Are you curious about how machinists determine the size of a lathe? Well, let me tell you, it’s like solving a puzzle! Each lathe comes with specific measurements that help machinists figure out its size. But wait, what is a lathe anyway? Imagine a spinning machine that shapes and cuts materials like metal or wood with precision. Cool, right?

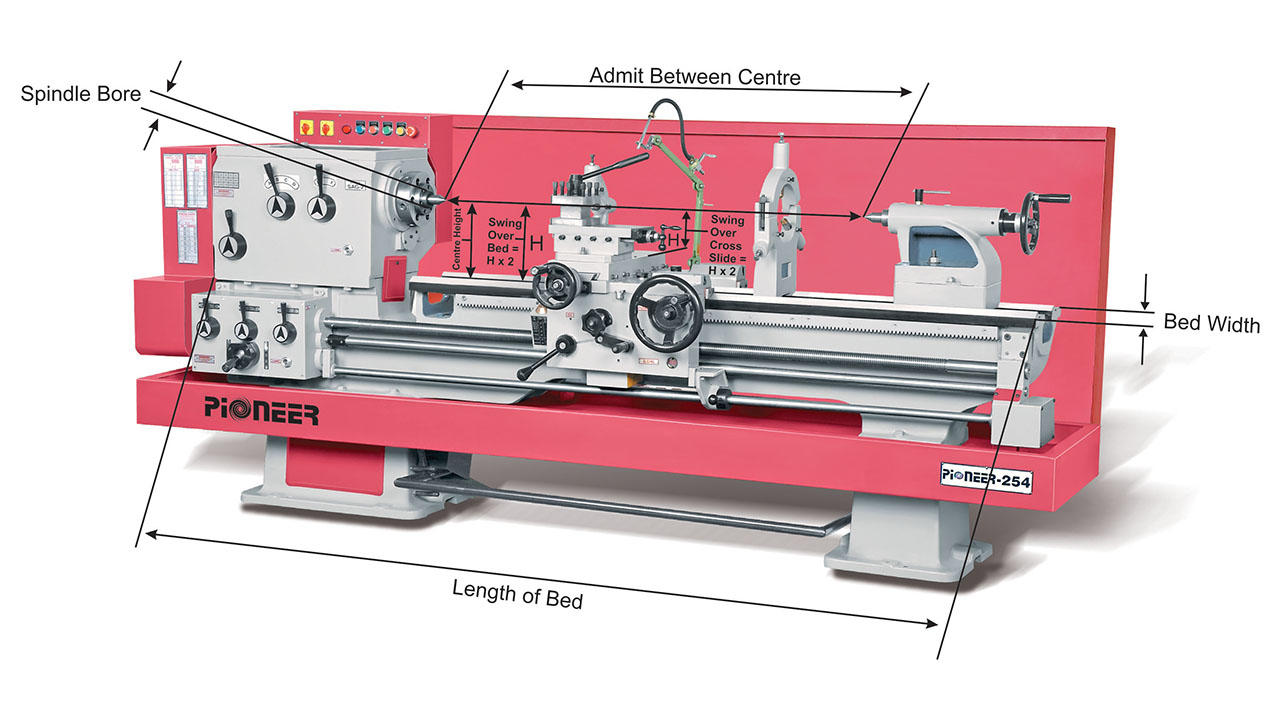

Now, let’s dive into the fascinating world of machining! When it comes to determining the size of a lathe, machinists consider a few key factors. First, they look at the swing over bed measurement, which is the maximum diameter of the workpiece that can fit on the lathe. Then, there’s the distance between centers, which tells them how long the lathe can handle a workpiece. So, in essence, the size of a lathe is determined by its capability to handle different workpiece dimensions.

But wait, there’s more! Machinists also take into account the horsepower of the lathe, which refers to the power it has to spin the workpiece. Additionally, they consider the size and type of tooling that the lathe can accommodate. All these factors combined help machinists determine the size of a lathe and select the right one for their specific needs.

So, if you’ve ever wondered how machinists determine the size of a lathe, now you know! It involves considering measurements like swing over bed and distance between centers, as well as factors like horsepower and tooling. It’s a fascinating process that allows machinists to work with precision and create amazing things. Isn’t it incredible how machines help us shape the world around us? Let’s delve deeper into the world of machining and uncover more exciting secrets!

- Measure the Swing: Measure the distance from the bed of the lathe to the lathe center for the swing measurement.

- Find the Bed Length: Measure the distance between the headstock and tailstock to determine the bed length.

- Calculate the Distance between Centers: Measure the maximum size of workpiece a lathe can hold by finding the distance between centers.

- Consider the Spindle Bore: Measure the diameter of the spindle bore to determine the maximum size of workpiece that can pass through.

- Check Motor Power: Look for the motor power rating to ensure it is suitable for the size and type of work you plan to do.

How Does a Machinist Determine the Size of a Lathe?

When it comes to the world of machining, lathes are an essential tool for turning, shaping, and creating cylindrical objects. But determining the right size of a lathe can be a daunting task for machinists. With various factors to consider, such as the diameter and length capacity, power requirements, and the type of workpiece, machinists need a systematic approach to ensure they select the appropriate size lathe for their machining needs. In this article, we will delve into the methods and considerations machinists use to determine the size of a lathe.

The Workpiece Dimensions

One of the primary factors affecting the choice of lathe size is the dimensions of the workpiece to be machined. Machinists need to consider both the maximum diameter and the length of the workpiece when selecting a lathe. The maximum diameter is crucial, as it determines the swing capacity of the lathe. The swing refers to the maximum diameter of a workpiece that can be accommodated on the lathe without any obstructions. Machinists must ensure that the lathe’s swing capacity is greater than the workpiece’s maximum diameter to allow for efficient turning operations.

Additionally, machinists must consider the length of the workpiece and select a lathe with an appropriate length capacity. The length capacity refers to the distance between the lathe’s headstock and tailstock, and it determines the maximum length of a workpiece that can be accommodated. Machinists need to ensure that the lathe’s length capacity is sufficient to accommodate the workpiece without any overhang or strain on the lathe’s components.

In summary, machinists determine the size of a lathe based on the dimensions of the workpiece, considering both the maximum diameter (swing capacity) and the length. By selecting a lathe with adequate capacity, machinists can ensure optimal machining results.

Power Requirements

Another crucial factor in determining the size of a lathe is the power requirements for the intended machining tasks. Different workpieces and machining operations require varying levels of power. Machinists need to consider the cutting forces, material hardness, and the desired cutting speed to assess the power needed.

Typically, lathes are categorized based on their horsepower rating. The higher the horsepower, the more power the lathe can deliver to handle demanding machining tasks. Machinists should take into account the material they will be machining and the depth and speed of the cuts to determine the suitable horsepower range for their lathe. It is important to select a lathe with sufficient power to prevent inadequate performance or motor overload during machining operations.

By considering the power requirements for their intended workpieces, machinists can ensure that they choose a lathe with the appropriate horsepower to effectively handle their machining needs.

Type of Workpiece and Machining Operations

The type of workpiece and the specific machining operations also play a significant role in determining the size of a lathe. Different lathes are designed to accommodate specific types of work, such as woodturning, metal turning, or precision machining. Machinists must select a lathe that is suitable for the intended workpiece material and the required precision.

For example, if a machinist primarily works with metal, they would typically opt for a metal lathe. Metal lathes are designed with features that make them suitable for handling metal workpieces, such as rigid construction, adjustable speeds, and various tooling options. On the other hand, if the machinist specializes in woodworking, a wood lathe would be the preferred choice.

Furthermore, machinists should also consider the specific machining operations they will be performing. Some lathes come with additional features, such as thread cutting capabilities or multiple chuck options, which may be necessary for certain types of work. By matching the type of lathe to the specific workpiece material and machining operations, machinists can ensure optimal results and productivity.

Beyond Size: Other Considerations for Machinists

While determining the size of a lathe is crucial, machinists also need to consider other factors that can contribute to their overall machining experience and efficiency.

Firstly, machinists should pay attention to the overall quality and durability of the lathe, as this can significantly impact its lifespan and performance. Choosing a reputable brand and reading reviews can help ensure that the lathe is built to withstand the demands of machining.

Additionally, machinists should consider the availability and cost of accessories, tooling, and replacement parts for the lathe they are considering. This includes things like chucks, tool posts, and cutting tools. Having a variety of options readily available can enhance the versatility and functionality of the lathe.

Lastly, machinists should also take into account their own work environment and budgetary constraints. The available space in the workshop should be considered to ensure that the chosen lathe can fit comfortably and safely. It is also important to find a balance between the desired features and the allocated budget.

Conclusion

Determining the size of a lathe is a critical decision for machinists. By considering the workpiece dimensions, power requirements, and the type of workpiece and machining operations, machinists can choose a lathe that meets their specific needs. It is essential to take into account other considerations, such as lathe quality and availability of accessories, to ensure a well-rounded choice. By selecting the right size lathe, machinists can optimize their machining capabilities and achieve superior results.

Key Takeaways: How Does a Machinist Determine the Size of a Lathe?

- A machinist can determine the size of a lathe by considering the swing over bed measurement, which is the maximum diameter of a workpiece that can be accommodated by the lathe.

- The center height is another important factor to consider, as it determines the distance between the lathe’s bed and the lathe’s centerline, allowing for proper machining of cylindrical workpieces.

- The distance between centers is a key measurement that indicates the maximum length of workpiece that can be turned on the lathe without additional support.

- Spindle bore size is crucial when working with long workpieces or those that require larger spindle openings to pass through.

- Machinists also need to consider the horsepower rating of the lathe, which determines the machine’s power and ability to handle different types of materials and machining operations.

Frequently Asked Questions

Welcome to our FAQ section on determining the size of a lathe! Here, we will provide answers to some common questions about how machinists determine the size of a lathe. Whether you’re a beginner or a seasoned machinist, we’ve got you covered. Read on to find out more!

Q1. What factors should a machinist consider when determining the size of a lathe?

When determining the size of a lathe, a machinist needs to consider several factors:

Firstly, they should think about the size of the workpiece they will be working with. This will help them determine the maximum swing (diameter) and the center distance (length) needed for the lathe. Additionally, they need to consider the weight and material of the workpiece, as heavier or more rigid materials may require larger lathes for stability.

Secondly, the type of operations the machinist intends to perform is crucial. Different operations, such as turning, facing, or threading, may require specific lathe sizes or capabilities. For example, if the machinist plans to turn large-diameter tapers, they will need a lathe with a larger swing.

Q2. How does the swing over the bed impact the size determination of a lathe?

The swing over the bed is a key factor when determining the size of a lathe. It refers to the maximum diameter of the workpiece that can be turned while the bed remains stationary. The swing over the bed helps machinists determine the size they need to accommodate their workpieces.

A larger swing over the bed is particularly important when working with larger or longer workpieces. It ensures that the workpiece fits within the lathe, allowing for smooth and accurate machining. However, it’s also worth noting that a larger swing may require a more substantial and expensive lathe. Machinists need to strike a balance between the size they need for their workpieces and the practicality of the lathe for their overall operations.

Q3. What role does the center distance play in determining the size of a lathe?

The center distance, also known as the distance between centers, is another crucial factor in determining the size of a lathe. It refers to the maximum length of the workpiece that can be accommodated between the lathe’s headstock and tailstock centers.

When selecting a lathe, machinists must consider the length of the workpieces they will be dealing with. It’s important to choose a lathe with a center distance that is suitable for the longest workpiece they plan to machine. If the workpiece exceeds the center distance, it won’t fit on the lathe, resulting in limitations or the need for additional tooling or setups.

Q4. How does the horsepower rating affect the size determination of a lathe?

The horsepower rating of a lathe is an important consideration in determining its size. The horsepower rating determines the amount of power the lathe’s motor can provide.

Machinists need to calculate the required horsepower based on the type of work they perform. Heavy-duty machining operations, such as turning large diameter workpieces or cutting hard materials, may require a lathe with a higher horsepower rating. Adequate horsepower ensures that the lathe can handle the workload without straining the motor or affecting the quality of the machining process.

Q5. Are there any other factors a machinist should consider when determining the size of a lathe?

While factors like swing over the bed, center distance, and horsepower rating are key considerations, there are a few other factors to keep in mind:

Firstly, the available space in the workshop should be taken into account. It’s important to choose a lathe that fits within the available space while still allowing for comfortable operation and maintenance.

Secondly, the reputation and reliability of the lathe manufacturer should also be considered. Opting for a reputable brand ensures that the machinist gets a high-quality lathe that is durable and comes with good customer support.

Summary

So, how does a machinist determine the size of a lathe? Well, it turns out that there are a few important factors to consider.

First, the machinist needs to measure the swing of the lathe, which is the maximum diameter of the workpiece that can fit. They do this by measuring the distance from the center of the lathe’s spindle to the closest point on the bed.

Next, the machinist needs to determine the distance between the lathe’s centers, which is called the “between centers” length. This measurement tells them the maximum length of the workpiece that can be turned.

Finally, the machinist needs to consider the horsepower of the lathe’s motor. The size and type of workpiece that can be turned is often limited by the power of the motor.

By taking these factors into account, a machinist can determine the size of a lathe and choose the right one for their needs.