Have you ever wondered how a lathe machine works? Well, you’re in luck! In this article, we’ll explore the fascinating world of lathes and uncover how they magically transform raw materials into intricate objects. So buckle up and get ready to dive into the mesmerizing world of lathe machines!

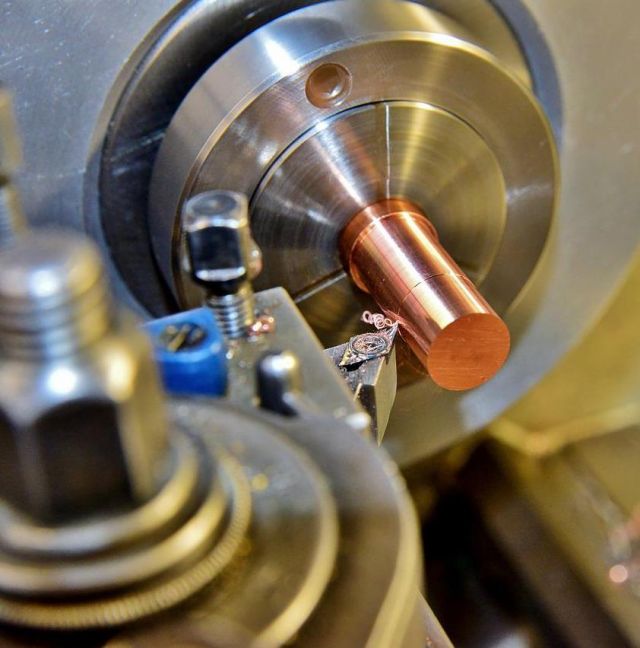

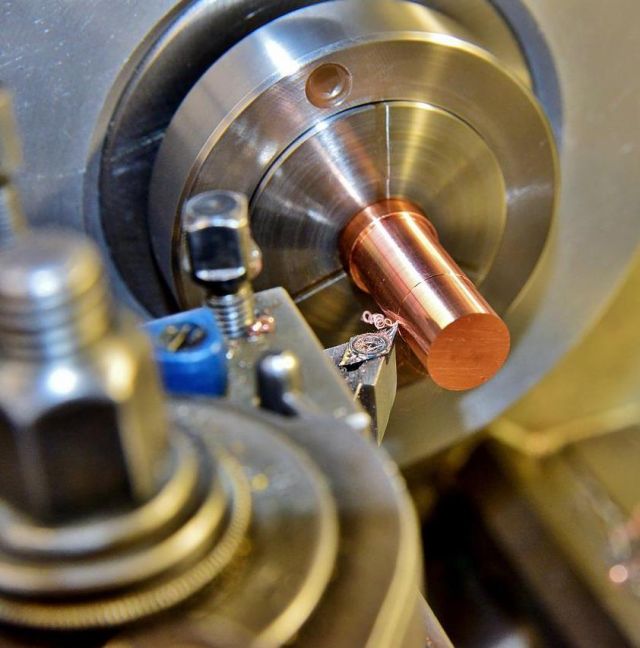

Picture this: a sturdy machine, spinning rapidly, with a chunk of metal locked in its grip. As the machine rotates, a sharp cutting tool skims the surface of the metal, shaping it into something entirely new. It’s like watching a sculpture come to life right before your eyes! But how does it all happen? Let’s find out!

Welcome to the magical realm of lathe machines, where the power of rotation brings dreams to reality. With precision and finesse, these machines shape, cut, and carve materials with absolute precision. From metal to wood, lathe machines can work their magic on a variety of materials. So, are you ready to unlock the secrets behind this incredible machine? Let’s dive in!

A lathe machine is a versatile tool used in woodworking and metalworking projects. It works by rotating the workpiece on its axis while a cutting tool shapes it. The machine’s basic components include the headstock, tailstock, bed, and carriage. The headstock holds the workpiece and provides rotational movement, while the tailstock supports the other end. The bed provides a stable base, and the carriage moves along it to position the cutting tool. This process allows for precise shaping, cutting, drilling, and turning of various materials.

How Does a Lathe Machine Work: An In-Depth Explanation

A lathe machine is a versatile and essential tool used in various industries, including woodworking, metalworking, and machining. It operates by spinning a workpiece around its axis and holding cutting tools against the workpiece to remove material and shape it into the desired form. While the basic concept of a lathe machine remains the same, there are different types and variations, each with its specific applications and functionalities.

Understanding how a lathe machine works is essential for anyone interested in manufacturing, fabricating, or repairing. In this article, we will delve into the inner workings of a lathe machine, discussing its components, operations, and the types of projects it is suitable for. Whether you are a seasoned professional or a curious hobbyist, this article will provide you with a comprehensive understanding of how a lathe machine functions and how it can be utilized to create precise and intricate workpieces.

The Components of a Lathe Machine

Before we explore the workings of a lathe machine, let’s first familiarize ourselves with its key components. These components work in harmony to ensure the smooth and efficient operation of the machine:

1. Bed: The bed is the foundation of the lathe machine and provides support and stability. It is typically made of solid cast iron to minimize vibrations and ensure accuracy.

2. Headstock: The headstock houses the main spindle, which holds and rotates the workpiece. It contains gears and pulleys that transmit power from the motor to the spindle.

3. Tailstock: The tailstock is located at the opposite end of the lathe machine and functions as a support for longer workpieces. It can be adjusted along the bed and clamps the workpiece securely.

4. Carriage: The carriage is responsible for holding and moving the cutting tool across the workpiece. It consists of several components, including the saddle, cross-slide, and apron, which house various controls and mechanisms.

5. Tool Rest: The tool rest is a support for the cutting tool and is positioned in proximity to the workpiece. It provides stability and precision, allowing the cutting tool to effectively remove material.

6. Compound Rest: The compound rest allows for precise angle adjustments of the cutting tool. It is often used when creating tapered or angled cuts.

7. Chuck: The chuck is responsible for securing the workpiece onto the spindle. It provides a strong grip to prevent slippage during machining.

The Operations of a Lathe Machine

Now that we are familiar with the components, let’s delve into the operations of a lathe machine. There are several fundamental operations that a lathe machine can perform:

1. Turning: This is the most basic operation of a lathe machine. It involves removing material from the surface of the workpiece to create a cylindrical shape. The cutting tool is fed into the workpiece while it rotates, resulting in a smooth and even surface.

2. Facing: Facing is the process of creating a flat surface perpendicular to the axis of the workpiece. The cutting tool moves parallel to the axis and removes material from the face of the workpiece.

3. Drilling: With the help of special attachments, a lathe machine can also perform drilling operations. The workpiece is rotated, and the cutting tool is fed into it to create holes of various sizes and depths.

4. Tapering: Tapering involves gradually reducing the diameter of the workpiece to create a tapered shape. The compound rest is used to set the desired angle, and the cutting tool is fed into the workpiece accordingly.

5. Grooving: Grooving is the process of creating a channel or groove on the surface of the workpiece. A specialized cutting tool is employed to remove material and create the desired groove shape and depth.

These are just a few of the operations that a lathe machine can perform. By combining these operations and utilizing different cutting tools, it is possible to create an infinite variety of shapes, profiles, and designs.

The Types of Lathe Machines

Lathe machines come in various types and configurations, each designed for specific applications and project requirements. Here are some of the commonly used types of lathe machines:

1. Engine Lathe: Engine lathes are the most common type of lathe machine. They are versatile and suitable for a wide range of applications, from small-scale hobby projects to large-scale industrial productions.

2. Turret Lathe: Turret lathes are known for their automated tooling capabilities. They feature a turret that can hold multiple cutting tools, allowing for quick and efficient tool changes during machining.

3. CNC Lathe: Computer Numerical Control (CNC) lathes are equipped with computerized controls and programmable cutting paths. They offer precise and automated machining capabilities, making them ideal for complex and high-precision applications.

4. Vertical Lathe: Vertical lathes, also known as VTL (Vertical Turning Lathe), have a vertical spindle and workpiece orientation. They are commonly used for machining large, heavy workpieces that are difficult to handle on horizontal lathes.

5. Automatic Lathe: Automatic lathes are designed for high-volume production of small, simple parts. They are capable of automatically feeding and machining workpieces, significantly increasing productivity.

These are just a few examples of the types of lathe machines available. Each type has its advantages and is suitable for specific applications and project requirements.

Benefits of Using a Lathe Machine

Now that we have explored the inner workings of a lathe machine, let’s discuss the benefits of using this versatile tool:

1. Versatility: A lathe machine can be used for a wide range of operations, from basic turning and facing to complex tapering and grooving.

2. Precision: Lathe machines offer exceptional accuracy and precision, allowing for the creation of intricate and finely detailed workpieces.

3. Efficiency: With the ability to perform multiple operations in a single setup, lathe machines streamline the machining process, saving time and increasing productivity.

4. Customization: Lathe machines enable the creation of custom-designed parts and components, catering to specific project requirements and specifications.

5. Skill Development: Learning to operate a lathe machine enhances one’s technical skills and opens up opportunities for career advancement in various industries.

These benefits make a lathe machine an essential tool for craftsmen, engineers, and manufacturers across different sectors. Whether you are a professional or an enthusiast, a lathe machine can unleash your creativity and transform your ideas into tangible objects.

Key Takeaways: How Does a Lathe Machine Work?

- A lathe machine is a tool used to shape and cut materials like wood or metal.

- It works by rotating the material on a spindle while a cutting tool is used to shape it.

- The operator controls the movement of the tool using various knobs and handles.

- Lathe machines can create cylindrical objects, threads, or smooth surfaces.

- They are commonly used in woodworking, metalworking, and manufacturing industries.

Frequently Asked Questions

Welcome to our FAQ section where we answer some common questions about how a lathe machine works. Whether you’re a beginner or have some familiarity with lathe machines, we’ve got you covered! Read on to learn more about this fascinating tool.

Can you explain the basic functionality of a lathe machine?

A lathe machine is a versatile tool used in machining processes to shape and size various materials, such as metal, wood, and plastic. It works by rotating the workpiece against a cutting tool to remove excess material and create the desired shape. The workpiece is secured firmly in place and spins on its axis, allowing the cutting tool to smoothly remove material from its surface.

Lathe machines come in different types, including engine lathes, turret lathes, and CNC lathes. They have various attachments and accessories that enable different machining operations such as turning, facing, drilling, and threading. Overall, the basic functionality of a lathe machine involves rotating the workpiece and using a cutting tool to shape it.

What are the key components of a lathe machine?

A lathe machine consists of several key components. The main parts include the headstock, tailstock, bed, carriage, and the cutting tool. The headstock holds the workpiece and is responsible for providing rotational motion. It contains the spindle, which rotates the workpiece, allowing it to be machined.

The tailstock, on the other hand, acts as support for the other end of the workpiece, ensuring stability during machining processes. The bed is the foundation of the machine, providing support and alignment for the other components. The carriage is responsible for moving the cutting tool along the axis of the workpiece, enabling accurate machining operations.

How does a lathe machine control the speed of rotation?

A lathe machine controls the speed of rotation through the use of a gearbox or a variable speed control system. In traditional engine lathes, a gearbox with a set of gears allows for different speed settings. By shifting gears, the operator can adjust the speed to match the requirements of the machining operation.

In modern CNC lathes, the speed is controlled electronically using a variable speed control system. This system allows for precise and automated adjustments of the rotational speed, providing more flexibility and control during machining processes.

What safety precautions should be taken when operating a lathe machine?

When operating a lathe machine, it is essential to follow proper safety precautions to prevent accidents and injury. Some key safety measures include wearing appropriate personal protective equipment (PPE) such as safety glasses and gloves, securing the workpiece properly using a chuck or vise, and keeping long hair and loose clothing away from moving parts.

It is also important to use the correct cutting tools for the intended operation, ensuring they are sharp and properly secured. Additionally, operators should be familiar with emergency stop procedures and always maintain a clear and organized work area to avoid tripping hazards or clutter that could interfere with safe machine operation.

What are some common applications of lathe machines?

Lathe machines have a wide range of applications across various industries. They are commonly used for turning and shaping cylindrical objects such as shafts, bushings, and pulleys. In the automotive industry, lathe machines are used for machining engine components like pistons and crankshafts.

In woodworking, lathe machines are used to create decorative objects like bowls, table legs, and other turned wood pieces. Additionally, lathe machines are extensively used in metalworking, jewelry making, and prototype manufacturing processes. The versatility of lathe machines makes them an indispensable tool in many industries.

Summary

So, let’s quickly go over what we’ve learned about how a lathe machine works. First, a lathe machine is a tool used for shaping and cutting materials like wood or metal. It has a spinning chuck that holds the material in place. The material is then rotated as a cutting tool comes in contact with it, shaping and smoothing it. This process can create different shapes and designs. The lathe machine is controlled by a skilled operator who adjusts the speed and depth of the cuts. Overall, it’s a fascinating machine that helps create many useful things we use every day!