Are you curious about how fast a wood lathe can spin? Well, you’re in the right place! Let’s dive into the exciting world of woodturning and find out just how fast these machines can go.

Wood lathes are fascinating tools used by artisans to shape and carve wood into beautiful creations. One of the key factors in determining how fast a wood lathe spins is the speed control mechanism. Different lathes offer varying speed ranges, allowing users to adjust the speed to suit their specific woodworking needs.

Now, you might be wondering, why does the speed matter? Well, the speed at which a wood lathe spins affects the cutting efficiency, surface finish, and safety of your work. Whether you’re turning a delicate spindle or roughing out a bowl, finding the right speed is crucial to achieve the best results.

So, join us as we explore the fascinating world of wood lathes and discover how the speed of these machines can have a significant impact on your woodworking projects. Let’s get spinning!

How Fast Does a Wood Lathe Spin?

A wood lathe is a powerful tool used by woodworking enthusiasts to shape and create various wooden objects. One crucial aspect of using a wood lathe is understanding how fast it spins. The speed at which a wood lathe rotates can greatly impact the accuracy and quality of your work. In this article, we will explore the different factors that affect the speed of a wood lathe and provide valuable information on choosing the right speed for your woodworking projects.

The Importance of Wood Lathe Speed

When using a wood lathe, the speed at which the piece of wood rotates affects several key factors, including the smoothness of the surface, the ability to shape the wood accurately, and the overall safety when operating the machine. It is vital to have a firm understanding of the speed settings available on a wood lathe to achieve optimal results and ensure a safe working environment.

Factors Affecting Wood Lathe Speed

Before we dive into the specifics of how fast a wood lathe spins, let’s take a look at the factors that can affect the speed settings:

- Size and density of the wood: Larger and denser pieces of wood may require slower speeds to prevent vibration and maintain stability.

- Type of cutting tool: Different cutting tools work best at different speeds, and utilizing the correct speed for the particular tool is essential for achieving precise cuts.

- Desired outcome: Depending on the project, you may need to adjust the lathe’s speed to create intricate details or achieve a smooth finish.

- Safety considerations: Working at excessively high speeds can lead to accidents and cause the wood to burn or split, so it’s crucial to select an appropriate speed for both your safety and the preservation of the wood.

Now that we understand the factors influencing wood lathe speed, let’s explore the specific range of speeds typically available on these machines.

Typical Speed Ranges for Wood Lathes

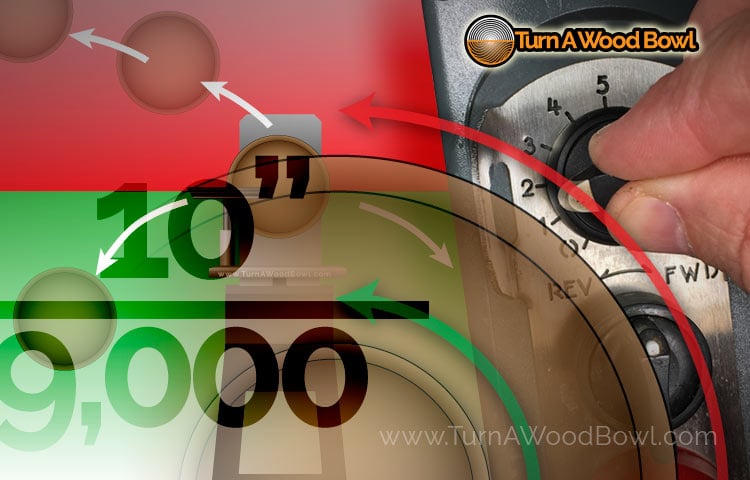

Wood lathes generally offer a range of speeds to accommodate different types of projects and materials. The speed of a wood lathe is measured in revolutions per minute (RPM). Let’s take a closer look at the different speed ranges:

| Speed Range | Recommended Uses |

|---|---|

| Up to 500 RPM | Best for sanding, finishing, and applying finishes. |

| 500 – 1,500 RPM | Ideal for shaping and forming larger objects. |

| 1,500 – 2,500 RPM | Common range for general woodworking projects. |

| 2,500 – 4,000 RPM | Used for smaller, more detailed work. |

| Above 4,000 RPM | Reserved for highly specialized tasks and advanced users. |

It’s important to note that the speed ranges mentioned are general guidelines, and different wood lathes may have slight variations. Always refer to the manufacturer’s instructions for the specific speed settings of your lathe.

Tips for Choosing the Right Speed

Now that we have a better understanding of the factors influencing wood lathe speed and the typical speed ranges, let’s explore some helpful tips for choosing the right speed for your projects:

- Start slow: Begin at a lower speed and gradually increase it as you become more comfortable with the tool and the piece of wood you are working on.

- Consider the size and density of the wood: Larger or denser wood may require slower speeds to prevent vibration and maintain control over the piece.

- Match the speed to the cutting tool: Different cutting tools perform best at specific speeds. Refer to the manufacturer’s recommendations for each tool to achieve the desired results.

- Experiment: Don’t be afraid to adjust the speed during your project. Sometimes, finding the perfect speed requires a bit of trial and error.

- Put safety first: Always prioritize safety when selecting the speed. Avoid operating the lathe at excessively high speeds, as it can lead to accidents and damage to the wood.

Additional Factors to Consider

In addition to the factors mentioned above, there are a few more considerations to keep in mind when determining how fast a wood lathe should spin:

Wood Species

Some wood species may react differently to certain speeds. Hardwoods, like oak or maple, may require slower speeds, while softer woods, like pine or cedar, can tolerate higher speeds. Consider the specific characteristics of the wood you are working with to ensure optimal results.

Project Complexity

The complexity of your project can also influence the speed at which you should set your wood lathe. Intricate or delicate designs may require slower speeds. Conversely, larger, simpler projects may benefit from higher speeds to achieve efficient material removal.

User Skill Level

Finally, the skill level of the person operating the wood lathe should be taken into account when determining the speed. Novices may be more comfortable starting at lower speeds until they gain confidence and proficiency with the tool.

Conclusion

Understanding how fast a wood lathe spins is essential for any woodworking enthusiast. By considering factors such as wood size and density, type of cutting tool, desired outcome, and safety considerations, you can select the appropriate speed range for your projects. Remember to start slow, experiment, and prioritize safety to achieve optimal results. So, whether you’re shaping a bowl, turning a spindle, or creating decorative pieces, the speed at which your wood lathe spins is a crucial factor in achieving excellent craftsmanship.

Key Takeaways: How Fast Does a Wood Lathe Spin?

- A wood lathe can spin at various speeds, typically measured in revolutions per minute (RPM).

- The speed at which a wood lathe spins depends on the type of lathe and the project being worked on.

- Smaller wood lathes used for pen turning or small projects usually have a range of around 500 to 3000 RPM.

- Medium-sized lathes for bowls and larger projects typically have a range of 300 to 2000 RPM.

- Large lathes for turning large diameter projects, such as furniture legs or balusters, might have a range of 200 to 1000 RPM.

Frequently Asked Questions

When it comes to wood lathes, there are a lot of questions that come up. Here are some common questions and their answers to help you understand how fast a wood lathe spins.

1. What is the typical speed range for a wood lathe?

Wood lathes have a speed range that can vary depending on the model and manufacturer. However, most wood lathes have a minimum speed of around 500 RPM (rotations per minute) and a maximum speed of around 4000 RPM. The speed range allows for versatility in turning different sizes and types of wood. Lower speeds are usually used for roughing out and shaping, while higher speeds are ideal for finishing and adding details.

It’s important to note that some advanced wood lathes may have a wider speed range, reaching lower or higher RPMs. Always refer to the lathe’s user manual for specific speed recommendations and limitations.

2. Are there any safety considerations when it comes to the speed of a wood lathe?

Yes, safety is crucial when dealing with fast-spinning machinery like wood lathes. It’s important to wear appropriate personal protective equipment (PPE), such as safety goggles, a face shield, and a dust mask, to protect yourself from flying wood chips and debris. Additionally, make sure your workpiece is securely fastened to the lathe and that the lathe is properly balanced and stable.

As for speed, always follow the manufacturer’s recommendations and guidelines. Operating the lathe at speeds beyond its limits can pose a safety risk and can damage the lathe or your workpiece. If you are unsure about the appropriate speed for a specific task, it’s best to consult the lathe’s user manual or seek advice from experienced woodworkers.

3. Can I change the speed of a wood lathe while it’s running?

Generally, it’s not recommended to change the speed of a wood lathe while it’s running. Most wood lathes require you to turn off the machine, make the speed adjustment, and then turn it back on. Attempting to change the speed while the lathe is running can be dangerous and may cause damage to the lathe.

Some advanced wood lathes do offer electronic variable speed control, allowing you to adjust the speed while the lathe is running. However, even with this feature, it’s best to exercise caution and make adjustments gradually to avoid sudden shifts in speed that could affect your workpiece or compromise your safety.

4. Can the speed of a wood lathe be adjusted for different types of wood?

Yes, adjusting the speed of a wood lathe is essential when working with different types of wood. Softer woods, like pine, may require slower speeds to prevent excessive tearing or splintering. Harder woods, such as oak or maple, can typically handle higher speeds. Adapting the speed based on the wood species and the desired outcome is crucial for achieving clean and smooth turning results.

Experimenting with different speeds and observing the effects on different woods will help you develop a better understanding of which speed settings work best for specific projects. Remember to take your time and practice on scrap pieces before working on valuable or intricate pieces.

5. Are there any additional accessories or attachments needed to adjust the speed of a wood lathe?

Typically, wood lathes come with a control mechanism or a belt pulley system for changing the speed. These mechanisms allow you to adjust the position of the drive belt, which in turn changes the speed of the lathe. Most wood lathes also provide a chart or recommended speed settings for various turning operations, which can be referred to for guidance.

However, some advanced wood lathes offer electronic speed control or other specialized speed-adjusting features. These lathes may come with additional attachments or accessories, such as digital speed readouts or remote speed control panels. If you have a wood lathe with such features, consult the manufacturer’s instructions to understand how to use these accessories to adjust the speed effectively.

Summary

Wood lathes spin at different speeds depending on the type of wood and the desired outcome. Slower speeds are used for rough shaping, while faster speeds are used for finer details. Safety precautions should always be followed when operating a wood lathe.

Wood lathe speeds vary based on the type of wood and the desired result. Lower speeds are for shaping, while higher speeds are for finer finishes. Keep safety in mind when using a wood lathe.