Looking to learn how a reciprocating saw works? You’re in the right place! This powerful tool is a must-have for any DIYer or professional. Let’s dive in and discover the inner workings of this versatile and efficient cutting machine.

Ever wondered how the blade of a reciprocating saw moves back and forth so effortlessly? Well, it’s all thanks to a remarkable mechanism called a reciprocating motion. This mechanism allows the saw to quickly and efficiently cut through a wide range of materials, from wood to metal and everything in between.

Now, you may be wondering, “How does this reciprocating motion actually work?” It’s quite fascinating! The blade of the saw is attached to a motor that rapidly moves the blade forward and backward in a linear motion. This back-and-forth motion allows the blade to slice through the material with precision and ease.

So, whether you’re tackling a demolition project, trimming tree branches, or creating intricate cuts in a piece of lumber, understanding how a reciprocating saw works is essential. Get ready to unleash your inner handyman as we delve deeper into the mechanics of this fantastic tool. Let’s get started!

How Does a Reciprocating Saw Work?

1. Understanding the Mechanism

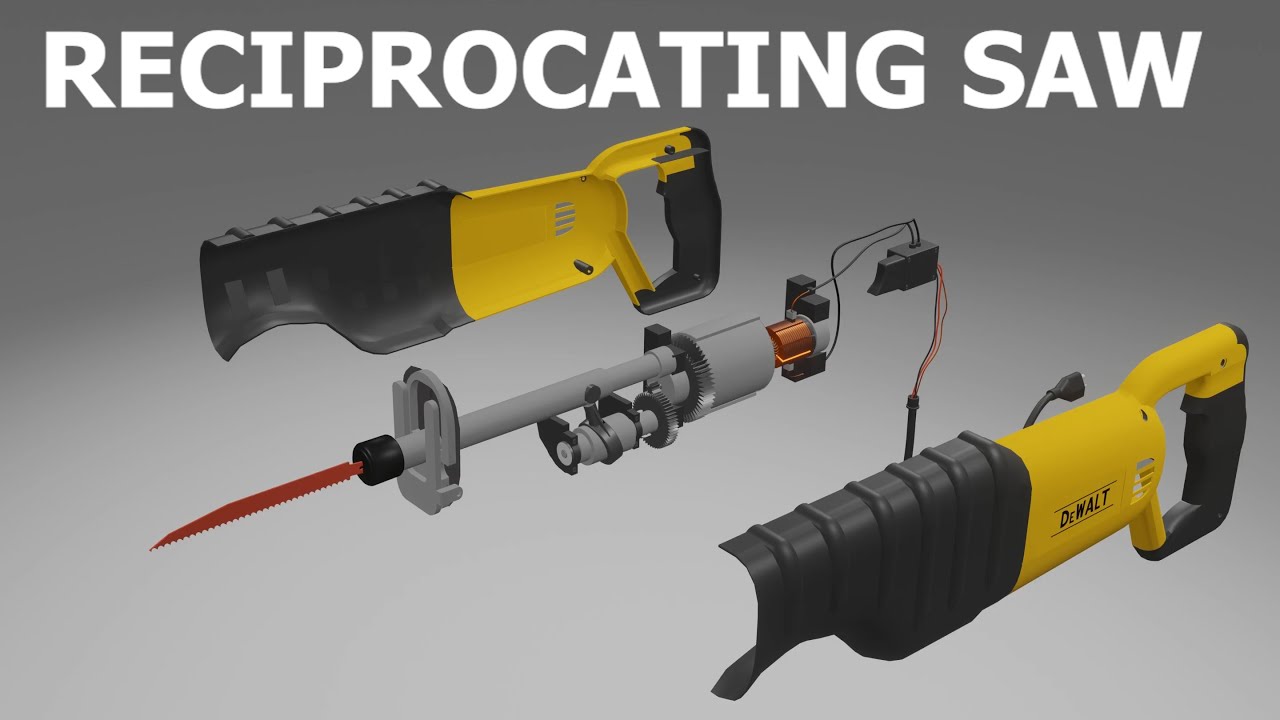

A reciprocating saw, also known as a sabre saw or a sawzall, is a powerful tool that is widely used in construction, woodworking, plumbing, and other industries. The working principle of a reciprocating saw is quite simple. It consists of a motor that drives a blade back and forth in a rapid up-and-down motion. This back-and-forth motion of the blade is what gives the reciprocating saw its name.

The reciprocating saw’s motor is connected to a gearbox, which converts the rotational motion of the motor into the linear motion of the blade. This motion is achieved by the use of a crank and connecting rod mechanism. The motor drives the crankshaft, which is connected to a connecting rod. As the crankshaft rotates, it pushes and pulls the connecting rod, causing the blade to move back and forth.

2. Blade Selection and Insertion

One of the key features of a reciprocating saw is its versatility when it comes to blade selection. There is a wide range of blades available for different cutting tasks, such as wood, metal, plastic, and even demolition work. The blades vary in length, width, and tooth design, allowing you to choose the most suitable blade for the job at hand.

To insert a blade into the reciprocating saw, you need to follow a few simple steps. First, make sure the tool is unplugged or the battery is removed for safety. Then, locate the blade clamp near the front end of the saw and loosen it. Insert the blade into the clamp, making sure it is properly aligned with the blade guide. Tighten the blade clamp securely to ensure the blade doesn’t come loose during operation.

3. Trigger Control and Speed Adjustment

Reciprocating saws offer variable speed control, allowing you to adjust the cutting speed according to the material being cut and the desired level of precision. The speed control is usually located near the trigger, and it can be adjusted by turning a dial or pressing buttons. Lower speeds are ideal for cutting through delicate materials, while higher speeds are better for tougher materials or faster cutting.

The trigger of a reciprocating saw is used to control the on/off function and the speed of the blade. By squeezing the trigger, you activate the motor and start the up-and-down motion of the blade. Releasing the trigger stops the blade’s motion. It’s important to have a firm grip on the handle and to only squeeze the trigger when you are ready to make a cut. This helps ensure safety and control over the tool.

4. Safety Features and Precautions

Like any power tool, using a reciprocating saw requires taking proper safety precautions. Always wear appropriate personal protective equipment (PPE), such as safety glasses, a dust mask, and gloves, to protect yourself from flying debris and potential hazards. It’s also recommended to secure your workpiece firmly in place to prevent it from moving during cutting.

Many modern reciprocating saws come equipped with safety features that enhance user safety. These may include an adjustable shoe, which provides stability and helps prevent the blade from binding or kickback. Some models also feature a blade guard or a lock-off switch that prevents accidental starting. Familiarize yourself with the safety features of your specific saw and always follow the manufacturer’s instructions.

5. Applications and Benefits of a Reciprocating Saw

The versatility and power of a reciprocating saw make it an essential tool for a wide range of applications. It is commonly used for tasks such as cutting through wood, metal, plastic pipes, and nails. The ability to make plunge cuts and navigate tight spaces makes it invaluable in demolition work. Additionally, reciprocating saws are often used for pruning tree branches and cutting through roots.

The benefits of using a reciprocating saw include its portability, as it can be used with a cord or a battery-powered version for increased mobility. It is also a versatile tool that can replace several other handheld cutting tools, saving space and reducing the need for multiple tools. The ability to use different blades for various applications makes it highly adaptable to different materials and cutting tasks.

6. Maintenance and Care

To ensure optimal performance and longevity of your reciprocating saw, proper maintenance and care are essential. After each use, clean the tool of any debris or dust that may have accumulated during operation. Regularly check the blade for any signs of wear or damage and replace it if necessary. Keep the tool lubricated according to the manufacturer’s instructions to prevent premature wear of moving parts.

Store your reciprocating saw in a clean and dry place, away from extreme temperatures and humidity. If the saw is battery-powered, ensure the battery is fully charged before storing it to prevent deterioration. Regularly inspect the power cord for any wear or damage and replace it if needed. By following these maintenance practices, you can prolong the lifespan of your reciprocating saw and ensure its optimal performance.

Choosing the Right Reciprocating Saw for Your Needs

1. Corded vs. Cordless Reciprocating Saws

When it comes to choosing a reciprocating saw, one of the primary considerations is whether to go for a corded or cordless model. Corded saws provide continuous power and are typically more powerful than cordless ones. They are ideal for tasks that require extended use or cutting through tougher materials. On the other hand, cordless reciprocating saws offer greater portability and convenience, allowing you to work in areas without access to electrical outlets.

2. Power and Stroke Length

The power of a reciprocating saw is typically measured in amps for corded models and volts for cordless ones. Higher amp ratings or voltage indicate more power, which can be beneficial for cutting through thick or hard materials. Additionally, consider the stroke length of the saw, which refers to the distance the blade travels in one back-and-forth motion. Longer stroke lengths generally allow for faster cutting and greater versatility.

3. Tool-less Blade Change and Adjustable Shoe

Look for a reciprocating saw that offers tool-less blade change, as it allows for quick and hassle-free blade swaps. This feature is especially useful when working on different materials or making intricate cuts that require frequent blade changes. An adjustable shoe is also advantageous, as it provides stability and control during cutting and helps prevent the blade from binding or kickback.

Tips for Safe and Effective Use of a Reciprocating Saw

1. Wear proper personal protective equipment (PPE)

Always wear safety glasses, hearing protection, and gloves when operating a reciprocating saw. These will protect you from flying debris, noise, and potential injuries.

2. Plan your cuts carefully

Take the time to plan out your cuts and ensure you have a clear path free of obstructions. This will help prevent damage to the blade, the workpiece, and yourself.

3. Secure your workpiece

Use clamps or a vise to secure your workpiece firmly in place. This prevents it from moving or vibrating during cutting, ensuring a smooth and controlled cutting process.

4. Start with a low speed

When starting a cut, begin with a low speed and gradually increase it as needed. This allows for better control and prevents the blade from binding or getting stuck.

5. Avoid applying excessive pressure

Let the blade do the work and avoid pushing or forcing the saw into the material. Applying excessive pressure can lead to inefficient cutting, increased blade wear, and potential kickback.

6. Use the right blade for the job

Select the appropriate blade for the material you are cutting. Using the wrong blade can result in poor performance, damage to the blade or workpiece, and potential safety hazards.

In conclusion, reciprocating saws are versatile and powerful tools that can handle a wide range of cutting tasks. By understanding their mechanism, following safety precautions, and selecting the right saw for your needs, you can effectively and safely use a reciprocating saw in various applications. Remember to prioritize safety and maintenance to prolong the lifespan of your tool and ensure its optimal performance.

Key Takeaways: How Does a Reciprocating Saw Work?

- A reciprocating saw is a power tool that cuts through various materials using a back-and-forth sawing motion.

- It has a motor that drives a blade attached to the saw’s arm, which moves in a reciprocating motion.

- The blade’s teeth are designed to cut through different materials such as wood, metal, and plastic.

- Reciprocating saws have adjustable speed settings to match the cutting requirements of different materials.

- When using a reciprocating saw, it’s important to wear protective gear like goggles and gloves to ensure safety.

Frequently Asked Questions

Curious about how a reciprocating saw works? Look no further! We’ve got answers for you right here. Dive into these commonly asked questions to understand the inner workings of a reciprocating saw.

1. What powers a reciprocating saw?

A reciprocating saw is powered by an electric motor or a battery pack, depending on the model. This motor or battery pack provides the necessary energy to drive the saw’s back-and-forth cutting motion. Some powerful reciprocating saws can even be operated using compressed air.

The motor converts electrical energy into mechanical energy, which is essential for the saw blade’s rapid movement. The power source fuels the motor, enabling the saw to work effectively and cut through various materials.

2. How does the cutting action of a reciprocating saw work?

The cutting action of a reciprocating saw is quite unique. It features a back-and-forth motion, where the saw blade rapidly moves back and forth. This movement is achieved by the motor’s reciprocating mechanism.

As the motor powers the saw, an eccentric offset drives the saw blade forward and backward in a linear motion. This reciprocating action, combined with the sharp teeth of the blade, allows the saw to effortlessly cut through materials like wood, metal, and plastic.

3. Can a reciprocating saw be used for different cutting tasks?

Absolutely! One of the remarkable features of a reciprocating saw is its versatility. It can tackle a wide range of cutting tasks, making it a handy tool for both professionals and DIY enthusiasts.

Whether you need to prune tree branches, demolish walls, or even cut pipes, a reciprocating saw can handle it all. With the right blade, it can slice through various materials with ease, making it a go-to tool for many construction, remodeling, and demolition projects.

4. What safety precautions should I take when using a reciprocating saw?

When using a reciprocating saw, safety should always be a top priority. Here are some important precautions to remember:

Firstly, always wear safety goggles or a face shield to protect your eyes from flying debris. Additionally, it’s crucial to wear heavy-duty gloves for a secure grip and to avoid accidental cuts.

Furthermore, never wear loose clothing or jewelry that could get caught in the saw. Always ensure that the saw is switched off and unplugged (or the battery removed) before changing the blade or performing any maintenance. Lastly, be cautious of the saw’s powerful vibrations and always maintain a firm stance and proper balance while operating it.

5. Can I use a reciprocating saw for precision cutting?

While reciprocating saws excel in rough and aggressive cutting tasks, they are not typically designed for precise and intricate cutting. Their primary strength lies in their ability to quickly cut through tough materials.

If you require precise cuts, it is recommended to use other tools such as a jigsaw or a handsaw. These tools provide better control and accuracy for detailed work. However, a reciprocating saw can still be useful for certain rough cutting jobs where precision is not as crucial.

Summary

A reciprocating saw is a powerful tool that cuts through objects by moving back and forth. It is like a tiny saw that goes really fast. When you turn it on, the saw blade moves forward, then backward, and keeps repeating this motion. This makes it easy to cut through things like wood, metal, and even pipes. The saw blade has sharp teeth that bite into the material and cut it smoothly. Reciprocating saws are handy for many jobs, like construction, demolition, and even gardening. Just be sure to be safe and use protective gear when using this cool tool!

In conclusion, a reciprocating saw works by moving its saw blade back and forth really fast. This motion, along with the sharp teeth on the blade, allows it to cut through all kinds of materials. It’s a handy tool to have around for various projects, just remember to stay safe!