Have you ever wondered how a random orbital sander works? Well, let me break it down for you in a fun and engaging way!

Imagine you have a favourite toy car that needs a new paint job. If you were to use a regular sandpaper and rub it back and forth, it would take forever and your hand would get tired, right? But fear not, that’s where the random orbital sander swoops in to save the day!

This high-tech tool not only makes sanding faster and easier, but it also creates a smooth and flawless finish. So, buckle up and let’s take a closer look at how this magical gizmo works its wonders!

How Does a Random Orbital Sander Work?

A random orbital sander is a versatile power tool commonly used in woodworking and refinishing projects. With its circular sanding pad that moves in a random pattern, it can quickly and efficiently smooth surfaces, remove old finishes, and create a smooth and polished result. To understand how a random orbital sander works, it’s important to delve into its key components and the science behind its unique sanding motion.

1. Understanding the Components

A random orbital sander consists of several essential components that work together to produce its sanding action. The main parts include:

The Motor: Similar to other power tools, the random orbital sander is powered by an electric motor. The motor generates the necessary power to spin the sanding pad.

Sanding Pad: The sanding pad is the point of contact between the tool and the workpiece. It is usually made of a durable material such as hard rubber or foam and is attached to the sander using a hook-and-loop system or adhesive.

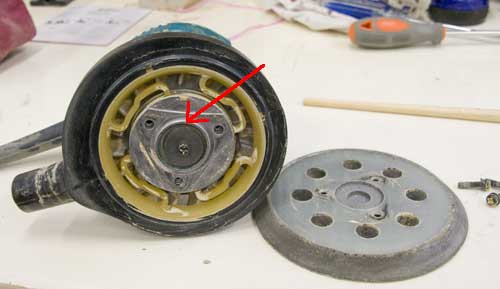

Orbit Mechanism: The orbit mechanism is what sets the random orbital sander apart from other types of sanders. It consists of an eccentric bearing that causes the sanding pad to move in an elliptical or random pattern. This random motion eliminates the risk of sanding marks or patterns on the workpiece.

How the Orbit Mechanism Works:

The eccentric bearing is situated off-center from the sanding pad’s axis of rotation. As the motor spins, it causes the bearing to move in a circular motion. This circular motion, combined with the off-center placement of the bearing, creates an uneven orbit that results in a random sanding pattern. This prevents the formation of swirl marks and produces a smooth and even finish.

2. The Sanding Process

When using a random orbital sander, it’s important to follow proper techniques to achieve the best results. The sanding process typically involves the following steps:

Preparation: Start by preparing the work area and ensuring the workpiece is securely clamped or supported. This prevents movement and allows for precise sanding.

Grit Selection: Choose the appropriate sandpaper grit based on the desired level of sanding aggressiveness and the condition of the workpiece. Begin with a coarser grit to remove imperfections and gradually progress to finer grits for a smoother finish.

Sanding Motion: Hold the sander firmly and turn it on, applying even pressure to the workpiece. Move the sander in a back-and-forth or circular motion, allowing the random orbital action to do the work. Avoid tilting the sander as it can cause uneven sanding. Let the weight of the sander and the sandpaper grit do the work for you.

Progression: As you sand, periodically check the workpiece to monitor the progress and ensure even sanding. Work systematically, overlapping each sanding pass slightly to avoid creating uneven patches.

Tips for Optimal Results:

- Start with a lower grit sandpaper to remove any rough imperfections.

- Use a lighter touch when sanding delicate surfaces to avoid accidental damage.

- Vary the sanding directions to achieve a more uniform finish.

- Clean the sanding pad or replace it with a fresh one if it becomes clogged with debris.

- Wear appropriate safety gear such as goggles and a dust mask to protect yourself from flying dust particles.

3. Benefits of Using a Random Orbital Sander

Random orbital sanders offer several advantages over traditional sanding methods. Here are some key benefits:

- Efficient Sanding: The random orbital motion allows for quick and efficient sanding, saving time and effort

- Uniform Finish: The random sanding pattern eliminates swirl marks or sanding lines, resulting in a smooth and uniform finish

- Versatility: Random orbital sanders can be used on various materials such as wood, metal, and plastic, making them suitable for a wide range of projects

- Less Risk of Surface Damage: The random orbital action reduces the risk of over-sanding or creating uneven patches, minimizing the chance of damaging the workpiece

- Dust Extraction: Many random orbital sanders come with built-in dust collection systems or can be connected to a vacuum, ensuring a cleaner and healthier working environment

The Importance of Proper Sanding Techniques

When using a random orbital sander, it’s crucial to follow proper sanding techniques to achieve the best results. Here are a few key points to keep in mind:

Selecting the Right Grit

Choosing the appropriate sandpaper grit is essential for achieving the desired level of smoothness and finish. A lower grit, such as 80 or 100, is suitable for removing rough imperfections, while higher grits like 150 or 220 are ideal for fine finishing and smoothing surfaces. Start with a coarser grit and gradually progress to finer grits for optimal results.

Moving in the Right Direction

When sanding with a random orbital sander, it’s important to move the tool in the right direction to prevent swirl marks or uneven sanding. Typically, it’s best to move the sander in the direction of the wood grain. If you’re not sure about the direction of the grain, test a small area before proceeding.

Applying Even Pressure

To achieve a uniform finish, it’s crucial to apply even pressure while sanding. Avoid pressing too hard on the sander, as it can create uneven patches or damage the workpiece. Instead, let the weight of the sander and the grit do the work for you. Keep a light grip on the tool and let it glide smoothly over the surface.

Choosing the Right Sandpaper Grit

When using a random orbital sander, selecting the appropriate sandpaper grit is essential for achieving the desired results. Here’s an overview of the different grits and their recommended uses:

Coarse Grits (60-80)

Coarse grits are typically used for aggressive material removal and leveling uneven surfaces. They are ideal for removing rough spots, paint, or stains from wood. However, they may leave visible scratches, so it’s crucial to follow up with finer grits for a smooth finish.

Medium Grits (100-120)

Medium grit sandpaper is suitable for general sanding tasks and removing moderate imperfections. It can help smooth rough surfaces and prepare them for the final finish. Medium grits are commonly used between coats of paint or varnish to achieve a smooth transition.

Fine Grits (150-180)

Fine grit sandpaper is used for final smoothing and preparing the surface for finishing touches. It is ideal for removing finer scratches, achieving a silky smooth surface, and ensuring a flawless result. Fine grits are commonly used for wood finishing, lacquer sanding, or prepping surfaces for staining.

Extra Fine Grits (220+)

Extra fine grit sandpaper is often used for ultra-smooth finishes and surface preparation before applying delicate coatings such as varnish or shellac. It helps remove tiny imperfections and leaves the surface ready for the final touch. Extra fine grits are commonly used in the final stages of sanding or in fine woodworking applications.

Wrap-Up:

Random orbital sanders are powerful and versatile tools that offer efficient and high-quality sanding results. By understanding their components and using proper sanding techniques, you can achieve smooth and professional finishes in your woodworking and refinishing projects. Remember to choose the right grit, move in the right direction, and apply even pressure for optimal results. With a random orbital sander in your arsenal, you’ll have the power to transform rough surfaces into polished masterpieces.

Key Takeaways: How Does a Random Orbital Sander Work?

- A random orbital sander works by combining spinning and oscillating movements to sand surfaces.

- It features a round sanding pad that moves in a random pattern, reducing the chance of creating visible swirl marks.

- Electrically powered, it uses sandpaper discs that attach to the sanding pad for effective material removal.

- The sander’s random orbital motion prevents sanding in a single direction, minimizing the risk of uneven sanding.

- It provides a smoother finish compared to other sanders, making it popular for woodworking and refinishing projects.

Frequently Asked Questions

Welcome to our frequently asked questions section on how a random orbital sander works! Here, we’ll explore the ins and outs of this handy tool and demystify its functionality. Read on to find out everything you need to know!

1. What makes a random orbital sander different from other types of sanders?

A random orbital sander is unique because it combines the best of both worlds: the sanding power of a belt sander and the finishing ability of a finish sander. It operates by simultaneously spinning the sanding disc and moving it in a random, elliptical pattern. This dual-action motion eliminates the risk of swirl marks and ensures a smooth, even finish on the surface being sanded.

Additionally, unlike other sanders, a random orbital sander uses hook-and-loop sanding discs, commonly known as Velcro discs. These discs are easy to attach and replace, making the sanding process more efficient.

2. How does a random orbital sander prevent gouging or uneven sanding?

A random orbital sander is designed to prevent gouging or uneven sanding through its innovative sanding pattern. By spinning the sanding disc while also moving it in a random, elliptical motion, the sander distributes the sanding force evenly across the surface. This reduces the risk of creating deep scratches or uneven spots, resulting in a more uniform finish.

Additionally, the random orbital sander often has a variable speed control feature, allowing the user to adjust the sanding speed according to the material being sanded. This control helps prevent the tool from removing too much material too quickly, further reducing the chance of gouging or uneven sanding.

3. Can I use a random orbital sander for multiple types of projects?

Yes, a random orbital sander is versatile and can be used for a wide range of projects. Whether you need to remove paint or varnish from furniture, smooth out rough wooden surfaces, or polish metal, a random orbital sander can handle the job. Its dual-action sanding motion and interchangeable sanding discs make it suitable for both heavy-duty sanding and fine finishing tasks.

However, keep in mind that the grit of the sanding discs should be adjusted based on the project requirements. Coarser grits, such as 60 or 80, are ideal for removing paint or heavy material, while finer grits, like 120 or 220, are better suited for achieving a smooth, polished finish.

4. How do I maintain a random orbital sander for optimal performance?

To ensure your random orbital sander performs at its best, regular maintenance is key. First and foremost, always disconnect the tool from the power source before cleaning or performing any maintenance. After each use, remove the sanding disc and clean any residual dust or debris from both the disc and the sander’s pad using a brush or compressed air.

Additionally, inspect the sanding pad for any signs of wear and replace it if necessary. Lubricating the pad’s hooks and loops with silicone spray or lubricant designed specifically for sanders can extend its lifespan. Lastly, make sure to store the sander in a clean, dry area to prevent any damage or deterioration.

5. Are there any safety precautions I should follow when using a random orbital sander?

Absolutely! Safety should always be a top priority when using power tools. When operating a random orbital sander, it’s crucial to wear safety goggles to protect your eyes from flying debris, as well as a dust mask to prevent inhaling harmful particles. Additionally, consider wearing hearing protection, especially if you’ll be using the sander for an extended period.

Make sure to keep your hands away from the rotating sanding disc and always maintain a firm grip on the sander while it’s in operation. Avoid applying excessive pressure, as the sander’s weight and motion should do the work for you. Finally, carefully read and follow the manufacturer’s instructions and guidelines to ensure safe and proper usage of the random orbital sander.

Summary

So, to sum it all up, a random orbital sander is a tool that helps smooth surfaces. It works by moving in circular and random patterns, preventing any noticeable swirl marks. The sanding pad spins and also moves in an elliptical motion to provide a smooth finish. Overall, it’s a handy tool for woodworking and DIY projects, making sanding a lot easier and more efficient.