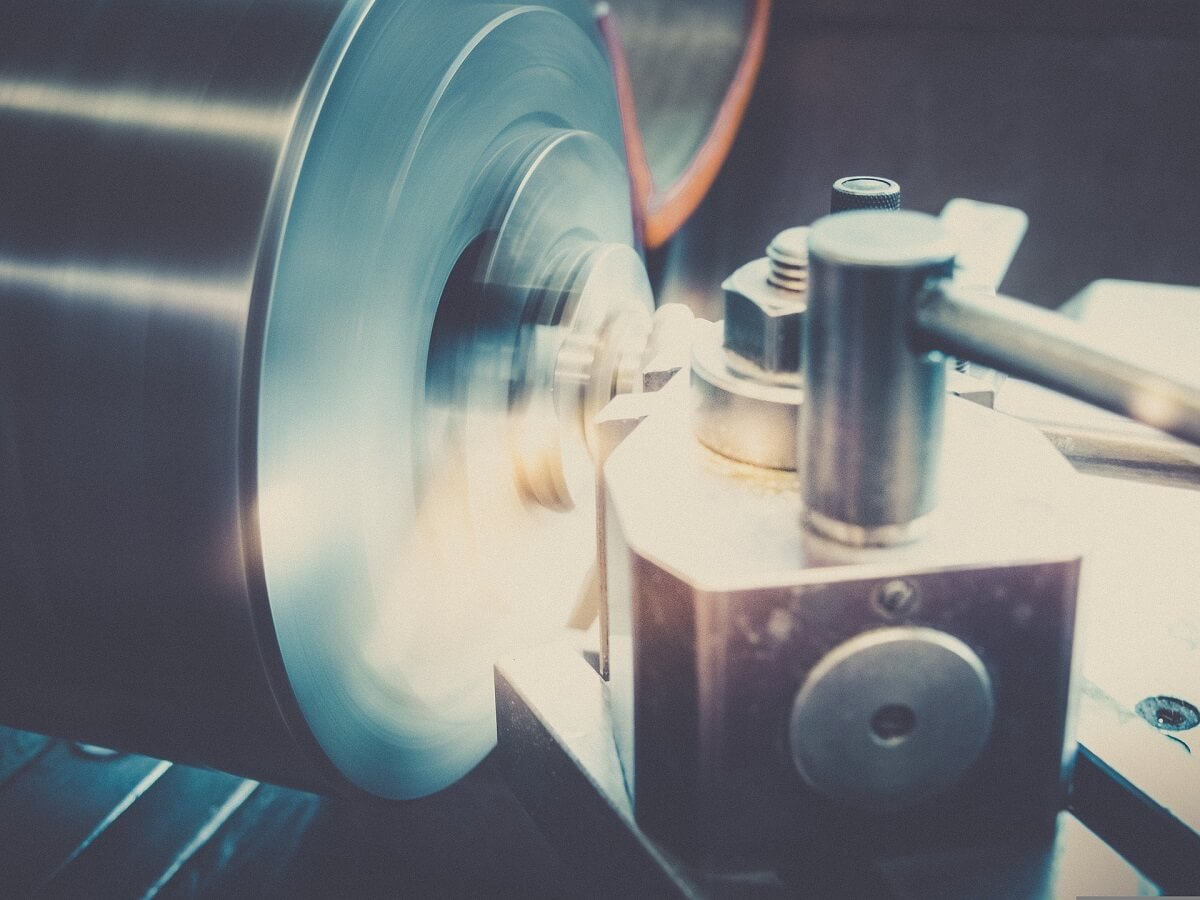

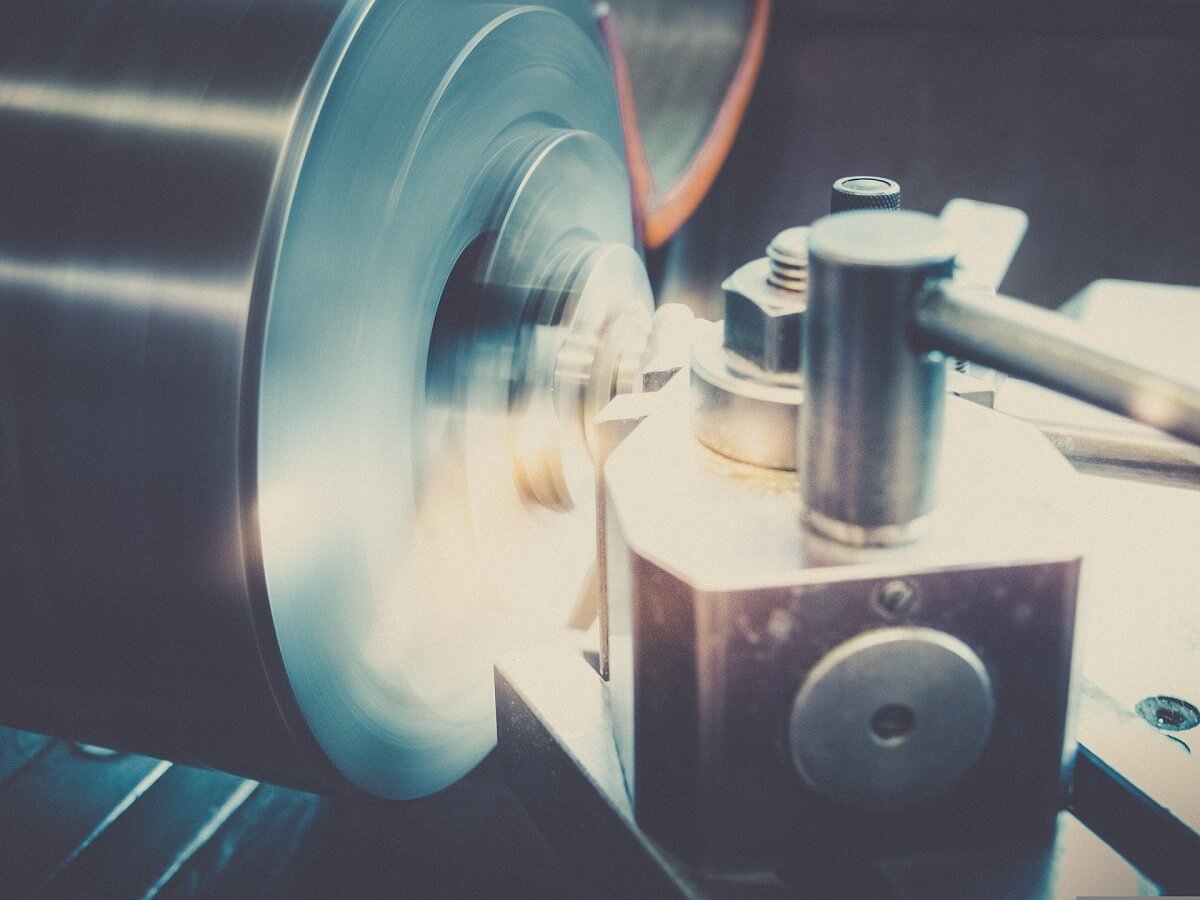

Wondering how fast a lathe can spin? Well, hold on tight and let’s dive into this fascinating topic!

You might be thinking, “Why does it matter how fast a lathe can go?” Well, my curious friend, the speed of a lathe can make all the difference in shaping and transforming materials.

In this article, we’ll explore the thrilling world of lathes and uncover just how fast these precision machines can spin. So, grab your safety goggles and let’s get started!

How Fast is a Lathe?

A lathe is a powerful machine used in various industries and workshops to shape and cut materials. One common question that often arises is, “How fast is a lathe?” In this article, we will explore the different speeds at which a lathe operates, the factors that influence its speed, and how it affects the workpiece. Whether you are a professional machinist or someone interested in learning more about lathes, this article will provide you with all the information you need.

Understanding Lathe Speed

Lathe speed refers to the rotational speed of a lathe’s spindle, which is responsible for spinning the workpiece. The speed at which a lathe operates can vary depending on various factors, including the material being machined, the tool being used, and the desired outcome. Different materials and cutting tools require different speeds to achieve optimal results.

Most lathes have multiple speed settings, allowing operators to choose the best speed for the specific task at hand. These speed settings are typically measured in rotations per minute (RPM) and can range from as low as 100 RPM to over 10,000 RPM. The ability to adjust the speed of a lathe is crucial in achieving precision and accuracy in machining.

It’s important to note that not all lathes have the same speed range. The maximum speed of a lathe depends on its design, motor power, and capabilities. Additionally, lathes can be equipped with different gear ratios that allow for further customization of speed settings. Now that we have a basic understanding of lathe speed, let’s dive deeper into the factors that influence it.

Factors Affecting Lathe Speed

Several factors come into play when determining the ideal speed for a lathe. These factors include:

- Material type: Different materials have different hardness and cutting properties, requiring varying speeds. For example, softer materials like wood may require slower speeds, while harder materials like metal may require higher speeds.

- Tool type: Different cutting tools have specific speed recommendations based on their design and the material they are intended to cut.

- Workpiece diameter: The diameter of the workpiece also affects the ideal speed. Larger workpieces require slower speeds to maintain stability and prevent excessive vibration.

- Cutting operation: The specific operation being performed, such as facing, turning, or threading, can influence the required speed to achieve desired results.

- Cooling and lubrication: Proper cooling and lubrication of the cutting tool and workpiece can also impact the speed at which a lathe should operate to avoid overheating and tool wear.

By taking these factors into account, operators can optimize lathe speed to achieve the best results for their specific machining tasks. However, it’s also essential to understand the potential drawbacks and limitations of operating at high speeds.

Advantages and Limitations of High-Speed Lathe Operations

Operating a lathe at high speeds offers several advantages and can lead to increased productivity and efficiency. Some key benefits of high-speed lathe operations include:

- Faster material removal: High-speed machining allows for faster material removal rates, making it ideal for large-scale production and reducing machining time.

- Improved surface finish: Higher speeds can result in smoother surface finishes due to reduced tool chatter and improved chip evacuation.

- Enhanced tool life: Certain materials and cutting tools perform better at higher speeds, resulting in extended tool life and reduced downtime for tool changes.

Despite the advantages, there are also limitations to high-speed lathe operations that need to be considered:

- Heat generation: Operating at high speeds generates more heat, which can lead to thermal expansion, distortion, and possible damage to the workpiece.

- Vibration and stability: Higher speeds can introduce increased vibration and decrease stability, affecting machining precision.

- Tool wear: Certain cutting tools may wear out faster at higher speeds, requiring more frequent replacement and maintenance.

To overcome these limitations, it’s essential to balance the speed of the lathe with the material, tooling, and specific machining requirements for each application.

Understanding Lathe Speed Controls

Lathe speed controls play a crucial role in adjusting and maintaining the desired rotational speed of a lathe’s spindle. There are various types of lathe speed controls available, each with its advantages and limitations. Here are three common types:

The Impact of Speed on Turning Operations

When it comes to turning operations on a lathe, the speed at which the workpiece rotates can significantly influence the cutting process and the quality of the finished part. Let’s explore the impact of speed on turning operations:

Choosing the Right Speed for Your Lathe

Selecting the appropriate speed for your lathe depends on several factors, including the material being machined, the cutting tool, and the desired outcome. Here are some tips to help you choose the right speed:

The Role of Horsepower in Lathe Speed

When it comes to lathe speed, horsepower plays a significant role. The horsepower of a lathe’s motor determines its overall power and ability to maintain consistent speed under load. Here’s how horsepower affects lathe speed:

Understanding the Speed Range of Lathes

Not all lathes have the same speed range. The speed range of a lathe depends on various factors, including the type of lathe, motor power, and design. Let’s take a closer look at the speed range of lathes:

Maintaining Optimal Lathe Speed

Proper maintenance is crucial to ensure optimal lathe speed and performance. Here are some essential tips for maintaining the speed of your lathe:

In conclusion, the speed of a lathe is a crucial aspect of machining operations. It is influenced by several factors, including the material being machined, the cutting tool, and the desired outcome. Understanding the relationship between speed and these factors is essential for achieving optimal results. By selecting the right speed, operators can improve productivity, surface finish, and tool life while minimizing potential drawbacks. Remember to consider the limitations of high-speed operations and perform regular maintenance to ensure the longevity and performance of your lathe.

Key Takeaways: How Fast is a Lathe?

- A lathe is a machine used for shaping and cutting materials like wood or metal.

- Lathe speed is measured in revolutions per minute (RPM).

- The speed of a lathe can vary depending on the size and type of lathe.

- Smaller lathes typically have higher RPMs, while larger lathes have lower RPMs.

- The speed of a lathe also depends on the material being worked on and the desired outcome.

Frequently Asked Questions

When it comes to understanding the speed of a lathe, here are some common questions and answers.

1. How does the speed of a lathe affect the workpiece?

The speed of a lathe plays a crucial role in shaping the workpiece. When a lathe spins at a higher speed, the cutting tool removes material more rapidly. On the other hand, slower speeds allow for more precision and can produce smoother finishes. Different materials and tasks may require varying speeds to achieve the desired results.

For instance, turning a soft wood may require a lower speed, while turning a hard metal would demand a higher speed. A skilled operator will select the appropriate speed to balance efficiency, accuracy, and the desired outcome.

2. What factors determine the speed of a lathe?

Several factors influence the speed of a lathe. One important factor is the diameter of the workpiece. Smaller diameters require higher speeds to achieve the same cutting speed as larger diameters. Additionally, the type of material being worked on also impacts the speed. Softer materials may require slower speeds compared to harder materials.

Furthermore, the type of lathe tool being used is a crucial consideration. Different cutting tools have specific speed recommendations that need to be followed for optimal performance. Lastly, the skill level and experience of the operator also play a role in determining the optimal speed for a lathe.

3. Can a lathe run at unlimited speeds?

No, lathes do have limitations on their operational speeds. Every lathe has a certain range of speeds that it can safely and effectively handle. Exceeding these limits can cause damage to the lathe, the workpiece, and even pose a safety risk to the operator. It is essential to follow the manufacturer’s guidelines and recommendations for speed settings.

Modern lathes often have variable speed control, allowing operators to adjust within the safe range for different tasks. This flexibility ensures that the lathe can be optimized for various materials and machining operations, while still operating within its designated limits.

4. What role does speed control play in achieving good lathe work?

Speed control is crucial for achieving quality lathe work. It allows the operator to adapt the lathe’s speed to suit the specific material, cutting tool, and desired outcome. By adjusting the speed, the operator can prevent issues such as chattering or tool breakage.

For example, with a very high speed, a cutting tool may generate excessive heat that can damage the workpiece or even dull the tool. On the other hand, turning at a very low speed may create vibrations that affect the precision of the work and result in an inferior finish. Adjusting the speed correctly helps to achieve smooth and accurate cuts, ensuring a high-quality final product.

5. Are there standard speed ranges for different lathe operations?

Yes, there are general guidelines for speed ranges based on various lathe operations. However, it’s important to note that these ranges are not set in stone and may vary depending on factors such as the diameter of the workpiece, the material being worked on, and the cutting tool being used.

A rough guideline for spindle speeds is to start with lower speeds (around 400-800 RPM) for larger diameters and harder materials. As the diameter decreases or the material gets softer, the speed can be increased gradually. For finishing operations, speeds between 800-3000 RPM are commonly used. But it’s always best to refer to the manufacturer’s recommendations and consult with experienced machinists for specific applications.

Determining Safe Lathe Speeds (Woodturning How-to)

Summary

So, to wrap things up, a lathe is a machine that spins really fast to shape materials like wood or metal. The speed of a lathe can vary depending on the size and type, but it can reach hundreds or even thousands of rotations per minute. It’s important to use the right speed for different tasks to get the best results and ensure safety. Remember, always follow the guidelines and take precautions to stay safe when using a lathe.