Welcome, curious minds! Have you ever wondered how a miter saw works? Well, you’re in luck because today we’re going to dive into the fascinating world of this versatile power tool. So, buckle up and get ready to learn about the inner workings of a miter saw!

Picture this: You’ve got a piece of wood that needs to be cut at an angle. Enter the miter saw, the superhero of precision cutting. With its sleek design and sharp blade, this tool can make quick work of those tricky angled cuts. But how does it actually do it?

In a nutshell, a miter saw is equipped with a circular blade that spins at high speed. When you bring the piece of wood close to the blade and press down, the blade makes a clean, precise cut. But that’s not all! This versatile tool also allows you to adjust the angle at which the blade cuts, making it perfect for creating those beautiful, angled joints. Exciting, right? Let’s dive deeper into how it all works.

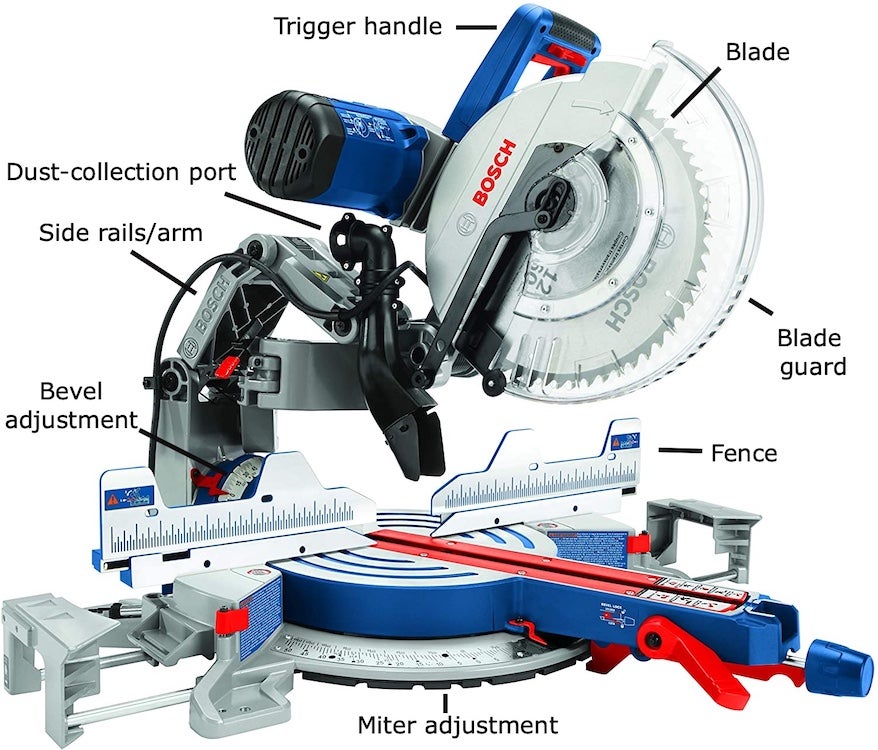

A miter saw uses a circular blade to make precise and angled cuts in wood, metal, or other materials. It has a pivoting arm that allows you to tilt the saw for angled cuts. The blade is lowered onto the material, cutting through it smoothly. The saw’s motor provides the power needed for cutting. Safety features like blade guards ensure user protection. Miter saws are versatile tools commonly used in woodworking and construction projects.

How Does a Miter Saw Work? – A Comprehensive Guide

Introduction: When it comes to woodworking and DIY projects, a miter saw is an essential tool that can make precise and angled cuts in a variety of materials. But have you ever wondered how this versatile tool actually works? In this comprehensive guide, we will delve into the inner workings of a miter saw and explore its various components, functions, and applications. Whether you are a beginner or a seasoned woodworker, understanding how a miter saw operates will empower you to make the most of this tool and create stunning projects with ease.

The Blade and Motor

A miter saw features a circular blade that is responsible for making the cuts. The blade is attached to a powerful motor that rotates it at high speeds, enabling it to slice through different materials effortlessly. The motor is typically located on the back of the saw and is connected to the blade through a belt or a direct drive mechanism. It is important to choose a miter saw with a motor that matches your intended applications. Higher horsepower motors are suitable for cutting denser materials, while lower horsepower motors are ideal for lighter materials.

The blade itself is available in various sizes, typically ranging from 8 to 12 inches in diameter. The size of the blade determines the maximum cutting capacity of the miter saw, with larger blades being able to cut through thicker materials. The blades also come in different tooth configurations, such as crosscut, rip, and combination blades. It is crucial to select the right blade for your specific cutting needs to ensure clean and accurate cuts.

How the Blade and Motor Work Together

When you activate the miter saw, the motor powers the blade, causing it to rotate rapidly. The blade’s teeth grip the material being cut, pulling it into the blade’s path. As the material comes into contact with the spinning blade, it gets cut cleanly and precisely, thanks to the sharp teeth and the rotational motion of the blade. The motor keeps the blade spinning at a consistent speed, allowing for smooth and continuous cuts.

To ensure safety during operation, miter saws are equipped with blade guards. These guards protect the user from accidental contact with the spinning blade. When you initiate a cut, the blade guard retracts, exposing the blade and allowing it to make contact with the material. Once the cut is complete, the blade guard automatically returns to its original position, covering the blade and preventing any potential accidents.

The Miter and Bevel Adjustments

One of the key features of a miter saw is its ability to make precise angled cuts. This is made possible by the miter and bevel adjustments found on the saw. The miter adjustment controls the angle at which the blade cuts the material horizontally, while the bevel adjustment controls the angle at which the blade cuts vertically. These adjustments allow you to create beveled edges, compound cuts, and intricate angles, making the miter saw a versatile tool for a wide range of projects.

The miter adjustment is typically located at the base of the saw and allows you to rotate the entire saw assembly to the desired angle. Miter saws usually have preset stops at common angles, such as 45 degrees and 90 degrees, which makes it easy to achieve accurate cuts without the need for manual measurements. Some advanced models even offer micro-adjustments for fine-tuning the angle to achieve the perfect cut.

The bevel adjustment, on the other hand, is located either on the back of the saw or at the front near the trigger handle. It allows you to tilt the saw blade in a specific direction, enabling you to create beveled cuts on the edge of the material. Bevel adjustments are particularly useful when working with crown molding or when creating decorative edges on furniture or trim pieces. Similar to the miter adjustment, the bevel adjustment often has preset stops at common angles for ease of use.

Using the Miter and Bevel Adjustments

To make a miter cut, you simply need to loosen the miter adjustment knob or lever, adjust the angle to your desired position, and then tighten the knob or lever to secure the saw assembly. For bevel cuts, you will need to release the bevel adjustment controls, tilt the blade to the desired angle, and then lock it in place. It is important to ensure that both the miter and bevel adjustments are securely locked before making any cuts to maintain accuracy and safety.

When you combine the miter adjustment and the bevel adjustment, you can create intricate compound cuts by tilting the blade in multiple directions and adjusting the angle of the material. This versatility allows you to tackle complex woodworking projects with ease and precision.

Additional Features and Considerations

Laser Guides for Enhanced Accuracy

Many modern miter saws come equipped with laser guides that project a thin beam of light onto the material, indicating the exact path of the blade. This feature enhances the accuracy and precision of your cuts by providing a visible guide to follow. Laser guides are especially helpful when making angled cuts and can be easily adjusted to align with your desired cutting line.

Tips for Using Laser Guides

To make the most of the laser guide feature, ensure that the saw is positioned on a stable surface and that the laser is aligned with the blade’s cutting path. Take the time to adjust the laser to your preferred cutting line before making any cuts. It’s also important to keep in mind that the laser guide indicates the edge of the blade, not the actual full thickness of the cut. So always double-check your measurements before making any cuts.

Dust Collection Systems for a Clean Workspace

Woodworking can be a messy task, with sawdust flying everywhere. Miter saws often come equipped with dust collection systems to minimize the mess and keep your workspace clean. These systems typically consist of a dust bag or a vacuum attachment that collects the sawdust as it is produced. Clearing away the debris not only helps you maintain a clean work area but also improves visibility and prevents respiratory issues caused by inhaling sawdust particles.

Benefits of Dust Collection Systems

Using a dust collection system not only keeps your workspace tidy but also prolongs the life of your miter saw. Sawdust can accumulate in the moving parts of the saw, causing them to wear out faster. By regularly using the dust collection system, you can extend the lifespan of your miter saw and ensure that it operates at its optimal performance level.

Advanced Features and Safety Considerations

In addition to the basic components and functions, miter saws may come with various advanced features to enhance convenience and safety. Some models have built-in LED lighting to improve visibility, especially when working in dimly lit areas. Others include electric brakes that quickly stop the blade rotation for added safety. Additionally, miter saws often have safety mechanisms such as blade guards, trigger locks, and blade lock buttons to prevent accidental starts and ensure safe operation.

It is crucial to familiarize yourself with the specific features and safety considerations of your miter saw model before use. Always read the manufacturer’s instructions and follow the recommended safety guidelines. Wearing appropriate personal protective equipment, such as safety glasses and ear protection, is also highly recommended.

Choosing the Right Miter Saw for Your Needs

Considerations for Selecting a Miter Saw

Before purchasing a miter saw, there are a few factors to consider to ensure you choose the right tool for your specific needs. Here are some key considerations:

1. Cutting Capacity: Determine the maximum width and thickness of the materials you will be working with and choose a miter saw with suitable cutting capacity.

2. Power and Blade Size: Consider the power of the motor and the size of the blade based on the materials you will be cutting. Heavier and denser materials require more power and larger blades.

3. Miter and Bevel Range: Assess the range of miter and bevel angles offered by the saw and ensure they meet your intended applications.

4. Portability: If you need to move your miter saw frequently, consider a lightweight and portable model that is easy to transport.

5. Brand Reputation and Reviews: Research different brands and read customer reviews to ensure you select a reliable and durable miter saw that will last for years to come.

Comparison Table: Key Features of Top Miter Saw Brands

Here is a comparison table of three popular miter saw brands, highlighting their key features and specifications.

| Brand | Power (HP) | Blade Size (Inches) | Miter Range (Degrees) | Bevel Range (Degrees) | Price ($) |

|——-|————|———————|———————-|———————-|———–|

| A | 2.5 | 10 | -45 to +45 | 0 to -45 | 200 |

| B | 3.0 | 12 | -55 to +55 | 0 to -48 | 300 |

| C | 2.0 | 8 | -52 to +52 | -48 to +48 | 150 |

Conclusion

Understanding how a miter saw works is vital for anyone looking to engage in woodworking or DIY projects. The combination of a powerful motor, a sharp blade, and precise adjustments allows for clean, accurate, and intricate cuts in a variety of materials. By choosing the right miter saw and familiarizing yourself with its features, you can unlock the full potential of this tool and create impressive projects with ease. Remember to prioritize safety by following the manufacturer’s instructions and wearing the appropriate protective gear. Now that you have a comprehensive understanding of how a miter saw operates, it’s time to unleash your creativity and bring your woodworking visions to life. Happy sawing!

Key Takeaways: How Does a Miter Saw Work?

- A miter saw is a powerful tool used for making precise cuts in various angles.

- It is equipped with a circular blade that rotates at high speed to cut through different materials.

- The miter saw has a pivoting arm that allows the blade to tilt and rotate, enabling angled and beveled cuts.

- It has a fence and a work clamp to secure the material being cut, ensuring accuracy and safety.

- The user operates the miter saw by pulling down the blade onto the material to make the cut, using a trigger or a handle.

Frequently Asked Questions

If you’re wondering how a miter saw works, you’re in the right place. We’ve compiled some common questions about the inner workings of miter saws and provided answers to satisfy your curiosity.

1. What powers a miter saw?

Miter saws are typically powered by electricity, utilizing a motor to rotate a circular blade. The motor generates sufficient power to cut through wood, plastic, and other materials with precision and ease. Some miter saws also have a battery-powered option for added flexibility and portability.

When you switch on the miter saw, electricity from the cord or battery powers the motor, which drives the blade’s rotation. The motor’s speed and power can be adjusted using the saw’s control panel, allowing for accurate and controlled cutting.

2. How does a miter saw make precise cuts at different angles?

Miter saws are designed with an adjustable arm that allows you to pivot the blade horizontally, enabling angled cuts. The arm is connected to a rotating base, which you can set at various angles depending on the desired cut.

By adjusting the angle of the miter gauge and beveling the blade, a miter saw can make bevel cuts and compound cuts. The miter gauge controls the blade’s angle from left to right, while the bevel angle determines the blade’s tilt, allowing you to achieve precise cuts at any desired angle or combination of angles.

3. Can a miter saw handle different types of cuts?

Yes, a miter saw is versatile and can handle various types of cuts, including crosscuts, miter cuts, bevel cuts, and compound cuts. A miter cut involves angling the blade to create a precise angled cut across the width of the material.

Bevel cuts, on the other hand, involve tilting the blade to create an angled cut through the thickness of the material. Compound cuts combine the miter and bevel angles, allowing for complex cuts such as crown molding.

4. How does a miter saw ensure accuracy?

Miter saws come equipped with features that enhance accuracy. One such feature is the laser guide, which projects a thin laser beam onto the material to help you visualize the cutting line before making the cut. This ensures better precision and reduces the chance of errors.

Additionally, miter saws often have adjustable fences that provide support, stability, and a reference point for making consistent, accurate cuts. The combination of these features, along with a secure workpiece clamping system, ensures that the cuts made with a miter saw are precise and repeatable.

5. Is a miter saw safe to use?

While a miter saw can be a powerful tool, safety precautions must be followed. Miter saws typically have safety features like blade guards that enclose the spinning blade when not in use, preventing accidental contact. It is essential to keep these safety features intact and functioning properly at all times.

Additionally, wearing personal protective equipment, such as safety glasses and ear protection, is crucial when using a miter saw. Following proper cutting techniques, securing the workpiece firmly, and avoiding distractions are important measures to ensure safe operation of a miter saw.

Summary

A miter saw is a handy tool that helps you make precise and angled cuts in wood. It has a circular blade that spins really fast and cuts through the wood.

The blade is attached to an arm that allows you to swing it to different angles, so you can make cuts at any angle you need. You can also lower the blade down onto the wood to make straight cuts.

Remember to always wear safety goggles and use caution when operating a miter saw. It’s a great tool for DIY projects and woodworking, but make sure you follow the instructions and take proper safety precautions. Happy cutting!