Are you curious about how the boring machine works? Well, buckle up and get ready for an exciting journey underground! In this introduction, we’ll dive into the fascinating world of boring machines and explore how they make tunnels and excavations possible. So, let’s dig in and uncover the mysteries behind these powerful machines!

Picture this: you’re standing on the surface, and below your feet lies a whole new world hidden from view. How do we access this hidden realm? Enter the boring machine, a colossal contraption capable of cutting through rock and soil to create tunnels. It’s like having a giant mechanical mole doing all the hard work!

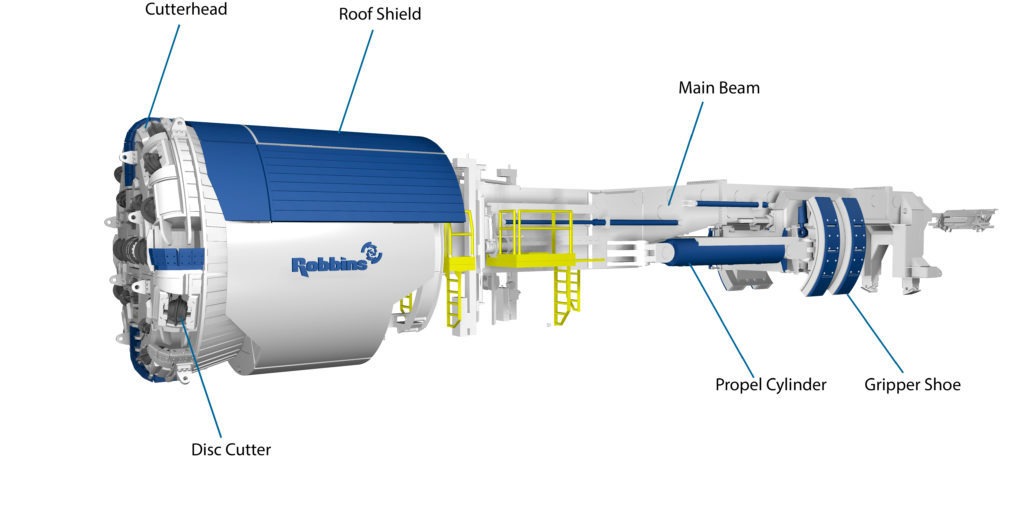

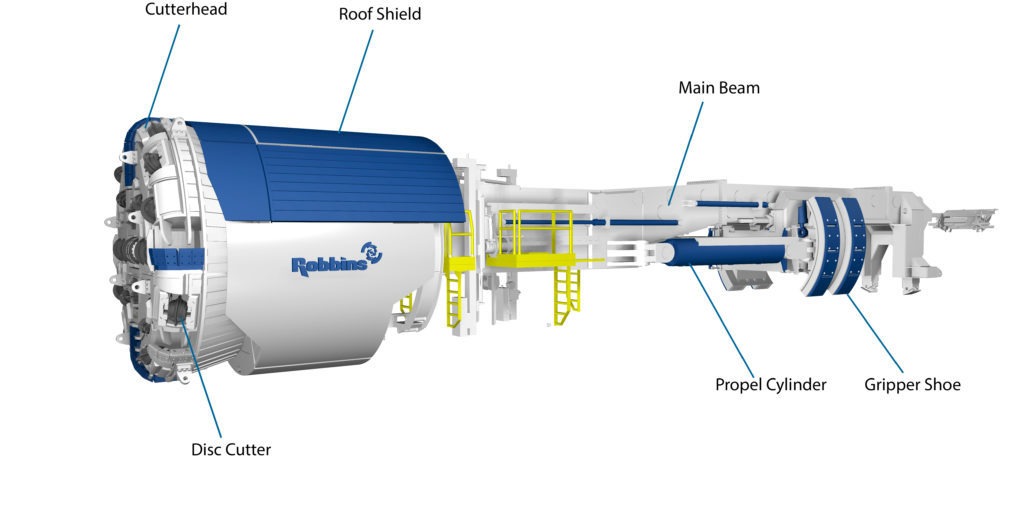

But how does this mammoth machine accomplish such a Herculean task? With drills, cutters, and a lot of determination! The boring machine consists of a rotating cutting head equipped with sharp teeth or disc cutters that tirelessly gnaw through the Earth. It’s like a massive drill bit on steroids, chewing through the ground with astonishing precision.

So, hold on tight because we’re about to embark on an underground adventure like no other. Join me as we explore the inner workings of the boring machine and unveil the secrets behind its incredible tunnel-making abilities. It’s time to unearth the magic behind this engineering marvel!

How Does the Boring Machine Work?

A boring machine is a powerful and efficient tool used in various industries to create precise holes and tunnels in different materials. From construction and mining to manufacturing and woodworking, boring machines play a crucial role in many applications. In this article, we will explore the inner workings of a boring machine, including its components, operation, and advantages.

Components of a Boring Machine

Understanding how a boring machine works requires knowledge of its key components. While different types of boring machines may have specific features, most share common elements:

- Motor: The motor provides the power needed to rotate the cutting tool or drill bit.

- Spindle: The spindle holds and rotates the cutting tool or drill bit.

- Feed Mechanism: The feed mechanism controls the movement of the cutting tool into the material being bored.

- Clamps: Clamps secure the workpiece in place to prevent movement during the boring process.

- Guides: Guides ensure accurate alignment and positioning of the cutting tool.

By combining these components, a boring machine can create holes or tunnels in materials with precision and efficiency.

The Boring Process: Step-by-Step

Now that we understand the basic components of a boring machine, let’s dive into the step-by-step process of how it works:

- Preparation: The operator prepares the workpiece by selecting the appropriate size and shape based on the desired hole or tunnel. They secure it to the machine’s table using clamps.

- Tool Selection: Based on the material and desired outcome, the operator selects the appropriate cutting tool or drill bit. Factors such as diameter, length, and cutting edge design are considered.

- Positioning: The operator adjusts the machine’s guides to ensure proper alignment and positioning of the cutting tool with respect to the workpiece.

- Adjusting Speed and Feed Rate: The operator sets the speed and feed rate of the machine based on the material being bored. This ensures optimal cutting performance and prevents damage to the tool or workpiece.

- Starting the Machine: Once all preparations are complete, the operator starts the machine, which activates the motor and begins rotating the cutting tool or drill bit.

- Boring: The operator gradually feeds the cutting tool into the material, either manually or with the assistance of an automatic feed mechanism. The tool removes material and creates the desired hole or tunnel as it progresses.

- Monitoring: Throughout the process, the operator monitors the machine, ensuring that the cut is clean, the feed rate is appropriate, and any necessary adjustments are made.

- Finishing: Once the desired depth or length is reached, the operator withdraws the cutting tool from the material.

The precise control and adjustments made during the process ensure accurate and high-quality results.

Advantages of Boring Machines

Now that we have explored how a boring machine works, let’s highlight some of its key advantages:

- Precision: Boring machines offer exceptional precision, allowing for the creation of holes and tunnels with tight tolerances.

- Efficiency: With their powerful motors and controlled feed mechanisms, boring machines can complete tasks quickly and efficiently.

- Versatility: Boring machines can handle various materials, including wood, metal, plastic, and more, making them suitable for a wide range of applications.

- Automation: Many modern boring machines feature automation capabilities, allowing for increased productivity and reduced operator fatigue.

- Clean Cuts: The design and precision of cutting tools used in boring machines result in clean and accurate cuts, minimizing the need for additional finishing work.

These advantages make boring machines indispensable in industries where precision, efficiency, and productivity are essential.

Different Types of Boring Machines

Horizontal Boring Machines

…

Vertical Boring Machines

…

Line Boring Machines

…

Portable Boring Machines

…

CNC Boring Machines

…

Tips for Using Boring Machines Safely

…

Boring Machines vs. Drilling Machines: Key Differences

…

Common Applications of Boring Machines

…

Buying and Maintaining a Boring Machine: What to Consider

…

Conclusion

In conclusion, boring machines are incredible tools that play a vital role in various industries. Their precise and efficient operation, along with the ability to work with different materials, makes them invaluable for creating holes and tunnels. Whether it’s construction, manufacturing, or woodworking, the boring machine’s versatility and advantages make it a must-have for many professionals. Remember to prioritize safety when working with a boring machine and follow the manufacturer’s guidelines to ensure optimal performance and longevity.

Key Takeaways: How Does the Boring Machine Work?

- A boring machine is used to create tunnels or holes in the ground.

- It works by rotating a cutting tool called a boring head.

- The boring head has sharp teeth that chip away at the ground.

- The machine also has a mechanism to remove the excavated material.

- Boring machines can be used for various purposes, such as mining or constructing underground tunnels.

Frequently Asked Questions

Curious about how boring machines work? We’ve got you covered with some commonly asked questions!

1. How does a boring machine create tunnels?

A boring machine creates tunnels by using a rotating cutting head to excavate the soil or rock. As it moves forward, the cutting head scrapes away the material, creating a hole. The machine then supports the hole with various methods, such as installing temporary support systems like steel casings.

Some boring machines also use a technique called tunnel boring, where they simultaneously support the tunnel walls while advancing. This is done by rotating large hydraulic jacks that push against the tunnel walls, ensuring stability as the machine moves forward.

2. What powers a boring machine?

Most boring machines are powered by diesel engines. These engines provide the necessary energy to operate the cutting head and other components of the machine. Diesel engines are commonly used because they offer high power output and are more fuel-efficient compared to other types of engines.

In addition to diesel engines, some boring machines also have electric motors. Electric machines are often used in urban areas where noise and air pollution need to be minimized, as they produce fewer emissions and are quieter during operation.

3. How does a boring machine navigate underground?

Boring machines typically have a guidance system that allows them to navigate accurately underground. One common method is laser-guided steering. The machine uses lasers to measure its position and direction, ensuring it follows a precise path.

Other navigation systems include GPS (Global Positioning System) and gyroscopes, which help track the machine’s movements and make adjustments to stay on course. These advanced technologies enable boring machines to navigate through various soil or rock formations with minimal deviations.

4. What safety precautions are taken when operating a boring machine?

Operating a boring machine requires strict adherence to safety protocols. Before starting the machine, operators ensure the surrounding area is clear of personnel and obstacles. They also wear personal protective equipment, such as helmets, safety goggles, and ear protection, to minimize the risk of accidents.

To ensure stability and prevent collapses, support systems like steel casings or tunnel linings are installed as the machine progresses. Regular inspections of the machine’s components are conducted to identify any potential issues that may compromise safety. Additionally, operators undergo comprehensive training to handle emergency situations and respond to potential hazards.

5. What are the different types of boring machines?

There are several types of boring machines used for different purposes. One common type is the tunnel boring machine (TBM), which is specifically designed for excavating tunnels. TBMs can range in size, from small machines used for utility tunnels to massive ones used in major infrastructure projects.

Other types of boring machines include horizontal directional drills (HDDs), which are used to drill underground paths for utilities like pipelines or fiber optic cables. Auger boring machines are used for creating holes with a larger diameter, such as for installing sewer lines. Each type of machine is tailored to suit specific excavation needs.

Horizontal Directional Drilling / Boring (HDD): How the Drill Bit is Steered

Summary

Boring machines are like giant drills that dig tunnels underground or through mountains. They have a rotating head that scrapes away soil and rock. The machine pushes forward slowly, adding support structures as it goes. Boring machines are used to make tunnels for things like highways, subways, and sewers.

Key Takeaways

Boring machines are big drill-like machines used to dig tunnels underground. They scrape away soil and rock with a rotating head while pushing forward slowly. These machines are important for creating tunnels for highways, subways, and sewers.