If you’ve ever wondered how heavy a lathe is, you’ve come to the right place! In this article, we’ll delve into the weight of this powerful machine and uncover some interesting facts. So, strap on your curiosity hat and let’s dive in!

Picture this: you stumble upon a massive object in a workshop, surrounded by sparks and the scent of metal. You can’t help but wonder, “Just how heavy is a lathe?” Well, my friend, you’re about to find out!

Grab a seat and get ready for a mind-blowing journey as we explore the weight of a lathe and uncover some surprising details along the way. Ready? Let’s roll!

How Heavy is a Lathe? Exploring the Weight of these Powerful Machines

Lathe machines are essential tools used in various industries for cutting, shaping, and drilling materials like metal, wood, and plastic. One of the questions that often arises when considering a lathe machine is, “How heavy is it?” In this article, we will explore the factors that contribute to the weight of a lathe machine, its implications, and the different types of lathes available in the market. So, let’s dive in and discover the weighty world of lathes!

Understanding the Factors Affecting the Weight of a Lathe

The weight of a lathe can vary significantly depending on several factors. One of the primary factors is the size and capacity of the machine. Generally, larger and more robust lathes are heavier due to the additional materials used in their construction. The bed length, swing over the bed, and maximum spindle speed are key specifications that determine the size and capacity of a lathe.

Materials used in construction also play a crucial role in the overall weight. Lathes can be made from cast iron, steel, or a combination of both. Cast iron is commonly used due to its durability and vibration-dampening properties. However, it is heavier than steel, which means a lathe made primarily from cast iron will be heavier compared to a lathe made from steel.

Other components and accessories, such as the headstock, tailstock, tool rest, and motor, also contribute to the overall weight of the lathe. Additionally, the presence of features like variable speed control, digital readouts, and hydraulic systems can add extra weight to the machine. It’s important to consider all of these factors when determining the weight of a lathe.

Exploring the Different Types of Lathes and their Weight Ranges

Lathes come in various types, each designed for specific applications and varying in weight range. Let’s take a look at some of the most common types of lathes and their corresponding weight ranges:

1. Benchtop Lathes: These compact lathes are designed to be mounted on a workbench or table. They are typically lighter, ranging from 40 to 250 pounds, making them portable and suitable for small-scale projects or hobbyists.

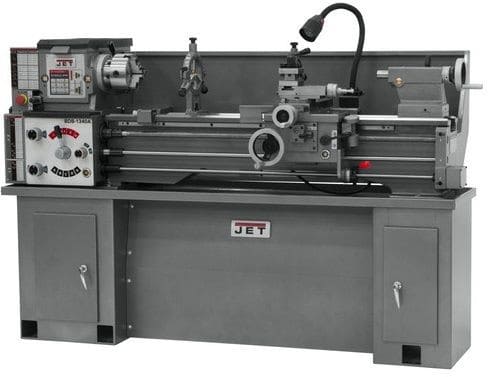

2. Engine Lathes: Engine lathes are larger machines used for general-purpose machining. They range in weight from 1,000 to 10,000 pounds, depending on the size and capacity. These lathes are commonly found in industrial settings.

3. Toolroom Lathes: Toolroom lathes are precision machines used for high-accuracy operations. They are heavier than the benchtop and engine lathes, weighing between 2,000 to 12,000 pounds. These lathes are commonly used in toolrooms, prototyping, and small-scale production.

4. Heavy-Duty Lathes: Heavy-duty lathes are designed for large-scale machining tasks in industries like aerospace and automotive. They can weigh anywhere from 10,000 to 100,000 pounds or more, depending on the size and capacity required.

5. CNC Lathes: Computer Numerical Control (CNC) lathes are automated machines that offer precise control and versatility. Their weight can vary from 2,000 to 20,000 pounds or more, depending on the size and level of automation.

Implications of Weight in Lathe Machines

The weight of a lathe machine has implications on various aspects of its performance, usability, and stability. Here are some key implications to consider:

1. Stability and Vibration Dampening: Heavier lathes tend to be more stable, reducing vibrations during machining operations. This stability allows for better precision and smoother finishes on the workpiece.

2. Durability: The weight of a lathe often correlates with its overall durability. Heavier lathes made from high-quality materials are more likely to withstand heavy usage and provide a longer service life.

3. Portability and Maneuverability: The weight of a lathe can impact its portability and ease of moving around the workshop. Lighter lathes are generally more portable, while heavier lathes require additional equipment or machinery for transportation.

4. Required Workspace: The weight and size of a lathe will determine the space needed for installation and operation. Heavier lathes may require a more robust workbench or dedicated floor space, while lighter lathes can fit in smaller work areas.

Ultimately, the weight of a lathe should be considered in tandem with your specific requirements, whether it’s for a professional workshop or personal use. Understanding the implications of weight can help you make an informed decision when selecting the right lathe for your needs.

Types of Lathes for Specific Applications

While considering the weight of a lathe is important, it is equally crucial to understand the different types of lathes available in the market. Each type serves specific purposes and offers unique features. Let’s explore a few types of lathes and their applications in more detail:

1. Benchtop Lathes: Perfect for Hobbyists and Small-Scale Projects

Benchtop lathes are compact machines designed for hobbyists, DIY enthusiasts, and small-scale projects. They are lightweight and portable, making them suitable for workshops with limited space. Benchtop lathes are ideal for tasks like pen turning, small bowl making, and intricate wood or metalwork. They can handle relatively smaller workpieces and are often considered entry-level lathes due to their simplicity and user-friendly nature.

2. Engine Lathes: Ideal for General-Purpose Machining

Engine lathes, also known as center lathes, are versatile machines used for general-purpose turning operations. They are commonly found in manufacturing industries and workshops. Engine lathes are more robust than benchtop lathes and offer greater workpiece capacity. They are designed to handle various materials, sizes, and shapes and can perform operations like facing, turning, knurling, and drilling. Engine lathes are suitable for both small and large-scale production.

3. CNC Lathes: Precision and Automation Combined

Computer Numerical Control (CNC) lathes have revolutionized the machining industry with their precise control and automation capabilities. CNC lathes are highly versatile and can execute complex turning operations with minimal manual intervention. They are commonly used in industries requiring high precision and repeatability, such as aerospace, automotive, and medical device manufacturing. CNC lathes offer incredible flexibility, allowing for the production of intricate and customized parts.

Factors to Consider When Choosing a Lathe

When deciding on the right lathe for your needs, several factors need to be taken into consideration. Here are some key aspects to keep in mind:

1. Size and Capacity

Consider the maximum swing over the bed, distance between centers, and workpiece weight capacity required for your projects. Ensure the lathe can accommodate the size and weight of the materials you plan to work with.

2. Power and Speed Control

Evaluate the motor horsepower and check if it aligns with your requirements. Consider the availability of variable speed control, as it provides greater control over cutting speeds for different materials and operations.

3. Construction and Durability

Look for lathes made from high-quality materials like cast iron or steel, ensuring durability and stability during machining operations. Consider the overall build quality and components used in the lathe’s construction.

4. Additional Features and Accessories

Check for features like digital readouts, quick-change tool posts, threading capabilities, and presence of accessories like chucks, faceplates, and steady rests. These additional features can enhance the versatility and functionality of the lathe.

5. Budget and Value for Money

Set a budget based on your requirements and do thorough research to find the best value for money. Consider factors like warranty, customer support, and availability of spare parts when evaluating the overall value of the lathe.

6. User Reviews and Recommendations

Read reviews and seek recommendations from experienced users or trusted sources. Real-world experiences and feedback can provide valuable insights into the performance and reliability of different lathe models.

In conclusion, the weight of a lathe is an important consideration when selecting the right machine for your machining needs. It directly influences stability, durability, portability, and the type of projects you can undertake. By understanding the factors that contribute to the weight of a lathe and exploring the different types available, you can make an informed decision and choose a lathe that aligns with your requirements. So, weigh your options and embark on your lathe journey with confidence!

Key Takeaways: How Heavy is a Lathe?

- A lathe machine can weigh anywhere from a few hundred pounds to several thousand pounds.

- The weight of a lathe depends on various factors, such as its size, type, and design.

- Smaller benchtop lathes typically weigh between 100 and 500 pounds.

- Medium-sized lathes can weigh between 1,000 and 5,000 pounds.

- Large industrial lathes can weigh over 10,000 pounds.

Frequently Asked Questions

Welcome to our FAQ section! Here, we’ll answer some common questions about the weight of a lathe machine. Whether you’re a woodworking enthusiast or a curious individual, we’ve got you covered with all the information you need.

1. How does the weight of a lathe machine affect its performance?

The weight of a lathe machine is an essential factor that greatly influences its performance. A heavier lathe tends to have better stability and reduced vibrations during use. This stability is essential for achieving precise cuts and smooth finishes on your workpiece. It also helps minimize the chance of the lathe “walking,” which can occur when a machine moves or shakes during operation.

Additionally, a heavier lathe often has more robust construction, which generally translates to better overall durability. This means it can withstand more demanding projects and is less likely to experience premature wear and tear. So, a heavier lathe not only enhances performance but also contributes to the longevity of the machine.

2. How heavy is an average benchtop lathe?

The weight of an average benchtop lathe can vary depending on its size and specifications. However, as a general guideline, smaller benchtop lathes typically weigh between 50 to 200 pounds (22 to 90 kilograms). These lathes are designed to sit on a workbench or table, offering convenience and portability while still being capable of handling a range of projects.

Keep in mind that the weight mentioned here is an estimate and can differ from one brand or model to another. It’s always a good idea to refer to the specific product specifications provided by the manufacturer to get an accurate weight measurement for the particular lathe you are interested in.

3. What about larger industrial lathes?

Larger industrial lathes can have significantly greater weight due to their size and heavy-duty build. These lathes are designed for professional use in industries such as manufacturing and metalworking. They are capable of handling larger and more complex projects.

Typically, industrial lathes can weigh anywhere from 1,000 to 30,000 pounds (450 to 13,600 kilograms) or even more in some cases. It’s important to note that the weight can vary depending on the specific model and features of the lathe. When considering an industrial lathe, it’s crucial to have a sturdy foundation or floor to support its weight and ensure safe operation.

4. Are there any lightweight options available for hobbyists?

Absolutely! If you’re a hobbyist or someone who prefers a more portable option, there are lighter lathe machines available. Mini or micro lathes are compact and lightweight, making them suitable for small-scale projects or individuals with limited space.

These smaller lathes can weigh anywhere from 10 to 50 pounds (4.5 to 22 kilograms), allowing for easy transportation and storage. Despite their lighter weight, they still offer decent performance and versatility for various woodworking or crafting tasks.

5. Does the weight of a lathe affect its price?

While the weight of a lathe can indirectly contribute to its price, it’s not the sole determining factor. The weight of the lathe is primarily influenced by the size, materials, and construction of the machine. Higher-quality materials and more durable construction might result in a heavier lathe, which can potentially increase the price.

However, it’s important to note that the price of a lathe is influenced by various other factors, such as brand reputation, features, and overall performance. Therefore, it’s always a good idea to consider your specific needs and budget when looking at different lathe options, rather than solely focusing on weight as an indicator of price.

The world’s largest lathe in operation

Summary

So, to sum it all up, a lathe is a big and heavy machine used for shaping metal. The weight of a lathe can vary depending on its size and capabilities, but it can range from a few hundred pounds to several thousand pounds. It’s definitely not something you can lift on your own!

In order to move a lathe, special equipment is needed, like a forklift or a crane. The weight of the lathe is an important factor to consider when setting it up or transporting it. So, if you ever come across a lathe, remember that it’s a heavy machine that requires proper handling and care.