Have you ever wondered how fast a metal lathe spins? Well, let’s dive into the exciting world of machining and find out! 🛠️💨 In this article, we’ll explore the speed at which a metal lathe rotates and why it matters for various machining processes. So, buckle up and get ready to spin into the fascinating world of metal lathes!

When it comes to metal lathes, speed is the name of the game. The rotation speed of a metal lathe is measured in revolutions per minute (RPM). ⏱️ But why does it matter? Well, the speed at which a lathe spins determines the cutting speed, accuracy, and surface finish of the workpiece. Whether you’re turning, facing, or threading, the right speed is crucial for achieving optimal results.

Now, you might be wondering, how fast does a metal lathe actually spin? The answer depends on several factors, such as the type of material being machined, the diameter of the workpiece, and the desired surface finish. Typically, metal lathes can range from speeds as low as 50 RPM all the way up to jaw-dropping speeds of 5,000 RPM or more! It’s like watching a high-speed action movie, but with metal chips flying instead of superheroes.

So, get ready to embark on an exciting journey through the world of metal lathe speeds. We’ll explore different types of lathes, the factors that influence speed selection, and the importance of finding the perfect balance for each machining operation. Let’s dive in and discover the spinning wonders of metal lathes! 💫

A metal lathe typically spins at high speeds to effectively shape and cut metal. The speed at which a metal lathe spins depends on the model and purpose. Some metal lathes have variable speed control, allowing you to adjust the rotation speed according to your needs. The speed range can vary from a few hundred RPM (Revolutions Per Minute) to several thousand RPM. It’s important to consult the user manual or manufacturer specifications for the specific speed range of your metal lathe.

How Fast Does a Metal Lathe Spin?

Metal lathes are versatile machines used in various industries, from woodworking to metalworking. One crucial factor to consider when using a metal lathe is the speed at which it spins. The rotation speed of a metal lathe determines the efficiency, precision, and quality of the workpiece. In this article, we will explore the factors that determine the speed at which a metal lathe spins and how to optimize it for different applications.

1. Understanding Spindle Speed

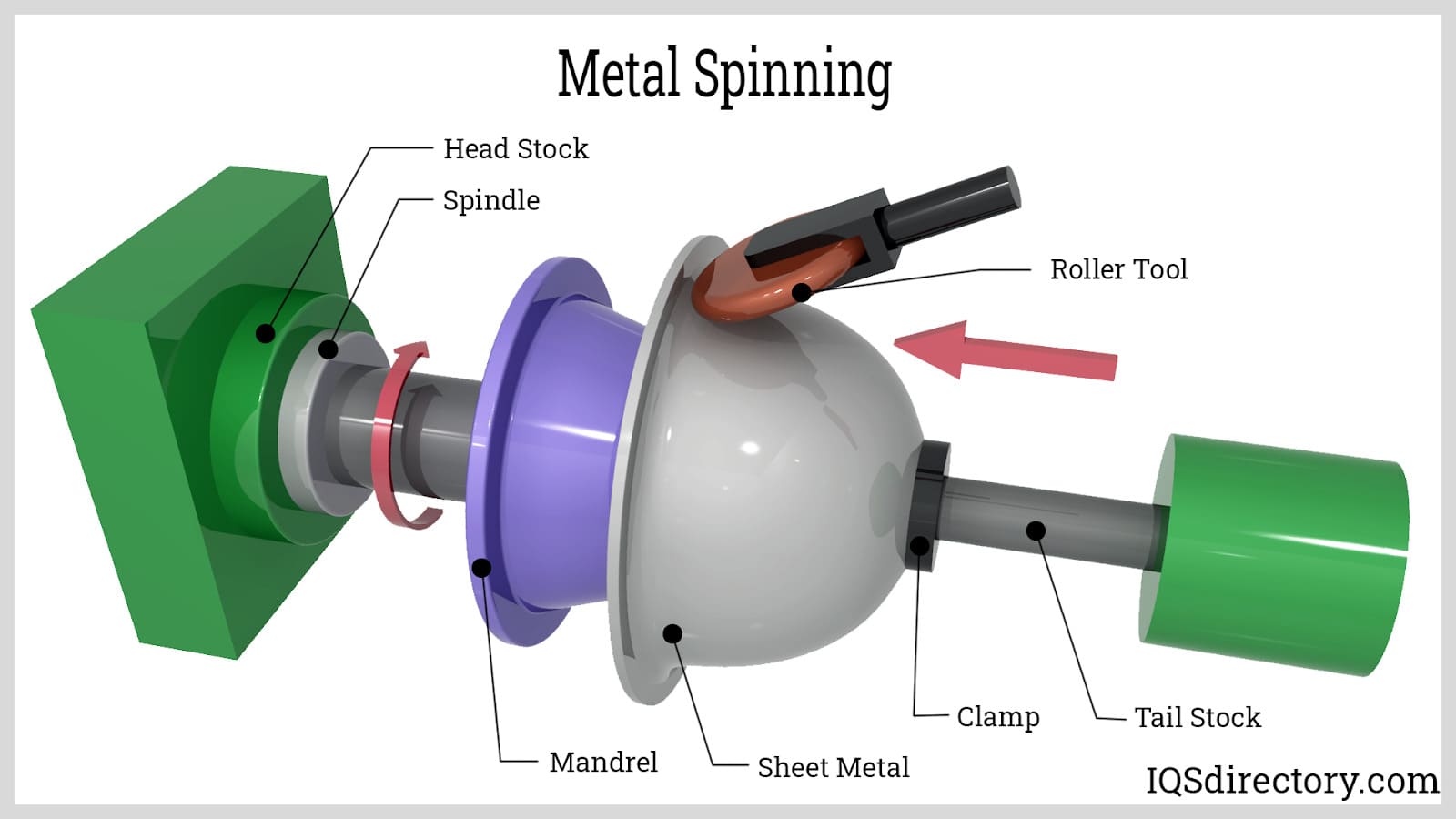

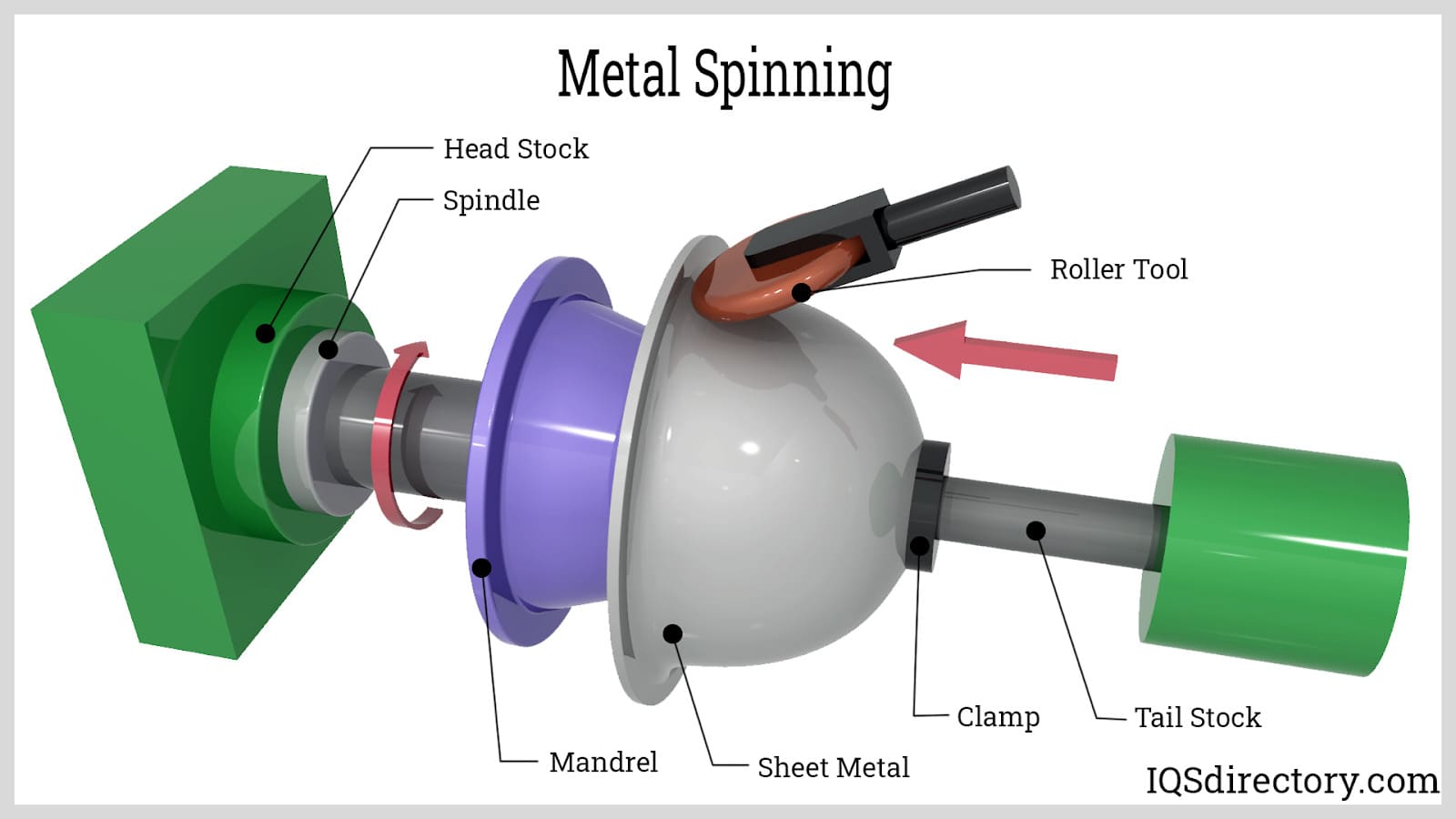

The spindle speed of a metal lathe refers to the number of revolutions per minute (RPM) at which the spindle, chuck, and workpiece rotate. It is a critical factor that directly influences the cutting speed and material removal rate. The spindle speed can be adjusted using the lathe’s control panel or by changing the gears and pulleys.

The spindle speed is determined by various factors, including the type of workpiece material, the diameter of the workpiece, and the type of cutting tool being used. Generally, larger workpieces require slower speeds, while smaller workpieces can handle higher speeds. It is essential to refer to the lathe’s user manual and consult machining guidelines to determine the appropriate spindle speed for each specific application.

2. Factors Affecting Spindle Speed

Several factors influence the optimal spindle speed for a metal lathe. These factors include the type of material being machined, the desired surface finish, the cutting tool’s composition and geometry, and the diameter of the workpiece.

When machining different materials, such as steel, aluminum, or brass, each material will have specific recommended cutting speeds. For example, harder materials like steel require slower speeds to prevent excessive heat generation and tool wear. Softer materials like aluminum can tolerate higher speeds for faster material removal.

The desired surface finish also affects the spindle speed. Finer finishes typically require slower speeds to ensure precision and minimize tool deflection. On the other hand, roughing operations that prioritize material removal may require higher speeds for increased efficiency.

3. Optimizing Spindle Speed for Different Applications

To optimize the spindle speed for different applications, it is crucial to consider the material, workpiece diameter, and cutting tool type. Most metal lathes have a range of spindle speed options that can be adjusted to accommodate various machining requirements.

For precision turning operations on smaller workpieces, it is advisable to start with a slower spindle speed and gradually increase it while monitoring the cutting results. Adjustments can be made based on the surface finish and the ease with which the material is being removed.

When working with larger workpieces, it is generally safer to begin with slower speeds to prevent any instability or vibrations. As the machining progresses, the spindle speed can be adjusted accordingly.

Additionally, using the appropriate cutting tools and coolant can significantly impact the spindle speed. Sharp, well-maintained tools reduce the risk of tool breakage and can tolerate higher speeds. Coolant helps dissipate heat, improving tool life and maintaining the desired surface finish.

In conclusion, the spindle speed of a metal lathe plays a crucial role in achieving precise and efficient machining results. Understanding the factors that influence spindle speed, such as workpiece material, diameter, and cutting tool type, allows operators to optimize their lathe’s performance for different applications. By following machining guidelines and adjusting spindle speed accordingly, operators can enhance productivity and produce high-quality workpieces.

Key Takeaways: How Fast Does a Metal Lathe Spin?

- A metal lathe spins at different speeds depending on the material being cut and the desired finish.

- Typically, metal lathes can spin anywhere from a few hundred to a few thousand revolutions per minute (RPM).

- Higher RPMs are used for softer materials, while lower RPMs are used for harder materials.

- The speed of a metal lathe can be adjusted using a variable speed control knob or a belt and pulley system.

- It is important to follow the manufacturer’s recommendations for optimal speed settings based on the specific material and cutting operation.

Frequently Asked Questions

Welcome to our FAQ section where we answer some common questions about metal lathe speeds. Below you will find valuable information on how fast a metal lathe spins, as well as other related questions.

1. What factors determine the speed at which a metal lathe spins?

The speed at which a metal lathe spins is determined by several factors. One of the main factors is the material you are working with. Different materials require different speeds to achieve optimal results. The type of tooling and the desired finish also play a role in determining the speed. Additionally, the diameter and length of the workpiece can affect the speed at which the lathe spins. It is important to consult the manufacturer’s guidelines and make adjustments accordingly to ensure the best results.

2. Can you provide some general guidelines on the speeds for various materials on a metal lathe?

While specific speeds may vary depending on the lathe and the specific machining operation, here are some general guidelines for metal lathe speeds:

– For turning soft materials like aluminum, you can typically use speeds between 800 and 1500 RPM (revolutions per minute).

– For turning stainless steel, speeds between 200 and 400 RPM are commonly used.

– Harder materials, such as hardened steel, may require even slower speeds, typically between 50 and 200 RPM.

Keep in mind that these are just rough guidelines, and it’s always best to refer to the lathe manufacturer’s recommendations and use your own judgment based on the specific conditions and requirements of your project.

3. What are the consequences of running a metal lathe at too high a speed?

Running a metal lathe at too high a speed can lead to a variety of undesirable consequences. One of the main issues is tool wear. When a lathe spins too fast, it puts excessive stress on the cutting tool, causing it to wear out quickly. This can result in poor surface finish, decreased accuracy, and shortened tool life.

Another consequence is excessive vibration, which can affect the overall stability of the lathe and compromise the quality of the workpiece. Additionally, running a lathe at high speeds can generate excessive heat, which can damage both the tool and the workpiece. It is essential to operate the lathe within the recommended speed range to achieve optimal results.

4. What safety precautions should be taken when working with a metal lathe operating at high speeds?

Working with a metal lathe operating at high speeds requires strict adherence to safety precautions. Some important safety measures to follow include:

– Always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from any potential hazards.

– Ensure that the workpiece is securely fastened to prevent it from becoming dislodged during high-speed operations.

– Regularly inspect the lathe for any signs of damage or wear, and promptly address any issues to maintain safe operation.

– Familiarize yourself with emergency stop procedures and keep them in mind in case of any unexpected situations.

5. Can a metal lathe speed be adjusted during operation?

Yes, a metal lathe’s speed can be adjusted during operation, but it depends on the lathe model. Some metal lathes have variable speed control options that allow you to make adjustments while the lathe is running. This feature can be particularly useful when working with materials that require different speeds for roughing and finishing cuts. However, not all lathes have this capability, so it’s important to check the specifications of your specific lathe to determine if it offers this feature.

Regardless of whether your lathe has variable speed control or not, it is always recommended to start at a lower speed when beginning an operation and gradually increase as needed, following the manufacturer’s guidelines and taking into account the material and other factors mentioned earlier. Adjusting the speed appropriately can help achieve better results and prolong the life of your cutting tools.

Summary

Metal lathes are machines used to shape metal objects. They spin really fast to do their job. The speed can be adjusted depending on the project. However, the highest speed should not exceed the manufacturer’s guidelines. Safety is the most important thing when using a metal lathe. Always follow the instructions and wear protective gear. It’s cool to learn about these machines, but make sure to use them responsibly.

Explanation

Metal lathes spin quickly to shape metal objects, but the speed can be adjusted. Safety is crucial, so follow the guidelines and use protective gear. Be responsible when using a metal lathe.