Have you ever wondered how fast a lathe can spin? Well, you’re in luck! In this article, we’ll dive into the fascinating world of lathes and discover just how speedy they can get.

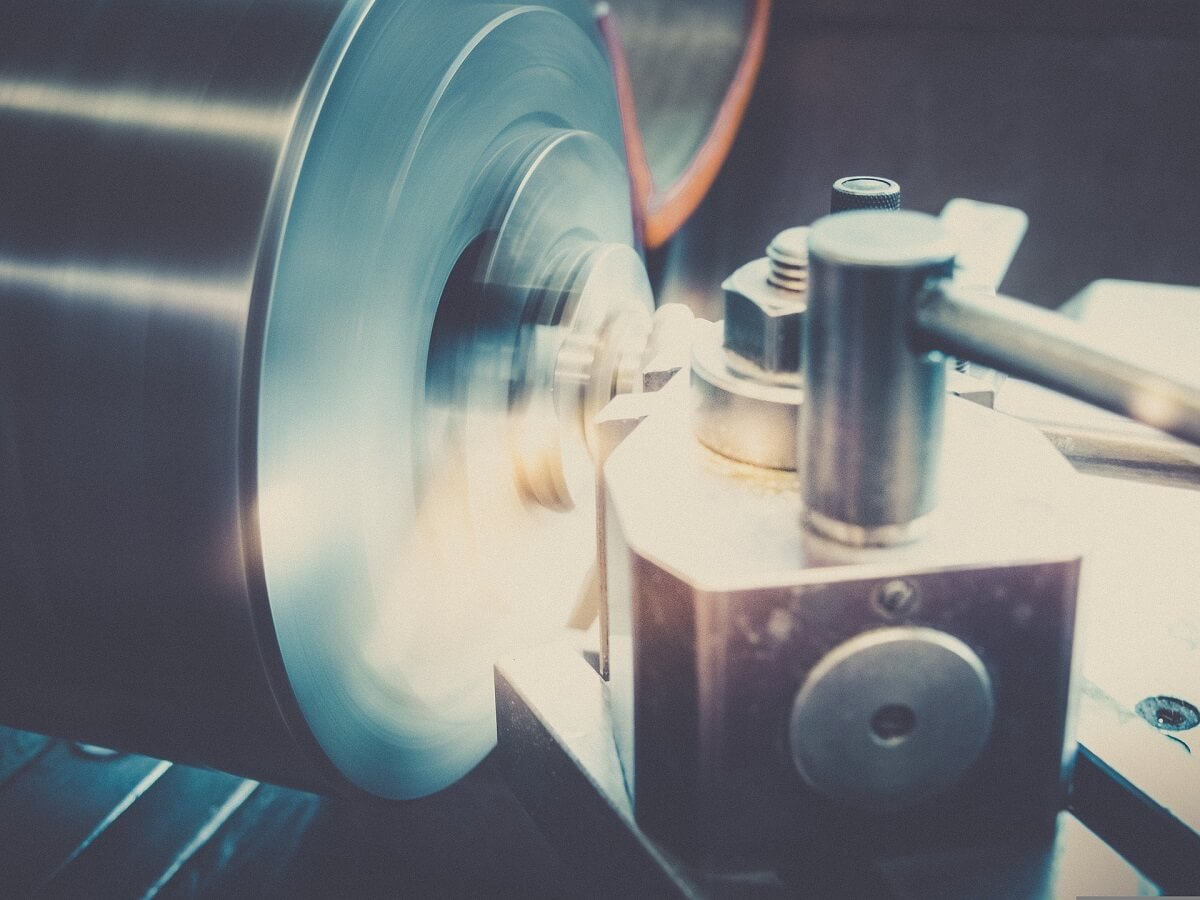

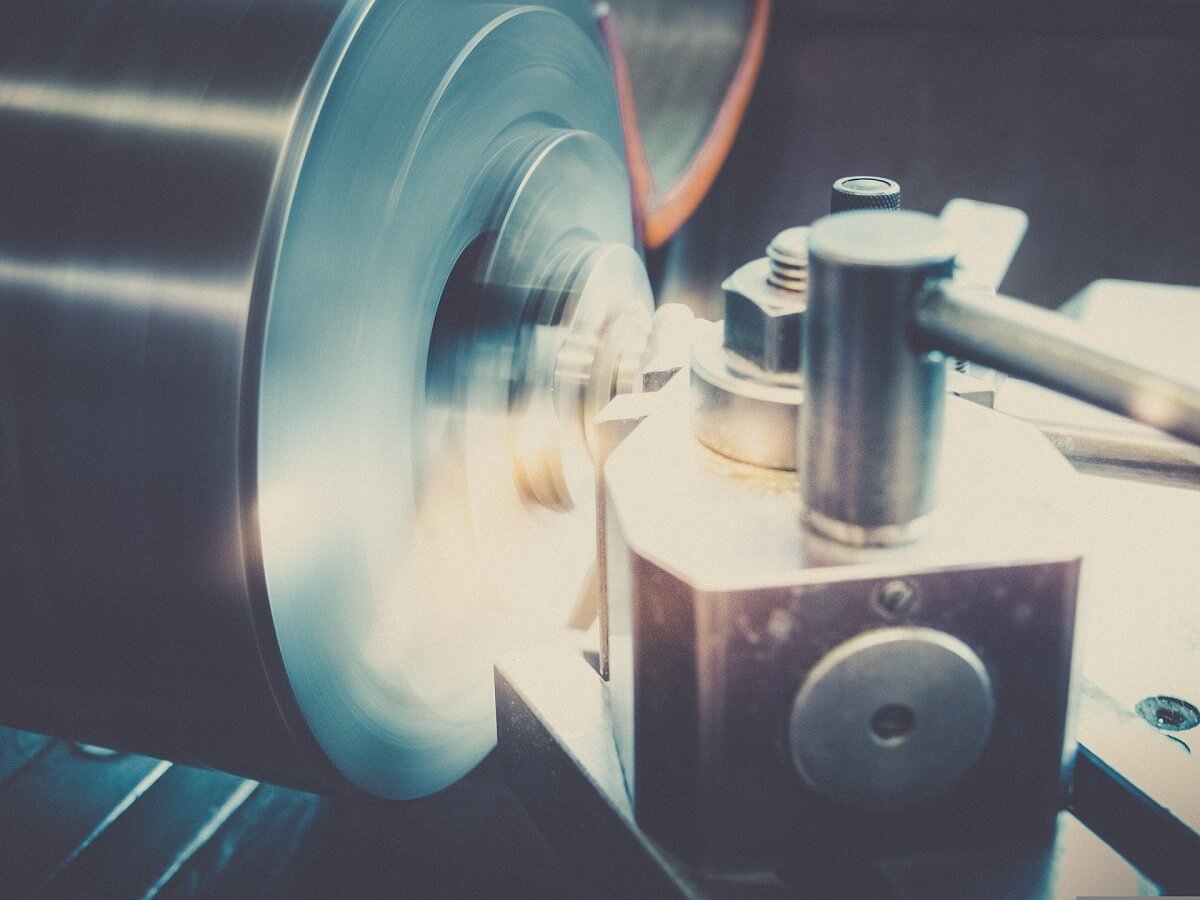

Now, you might be thinking, “What’s a lathe?” Good question! A lathe is a machine that rotates a workpiece while a cutting tool shapes it. It’s used in woodworking, metalworking, and even pottery.

But let’s get back to the main topic: speed. How fast can a lathe spin? Stick with me, and we’ll find out together! So, without further ado, let’s jump right into the spinning world of lathes!

How Fast Can a Lathe Spin?

Lathe machines are essential tools in the manufacturing industry, enabling precise shaping and cutting of various materials. One crucial aspect of a lathe machine is its spinning speed. The speed at which a lathe can spin determines its efficiency, productivity, and the quality of the finished product. In this article, we will delve into the factors that influence the speed of a lathe and explore the limits of how fast a lathe can spin.

The Basics of Lathe Spindle Speed

Before we dive into the specific speed limits, let’s understand the basics of lathe spindle speed. The spindle speed is typically measured in revolutions per minute (RPM) and represents the number of complete rotations the lathe spindle can make in a minute. The spindle speed directly affects the cutting speed and feed rate, which impact the material removal rate and the surface finish of the workpiece.

The lathe spindle speed is determined by several factors, including the material being machined, the type and size of the cutting tool, and the diameter of the workpiece. Typically, smaller workpieces require higher spindle speeds, while larger workpieces require slower speeds to maintain optimal cutting conditions.

The Influence of Workpiece Material

The material being machined plays a significant role in determining the spindle speed. Different materials have varying hardness and susceptibility to heat. For example, softer materials like aluminum can be machined at higher speeds compared to harder materials like steel. Machining at the right speed for the specific material ensures efficient material removal and prevents overheating, which can lead to tool wear and poor surface finish.

When determining the spindle speed for a specific material, machinists often refer to cutting speed guidelines and use cutting speed calculations that take into account the workpiece material properties and the desired surface finish. By selecting the optimal spindle speed, manufacturers can achieve precise and efficient machining of different materials.

It is essential to note that certain materials may have maximum recommended spindle speeds due to their inherent characteristics. Exceeding these limits can result in tool damage, workpiece deformation, or even safety hazards. Manufacturers must follow the recommended guidelines and industry standards to ensure safe and productive machining practices.

The Impact of Cutting Tools on Spindle Speed

The selection and condition of the cutting tool also play a crucial role in determining the safe and efficient spindle speed. Different cutting tools have specific speed limits based on their design, material, and coating, if present. Inadequate tool selection or using worn-out tools at high speeds can lead to tool failure, poor surface finish, and even accidents.

Manufacturers must consider the tool manufacturer’s recommendations for the maximum allowable speed for a particular tool. This information is usually provided in the form of cutting speed charts or specifications. Following these guidelines ensures that the cutting tool can withstand the forces generated during high-speed machining, resulting in improved productivity and extended tool life.

Regular maintenance and inspection of cutting tools are crucial for safe and efficient spindle speed operation. Dull or damaged tools can negatively impact the cutting process, leading to inconsistencies in the workpiece and increased production time. Machinists must regularly check the tool condition and replace or recondition them as needed.

The Size and Balance of the Workpiece

Another factor that influences the spindle speed is the size and balance of the workpiece. Larger workpieces require slower spindle speeds to maintain tool stability and prevent excessive vibrations. Unbalanced workpieces can cause the lathe to vibrate, affecting the machining accuracy and potentially damaging the machine or the workpiece.

Proper workholding techniques, such as using steady rests, chucks, or centers, help maintain stability and balance during machining. Additionally, choosing the correct cutting parameters and spindle speed for the workpiece size ensures optimal chip load and tool engagement, contributing to efficient material removal and optimal surface finish.

Furthermore, certain workpieces may have specific speed limits due to their design or specific requirements. For example, delicate or heat-sensitive workpieces may require lower spindle speeds to prevent distortion or damage. It is crucial to consider these factors and refer to any design specifications or guidelines provided by the workpiece manufacturer.

External Factors and Machine Limitations

While the factors mentioned above primarily influence the spindle speed, it is also essential to consider external factors and machine limitations. The power and design of the lathe machine, the available motor speed, and the rigidity of the machine structure can impose restrictions on the achievable spindle speed.

High-speed machining requires robust machine construction to handle the increased forces and vibrations. Insufficient machine rigidity can lead to poor surface finish, reduced accuracy, and increased wear on machine components. Manufacturers must ensure that their lathe machines are suitable for the desired spindle speeds and machining operations.

External factors such as cooling and lubrication systems, ambient temperature, and workshop conditions can also influence the safe and effective spindle speed. Maintaining proper cooling and lubrication, controlling the temperature, and providing a clean and well-maintained machining environment contribute to better machining performance and prolonged machine life.

Innovation and Advancements in Lathe Speeds

The speed potentials of lathe machines have significantly advanced over the years, thanks to innovations in technology and machining practices. With the introduction of high-speed machining (HSM) techniques, lathe machines can achieve much higher spindle speeds, resulting in increased productivity and improved surface finish.

Modern lathe machines often come equipped with variable speed drives and high-torque motors, allowing machinists to adjust the spindle speed to suit different machining requirements. Furthermore, advances in cutting tool materials, coatings, and designs have contributed to higher cutting speeds and improved tool life.

As technology continues to evolve, lathe machines are likely to see further advancements in spindle speed capabilities. Machinists and manufacturers should stay updated on the latest developments in machining processes and equipment to leverage these advancements and optimize their operations.

Choosing the Right Speed for Your Lathe

When determining the appropriate speed for your lathe machine, it is crucial to consider the factors discussed in this article. Here are a few tips to help you choose the right speed:

1. Refer to Cutting Speed Charts:

Consult cutting speed charts or guidelines provided by the tool and material manufacturers to determine the recommended speeds for specific materials and tools.

2. Consider Workpiece Size and Material:

Take into account the size, balance, and material properties of the workpiece to select an optimal spindle speed that ensures efficient and safe machining.

3. Check Tool Condition:

Regularly inspect and maintain your cutting tools, ensuring they are in good condition and can withstand the desired spindle speeds.

4. Follow Machine and Tool Manufacturer’s Recommendations:

Adhere to the recommended spindle speed limits provided by the lathe machine and cutting tool manufacturers to ensure optimal performance and safety.

5. Stay Informed About Technological Advancements:

Keep up with the latest technological advancements in machining processes and lathe machine capabilities to leverage new opportunities for improved productivity and surface finish.

In Conclusion

The spinning speed of a lathe machine is a critical parameter that influences the efficiency, productivity, and quality of the machining process. Factors such as the workpiece material, cutting tool, workpiece size, and machine limitations play essential roles in determining the optimal spindle speed. By considering these factors and following the recommendations of tool and machine manufacturers, manufacturers can achieve precise and efficient machining operations. Staying informed about technological advancements allows them to leverage new opportunities and continuously improve their machining processes.

Key Takeaways: How Fast Can a Lathe Spin?

- A lathe can spin at different speeds depending on the size and type of lathe.

- Most lathes have variable speed controls, allowing operators to adjust the speed as needed.

- Smaller lathes typically have faster spinning speeds, while larger industrial lathes may have slower speeds for heavy-duty tasks.

- Wood lathes usually spin at speeds ranging from 500 to 4,000 revolutions per minute (RPM).

- For metal lathes, the maximum speed can vary but is typically around 2,000 RPM.

Frequently Asked Questions

When it comes to the speed of a lathe, there are various factors to consider. Below are some common questions about how fast a lathe can spin and their answers.

1. What determines the maximum speed of a lathe?

The maximum speed of a lathe is determined by its design, power, and the type and size of the material being worked on. Lathes with higher horsepower motors and sturdier constructions can typically handle higher speeds. Additionally, the type of material being turned and its diameter also play a role in determining the maximum speed. Smaller diameter workpieces can generally be spun at higher speeds compared to larger ones.

It’s important to reference the specific lathe’s manufacturer guidelines to ensure safe usage and to determine the recommended maximum speed for a given material and diameter. Following these guidelines is crucial for both optimal performance and operator safety.

2. Can a lathe spin faster than its maximum speed?

No, it is not recommended to spin a lathe faster than its maximum speed as this can lead to various issues. Exceeding the recommended speed can cause the lathe’s components, such as the spindle and bearings, to wear out prematurely. It can also result in excessive vibration, which affects the quality of the workpiece and may compromise operator safety.

Adhering to the recommended maximum speed not only ensures the longevity of the lathe but also promotes accuracy and precision in the turning process. It’s always best to operate within the specified limits to maintain the overall integrity of the lathe and produce high-quality results.

3. What are the advantages of higher lathe speeds?

Higher lathe speeds offer several advantages, depending on the type of material being turned and the desired outcome. When working with certain materials, like aluminum or plastics, higher speeds can help achieve smoother finishes and reduce the likelihood of tool chattering or workpiece deformation. They can also enhance the efficiency of the turning process by allowing for faster stock removal.

However, it’s important to note that not all materials benefit from higher speeds. For some metals, slower speeds may be more appropriate to prevent tool wear or excessive heat buildup. It’s crucial to consider the specific material and its characteristics when determining the optimal lathe speed for a particular turning operation.

4. Can a lathe speed be adjusted during operation?

Yes, many lathes offer variable speed controls that allow operators to adjust the spindle speed while the lathe is in operation. This feature provides flexibility and the ability to optimize the speed for different types of materials, workpiece sizes, and turning operations. It allows operators to adapt to changing conditions and achieve the desired results.

However, it’s essential to make speed adjustments gradually and cautiously to prevent sudden changes that can lead to tool breakage, workpiece damage, or accidents. It’s advisable to consult the lathe manufacturer’s guidelines or seek expert advice when making significant speed adjustments.

5. Are there any safety considerations when working with high lathe speeds?

Yes, safety is paramount when working with high lathe speeds. Operators should always wear appropriate protective gear, such as safety glasses and gloves, to prevent injury from rotating parts or flying debris. It’s crucial to secure the workpiece properly and ensure it is balanced to minimize vibrations and potential accidents.

Additionally, regular maintenance and inspection of the lathe, including checking for any signs of wear or damage, are essential for operator safety. Following proper operating procedures and adhering to manufacturer guidelines will help mitigate risks and ensure a safe working environment when using high lathe speeds.

Summary:

A lathe is a machine used to shape objects by spinning them around. The speed at which a lathe can spin depends on various factors such as its size, power, and the material being worked on. Small hobbyist lathes can spin at speeds up to a few thousand rotations per minute (RPM), while larger industrial lathes can reach speeds of tens of thousands of RPM. The speed is typically adjustable to suit different materials and cutting operations. It’s important to operate a lathe at the correct speed to ensure safety and achieve the desired results.

Overall, the speed at which a lathe can spin varies depending on the machine’s size, power, and the material being used. It’s crucial to follow proper safety guidelines and adjust the speed as needed for different projects. So, whether you’re making a wooden bowl or turning metal parts, understanding the speed at which a lathe can spin is essential for achieving the best and safest results.