Are you curious about the optimal speed for a table saw blade? Wondering how fast should a table saw blade spin? Well, you’ve come to the right place! In this article, we’ll dive into the world of table saws, exploring the importance of blade speed and safety precautions. So, let’s get started and find out everything you need to know!

Now, you might be thinking, “Why does the speed of a table saw blade matter?” Great question! The speed of the blade affects both the quality of your cuts and your safety while operating the table saw. Understanding the ideal blade speed will help you achieve accurate and clean cuts without compromising on safety.

But wait, how fast should a table saw blade actually spin? Ah, the million-dollar question! The answer depends on various factors such as blade diameter, teeth per inch, and the material you’re cutting. To make things simpler, manufacturers provide recommended speeds for their blades, taking these factors into account. Following these guidelines ensures optimal performance and reduces the risk of accidents.

So, whether you’re a seasoned woodworker or just starting out, it’s crucial to grasp the concept of table saw blade speed. By doing so, you’ll not only improve your woodworking skills but also prioritize safety in your workshop. So, let’s delve deeper into this fascinating topic and explore the world of table saws together!

How Fast Should a Table Saw Blade Spin?

A table saw is a powerful tool that is commonly used in woodworking and construction. One important factor to consider when using a table saw is the speed at which the blade spins. The speed of the blade can greatly impact the quality and safety of your work. In this article, we will explore the ideal speed for a table saw blade, as well as the factors that influence this speed.

Understanding Blade Speed

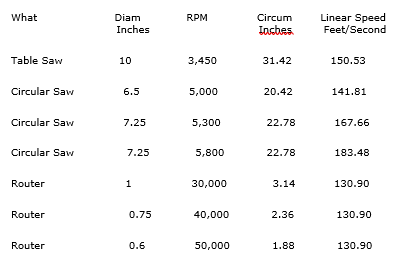

The speed at which a table saw blade spins is measured in revolutions per minute (RPM). The ideal speed for a table saw blade depends on various factors, including the type of material being cut, the size and design of the blade, and the horsepower of the motor driving the blade.

Generally, most table saws have a blade speed range of 3000 RPM to 5000 RPM. This speed range allows for efficient cutting across different materials, including wood, plastic, and metal. However, it’s important to note that different blades may have specific speed requirements, so it’s crucial to consult the manufacturer’s guidelines for the specific blade you are using.

Factors such as the number of teeth on the blade, the blade diameter, and the thickness of the material being cut can also influence the ideal blade speed. Blades with more teeth tend to produce smoother cuts and may require slower speeds, while blades with fewer teeth are better suited for rough cuts and may require faster speeds.

Determining the Right Speed for Your Needs

To determine the ideal speed for your table saw blade, consider the following factors:

- Material: Different materials have different cutting requirements. Hardwoods, for example, may require slower speeds to prevent burning, while softer materials like plywood may require faster speeds.

- Blade Type: The type of blade you are using will also impact the ideal speed. Fine-toothed blades are best for crosscuts and may require slower speeds, while rip-cut blades with fewer teeth may require faster speeds.

- Blade Diameter: The diameter of the blade also affects the ideal speed. Larger blades typically require slower speeds to maintain cutting efficiency.

- Motor Power: The horsepower of the motor driving the blade plays a role in determining the ideal speed. A more powerful motor can handle higher speeds and heavier load without straining.

It’s important to note that some table saws come with speed control features that allow you to adjust the blade speed. This can be useful if you frequently work with different materials or blade types.

Benefits of Operating at the Optimal Speed

Operating your table saw blade at the optimal speed offers several benefits. Firstly, it ensures cleaner and more precise cuts, minimizing the need for additional finishing work. Secondly, it reduces the risk of overheating or damaging the blade or the material being cut. Lastly, using the appropriate blade speed promotes safer operation by reducing the likelihood of kickbacks and other accidents.

By taking the time to determine and adjust the speed of your table saw blade according to the specific requirements of your project, you can achieve better results and enhance safety.

Tips for Optimizing Table Saw Blade Speed

When working with a table saw, here are a few tips to optimize the speed of your blade:

1. Follow Manufacturer Guidelines

Always refer to the manufacturer’s guidelines and instructions for the specific blade and table saw you are using. They will provide you with important information on recommended blade speed settings.

2. Perform Test Cuts

If you are unsure about the ideal speed for a specific material or blade type, it’s a good idea to perform test cuts on scrap pieces before proceeding with your actual project. This allows you to evaluate the results and make any necessary adjustments.

3. Maintain the Blade

A sharp and well-maintained blade will perform better at any speed. Regularly check and sharpen your blade to ensure optimal cutting performance.

4. Use Proper Feeding Techniques

How you feed the material into the blade can also affect the quality of the cut. Always use a steady and consistent feeding motion, and avoid forcing the material through the blade.

5. Consider External Factors

External factors such as temperature and humidity can also impact the blade speed and the material’s behavior. Take these factors into account when determining the optimal speed for your table saw blade.

Conclusion

Ensuring the proper speed for your table saw blade is essential for achieving clean, accurate cuts and ensuring safety. Consider the materials, blade type, diameter, and motor power when setting the blade speed. Following manufacturer guidelines and performing test cuts will help you determine the ideal speed for your specific project. Maintaining a well-sharpened blade and employing proper feeding techniques further enhance cutting results.

Remember, always prioritize safety when working with a table saw. Familiarize yourself with the specific requirements of your table saw and blade, and exercise caution by wearing appropriate safety gear and following best practices recommended by experts.

Key Takeaways: How Fast Should a Table Saw Blade Spin?

- A table saw blade should spin at the manufacturer’s recommended speed, which is typically stated on the blade itself or in the user manual.

- Most table saw blades have a maximum RPM (revolutions per minute) rating, and it’s important to not exceed this limit for safety reasons.

- The blade speed also depends on the type of material being cut. For example, a general-purpose blade may spin at a different speed than a blade specifically designed for cutting metal or plywood.

- Higher blade speeds generally result in smoother cuts, while lower speeds may be suitable for more intricate or delicate work.

- Always follow the manufacturer’s guidelines and use proper safety precautions when operating a table saw.

Frequently Asked Questions

When using a table saw, it’s crucial to understand how fast the blade should spin to ensure both safety and optimal performance. Let’s explore some common questions related to the speed of a table saw blade.

1. What factors determine the speed at which a table saw blade should spin?

The speed of a table saw blade is determined by several factors, including the blade size and the type of material being cut. As a general rule, larger blades typically spin at a lower speed than smaller blades. Additionally, the type of material being cut, such as hardwood or softwood, can also influence the required blade speed.

It’s important to consult the manufacturer’s guidelines for your specific table saw model to determine the recommended blade speed for various materials. Following these guidelines ensures that you’re operating your table saw safely and efficiently.

2. Can I adjust the speed of the table saw blade?

In most cases, the speed of a table saw blade is fixed and cannot be adjusted. The speed is typically determined by the power and design of the motor. However, some advanced table saw models may offer adjustable blade speeds, allowing you to tailor the speed to suit different cutting tasks.

If you require variable speed control for your projects, it’s worth considering a table saw with this feature. Adjustable blade speed can be advantageous when working with different materials or when precision cutting is necessary.

3. What are the safety considerations regarding the speed of a table saw blade?

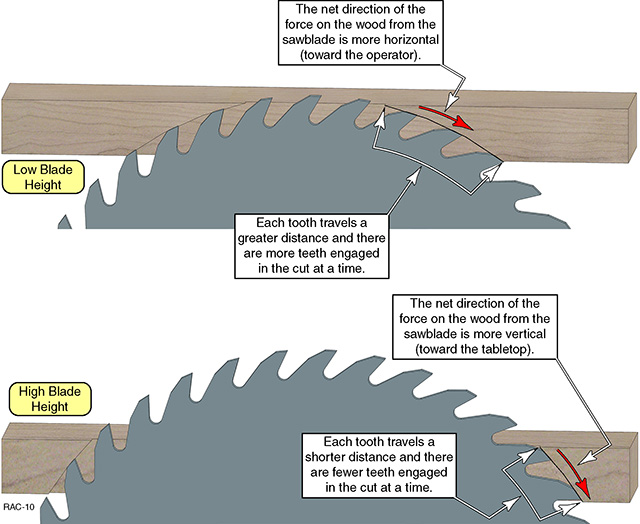

Operating a table saw at the correct blade speed is crucial for both safety and the quality of the cuts. If the blade spins too slowly, it can cause kickback, resulting in the workpiece being forcibly thrown back towards the operator. On the other hand, a blade spinning too fast can increase the risk of accidents, as it becomes more difficult to control and could potentially overheat and damage the blade.

Always prioritize safety when using a table saw. Make sure the blade speed is appropriate for the material and use proper safety precautions, such as wearing protective eyewear, using a push stick, and maintaining a safe distance from the blade.

4. Are there specific blade speeds recommended for different materials?

Yes, different types of materials require different blade speeds when using a table saw. Hardwood typically requires a slower blade speed to prevent overheating and ensure smooth cuts. Softwood, on the other hand, can be cut at a slightly higher speed. Consult the manufacturer’s guidelines or refer to reputable sources to determine the recommended blade speed for the specific material you are working with.

Remember, it’s always better to err on the side of caution and choose a slightly lower speed if you’re unsure. This will help prevent damage to the material, the blade, and minimize any potential safety hazards.

5. Can using the wrong blade speed affect the quality of the cuts?

Using the wrong blade speed can indeed impact the quality of the cuts made with a table saw. If the blade spins too fast, it might cause tear-out or rough cuts, particularly on delicate or brittle materials. On the other hand, using a blade speed that’s too slow can result in burning or scorch marks on the cut surface, indicating excessive friction and potential damage to the blade.

To ensure clean and precise cuts, it’s crucial to use the appropriate blade speed for the specific material and adjust as needed. Taking the time to set the correct blade speed will help you achieve accurate and professional-looking results with your table saw.

How To CHANGE MITER SAW + TABLE SAW BLADES–Fast and Easy Tips! (Blade Arbor/Blade Spin Direction)

Summary

So, to wrap it up, the speed of a table saw blade should match the recommendations from the manufacturer. You shouldn’t just randomly change the speed, because it could lead to accidents or damage the blade. It’s important to follow the guidelines for the safety and efficiency of your work.

Remember, a slower speed is ideal for cutting harder materials like metal, while a faster speed is better for softer materials like wood. Always be cautious and take your time when adjusting the speed on your table saw. Safety should be your top priority when working with power tools.