Have you ever wondered how a sliding head lathe works? Well, you’re in luck because we’re about to dive into the fascinating world of machining! 🛠️ In this article, we’ll explore the inner workings of a sliding head lathe and uncover the secrets behind its precision and efficiency. So, fasten your seatbelts and get ready to embark on a mechanical adventure!

Picture yourself in a workshop surrounded by metal chips flying and machines humming. Now, imagine a powerful lathe with a sliding head, ready to bring your designs to life. A sliding head lathe is a remarkable piece of engineering that allows for intricate and complex machining operations. But how does it actually work?

In simple terms, a sliding head lathe is designed to hold and rotate a workpiece while cutting tools shape the material into the desired form. The magic lies in its ability to move the cutting tools horizontally and vertically, allowing for precise and multifaceted machining. So, whether you’re creating intricate threads or turning a perfectly symmetrical component, a sliding head lathe is the master of versatility and precision. Let’s dive deeper into the mechanics behind this marvelous machine!

How Does a Sliding Head Lathe Work?

A sliding head lathe is a precision machine tool used in the manufacturing industry for machining complex parts with high precision. It operates by rotating a workpiece while a cutting tool moves along the length of the workpiece to remove material and shape it into the desired form. Sliding head lathes are particularly useful for producing small and intricate components, such as screws, pins, and dental implants, with great accuracy and efficiency. In this article, we will explore the inner workings of a sliding head lathe and how it performs its operations.

1. The Main Components of a Sliding Head Lathe

A sliding head lathe consists of several key components, each playing a crucial role in the machine’s operation:

- Headstock: The headstock holds and rotates the workpiece.

- Main spindle: The main spindle is connected to the headstock and provides rotational motion to the workpiece.

- Collet chuck: The collet chuck holds the workpiece firmly in place while allowing it to rotate.

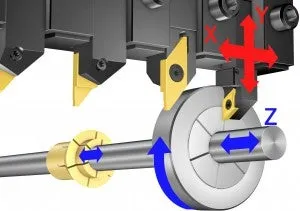

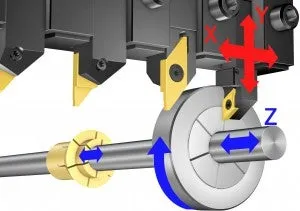

- Tooling system: The tooling system holds various cutting tools and allows them to move precisely along the workpiece.

- Control panel: The control panel consists of the user interface and control mechanisms for programming and operating the lathe.

These components work together seamlessly to achieve the desired machining result.

2. The Operation of a Sliding Head Lathe

The operation of a sliding head lathe involves several steps, starting from the setup of the workpiece and tooling to the final machining process:

2.1 Workpiece Setup

First, the operator secures the workpiece in the collet chuck, ensuring it is centered and aligned correctly. This guarantees precision machining without any errors due to misalignment.

2.1.1 Workpiece Fixturing

Once the workpiece is secured in the collet chuck, additional fixturing may be required to support and stabilize it during machining. This can involve the use of additional clamps, supports, or custom fixtures tailored to the specific workpiece.

2.1.2 Tooling Preparation

Simultaneously, the operator selects the cutting tools required for the job and prepares them by inserting them into the tooling system. Tooling selection depends on the desired machining operations, such as turning, drilling, or threading.

2.2 Programming and Operation

Once the workpiece and tooling setup are complete, the operator uses the control panel to program the specific machining operations required. This involves specifying parameters such as cutting speed, feed rate, and tool paths.

3. Machining Operations Performed by a Sliding Head Lathe

A sliding head lathe is capable of performing various machining operations, including:

- Turning: The cutting tool moves along the length of the workpiece, removing material and shaping it to the desired diameter.

- Drilling: The cutting tool creates holes of varying diameters in the workpiece.

- Threading: The cutting tool cuts threads on the workpiece, allowing for the insertion of screws or other threaded components.

- Parting: The cutting tool severs the workpiece into separate components, either completely or partially.

- Milling: In some sliding head lathes, additional milling capabilities are available for more complex machining operations.

- Deburring: The sliding head lathe can also remove any burrs or sharp edges left on the workpiece after machining.

These operations can be performed in a single setup, reducing processing time and increasing efficiency.

4. Advantages of Using a Sliding Head Lathe

Sliding head lathes offer several advantages over traditional lathes and machining methods:

- Precision: The sliding head lathe enables extremely accurate machining, resulting in parts with tight tolerances and superior surface finishes.

- Efficiency: The ability to perform multiple machining operations in a single setup reduces cycle times and increases productivity.

- Complexity: Sliding head lathes can handle small, intricate parts with ease, allowing for the production of complex geometries that would be challenging or impossible with other machines.

- Automation: Many sliding head lathes are equipped with advanced automation features, such as robotic loaders, that further enhance productivity and reduce operator intervention.

- Material Savings: The sliding head lathe’s precision and efficiency contribute to minimizing material waste, resulting in cost savings for manufacturers.

5. Tips for Operating a Sliding Head Lathe

To optimize the performance of a sliding head lathe, consider the following tips:

- Choose the right cutting tools for the job to ensure proper chip evacuation and minimize tool wear.

- Regularly inspect and maintain the collet chuck to ensure proper clamping force and prevent workpiece slippage.

- Monitor the cutting fluid to maintain optimal lubrication and cooling, extending tool life and improving surface finish.

- Use high-quality workholding fixtures and ensure proper alignment to minimize part runout and achieve accurate machining.

- Stay updated with the latest software and programming techniques to take full advantage of the lathe’s capabilities.

6. Safety Considerations When Operating a Sliding Head Lathe

Operating a sliding head lathe requires adherence to strict safety protocols to protect both the operator and the machine:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection.

- Ensure adequate lighting and visibility in the workplace to identify any potential hazards.

- Follow lockout/tagout procedures when performing maintenance or adjustments on the machine.

- Regularly inspect and replace worn or damaged cutting tools to prevent accidents.

- Train operators thoroughly on the safe operation of the sliding head lathe and provide ongoing refresher training.

7. Conclusion

A sliding head lathe is a versatile and efficient machine tool that plays a vital role in modern manufacturing. By understanding its components, operation, and capabilities, operators can harness its full potential to produce high-precision parts with ease. However, it is crucial to prioritize safety, proper tooling, and maintenance practices to ensure optimal performance and minimize risks. With the right knowledge and precautions, a sliding head lathe can be a valuable asset in any manufacturing facility.

Key Takeaways: How Does a Sliding Head Lathe Work?

- A sliding head lathe is a machine used to shape metal parts by removing excess material.

- It has a sliding headstock that moves along a horizontal rail, allowing for precise positioning.

- The sliding headstock holds the workpiece and rotates it while a cutting tool shapes the metal.

- This type of lathe is often used for making intricate and small-sized components.

- Sliding head lathes are commonly used in industries such as automotive, aerospace, and electronics.

Frequently Asked Questions

When it comes to understanding how a sliding head lathe works, you might have some questions. Check out the answers below to learn more!

1. What is a sliding head lathe?

A sliding head lathe is a type of lathe machine that is equipped with a sliding headstock. This allows the workpiece to be moved longitudinally as well as radially. Unlike a conventional lathe where the headstock remains stationary, a sliding head lathe provides greater flexibility in machining complex parts.

With a sliding head lathe, the workpiece is held by a collet or a chuck, while the cutting tools are mounted on the tool turret. As the workpiece rotates, the cutting tools are brought into contact with the material, enabling precision machining operations.

2. What are the advantages of using a sliding head lathe?

A sliding head lathe offers several advantages. Firstly, it allows for the production of complex parts with multiple machining operations in a single setup. This saves time and improves efficiency. Secondly, the sliding headstock enables machining close to the guide bush, resulting in improved accuracy and surface finish.

Additionally, sliding head lathes are known for their ability to work with small diameters and long lengths, making them suitable for industries such as automotive, medical, and electronics. They also excel in high-volume production, thanks to their rapid tool indexing and short non-cutting time. Overall, sliding head lathes provide versatility and precision, contributing to cost-effective manufacturing.

3. How does the sliding head mechanism work in a lathe?

In a sliding head lathe, the sliding head mechanism allows the headstock to move longitudinally. This movement is typically controlled by a combination of hydraulic or servo motors. The axial movement of the headstock, along with rotational movement, enables the cutting tools to reach various sections of the workpiece, facilitating complex machining processes.

The sliding head mechanism also helps support the workpiece during machining. It reduces vibrations and improves cutting stability, resulting in better surface finish and dimensional accuracy. This mechanism, combined with the precision of the tool turret, allows for high-quality machining operations in sliding head lathes.

4. What materials can be machined using a sliding head lathe?

Sliding head lathes are versatile machines that can work with a wide range of materials. They are commonly used for machining small parts made from materials such as brass, aluminum, stainless steel, titanium, and plastics. These lathes excel in precision machining applications, making them suitable for industries that require high-quality components.

It’s worth noting that the choice of cutting tools and machining parameters can vary depending on the material being machined. However, with the right setup and proper tool selection, a sliding head lathe can effectively machine a variety of materials while maintaining tight tolerances and excellent surface finish.

5. What are some common applications of sliding head lathes?

Sliding head lathes find applications in various industries. They are particularly useful for manufacturing precision components, such as small medical devices, automotive parts, electronic connectors, and watches. These machines are capable of producing intricate shapes, threads, and complex geometries, making them invaluable in industries that demand high precision.

Sliding head lathes also play a crucial role in high-volume production environments, where time and efficiency are key. Their ability to perform multiple machining operations in a single setup significantly reduces production time, making them ideal for industries that require mass production while maintaining tight tolerances and high-quality standards.

How easy is it to learn CNC sliding head turning?

Summary

A sliding head lathe is a machine that cuts and shapes metal. It has a sliding headstock that moves back and forth to cut the metal. This allows for precise and efficient machining. The lathe also has a spindle that holds the metal workpiece in place while it is being cut. The sliding head lathe uses various tools, like drills and cutters, to shape and finish the metal. This machine is commonly used in industries such as automotive and aerospace for manufacturing parts with high precision. It’s an important tool for creating many of the things we use in our everyday lives.