Hey there! Have you ever wondered how a lathe dog works? Well, let’s dive right in and explore the fascinating world of lathe dogs!

So, what exactly is a lathe dog and what does it do? A lathe dog is a handy tool used in machining and metalworking to hold and rotate a workpiece on a lathe machine. Think of it as a trusty assistant that grips the workpiece tightly as the lathe spins it, allowing for precise shaping and cutting.

Now, you might be wondering how this contraption actually works. It’s quite simple, really! The lathe dog consists of two main parts: the body and the clamp. The body is designed to fit securely onto the lathe’s driving plate, while the clamp has a curved shape that wraps around the workpiece. As the lathe dog rotates with the driving plate, the clamp grips the workpiece firmly, preventing it from slipping or moving during the machining process.

Fascinating, isn’t it? In the next sections, we’ll dive deeper into the mechanics and types of lathe dogs, so stay tuned! And trust me, by the end of this article, you’ll have a crystal-clear understanding of how a lathe dog works and why it’s an essential tool in the world of machining. Let’s get started!

How Does a Lathe Dog Work? Understanding the Mechanics Behind this Essential Lathe Accessory

If you’ve ever worked with a lathe, you’ve likely come across a tool called a lathe dog. While its name might be misleading, a lathe dog isn’t a canine companion in the workshop. Rather, it is an indispensable device used to drive and secure the workpiece being turned on the lathe. In this article, we’ll delve into the intricacies of how a lathe dog works, uncovering its design, function, and importance in the world of lathe operations.

The Anatomy of a Lathe Dog: Components and Design

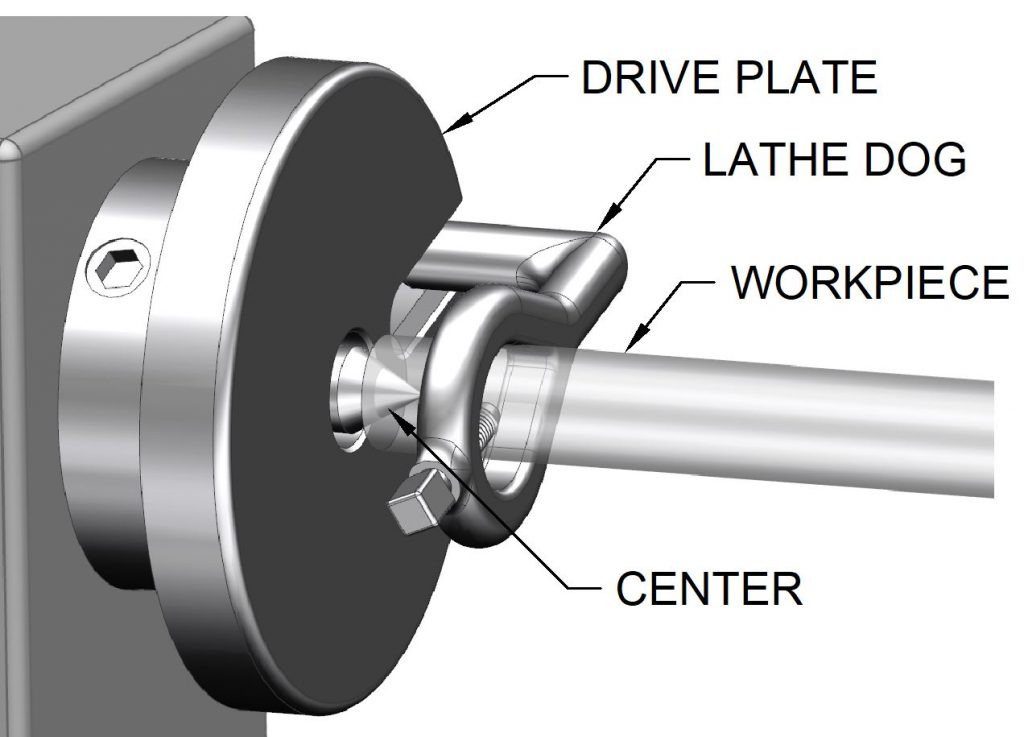

A lathe dog consists of three main components: the body, the driving pin, and the faceplate. The body is the central part of the lathe dog and is typically made of cast iron or steel to provide strength and durability. It is shaped like a clamp or a collar and is designed to grip the workpiece tightly without causing any damage or distortion to its shape or surface finish.

At one end of the body, you’ll find the driving pin. This is a pointed or rounded extension that sticks out perpendicular to the body and serves as the point of contact with the driving mechanism of the lathe. On the other end of the body, you’ll find a flat faceplate. This faceplate acts as the interface between the lathe dog and the workpiece, ensuring a secure grip and preventing the workpiece from rotating independently.

The Function of a Lathe Dog: Power Transmission and Workpiece Stability

While the primary function of a lathe dog is to transmit power from the lathe’s drive mechanism to the workpiece, it also plays a crucial role in ensuring the stability of the workpiece during turning operations. When attached to the workpiece, the lathe dog’s driving pin interfaces with the lathe’s driving mechanism, allowing rotational force to be applied to the workpiece.

As the lathe spins, the driving pin engages with corresponding features on the lathe’s spindle, such as slots or holes, effectively locking the workpiece in place and providing a secure method of power transmission. The lathe dog’s body then wraps around the circumference of the workpiece, gripping it firmly to prevent any slipping or movement during turning. This combination of power transfer and workpiece stability allows for precise and controlled shaping and machining.

It’s worth noting that different types of lathe dogs exist, each with its own unique design and purpose. Some are specialized for certain types of workpieces, while others are more versatile and suitable for a broader range of applications. Regardless of the specific design, the underlying principle remains the same: to securely hold the workpiece in place and facilitate power transmission for efficient and accurate turning.

Benefits of Using a Lathe Dog for Your Turning Projects

Now that we understand how a lathe dog works, let’s explore some of the benefits it brings to your turning projects.

- Secure Workholding: The primary advantage of using a lathe dog is the secure grip it provides on the workpiece. This ensures minimal movement and prevents accidents or damage during turning.

- Efficient Power Transmission: By firmly connecting the workpiece to the lathe’s driving mechanism, a lathe dog allows for efficient power transmission, enabling the turning process to be carried out smoothly and effectively.

- Versatility: With various types and designs available, lathe dogs offer versatility and adaptability, allowing you to use them for different workpiece shapes and sizes.

By harnessing the power of a lathe dog, you’ll not only enhance the overall safety of your turning operations but also achieve greater precision and control in shaping your workpieces.

Key Takeaways: How Does a Lathe Dog Work?

- A lathe dog is a device used in metalworking to hold and rotate a workpiece.

- It consists of two main parts, a body and a pawl, which engage with the workpiece.

- The body of the lathe dog is attached to the lathe and provides support and stability.

- The pawl, or the “dog,” has teeth that grip onto the workpiece, allowing it to rotate.

- Lathe dogs come in different sizes and shapes to accommodate various workpiece dimensions and shapes.

Frequently Asked Questions

Learn more about how lathe dogs work and their role in a lathe machine.

What is a lathe dog and how does it function?

A lathe dog, also known as a lathe carrier, is a device used in a lathe machine to hold and rotate the workpiece. It consists of two main parts: the body and the driving prong. The body is shaped like a curved bar with a projection or prong extending from it. The workpiece is clamped between the driving prong and a center, allowing it to rotate symmetrically while being machined.

As the lathe motor turns the spindle, it transfers the rotation to the lathe dog, which then rotates the workpiece. The lathe dog is attached to the workpiece by clamping it onto a groove or an external surface. This allows for precise cutting, shaping, or drilling of the workpiece as it rotates.

Can I use a lathe dog with any type of workpiece?

Lathe dogs are generally used with cylindrical or round workpieces. The shape and size of the workpiece determine the specific type of lathe dog to be used. There are different designs available, such as straight lathe dogs, bent lathe dogs, and spring lathe dogs, each suited for different workpiece shapes and sizes.

However, it’s important to note that lathe dogs may not be suitable for all types of workpieces. For irregularly shaped, delicate, or small workpieces, alternative holding methods like chucks, collets, or a faceplate may be more appropriate.

How do I select the right lathe dog for my workpiece?

When selecting a lathe dog, you should consider factors such as the workpiece’s shape, size, and material. It’s important to choose a lathe dog with a driving prong that matches the groove or surface of the workpiece to ensure a secure grip without damaging it.

Additionally, the lathe dog should be sturdy enough to withstand the forces exerted during machining. It’s advisable to consult the lathe machine’s manual or seek guidance from experienced machinists to determine the appropriate lathe dog for your specific workpiece and machining requirements.

Are there any safety precautions to consider when using a lathe dog?

Yes, there are a few safety precautions to keep in mind when using a lathe dog. Firstly, ensure that the lathe dog is securely clamped to the workpiece to prevent any slippage during machining, as this can lead to accidents and injuries.

Always wear appropriate protective gear, such as safety glasses and gloves, to protect yourself from flying debris or accidental contact with rotating parts. Regularly inspect the lathe dog for any signs of wear, damage, or defects, and replace it if necessary to maintain optimal performance and safety. Lastly, follow safe lathe operating procedures and adhere to all recommended safety guidelines provided by the lathe machine manufacturer.

Can I use multiple lathe dogs on a single workpiece?

Yes, in certain cases, multiple lathe dogs can be used on a single workpiece. This is particularly useful when machining long workpieces that require additional support and stability. By strategically placing and clamping multiple lathe dogs along the length of the workpiece, the rotation can be evenly distributed, minimizing vibrations and ensuring accurate machining.

However, it’s important to ensure that the lathe dogs are properly aligned and evenly spaced to prevent uneven distribution of forces, which can result in workpiece distortion or damage. Careful consideration should also be given to the gripping pressure applied by each lathe dog to prevent deformation of the workpiece.

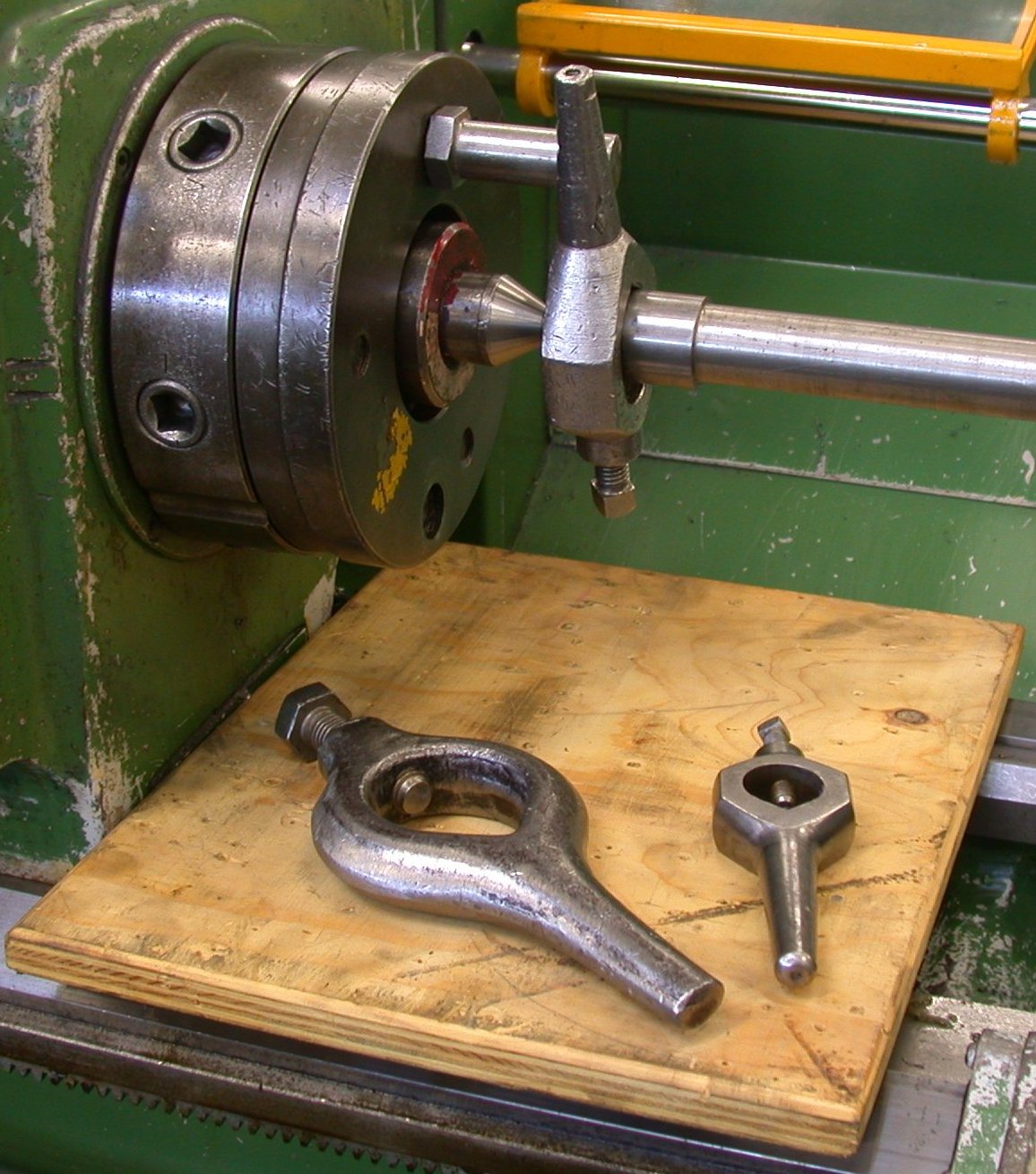

Metal Lathe 124 – Work Holding with Centers

Summary

Here’s a quick recap of how a lathe dog works! A lathe dog is a useful tool that holds materials in place while using a lathe. It clamps onto the workpiece and spins it around, making it easier to shape and cut. It’s important to choose the right size lathe dog for the job to ensure a secure grip. Just remember to always be cautious when using a lathe dog to prevent accidents. So, that’s how a lathe dog works – a simple tool that makes working with a lathe easier and safer!

In conclusion, a lathe dog is a handy tool for anyone using a lathe. It holds your workpiece securely and helps you shape and cut it effectively. Remember to stay safe while using it and choose the appropriate size for your project. Happy lathe work!