Looking to uncover the mysteries of a lathe’s spinning speed? Well, you’ve come to the right place! Just how fast does a lathe spin? Let’s dive in and find out together.

Now, you might be wondering why anyone would even care about the speed of a lathe’s spin. But trust me, it’s an important question! Understanding the speed at which a lathe spins is crucial for achieving precision and getting the best results in anything from woodworking to metalworking.

So, grab your curiosity and let’s embark on this fascinating journey into the world of lathe spinning speed! Get ready to have your questions answered and your knowledge expanded as we explore the ins and outs of this mechanical marvel.

Now, let’s crank up the excitement and delve into the captivating world of lathe spinning speed, shall we?

How Fast Does a Lathe Spin? Exploring the Speeds of a Key Machining Tool

When it comes to machining and metalworking, lathes play a pivotal role. These powerful tools are designed to shape and cut materials with precision. One of the key factors in operating a lathe effectively is understanding the speed at which it spins. In this article, we will delve into the details of lathe speeds, discussing the different types of lathes and their respective speed ranges. Whether you are a seasoned machinist or just starting out, this comprehensive guide will provide you with valuable insights into the fascinating world of lathe rotation speeds.

The Basics: Understanding Lathe Speeds

Before we dive into the specifics, let’s start with the basics. The speed at which a lathe spins, commonly referred to as RPM (revolutions per minute), is a fundamental parameter that affects the machining process. It determines the rate at which the workpiece rotates and the cutting tool engages with the material, ultimately influencing the efficiency and quality of the machining operation.

There are two primary types of lathes in terms of speed control: variable speed lathes and fixed speed lathes. Variable speed lathes allow the operator to adjust the rotational speed according to specific requirements, providing versatility and flexibility. On the other hand, fixed speed lathes have predetermined speed settings, limiting the range of applications but ensuring consistent performance within those bounds.

Now, let’s explore the different speed ranges for various types of lathes:

1. Engine Lathes

Engine lathes are among the most common types of lathes found in metalworking shops. These robust machines are capable of handling a wide range of machining tasks, including turning, facing, threading, and drilling. Engine lathes typically feature a speed range of 50 to 2500 RPM, allowing for precision and efficiency in various applications.

The optimal rotational speed for an engine lathe depends on factors such as the material being machined, the type of cutting tool, the desired surface finish, and the overall cutting conditions. When working with different materials or performing specific operations, adjusting the lathe’s speed accordingly can significantly impact the outcome of the machining process.

It is important to note that some engine lathes may come with additional gearboxes to enable slower speeds for heavy-duty cutting or faster speeds for lighter cuts. These gearboxes provide further versatility and enhance the range of applications for the machine.

2. Wood Lathes

Wood lathes, as the name suggests, are specifically designed for woodworking applications. These lathes are used to shape and form wooden workpieces, such as spindles, bowls, and other decorative items. Wood lathes typically operate at slower speeds compared to their metalworking counterparts.

The rotational speed of a wood lathe generally falls within the range of 500 to 2000 RPM. The slower speeds ensure better control and reduced vibration when working with wood, which can be a more delicate material compared to metal. This allows woodworkers to achieve smoother finishes and precise shaping of their projects.

Wood lathes often come with multiple speed settings to cater to different wood species and project requirements. The choice of speed depends on factors such as the hardness of the wood, the desired surface finish, and the type and size of the cutting tool being used.

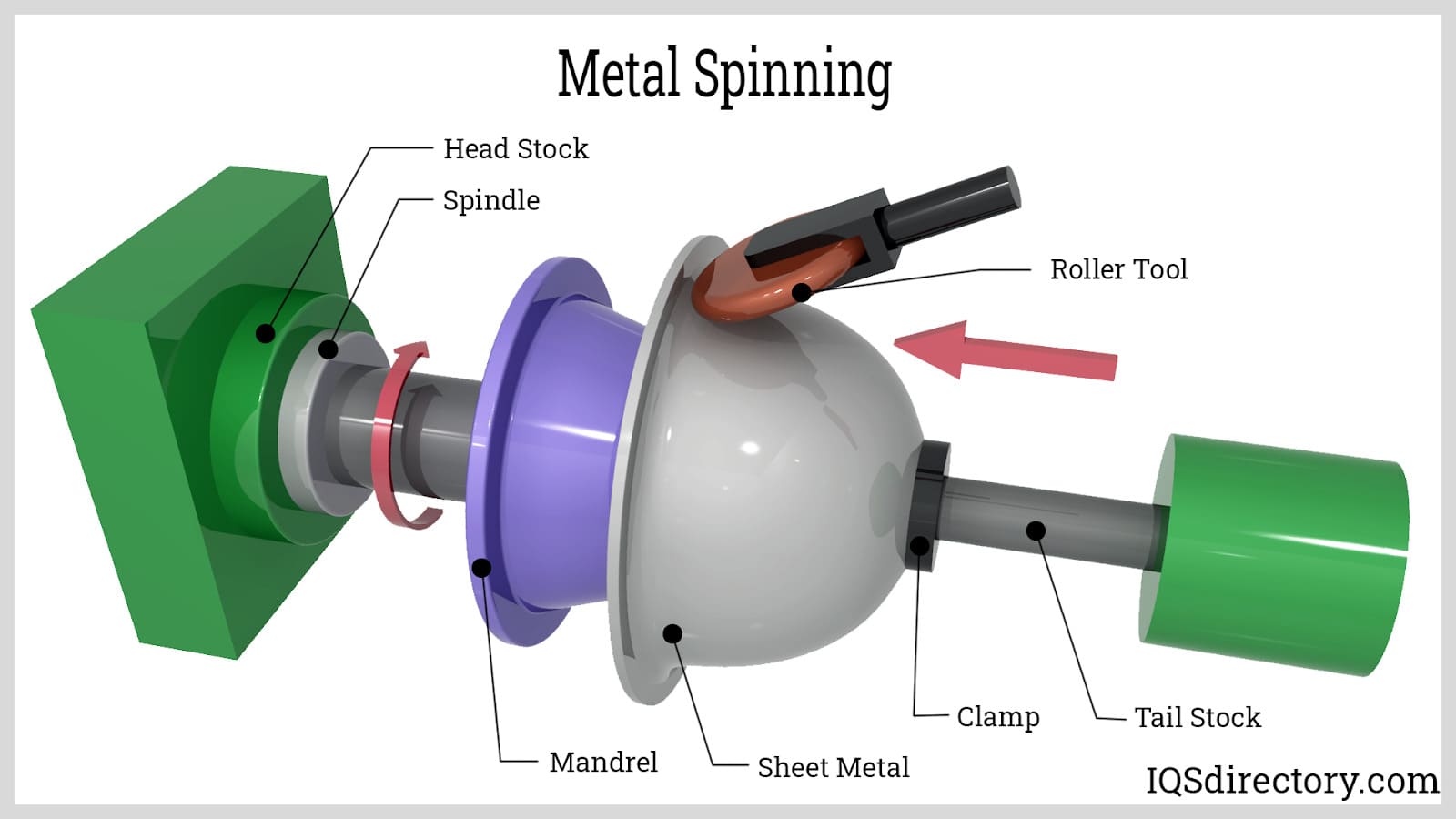

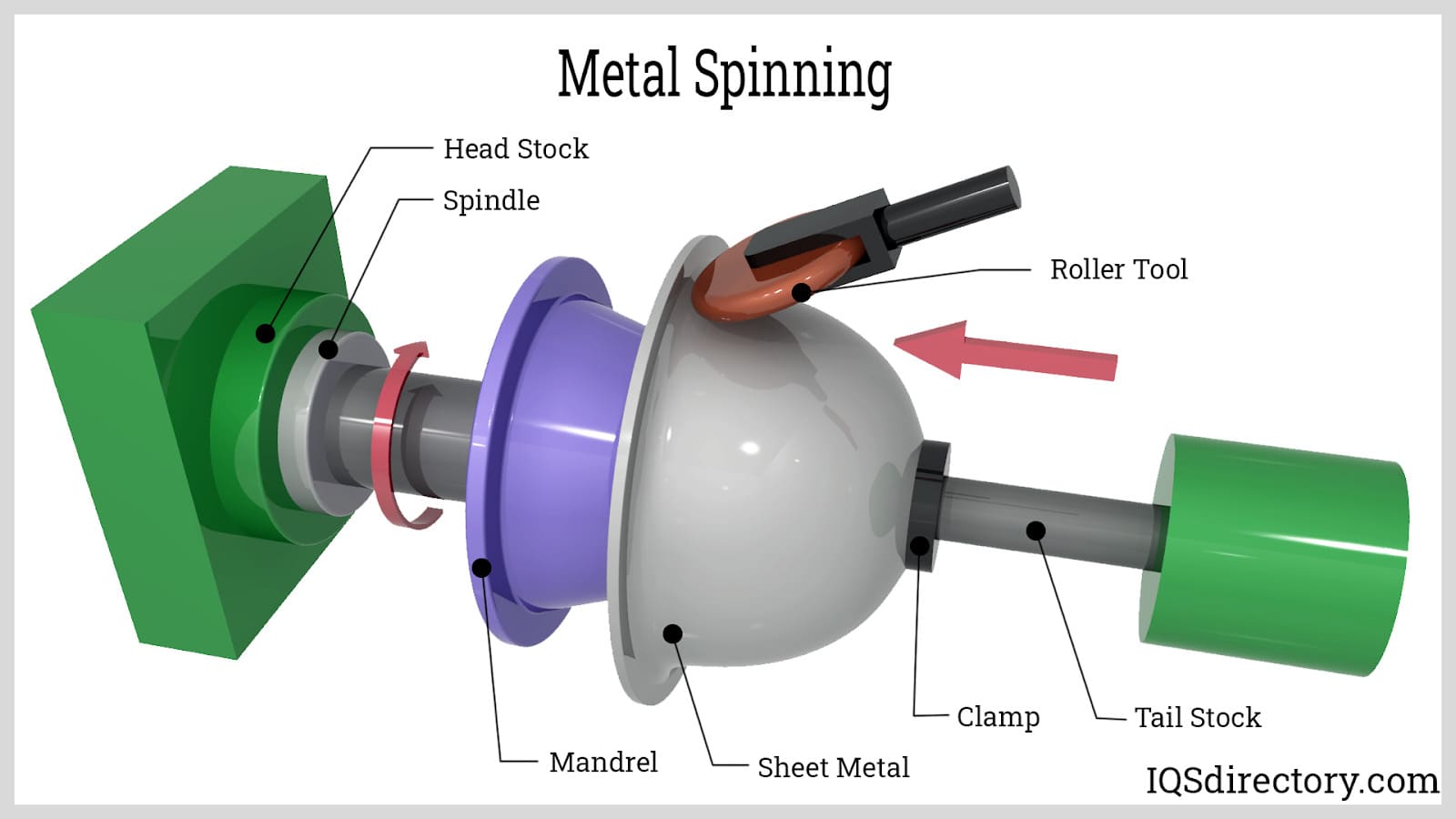

3. Metal Spinning Lathes

Metal spinning lathes, also known as spin forming lathes, are specialized machines used in the metal spinning process. This process involves rotating a metal blank on a lathe and forming it into a desired shape using various tools and molds. The rotational speed of metal spinning lathes varies based on the type of metal being spun and the complexity of the desired shape.

For softer metals such as aluminum or copper, metal spinning lathes typically operate at speeds ranging from 1000 to 2000 RPM. This range allows for efficient metal deformation without causing excessive strain or deformation. However, when working with harder metals like steel or stainless steel, the rotational speeds may be reduced to ensure stable machining conditions and avoid potential tool wear or breakage.

The speed selection in metal spinning lathes is a critical factor in achieving consistent and precise results. The operator must consider the material thickness, the desired shape, and the overall spinning process to determine the optimal rotational speed for the specific application.

Factors Affecting Lathe Speeds

While we have discussed the speed ranges for different types of lathes, it is essential to understand the factors that influence the selection of the appropriate speed for a given operation. Here are some key factors to consider:

1. Material Type

The type of material being machined is a crucial consideration when determining the optimal rotational speed for a lathe. Different materials have varying hardness and machinability, which affects the cutting tool’s performance and the overall machining process. Softer materials may require higher speeds for efficient chip formation, while harder materials may necessitate lower speeds to avoid excessive tool wear.

Additionally, the type of material may impact the desired surface finish. Finer finishes often require slower speeds to minimize vibrations and achieve smoother results, especially when working with materials susceptible to tearing or work hardening. Metal alloys, for example, often require lower speeds to ensure precise cuts without compromising the material’s integrity.

2. Cutting Tool and Tooling

The selection of the cutting tool and the overall tooling setup is another crucial factor in determining the appropriate lathe speed. Different cutting tools are designed to handle specific materials and cutting conditions, and their performance can vary with rotational speed.

High-speed steel (HSS) tools, for example, can operate effectively at higher speeds, allowing for faster material removal rates. Carbide tools, on the other hand, can withstand higher cutting temperatures and are often used at slower speeds for optimal performance and tool life.

In addition to the cutting tool, the tooling setup, including the tool holder, inserts, and tool geometries, plays a significant role in the lathe’s speed selection. Proper tool maintenance, adjustment, and alignment are critical to achieving consistent results and preventing any issues arising from high-speed machining.

3. Desired Surface Finish

The desired surface finish of the machined part is a key consideration when determining the appropriate lathe speed. Smoother surface finishes often require slower speeds to minimize vibrations and tool chatter, resulting in a more polished outcome. On the other hand, rougher finishes may be achieved at higher speeds, allowing for faster material removal rates and reduced machining time.

It is important to note that the lathe speed alone does not solely determine the surface finish. Factors such as the feed rate, depth of cut, and tooling parameters also play a significant role. However, finding the right balance between speed and other cutting parameters is crucial for achieving the desired surface finish without compromising the machining process’s efficiency.

Additional Considerations for Optimal Lathe Speeds

Now that we have covered the basics and explored the factors affecting lathe speeds, let’s discuss a few additional considerations to ensure optimal speed selection and machining performance:

1. Safety Precautions

Always prioritize safety when operating a lathe. Properly set up the machine, follow all safety guidelines and recommendations, and wear appropriate personal protective equipment (PPE) to minimize the risk of accidents or injuries.

When adjusting the lathe speed, ensure that the machine is powered off and the spindle has come to a complete stop before making any changes. Engage the necessary safety mechanisms, such as spindle locks or chuck keys, to prevent any unintended movement during speed adjustments.

2. Experimentation and Testing

Lathes offer a wide range of speed settings to accommodate various materials and applications. While general guidelines exist, it is often useful to experiment and conduct test cuts to determine the optimal speed for a specific operation. Start with conservative parameters and make adjustments based on the results obtained.

Keep a record of the lathe speed, cutting parameters, material type, and tooling specifications for future reference. This documentation can serve as a valuable resource when undertaking similar machining tasks in the future.

3. Regular Maintenance and Inspection

To ensure consistent performance and prolong the lifespan of the lathe, regular maintenance and inspection are essential. Clean the machine regularly, remove any debris or chips, and lubricate the necessary components as recommended by the manufacturer.

Inspect the lathe for any signs of wear, misalignment, or damage. Check the spindle, chuck, belts, gears, and other key components to ensure proper functionality. Any abnormalities should be addressed promptly to avoid any adverse impact on performance or safety.

In conclusion, understanding how fast a lathe spins is crucial for maximizing machining efficiency and achieving the desired results. With proper speed selection based on material type, cutting tool considerations, and desired surface finish, you can unlock the full potential of this versatile machining tool. Remember to prioritize safety, conduct experimentation when needed, and maintain the lathe regularly for optimal performance. Now that you are equipped with this knowledge, it’s time to put it into practice and take your machining skills to the next level!

Key Takeaways: How Fast Does a Lathe Spin?

- A lathe spins at different speeds depending on the material being worked on.

- For woodturning, a lathe can typically spin anywhere between 500 to 4,000 RPM (revolutions per minute).

- For metalwork, lathe speeds can range from 100 to 2,000 RPM, with higher speeds for softer metals and lower speeds for harder ones.

- The speed of a lathe can be adjusted using the pulleys and belts to achieve the desired rotation.

- It is important to choose the appropriate lathe speed to ensure a clean and safe cutting process.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we answer your burning inquiries about how fast a lathe spins. Whether you’re a beginner looking to learn more or a seasoned pro seeking some clarification, we’ve got you covered! Read on to find out the answers to your most pressing questions.

1. How does the speed of a lathe affect my work?

The speed at which a lathe spins plays a crucial role in the outcome of your work. When you increase the speed, the cutting tool removes material more quickly, allowing for faster shaping or turning. Conversely, lowering the speed provides greater precision and control, perfect for intricate details or delicate materials. By adjusting the lathe’s speed, you can achieve varying results to suit your specific project needs.

However, it’s important to note that different lathe operations require different speeds. For roughing cuts, a higher speed is recommended to remove material rapidly. Finishing cuts, on the other hand, typically demand a slower speed for better accuracy. Always consider the material you’re working with and the desired outcome before adjusting the lathe’s speed.

2. What factors determine the maximum speed of a lathe?

Several factors determine the maximum speed at which a lathe can spin. The first is the motor’s horsepower, which indicates how much power the lathe has to rotate the workpiece. Higher horsepower allows for faster speeds. Additionally, the design and construction of the lathe, as well as the quality of its components, play a significant role in determining the maximum speed.

The size and weight of your workpiece also have an impact. Larger and heavier workpieces may require slower speeds to ensure stability and prevent vibration. It’s important to consult your lathe’s user manual, which often provides guidelines or recommendations for maximum speeds based on different scenarios. Remember to prioritize safety and always operate your lathe within its specified limits.

3. Is there an optimal speed for every material?

While there isn’t a one-size-fits-all speed for every material, there are general guidelines to follow. Softer materials like wood generally require higher speeds, allowing for faster and smoother cuts. Harder materials, such as metal or ceramics, typically demand slower speeds to ensure better control and prevent damage or breakage.

Experimentation is key when determining the ideal speed for a specific material. Start with a moderate speed and adjust accordingly based on the results. Keep in mind that different tools and cutting techniques may also influence the optimal speed for a particular material. As you gain experience and familiarity with your lathe, you’ll develop a better understanding of the best speeds to achieve optimal results for different materials.

4. Can I change the speed of my lathe while it’s running?

It’s generally not recommended to change the speed of your lathe while it’s running. Abruptly adjusting the speed while the lathe is in motion can cause significant stress on the lathe’s components, leading to potential damage or even accidents. Always turn off the lathe and allow it to come to a complete stop before adjusting the speed.

To change the speed, consult your lathe’s user manual for specific instructions. Most lathes have multiple speed settings that can be adjusted manually or through electronic controls. Take the time to familiarize yourself with the correct way to change the speed on your specific lathe model. Prioritizing safety and following proper procedures will ensure a smooth operation and prolong the lifespan of your lathe.

5. Are there any safety precautions to consider when working with a lathe?

Absolutely! Safety should always be a top priority when working with a lathe. Here are a few essential safety precautions to consider:

– Wear appropriate protective gear, such as safety glasses, gloves, and a face shield.

– Ensure your workpiece is secured firmly in place using clamps or a chuck to prevent it from becoming loose and causing accidents.

– Keep your lathe’s workspace clean and organized to avoid potential trip hazards and ensure smooth operation.

– Familiarize yourself with the emergency stop button or switch on your lathe and always have it within easy reach.

– Seek proper training and instruction before operating a lathe, especially if you’re a beginner.

Remember, accidents can happen even to experienced users, so it’s crucial to maintain a safety-conscious mindset and follow all recommended precautions to protect yourself and those around you.

Summary

The speed of a lathe depends on the type of lathe and the task at hand. Wood lathes usually spin at speeds of around 500 to 3,000 revolutions per minute (RPM), while metal lathes can go much faster, sometimes up to 10,000 RPM. Safety is important when working with lathes, as high speeds can be dangerous. It’s crucial to follow proper guidelines and wear protective gear.

While lathes can spin really fast, it’s essential to choose the right speed for each job to ensure accuracy and safety. Now you know that lathes can vary in their rotational speed and the precautions needed when using them.