Got it! Here’s your professionally engaging and conversational introduction on “How Electric Planers Work”:

Paragraph 1:

So, have you ever wondered how electric planers work? Well, get ready to dive into the fascinating world of woodworking! Electric planers are essential tools that make smoothing and leveling wood surfaces a breeze. Whether you’re a DIY enthusiast or a professional carpenter, understanding how these mighty machines operate will unlock a whole new dimension of woodworking wizardry.

Paragraph 2:

Now, let’s take a closer look at the inner workings of an electric planer. Picture this: a small but powerful motor sits at the heart of the machine, delivering an impressive amount of torque. The motor is connected to a set of rotating blades called the cutterhead, which do the heavy lifting when it comes to removing material from the wood. As you glide the planer along the surface, these blades spin rapidly, efficiently shaving off layers of wood to create a smooth and even finish.

Paragraph 3:

But wait, there’s more! To ensure precision and control, electric planers are equipped with adjustable features. One such feature is the depth control knob, which allows you to determine the amount of wood you want to remove with each pass. Additionally, some planers boast a dust collection system, keeping your workspace cleaner and preventing wood chips from flying all over the place.

Now that you have a taste of what lies ahead, let’s dive deeper into the fascinating world of electric planers!

Electric planers are powerful tools used for woodworking projects. They feature a rotating blade that removes thin layers of material, creating smooth and even surfaces. Here’s a step-by-step guide to understanding how electric planers work:

– Step 1: Place the planer on a stable surface

– Step 2: Adjust the cutting depth

– Step 3: Hold the front handle and start the planer

– Step 4: Guide the planer along the workpiece

– Step 5: Repeat until the desired surface is achieved

With these simple steps, you can unleash the full potential of your electric planer!

How Electric Planers Work: A Comprehensive Guide

Electric planers are versatile tools that are used in woodworking projects to smooth out rough surfaces, trim material to size, and create beveled edges. They are an essential tool for both professional carpenters and DIY enthusiasts. In this guide, we will delve into the inner workings of electric planers, exploring their components, functions, and how they operate. Whether you’re a novice woodworker or an experienced craftsman, understanding how electric planers work will help you achieve precise and professional results in your projects.

1. Anatomy of an Electric Planer

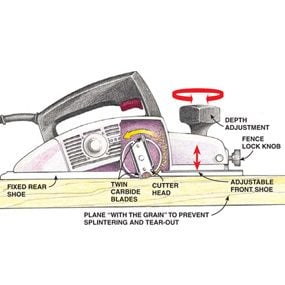

Electric planers consist of several essential components that work together to achieve efficient and accurate material removal. The main parts of an electric planer include the motor, cutterhead, feed rollers, depth adjustment knob, and dust collection system.

The motor is the heart of the planer, providing the power needed to drive the cutterhead and feed rollers. It is usually an electric motor that connects to the cutterhead via a system of belts or gears. The cutterhead is equipped with one or more blades that rotate at high speeds, cutting into the wood as it passes through the planer. The feed rollers are responsible for gripping and advancing the workpiece through the planer, ensuring a steady and controlled feed rate. The depth adjustment knob allows the user to set the desired depth of cut, determining the amount of material that will be removed with each pass. Lastly, the dust collection system helps to keep the work area clean by capturing and collecting the wood shavings and dust generated during planing.

2. Operation of an Electric Planer

The operation of an electric planer can be broken down into four main steps: setting the depth of cut, aligning the workpiece, turning on the planer, and guiding the workpiece through the planer.

To begin, you need to set the desired depth of cut on the planer’s depth adjustment knob. This determines how much material will be removed with each pass. It is important to start with a shallow depth of cut and gradually increase it until you achieve the desired result, as removing too much material in a single pass can lead to tear-out and produce an uneven surface.

Next, align the workpiece with the planer’s cutting edge. Most electric planers have a fence that can be adjusted to ensure the workpiece stays parallel to the cutterhead, resulting in a consistent and straight cut. Some planers also have a chamfering groove that allows for beveled edges to be created by tilting the workpiece at an angle as it passes through the planer.

Once the workpiece is properly aligned, turn on the planer and wait for the cutterhead to reach full speed. Then, gently push the workpiece into the planer, keeping a firm grip and ensuring a steady feed rate. It is crucial to maintain a consistent speed and pressure throughout the planing process to achieve an even and smooth surface.

Lastly, guide the workpiece through the planer, applying downward pressure to ensure proper contact between the feed rollers and the workpiece. Continue feeding the workpiece until the desired length or width is achieved. Be mindful of the grain direction to avoid tear-out, as planing against the grain can result in splintering and rough surfaces.

3. Safety Precautions and Maintenance

When operating an electric planer, it is important to prioritize safety and perform regular maintenance to ensure optimal performance and longevity.

First and foremost, always wear safety goggles or glasses to protect your eyes from flying debris. Consider using a dust mask or respirator to prevent inhalation of wood dust. Additionally, keep your hands clear of the cutterhead and avoid wearing loose clothing or jewelry that could get caught in the machinery.

Regular maintenance includes keeping the planer clean and free of debris, lubricating moving parts according to the manufacturer’s instructions, and periodically sharpening or replacing the planer blades. Check the power cord and plug for any signs of damage and ensure they are in good condition before each use. Lastly, store the planer in a dry and secure place, away from moisture and extreme temperatures.

By following these safety precautions and performing routine maintenance, you can ensure safe and efficient operation of your electric planer, prolong its lifespan, and consistently achieve professional results in your woodworking projects.

Key Features to Consider When Choosing an Electric Planer

1. Power and Motor Speed

When selecting an electric planer, it is essential to consider the power and motor speed. The power rating of the motor will determine the planer’s ability to handle different types of wood and thicknesses. Higher motor speeds allow for quicker and more efficient material removal.

2. Cutting Width and Depth Capacity

The cutting width and depth capacity of an electric planer determine the maximum size of the workpiece it can accommodate and the amount of material it can remove in a single pass. Consider the size of your typical woodworking projects and choose a planer with adequate capacity.

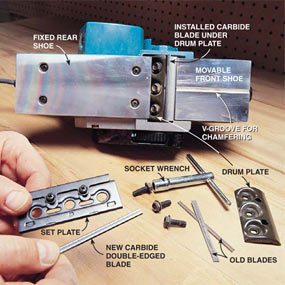

3. Blade Quality and Replacement

The quality of the planer blades is crucial for achieving smooth and clean cuts. Look for planers with high-quality, durable blades that can be easily replaced or sharpened when necessary. Some models have self-indexing blades that automatically align when replaced, ensuring optimal cutting performance.

4. Dust Collection System

Woodworking generates a significant amount of dust, so a built-in dust collection system is a valuable feature. Look for a planer with a dust port and consider connecting it to a dust extractor or shop vacuum for efficient debris removal and a clean working environment.

5. Ergonomics and Comfort

Since planing can be a repetitive task, ergonomics and comfort are essential considerations. Look for planers with rubberized grips and handles that offer a secure and comfortable grip, reducing fatigue and improving control during extended use.

6. Price and Warranty

Lastly, consider your budget and compare pricing among different models. While it is important to choose a planer that fits your budget, be mindful that higher-quality and more feature-rich options may come at a higher price. Additionally, check the warranty offered by the manufacturer to ensure coverage in case of any defects or malfunctions.

Tips for Using an Electric Planer

1. Take Light Passes

To avoid tear-out and achieve a smooth finish, take light passes and gradually increase the depth of cut until the desired result is achieved. It is better to make multiple passes than removing too much material in one go.

2. Pay Attention to Grain Direction

Always plane with the grain to minimize tear-out and produce a clean surface. Planing against the grain can result in splintering and rough finishes.

3. Secure the Workpiece

Ensure the workpiece is securely fastened or held in place before planing to prevent it from moving or vibrating during operation. This will result in more accurate and consistent cuts.

4. Mind the Width of the Planer

When planing wide workpieces, make overlapping passes to ensure full coverage and prevent ridges or uneven surfaces.

5. Use a Planing Sled for Thin Stock

When planing thin stock, consider using a sled or auxiliary base to provide additional support and prevent the workpiece from flexing or vibrating.

6. Keep the Planer Clean

Regularly remove debris and buildup from the planer’s feed rollers, cutterhead, and dust collection system. This will ensure optimal performance and prevent clogging.

7. Practice Safe Operation

Always follow the manufacturer’s safety guidelines and wear appropriate protective gear. Be cautious when handling the planer and keep your fingers away from the cutterhead at all times.

In summary, electric planers are versatile tools that play a crucial role in woodworking projects. Understanding their components, functions, and how they operate is essential for achieving precise and professional results. By following safety precautions, performing regular maintenance, and considering key features when choosing a planer, you can maximize its performance, prolong its lifespan, and ensure a successful woodworking experience.

How Electric Planers Work: Key Takeaways

- An electric planer is a tool used to smooth and shape wood surfaces.

- It works by using a rotating blade that shaves off thin layers of wood.

- The blade is powered by an electric motor, allowing for quick and efficient planing.

- Electric planers usually have adjustable depth settings to control the thickness of wood being removed.

- They are commonly used in woodworking projects to create smooth and even surfaces.

Frequently Asked Questions

Looking to learn more about how electric planers work? You’ve come to the right place! Below, we’ve answered some common questions to help you understand the inner workings of electric planers.

Can you explain how an electric planer operates?

An electric planer consists of a motor that drives a cutting head with two blades. When the motor is turned on, it rotates the cutting head at a high speed. As you slide the planer over the surface of the wood, the blades remove thin shavings, leaving behind a smooth and even finish. The depth at which the wood is cut can be adjusted using a setting on the planer. Electric planers are typically lightweight, portable, and efficient tools for woodworking projects.

Additionally, some advanced electric planers come with features like a dust collection system to help keep your workspace clean, and a chamfering function to create beveled edges. Overall, electric planers are designed to make woodworking tasks faster and easier, saving you time and effort.

What safety precautions should I take when using an electric planer?

While using an electric planer, it’s important to prioritize safety. Start by wearing protective gear, such as safety goggles to shield your eyes from flying debris, and ear protection to reduce noise levels. When handling the planer, make sure to hold it firmly with both hands and keep your fingers away from the cutting blades.

Before using the planer, ensure that the wood you’re working on is securely clamped to prevent any movement. This will help maintain stability and reduce the risk of any accidents. Finally, always disconnect the power supply before making any adjustments or changing blades. By following these precautions, you can enjoy a safe and productive woodworking experience with an electric planer.

Can an electric planer be used on different types of wood?

Yes, an electric planer can be used on various types of wood, including hardwoods, softwoods, and even some man-made materials like plywood and MDF. However, it’s important to consider the density and hardness of the wood when selecting the appropriate cutting depth. Hardwoods may require a slower feed rate and more passes to achieve a smooth finish, while softer woods may be planed more easily.

It’s also worth noting that some electric planers may be more suitable for certain types of wood due to their power and cutting speed. Always read the manufacturer’s instructions and recommendations before using your planer on different wood species to ensure optimal results.

What maintenance is required for an electric planer?

To keep your electric planer in good working condition, regular maintenance is essential. After each use, clean the planer’s cutting blades and remove any debris or wood shavings. You can use a brush or compressed air to clear out the dust. It’s also a good idea to lubricate any moving parts, such as the depth adjustment knob and the blade hinges, with a few drops of lubricating oil.

Periodically, check the condition of the blades and replace them if they become dull or damaged. Many planers have easily replaceable blades, making this task quick and straightforward. Additionally, store your electric planer in a dry and clean area to prevent rust and damage. By following these maintenance steps, you can prolong the lifespan of your planer and ensure it continues to deliver optimal performance.

Are there any limitations to using an electric planer?

While electric planers are versatile and efficient tools in the woodworking world, they do have certain limitations. One limitation is the width of the cutting path. Most electric planers have a fixed cutting width, typically ranging from 3 to 4 inches. This means that if you need to plane wider boards, you may have to make multiple passes or consider alternative tools.

Another limitation is the depth of cut. Electric planers have a specified maximum cutting depth, and if you wish to remove material beyond that depth, you may need to resort to other methods like a hand plane or a stationary planer. Additionally, electric planers may not be suitable for delicate or highly figured woods, as they can cause tear-out or damage to the wood grain. Understanding these limitations can help you make informed decisions when working on your woodworking projects.

Summary

Electric planers are handy tools used to smooth and shape wood surfaces. They work by using a spinning blade to scrape off thin layers of wood. The blade is powered by an electric motor and is adjustable to control the depth of the cut. It is essential to use the proper techniques and safety precautions when operating an electric planer to prevent accidents. With the right knowledge and practice, anyone can use an electric planer to transform rough wood into a smooth and polished finish.