brake on a lathe machine?

When operating a lathe machine and using the foot brake, it’s crucial to prioritize safety. Some essential precautions include wearing appropriate personal protective equipment (PPE), such as safety glasses and hearing protection, to safeguard against any potential hazards.

Additionally, operators should ensure that the lathe machine and foot brake are well-maintained and regularly inspected for any signs of wear or malfunction. Following the manufacturer’s guidelines and receiving proper training on the use of the machine is also essential to prevent accidents and promote a safe working environment.

Summary

So, to wrap things up, a lathe foot brake is a device used to stop the spinning of a lathe machine. It works by pressing down on a pedal, which activates a brake shoe to rub against a drum on the lathe’s spindle. This friction slows down and eventually stops the spindle’s rotation, bringing the lathe to a halt.

In addition to stopping the lathe, the foot brake also helps control the speed at which the machine rotates. By adjusting the pressure applied to the pedal, the operator can increase or decrease the braking force, allowing for more precise control over the lathe’s movements. So, the foot brake serves an important dual purpose of stopping and controlling the lathe’s speed, making it an essential safety feature in lathe machines.