Are you wondering how high your table saw blade should be? Well, let’s dive right in and find out! Getting the proper blade height is essential for smooth and accurate cuts on your woodworking projects. Whether you’re a beginner or an experienced woodworker, knowing the right height will make a world of difference in your results. So, let’s explore the optimal table saw blade height for your cutting needs.

When it comes to setting the height of your table saw blade, there are a few factors you need to consider. The type of cut you’re making, the thickness of your material, and the type of blade you’re using all play a role in determining the appropriate height. Finding the sweet spot will ensure clean cuts and minimize the risk of accidents. Trust me, safety always comes first!

Now, let’s get into the nitty-gritty details of blade height. Don’t worry, it’s not as complicated as it may sound! By understanding the basics and following a few simple guidelines, you’ll be able to adjust your blade height like a pro. So, grab your safety goggles, roll up your sleeves, and let’s unlock the secrets to the perfect table saw blade height!

Step 1: Turn off the saw and unplug it for safety.

Step 2: Raise the blade to its highest position using the elevation wheel.

Step 3: Measure the distance between the highest tooth and the table surface.

Step 4: Lower the blade and adjust it based on your desired depth of cut.

Step 5: Repeat the measurement process to ensure accuracy.

By following these steps, you can set your table saw blade to the correct height for your woodworking projects.

How High Should My Table Saw Blade Be? A Comprehensive Guide

When it comes to using a table saw, one question that often arises is, “How high should my table saw blade be?” The height of the blade plays a critical role in determining the quality and safety of your cuts. In this article, we will dive deep into this topic and provide you with all the information you need to know about setting the blade height on your table saw. Whether you are a beginner or an experienced woodworker, understanding the correct blade height is essential for achieving accurate and clean cuts.

Why Is Blade Height Important?

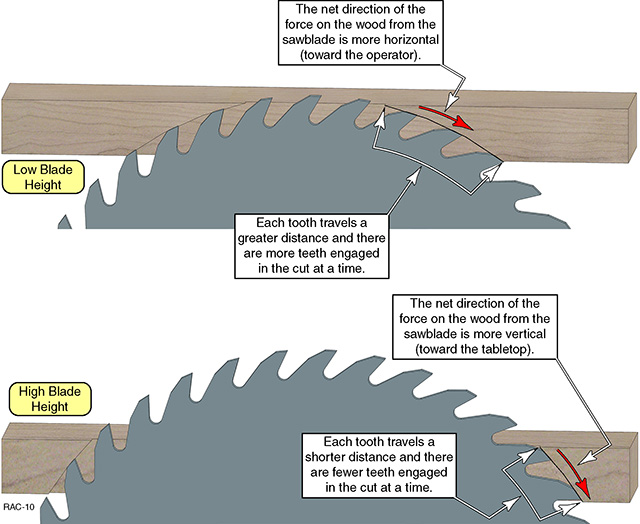

The height at which you set your table saw blade directly affects the quality of your cuts. If the blade is too low, it may not fully penetrate the material you are cutting, resulting in an incomplete and uneven cut. On the other hand, if the blade is set too high, it can cause excessive friction, leading to burning and scorching of the wood. Additionally, a blade that is set too high can increase the risk of kickback, which can be extremely dangerous.

Another crucial factor to consider is the thickness of the material you are working with. Different types of cuts require different blade heights. For example, when making a through cut, where the blade cuts through the entire thickness of the material, the blade should be set higher compared to a dado cut, where the blade only cuts a groove into the material.

Overall, setting the correct blade height ensures clean and precise cuts, minimizes the risk of accidents, and prolongs the lifespan of your table saw blade.

How to Set the Blade Height

Now that we understand the importance of blade height, let’s discuss how to set it correctly. Here is a step-by-step guide:

- Turn off the table saw and unplug it from the power source. Safety should always be a top priority.

- Locate the blade height adjustment wheel or knob on your table saw. It is usually located on the front or side of the saw.

- Ensure the blade guard is removed, allowing you to access the blade easily and safely.

- Rotate the blade height adjustment wheel or knob to raise or lower the blade. Refer to your table saw’s manual to determine the appropriate height for your specific cutting needs.

- Once you have set the desired blade height, verify that it is parallel to the table’s surface. You can use a small square or a specialized tool called a blade height gauge to ensure accuracy.

- Double-check your settings and make any necessary adjustments before proceeding with your cut.

- Remember to always wear appropriate safety gear, such as safety glasses and hearing protection, when operating power tools.

The Effect of Blade Height on Different Cuts

The blade height you choose will vary depending on the type of cut you are making. Let’s explore the optimal blade heights for different common cuts:

Rip Cuts

Rip cuts involve cutting wood along the grain to reduce its width. To achieve the best results, set the blade height so that it is slightly higher than the material being cut. This will prevent the wood from getting stuck and reduce the chances of kickback.

As a general rule, the blade should be set at a height where the gullets (the curved valleys between the teeth) are just above the top of the wood being cut. This allows for efficient chip removal and reduces the load on the motor.

However, it’s important to note that the specific blade height may vary depending on the thickness and hardness of the wood you are cutting. Experimentation and practice will help you find the ideal blade height for your particular project.

Crosscuts

Crosscuts involve cutting wood perpendicular to the grain. For clean and accurate crosscuts, the blade height should be set at or just above the thickness of the wood being cut. This ensures that the blade fully penetrates the material without excess friction or burn marks.

Using a miter gauge or a crosscut sled can also enhance the precision and safety of your crosscuts. These accessories provide support and stability throughout the cut.

When making crosscuts, always ensure that the blade height remains consistent throughout the entire cut. Inconsistent blade height can result in uneven cuts and a lack of squareness.

Dado Cuts

Dado cuts involve cutting a groove or channel into a piece of wood to accommodate other pieces. The blade height for dado cuts is typically shallower compared to rip cuts or crosscuts. It should be set to the desired depth of the groove you want to create.

When performing dado cuts, it’s essential to use a dado blade set specifically designed for this purpose. These blades typically consist of two outer blades and a series of removable chippers, allowing you to adjust the width of the groove.

Always refer to the dado blade set’s instructions and set the correct blade height to ensure a precise and safe cut.

Tips for Achieving the Perfect Blade Height

Now that you have a good understanding of blade height and its impact on different types of cuts, here are some additional tips to help you achieve the perfect blade height:

1. Consider the Material

The type of material you are cutting plays a role in determining the appropriate blade height. Softer materials may require a lower blade height, while harder materials may benefit from a slightly higher setting. Take into account the density and thickness of the material before adjusting the blade height.

2. Make Test Cuts

If you are unsure about the ideal blade height for a particular cut, it’s a good practice to make test cuts on scrap pieces of the same material. This will allow you to evaluate the quality and adjust the blade height as needed before working on your actual project.

3. Keep Blades Sharp

A dull blade can impact the quality of your cuts, regardless of the height setting. Regularly inspect and sharpen your blades to ensure optimal performance. A sharp blade will cut smoothly and require less force, reducing the chances of kickback and accidents.

Common Mistakes to Avoid

Now that you know how to set the blade height correctly, let’s highlight some common mistakes to avoid:

1. Neglecting Safety Measures

Always prioritize safety when working with power tools. Wear appropriate safety gear, follow safety guidelines, and ensure your workspace is clear of any potential hazards.

2. Inconsistent Blade Height

When working on longer cuts, it’s crucial to maintain a consistent blade height throughout the entire cut. Inconsistent blade height can result in uneven cuts and compromise the integrity of your project.

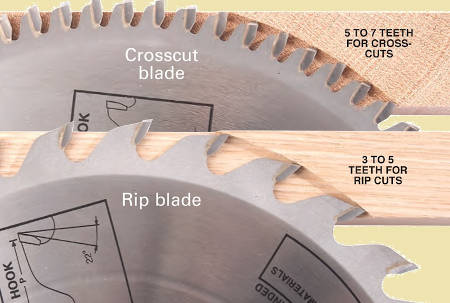

3. Poor Blade Selection

Ensure that you are using the right blade for your specific cutting needs. Different blades are designed for different materials and types of cuts. Using the wrong blade can lead to subpar results and potential damage to the blade and your workpiece.

In conclusion, setting the correct blade height is crucial for achieving accurate and clean cuts on your table saw. Understanding the different blade heights required for various types of cuts, practicing safe working habits, and staying mindful of common mistakes will help you become a more skilled and efficient woodworker. So, the next time you ask yourself, “How high should my table saw blade be?” remember to consider the material, follow the guidelines, and make adjustments based on your specific needs. Happy woodworking!

Key Takeaways: How High Should My Table Saw Blade Be?

- Maintaining the correct height of the table saw blade is crucial for safety and cutting accuracy.

- A general rule is to set the blade to a height where only the top three teeth are exposed above the material being cut.

- Adjusting the blade height can differ depending on the type of cut you’re making.

- Always refer to the manufacturer’s instructions for the specific table saw model you’re using.

- Regularly check and maintain the blade height to ensure optimal performance and prevent accidents.

Frequently Asked Questions

Welcome to our FAQ section on table saw blade height! If you’re wondering how high your table saw blade should be, you’ve come to the right place. Below are some commonly asked questions and answers on this topic. Read on to get all the information you need!

1. What factors should I consider when determining the height of my table saw blade?

When deciding how high your table saw blade should be, several factors come into play. First, you need to consider the depth of the material you’re cutting. The general rule of thumb is to position the blade so that it extends about 1/8 inch higher than the material being cut. Additionally, the type of cut you’re making and the type of blade you’re using will impact the blade height as well. For example, rip cuts may require a different blade height than crosscuts.

Another critical factor to consider is safety. It’s essential to ensure that the blade is not set too high, as this can increase the risk of accidents. Always refer to the manufacturer’s instructions and safety guidelines for your specific table saw model.

2. Can I use a fixed height for my table saw blade for all cutting tasks?

While it may be tempting to set a fixed height for your table saw blade and use it for all cutting tasks, it’s generally not recommended. Different types of cuts, materials, and blade configurations require different blade heights to achieve optimal results. For example, if you’re making a crosscut, a lower blade height will minimize tear-out and produce cleaner cuts. On the other hand, a higher blade height may be necessary for a through-cut or a rabbet joint.

By adjusting the blade height according to the specific cutting task at hand, you can improve the quality and precision of your cuts. Take the time to make those adjustments and achieve the best possible results for each project you undertake.

3. Are there any risks associated with setting the table saw blade too high?

Yes, setting the table saw blade too high can pose several risks. One of the most significant risks is that it increases the chance of kickback, where the workpiece is forcefully thrown back towards the operator. Kickback can cause serious injuries or damage to your work and equipment. Setting the blade excessively high can also lead to a greater chance of the material binding against the blade, resulting in kickback.

Another risk is that a higher blade height can cause more tear-out, especially with certain materials like plywood or veneer. Tear-out refers to the splintering or chipping of the wood as it is cut. To minimize these risks, it’s crucial to set the blade height within the recommended guidelines provided by the manufacturer and to follow safe operating practices.

4. Should I adjust the table saw blade height when cutting different materials?

Yes, it’s advisable to adjust the table saw blade height when cutting different materials. Different materials have varying densities and characteristics that can affect the quality of the cut. For example, cutting a softwood board may require a different blade height than cutting through a hardwood plank.

When cutting different materials, it’s important to consider not only the height of the blade but also the type of blade you’re using. Blades with different tooth configurations and cutting angles may yield better results with specific materials. A simple adjustment of the blade height can make a significant difference in the final outcome of your cuts.

5. Are there any safety precautions I should follow when adjusting the table saw blade height?

Absolutely! Safety should always be a top priority when working with power tools like table saws. When adjusting the table saw blade height, follow these safety precautions:

1. Ensure that the table saw is turned off and unplugged before making any adjustments.

2. Use the appropriate personal protective equipment, such as safety glasses and hearing protection.

3. Carefully read and follow the manufacturer’s instructions for blade height adjustment.

4. Avoid making adjustments while the blade is spinning or still in motion.

5. Make gradual adjustments and double-check the blade’s height before starting any cutting operation.

6. Keep your hands and fingers clear of the blade at all times.

7. Only make blade height adjustments using the designated adjustment mechanisms provided by the manufacturer.

By following these safety precautions, you can minimize the risk of accidents and create a safer working environment for yourself.

ENOUGH BS! Here’s how high your table saw blade should be.

Summary

When using a table saw, it’s important to set the blade height correctly. If the blade is too low, it won’t cut through the material properly. On the other hand, if the blade is too high, it can be dangerous and cause kickback. To find the right height, measure the distance between the highest point of the tooth and the table. It should be about 1/8 inch higher than the material you’re cutting. Make sure to adjust the blade height before starting any cuts to ensure safe and accurate results.

Additionally, consider using safety equipment like goggles and push sticks to protect yourself while operating a table saw. It’s always better to be safe than sorry when working with power tools. Remember, your safety should be the top priority. So, take your time, measure carefully, and use caution when adjusting the blade height on your table saw.