Have you ever wondered how an underground boring machine works? Well, buckle up and get ready to dig into the fascinating world of tunneling! These impressive machines are like giant moles, burrowing through the Earth to create tunnels for various purposes. In this article, we’ll uncover the secrets behind the operation of underground boring machines.

Underground boring machines, also known as tunnel boring machines (TBMs), are engineering marvels that revolutionized the way we construct tunnels. They are like superheroes of the underground world, effortlessly creating passageways for transportation systems, pipelines, and even underground chambers. But how do these mighty machines do their job?

Picture this: a colossal machine equipped with sharp cutting discs and conveyor belts, slowly inching its way through the ground. As the cutting discs grind away at the earth, loosened soil is collected and transported out of the tunnel through the conveyor belts. This efficient process allows the machine to create a safe and stable tunnel while minimizing disruption to the surrounding environment.

So, next time you find yourself traveling through an underground tunnel, take a moment to appreciate the amazing work of an underground boring machine. From digging tunnels for transportation networks to creating improvements in infrastructure, these extraordinary machines are the unsung heroes of the subterranean world. Get ready to explore the ins and outs of how they work in this exciting article!

How Does an Underground Boring Machine Work?

Introduction: Underground boring machines, also known as tunnel boring machines or TBMs, are fascinating pieces of engineering that revolutionize the construction of tunnels and underground structures. These powerful machines are used to dig tunnels with precision and efficiency, significantly reducing the time and labor required for such projects. In this article, we will delve into the inner workings of underground boring machines to understand how they operate and the remarkable technology behind them.

1. The Basics of an Underground Boring Machine

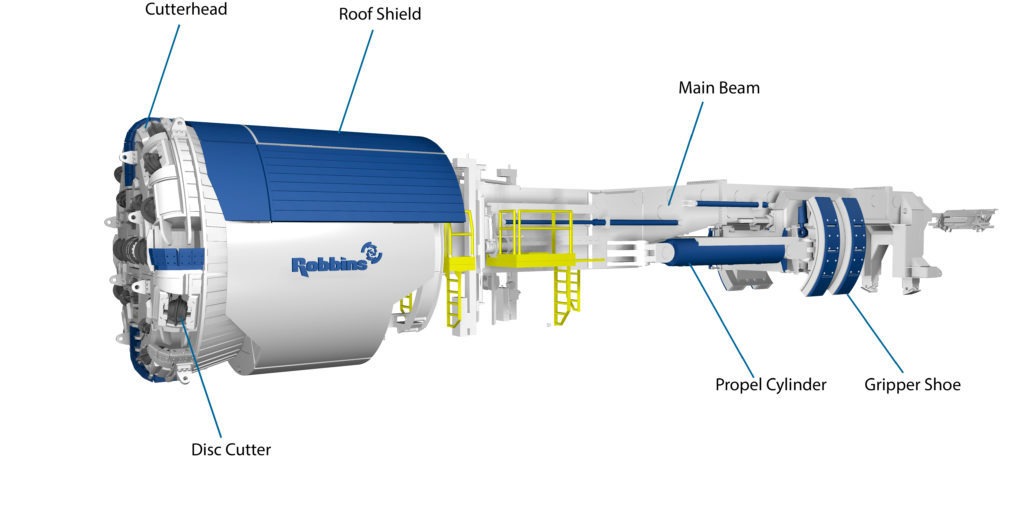

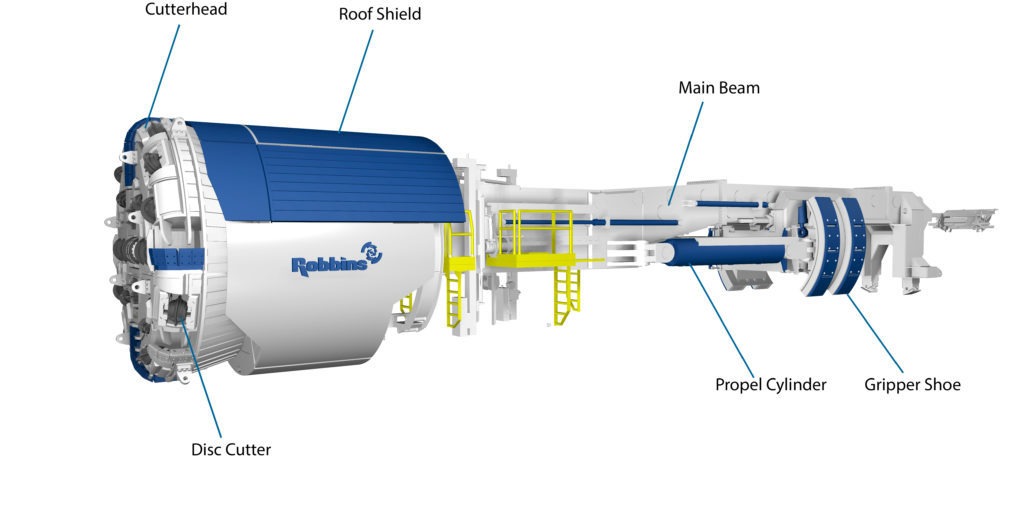

An underground boring machine is a massive piece of equipment that can dig tunnels in various soil conditions, from soft soils to hard rock. The machine consists of several key components, including a cutterhead, a shield, a thrust system, and a conveyor system. The cutterhead, located at the front of the machine, is responsible for excavating the soil or rock. It features a rotating disk with cutting tools that break and remove the material. The shield, which surrounds the cutterhead, provides stability and protects workers within the machine. The thrust system pushes the machine forward as the tunnel is being excavated, and the conveyor system transports the excavated material away from the tunnel.

To start the excavation process, the underground boring machine is assembled at the launch shaft. The cutterhead is positioned at the face of the tunnel, and the shield is assembled around it. The machine is then launched, and the cutterhead begins rotating and cutting into the soil or rock. As the cutterhead advances, the excavated material is transported through the conveyor system and taken out of the tunnel. The thrust system pushes the machine forward by applying force against the tunnel walls. This continuous process of excavation, removal of material, and forward movement continues until the entire tunnel is completed.

2. Advanced Technologies in Underground Boring Machines

Underground boring machines utilize cutting-edge technologies to ensure efficient and safe excavation. One key technology used is the laser guidance system. This system allows the machine to maintain a precise alignment and direction while digging the tunnel. It uses lasers and sensors to detect the position and orientation of the cutterhead, ensuring that the tunnel is excavated according to the desired specifications. This technology greatly reduces the chances of deviation or misalignment during the excavation process.

Another important technology in underground boring machines is the soil conditioning system. Depending on the soil or rock conditions, the machine may inject additives to modify the properties of the material being excavated. For instance, in soft soils, polymer-based additives can be injected to stabilize the ground and prevent collapse. In harder rock formations, water jets can be used to soften the material, making it easier for the cutterhead to penetrate and remove.

3. Benefits of Underground Boring Machines

Underground boring machines offer numerous benefits compared to traditional tunneling methods. Firstly, they significantly reduce the amount of time required to construct tunnels. These machines can work around the clock and complete excavation at a much faster pace. As a result, major tunneling projects that would take years to complete using manual methods can be finished in a matter of months using underground boring machines.

Additionally, these machines are incredibly precise, allowing for the construction of tunnels with minimal deviations from the planned alignment. This precision is essential for projects such as subway systems or utility tunnels, where accuracy is crucial. The use of underground boring machines also minimizes the disruption caused to the surface environment during construction. Unlike traditional open-cut methods, which require extensive excavation and disruption of the surroundings, boring machines operate underground, keeping the surface mostly intact and undisturbed.

In conclusion, underground boring machines are remarkable pieces of engineering that revolutionize tunnel construction. Through their advanced technologies and efficient operation, they are able to excavate tunnels with precision, speed, and minimal disruption to the surface environment. As technology continues to advance, we can expect further improvements and innovations in the field of underground boring machines, making tunnel construction safer, faster, and more efficient than ever before.

Key Takeaways: How Does an Underground Boring Machine Work?

1. Underground boring machines, also known as tunnel boring machines (TBMs), are used to create tunnels or boreholes beneath the surface of the Earth.

2. TBMs work by using a rotating cutterhead to excavate the soil or rock, which is then transported away from the cutterhead via a conveyor system.

3. The excavated material is either used to create the tunnel lining or transported to the surface for disposal.

4. TBMs can also install the tunnel lining as they move forward, reducing the need for manual labor and improving efficiency.

5. They are used for various applications, such as constructing subway tunnels, sewer systems, and utility tunnels.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about how underground boring machines work. Read on to discover the fascinating world of these powerful machines that help create tunnels beneath the earth’s surface.

How does an underground boring machine create tunnels?

An underground boring machine, also known as a tunnel boring machine (TBM), uses a rotating cutterhead, consisting of disc cutters, to excavate the soil or rock. As the cutterhead rotates, it grinds or digs into the ground, creating the tunnel. The machine then transports the excavated material through a conveyor system or uses a slurry to remove the debris.

At the same time, the TBM applies hydraulic pressure to the tunnel walls to stabilize them. This prevents collapses or other structural damages. The process continues as the machine moves forward, repeating the cycle of excavation, removal, and stabilization until the tunnel is complete.

What are the advantages of using underground boring machines?

Underground boring machines offer several advantages over traditional excavation methods. Firstly, they can create tunnels with minimal disturbance to the surrounding environment. This is particularly valuable in densely populated areas where disturbing the surface can have significant consequences.

Secondly, boring machines allow for faster tunnel construction. Their automated systems and steady progress enable projects to be completed more efficiently, saving both time and money. Additionally, the precision and accuracy of underground boring machines result in tunnels with consistent dimensions, ensuring high-quality infrastructure.

What types of projects use underground boring machines?

Underground boring machines are commonly used for a variety of projects. They are often employed in the construction of transportation tunnels, such as subway systems or highway tunnels. These machines are also utilized in utility installations, such as water or sewage pipelines, as well as in mining operations.

Furthermore, boring machines are indispensable in the construction of underground storage facilities, such as reservoirs or underground parking lots. Their versatility allows them to be used across various industries where the creation of tunnels or underground spaces is necessary.

Can underground boring machines work in all types of soil and rock?

While underground boring machines are highly efficient in various soil and rock types, their performance may vary depending on the geology of the area. Soft soils like clay or sand can be easily excavated using TBM with cutters specifically designed for softer materials.

However, when encountering hard rock formations, specialized disc cutters or drilling mechanisms are used to break and extract the rock. By adjusting the machine’s parameters and using appropriate tools, underground boring machines can effectively operate in diverse geological conditions.

What safety measures are in place when using underground boring machines?

Safety is a top priority when using underground boring machines. Workers involved in the process receive extensive training on operating and maintaining the machines. Personal protective equipment, including hard hats and safety harnesses, is worn to prevent accidents.

The machines themselves are equipped with multiple safety features, such as sensors that detect unstable ground conditions or potential hazards. These sensors can automatically stop the machine if any danger is detected. Regular inspections and maintenance ensure that the machines are in optimal working condition, minimizing risks during tunnel construction.

Summary

So, let’s quickly go over what we’ve learned about underground boring machines. They are big and powerful machines used to dig tunnels underground. They have a rotating cutting head that digs into the soil or rock, creating a tunnel as it goes. These machines are efficient and can dig tunnels quickly and safely. They are used for various purposes, like building tunnels for subways or laying pipes underground. They make our lives easier by creating underground passages without disturbing the surface. Underground boring machines are pretty cool inventions that help us build things underground.