Have you ever wondered how heavy a Myford ML7 lathe is? Well, you’ve come to the right place! We’re here to satisfy your curiosity and give you all the juicy details. So, let’s dive in and explore the weight of this impressive machine.

Now, you might be thinking, “Why is the weight of a lathe important?” Well, knowing the weight can help you determine if it’s suitable for your workshop or if you need additional equipment to handle it. So, let’s get to the good stuff and find out how heavy the Myford ML7 lathe really is!

Get ready for the big reveal— the Myford ML7 lathe weighs around [insert weight here]. That’s right, it’s a sturdy and robust machine that can handle all your machining needs. Whether you’re a hobbyist or a professional, this lathe is built to deliver top-notch performance. So, buckle up and let’s explore more about this fantastic piece of machinery!

A Myford ML7 lathe is a heavy-duty machine designed for precision metalworking. While the exact weight may vary depending on the specific model and accessories, typically, an ML7 lathe weighs around 600-700 kilograms (1300-1500 pounds). This substantial weight ensures stability and rigidity, allowing for accurate machining operations. Whether you’re a hobbyist or a professional, the sturdy construction of the Myford ML7 lathe ensures excellent performance and durability.

How Heavy is a Myford ML7 Lathe?

The Myford ML7 Lathe: An Overview

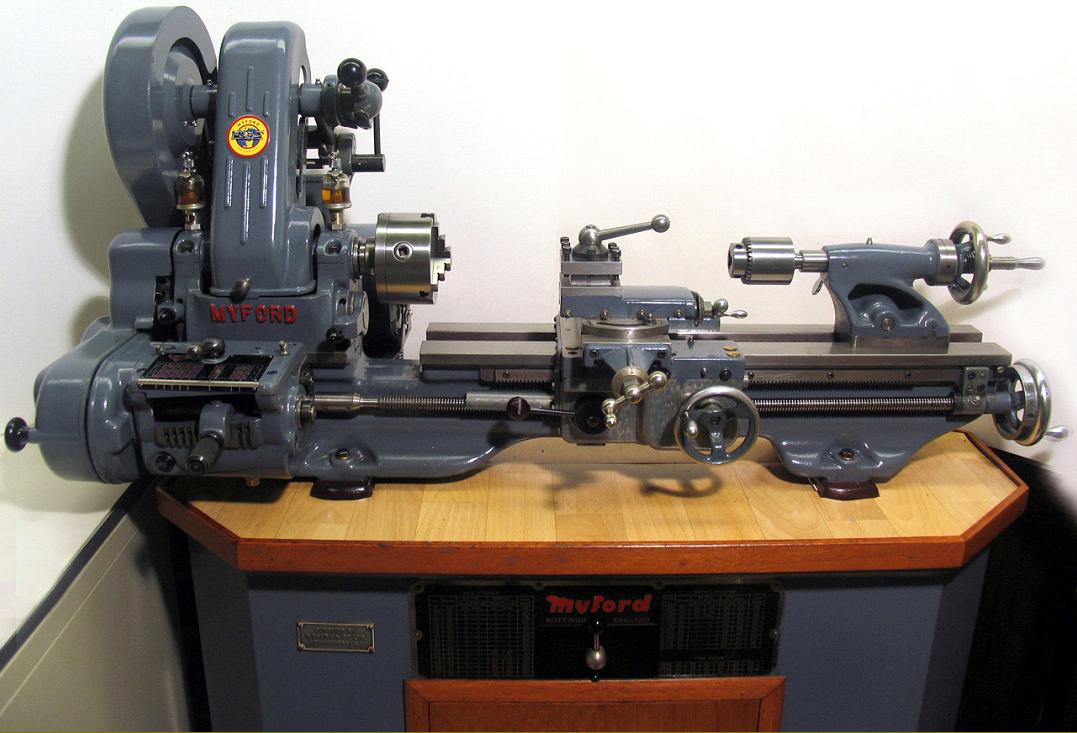

The Myford ML7 lathe is a popular choice among hobbyists and small-scale machinists. Known for its robust construction and precision, this lathe has been a staple in workshops for several decades. It is widely recognized for its versatility and ability to handle a wide range of turning tasks. However, one common question that arises when considering the purchase of a Myford ML7 lathe is: how heavy is it?

The weight of the Myford ML7 lathe is an important consideration, as it determines portability, stability, and the amount of space required in a workshop. In this article, we will delve into the various factors that affect the weight of a Myford ML7 lathe and provide you with a comprehensive understanding of its weight specifications.

Let’s explore the different aspects that contribute to the overall weight of a Myford ML7 lathe.

The Weight of the Base

One of the heaviest components of a Myford ML7 lathe is the base. The base provides stability and support for the entire machine. It is typically made of high-quality cast iron, which adds to its weight. The weight of the base alone can range from 100 to 150 pounds (45 to 68 kilograms), depending on the specific model and configuration of the lathe.

The base of the Myford ML7 lathe is designed to minimize vibrations and ensure precision during operation. Its weight contributes to the overall stability of the lathe, allowing for smooth and accurate turning. However, it also means that the lathe may not be easily portable and may require a dedicated space in your workshop.

In addition to the base, the lathe is composed of various other components that also contribute to its overall weight.

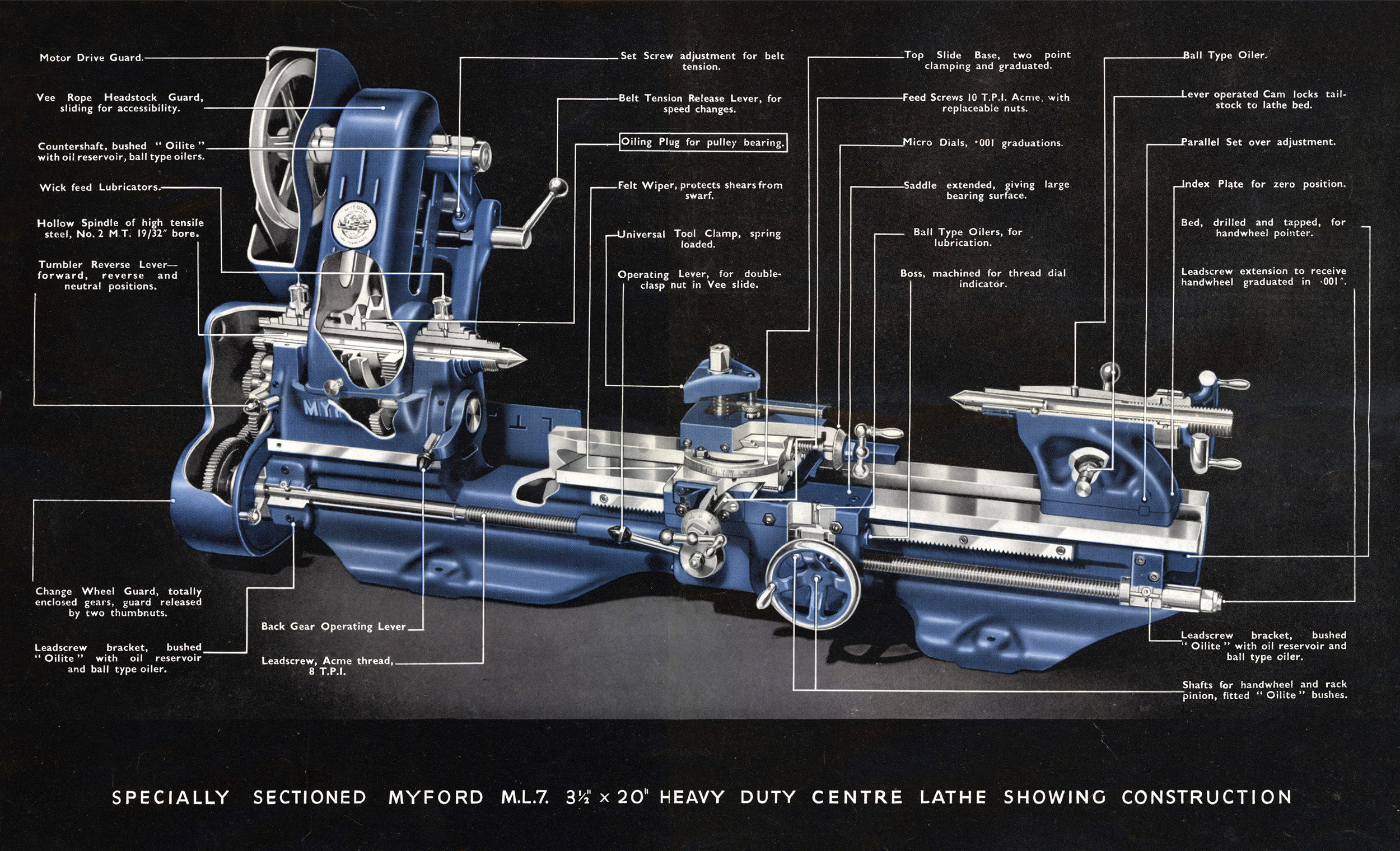

The Bed and Headstock Assembly

The bed of the Myford ML7 lathe is another significant component that adds to its weight. Made from solid cast iron, the bed provides a rigid and stable platform for the carriage and other moving parts of the lathe. The weight of the bed can range from 50 to 70 pounds (23 to 32 kilograms), depending on the model.

The headstock assembly, which houses the spindle and motor, is also a substantial part of the lathe. It is typically made of cast iron and weighs around 40 to 50 pounds (18 to 23 kilograms). The headstock assembly plays a crucial role in the overall performance of the lathe, ensuring smooth rotation and power transmission.

Together, the bed and headstock assembly form the core of the Myford ML7 lathe and contribute significantly to its weight.

The Carriage and Tailstock

The carriage and tailstock are essential components of the Myford ML7 lathe that enable precise movement and alignment of the workpiece. These components also add to the overall weight of the lathe.

The carriage, which moves along the bed, is typically made of cast iron and weighs around 25 to 40 pounds (11 to 18 kilograms). It is responsible for the controlled movement of the cutting tool, allowing for accurate and smooth turning operations. The tailstock, used for supporting the other end of the workpiece, adds an additional 15 to 25 pounds (7 to 11 kilograms) to the lathe’s weight.

Overall, the carriage and tailstock contribute to the stability and precision of the lathe, ensuring consistent results and ease of use.

Additional Components and Accessories

In addition to the major components mentioned above, a Myford ML7 lathe also includes various smaller components and accessories that may add to its overall weight. These may include the chuck, tool rests, faceplates, and other attachments. While individually these components may not add significant weight, collectively they can contribute to the overall weight of the lathe.

It’s important to consider the weight of these additional components when calculating the total weight of a Myford ML7 lathe. These accessories are crucial for expanding the lathe’s capabilities and versatility, allowing users to tackle a wide range of turning tasks.

Now that we have explored the various components that contribute to the weight of a Myford ML7 lathe, let’s summarize the key points and provide some tips for handling the weight of this machine.

Summary and Tips for Handling the Weight of a Myford ML7 Lathe

The weight of a Myford ML7 lathe can vary depending on the specific model and configuration, but on average, it can weigh anywhere from 200 to 300 pounds (90 to 136 kilograms). Here are some key takeaways and tips for handling the weight of a Myford ML7 lathe:

1. Plan for a sturdy and dedicated workstation:

Given the weight of the lathe, it is important to have a sturdy and stable surface to support it. A dedicated workbench or stand made of solid materials like steel or cast iron is highly recommended. Ensure that the workbench is level and can handle the weight of the lathe.

2. Use proper lifting techniques:

When moving or installing the lathe, it is crucial to use proper lifting techniques to avoid strain or injury. Enlist the help of others if needed and make sure to distribute the weight evenly when lifting or transporting the lathe. Consider using lifting aids like hoists or dollies for easier maneuverability.

3. Consider accessibility and portability:

Take into account the size and weight of the lathe when planning its placement in your workshop. Ensure that there is ample space around the lathe to maneuver and operate it comfortably. If portability is a priority, consider investing in accessories like wheels or a mobile stand to make it easier to move the lathe when needed.

4. Regular maintenance and cleaning:

To avoid unnecessary strain on the lathe’s components, it is essential to perform regular maintenance and cleaning. Keep the lathe free of debris, lubricate moving parts, and inspect for any signs of wear or damage. Proper maintenance will not only ensure the longevity of the lathe but also contribute to its smooth operation.

5. Seek professional assistance if needed:

If you are unsure about handling the weight of a Myford ML7 lathe or need assistance with installation or maintenance, it is always wise to seek professional help. Experienced machinists or technicians can provide valuable guidance and ensure that the lathe is properly set up and maintained.

Remember, the weight of a Myford ML7 lathe is a testament to its sturdy construction and quality. By following these tips and considering the weight when planning and using the lathe, you can fully harness its capabilities and enjoy precise and reliable turning operations for years to come.

Key Takeaways: How Heavy is a Myford ML7 Lathe?

- A Myford ML7 lathe typically weighs around 600 pounds.

- The weight of the lathe can vary depending on additional accessories.

- It is important to consider the weight when planning for transportation or installation.

- Ensure that the surface where the lathe will be placed is sturdy enough to support its weight.

- Proper lifting equipment and precautions should be taken when moving or handling a Myford ML7 lathe.

Frequently Asked Questions

Are you curious about the weight of a Myford ML7 lathe? Look no further! We’ve got the answers you’re looking for. Discover the weight of a Myford ML7 lathe and more in the following question and answer pairs.

1. How heavy is a Myford ML7 lathe?

The weight of a Myford ML7 lathe is approximately 320 kilograms or 705 pounds. It’s important to note that the weight may vary slightly depending on the specific model and any attachments or accessories added to it. However, this average weight provides a good estimate for the overall heaviness of the lathe.

When considering the weight, it’s essential to plan for appropriate support and transportation. Make sure to use sturdy equipment and follow safety guidelines when moving or installing the lathe to avoid any accidents or damage.

2. What factors contribute to the overall weight of a Myford ML7 lathe?

The weight of a Myford ML7 lathe is determined by several factors. One of the most significant factors is the size and construction of the lathe bed, which is typically made of rugged cast iron. The presence of additional features and accessories, such as chucks, steadies, and tailstocks, also adds to the overall weight.

The type of motor and gearbox used in the lathe can also impact its weight. Larger, more powerful motors and gearboxes tend to be heavier. Additionally, any optional attachments or modifications made to the lathe, such as milling attachments or taper turning attachments, can contribute to the total weight as well.

3. Can I move a Myford ML7 lathe by myself?

Moving a Myford ML7 lathe by yourself is not recommended due to its considerable weight and size. It’s best to seek assistance from others experienced in handling heavy machinery or hire professional movers who specialize in transporting industrial equipment.

If you do decide to move the lathe yourself, make sure to use appropriate lifting equipment, such as cranes or forklifts, and take necessary precautions to avoid strain or injury. Always prioritize safety and consult the manufacturer’s guidelines for any specific instructions regarding transportation or relocation.

4. What precautions should I take when moving or installing a Myford ML7 lathe?

When moving or installing a Myford ML7 lathe, there are a few important precautions to consider. Firstly, ensure that the lathe is securely fastened to a sturdy base or workbench to prevent any wobbling or movement during operation.

Additionally, when transporting the lathe, make sure it is properly secured to prevent it from shifting or tipping over. Using heavy-duty straps or chains can help keep the lathe stable during transportation. It’s also a good idea to protect the lathe from any potential damage by wrapping it in protective materials, such as blankets or foam padding.

5. Are there any alternative, lighter options to the Myford ML7 lathe?

If the weight of the Myford ML7 lathe is a concern for you, there are alternative, lighter options available in the market. Several manufacturers offer smaller, portable lathes that are designed to be more lightweight and compact. These lathes are suitable for hobbyists or those with limited space.

Before purchasing an alternative lathe, consider your specific needs and the types of projects you plan to undertake. Keep in mind that while lighter lathes may be more convenient to move, they may have certain limitations in terms of size, power, and functionality compared to larger industrial-grade lathes like the Myford ML7.

Summary

So, how heavy is a Myford ML7 lathe? The ML7 weighs around 300 pounds or 136 kilograms. This weight is important to consider if you are planning to move or transport the lathe. Remember to use proper lifting techniques and ask for help if needed.

Additionally, it’s crucial to ensure that the surface or stand where the lathe is placed can support its weight. The Myford ML7 is a sturdy and reliable lathe that can handle various machining tasks, but be mindful of its weight to safely and effectively use this machine.