Are you curious about how fast lathes spin? It’s an intriguing question that many people wonder about. Well, you’ve come to the right place! In this article, we’ll dive into the world of lathes and explore the fascinating speeds at which they operate. So, get ready to uncover the secrets behind the spinning marvels of lathe machinery.

Lathes are incredible machines that have been around for centuries. They’re used to shape and cut various materials, such as wood, metal, and even glass. But have you ever thought about how fast these machines spin? The speed at which a lathe operates is a crucial factor in determining the quality and precision of the work it produces. So, let’s take a closer look at the different speeds that lathes can achieve and how they impact the machining process.

Now that we’ve piqued your interest, let’s delve into the world of lathe speeds. We’ll discover the different speed settings and their effects on the outcome of your lathe projects. Whether you’re a DIY enthusiast or just fascinated by machinery, understanding how fast lathes spin will give you a deeper appreciation for these remarkable tools.

So, fasten your seatbelts and prepare for a whirlwind adventure into the realm of lathe speeds! By the end of this article, you’ll be equipped with the knowledge to appreciate the intricacies of lathe machinery and how its spinning speed can make all the difference in the world of machining. Ready? Let’s get started!

How Fast Do Lathes Spin? A Comprehensive Guide

Lathes are powerful machines used in various industries, from woodworking to metalworking. Understanding how fast lathes spin is crucial for ensuring the success and safety of any machining project. In this article, we will delve into the details of lathe speed, exploring different factors that determine the speed and offering insights into proper speed selection. Whether you are a professional machinist or a woodworking enthusiast, this guide will provide you with the knowledge you need to optimize lathe speed for your projects.

The Basics: Understanding Lathe Speed

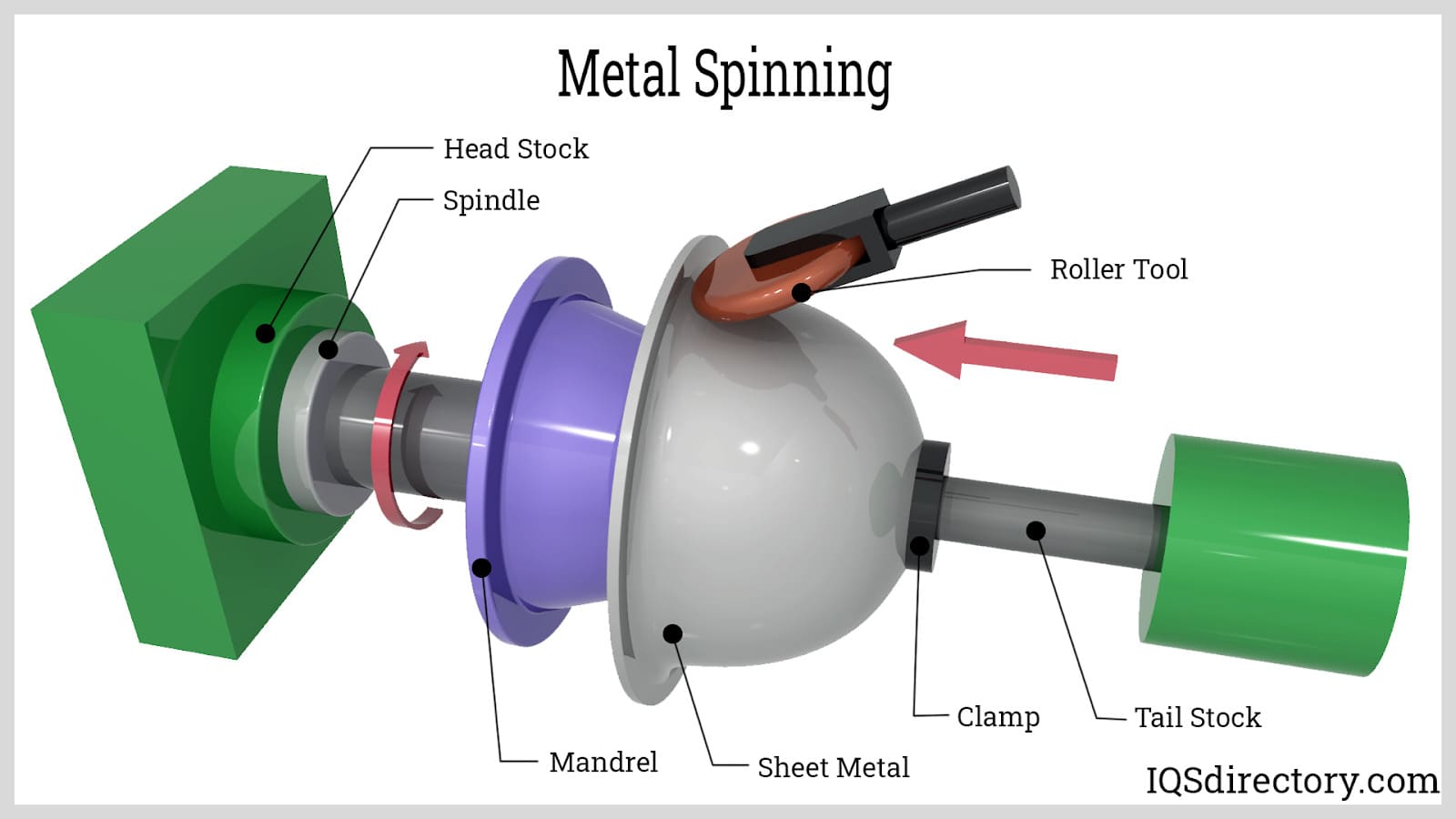

The speed at which a lathe spins is measured in revolutions per minute (RPM). RPM determines how fast the workpiece rotates as it is being cut or shaped by the lathe. The speed at which a lathe should spin depends on various factors, including the type of material being machined, the desired finish, and the type of lathe being used. It is essential to select the appropriate speed to achieve the best results while also taking safety into consideration.

The lathe speed is controlled through a combination of motor speed settings and gear ratios. Some lathes have multiple speed settings that allow operators to choose the optimal speed for each task. In other cases, gear changes are necessary to adjust the speed. Understanding the concepts of surface speed and cutting speed is crucial for determining the proper RPM for a specific job.

Surface Speed vs. Cutting Speed

When selecting the speed for a lathe, it is important to consider both surface speed and cutting speed. Surface speed refers to the linear speed at the cutting edge of the tool as it touches the workpiece. Cutting speed, on the other hand, calculates the speed at which the material being cut moves past the tool. Both factors play a significant role in achieving the desired cutting results.

The surface speed is calculated as the circumference of the workpiece multiplied by the RPM. For example, if you have a workpiece with a circumference of 10 inches and an RPM of 1,000, the surface speed would be 10,000 inches per minute. Similarly, the cutting speed is calculated by dividing the surface speed by the diameter of the workpiece.

The Relationship Between Material and Lathe Speed

Different types of materials require varying lathe speeds to achieve optimal results. Wood, for instance, may require slower speeds compared to metals. Softer materials like pine or balsa wood should be turned at lower RPM to prevent tearing or splintering. Harder woods can handle higher speeds but require sharp tools and proper machining techniques.

In metalworking, the type of metal being machined dictates the ideal lathe speed. For example, aluminum can be turned at a higher RPM compared to steel due to its lower density and softer characteristics. It is important to refer to manufacturer guidelines and recommendations for choosing the appropriate speed for specific materials.

Factors to Consider for Lathe Speed Selection

Choosing the right lathe speed involves assessing several factors to ensure a successful machining process. Here are some key considerations:

1. Material Type: As discussed earlier, different materials require specific lathe speeds. Take into account the density, hardness, and characteristics of the material to determine the appropriate RPM range.

2. Tooling: The type and condition of the cutting tools used also play a significant role in speed selection. Dull or damaged tools may require slower speeds to compensate for reduced cutting efficiency.

3. Desired Finish: The desired finish, whether you want a smooth surface or a textured one, affects the lathe speed as well. Higher speeds may result in a smoother finish, while lower speeds can create more defined textures.

4. Workpiece Size: The size and diameter of the workpiece influence the RPM range as well. Larger workpieces may require slower speeds to prevent vibration or instability during machining.

5. Cutting Depth: The depth of cut or how much material is being removed with each pass affects the speed selection. Deeper cuts may require slower speeds to maintain stability and prevent damage to the workpiece.

Tips for Optimizing Lathe Speed

Now that we have a clear understanding of lathe speed and its importance in machining, let’s explore some tips for optimizing lathe speed for different types of projects:

1. Experiment and Test

Every machining project is unique, and finding the optimal lathe speed often requires some trial and error. Start with a conservative speed, observe the results, and make adjustments as necessary. Gradually increase the speed while monitoring the quality of the cuts and finishes.

2. Consult Manufacturer Guidelines

Manufacturers provide guidelines and recommendations for their lathes and cutting tools. These guidelines can serve as a valuable resource to determine the appropriate speed settings for different materials and machining processes. Always refer to the manufacturer’s recommendations for optimal results and safety.

3. Keep Tools Sharp

Maintaining sharp cutting tools is crucial for achieving excellent machining results at higher speeds. Dull tools can cause vibration, poor surface finishes, and even damage to the workpiece. Regularly inspect and sharpen your tools to ensure optimal cutting performance.

Conclusion

In summary, the speed at which lathes spin is critical for achieving accurate and high-quality machining results. Understanding the relationship between material, cutting speed, and lathe speed is essential for selecting the optimal RPM. By considering factors such as material type, tooling, desired finish, workpiece size, and cutting depth, machinists can optimize their lathe speed to ensure successful outcomes. Experimentation, consultation with manufacturers, and maintaining sharp tools all contribute to finding the best lathe speed for each unique project.

Key Takeaways: How Fast Do Lathes Spin?

- Lathe spin speed is measured in revolutions per minute (RPM).

- Fast lathe speeds are typically used for cutting materials like plastic or aluminum.

- Slower speeds are used for cutting harder materials like steel.

- Some lathes have variable speed controls to adjust for different materials and cuts.

- Consult the lathe’s manual or a professional for the recommended speed for specific materials and cuts.

Frequently Asked Questions

Introduction: Lathes are versatile machines used in woodworking and metalworking. They are known for their ability to shape and mold materials, with the speed at which they spin being an important factor. Here are some commonly asked questions about the speed of lathes:

1. Why is the speed of a lathe important?

The speed of a lathe is important because it determines how efficiently and accurately the material can be shaped or cut. Different materials and cutting tools require different speeds to achieve the desired results. For example, a higher speed may be suitable for cutting metal, while a lower speed might be better for working with wood. Adjusting the speed allows for more precise control over the lathe’s cutting action.

Additionally, the speed of a lathe affects the quality of the finished product. The right speed helps in reducing vibrations, preventing tool wear, and achieving smoother cuts. By selecting the appropriate speed, you can ensure that the lathe operates optimally and produces the desired outcome.

2. What factors determine the speed of a lathe?

The speed of a lathe can be determined by various factors, including the size of the workpiece, the material being worked on, and the type of cutting operation being performed. Larger workpieces often require slower speeds to maintain stability during the cutting process. Harder materials may require slower speeds to prevent excessive tool wear, while softer materials may allow for higher speeds.

Furthermore, the type of cutting operation being performed plays a role in setting the speed. For example, roughing cuts typically require higher speeds to quickly remove material, while finishing cuts may benefit from lower speeds for more precise detail work. Considering these factors helps determine the optimal speed for each specific lathe operation.

3. Are there specific speed ranges for different materials?

Yes, there are general speed ranges for different materials when using a lathe. For instance, when working with wood, the speed range can typically vary from 500 to 4000 revolutions per minute (RPM). Smaller workpieces and delicate cuts may be done at lower RPMs, while larger workpieces and rougher cuts may require higher RPMs.

On the other hand, when working with metals, the speed range can be much higher. It can range from around 1000 to 6000 RPM or even higher for certain operations. The choice of speed will depend on factors such as the hardness of the metal, the type of cutting tool being used, and the specific operation being performed. It’s best to consult the lathe manufacturer’s guidelines or industry standards for recommended speed ranges for different materials.

4. How can the speed of a lathe be adjusted?

The speed of a lathe can be adjusted using the machine’s speed control mechanism. This mechanism may vary depending on the type and model of the lathe. Some lathes have a variable speed control that allows you to adjust the speed manually using a dial, lever, or digital interface. Others may require changing the belt position on the pulley system to switch between different speed settings.

It’s important to follow the instructions provided by the lathe manufacturer when adjusting the speed. They will provide guidance on how to safely modify the speed settings and ensure the lathe operates within its specified limits. Always take proper safety precautions and make sure you understand the lathe’s speed control mechanism before attempting to adjust the speed.

5. Are there safety considerations when working with different speeds on a lathe?

Yes, there are safety considerations when working with different speeds on a lathe. Higher speeds generate greater centrifugal forces, which can be dangerous if the workpiece is not properly secured. Always ensure that the workpiece is firmly held in place and that appropriate safety measures are in place, such as using tailstock support or a chuck to prevent the workpiece from coming loose during operation.

Additionally, when changing speeds or adjusting the lathe, it’s important to turn off the machine and wait for it to come to a complete stop before making any modifications. This helps prevent accidents and ensures that adjustments can be made safely. Observing proper safety protocols and using personal protective equipment, such as safety glasses and gloves, is crucial when working with lathes at different speeds.

Summary

Lathes are machines that spin really fast to shape and cut materials. They can spin at different speeds depending on what they’re used for. For example, smaller lathes might spin around 500 to 2000 revolutions per minute (RPM), while bigger ones can go up to 3000 RPM or even higher. The speed can be adjusted based on what you need to do.

Spinning fast helps lathes work efficiently and create precise cuts. However, it’s important to be careful when using them because they can be dangerous. Always follow safety guidelines and wear protective gear to stay safe while operating a lathe. Just keep in mind that lathes spin really fast to get the job done!