Are you wondering how high to set the blade on your table saw? Well, you’ve come to the right place! Setting the blade height is a crucial step for achieving clean, accurate cuts. In this guide, we’ll walk you through the process of determining the ideal blade height for your table saw. So, let’s dive in and unlock the secrets to using your table saw like a pro!

When it comes to setting the blade height, there’s no one-size-fits-all answer. It depends on the type of cut you’re making and the material you’re working with. Don’t worry, though – we’ll break it down for you and make it super easy to understand. By the end of this guide, you’ll have the confidence to adjust your table saw blade height like a seasoned woodworker.

Whether you’re a novice or an experienced DIY enthusiast, mastering the art of table saw blade height is essential. It ensures your safety, improves the quality of your work, and allows you to unleash your creativity. So, let’s get started on this exciting journey to unlocking the full potential of your table saw!

If you’re wondering how to adjust the height of your table saw blade, follow these steps:

- Ensure the saw is turned off and unplugged for safety.

- Locate the elevation or height adjustment wheel/knob.

- Rotate the wheel/knob to raise or lower the blade.

- Measure the height using a gauge or ruler.

- Repeat steps 3 and 4 until desired blade height is achieved.

With these simple steps, you’ll be able to adjust the height of your table saw blade easily.

How High Should a Table Saw Blade Be?

When it comes to using a table saw, one of the most crucial considerations is the height of the blade. Getting the blade height right ensures not only efficient and accurate cuts but also ensures the safety of the operator. Finding the perfect blade height depends on various factors, including the type of cut, the thickness of the material, and the type of saw being used. In this article, we will delve into the different considerations and techniques for determining the optimal height for your table saw blade.

The Importance of Blade Height in Table Saw Operations

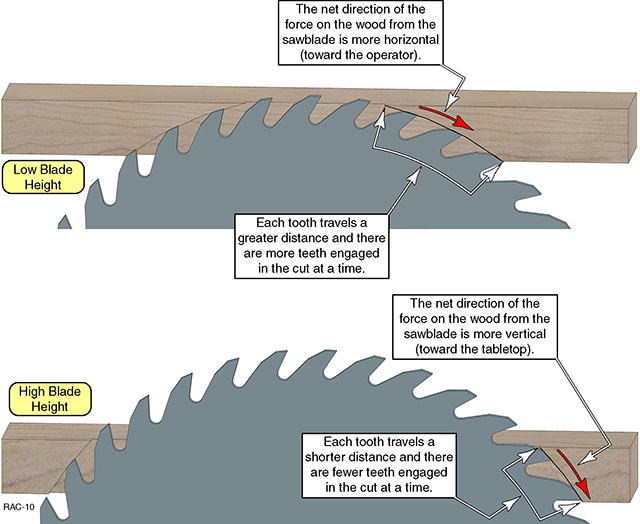

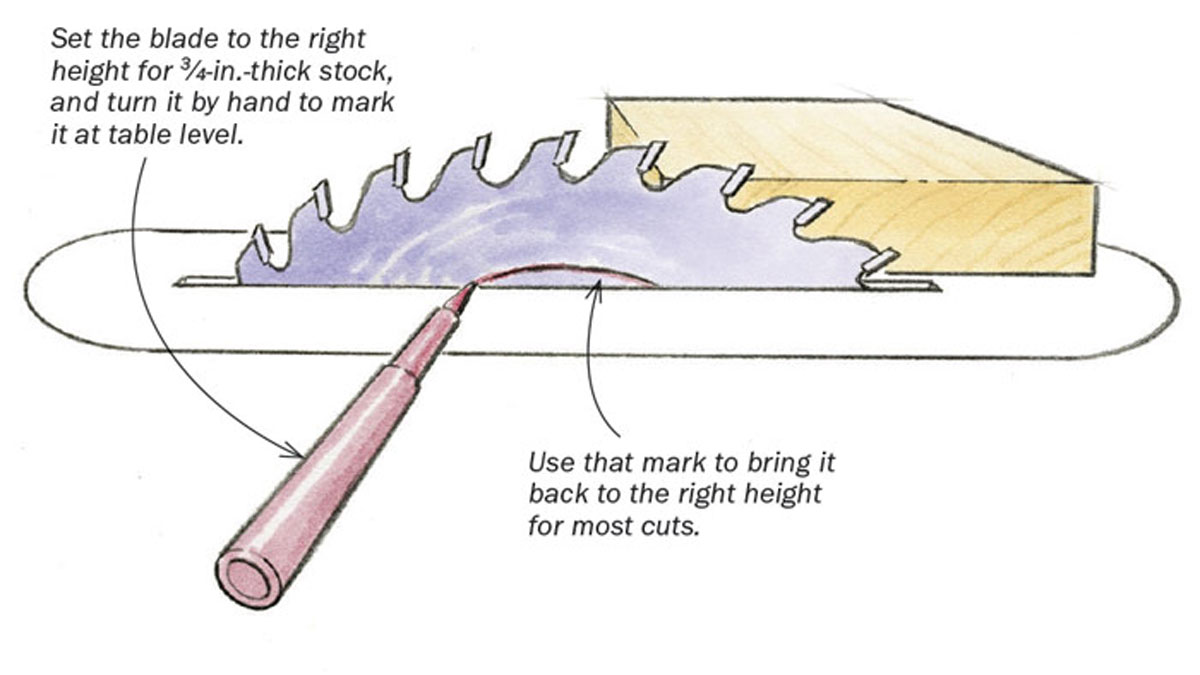

Before we delve into the specifics of finding the proper blade height for your table saw, let’s understand why it is so important. The blade height determines the depth of the cut and directly affects the quality and accuracy of the resulting piece. If the blade is set too low, it may not cut through the material cleanly, leading to jagged edges or incomplete cuts. On the other hand, if the blade is set too high, it can result in kickback, where the material is forcefully thrown back towards the operator, posing a serious safety hazard. Therefore, it is crucial to find the right balance to achieve both precision and safety.

Factors Affecting Table Saw Blade Height

The optimal blade height for your table saw depends on several factors. Let’s take a closer look at these factors:

- Material Thickness: The thickness of the material being cut plays a significant role in determining the blade height. For thicker materials, the blade needs to be set higher to cut completely through the material, whereas for thinner materials, a lower blade height may suffice.

- Type of Cut: The type of cut you are making also affects the blade height. For rip cuts, where you are cutting along the length of the material, a lower blade height is typically used. For crosscuts, where you are cutting across the width of the material, a slightly higher blade height is preferred to ensure a clean and precise cut.

- Saw Type: The type of table saw you are using can also influence the optimal blade height. Different table saw models may have different mechanisms for adjusting the blade height, so it is important to consult your saw’s user manual for specific instructions.

Techniques for Finding the Right Blade Height

Now that we understand the importance of blade height and the factors that affect it, let’s explore some techniques for finding the right blade height for your table saw:

- Test Cuts: One of the simplest and most effective ways to determine the right blade height is through test cuts. Start by setting the blade at a mid-range height and make a test cut on a scrap piece of material. Assess the quality of the cut and make adjustments as needed. Gradually raise or lower the blade height until you achieve the desired results.

- Manufacturer Guidelines: Consult the user manual or manufacturer guidelines for your specific table saw model. Manufacturers often provide recommendations and guidelines for setting the blade height based on the intended use of the saw.

- Experimentation: Every woodworker has their own preferences and techniques. Don’t be afraid to experiment with different blade heights to find what works best for you. Make adjustments in small increments and evaluate the quality of the cuts until you find your sweet spot.

Conclusion

Ensuring the proper blade height is crucial for achieving accurate and safe cuts on a table saw. Factors such as material thickness, the type of cut, and the type of table saw being used all play a role in determining the optimal blade height. By considering these factors and using techniques such as test cuts, consulting manufacturer guidelines, and experimenting, you can find the perfect blade height for your table saw. Remember to always prioritize safety and make adjustments as necessary to achieve the desired results.

Key Takeaways: How to Adjust the Table Saw Blade Height

- Always unplug the table saw before adjusting the blade height.

- Locate the blade height adjustment wheel or knob on your table saw.

- Turn the adjustment wheel clockwise to raise the blade and counterclockwise to lower it.

- Gradually adjust the blade height, making small increments for precise cuts.

- Ensure the blade is at the appropriate height for the material being cut to prevent accidents and achieve clean cuts.

Frequently Asked Questions

Welcome to our FAQ section where we’ll answer your burning questions about the height of a table saw blade. Read on to find out more!

1. How does the height of the table saw blade affect my cuts? Is it important to adjust?

The height of the table saw blade plays a vital role in the quality and precision of your cuts. When the blade is set too high, it can result in tear-out and splintering, leading to an unsatisfactory finish. On the other hand, if the blade is set too low, your cuts may be incomplete or uneven.

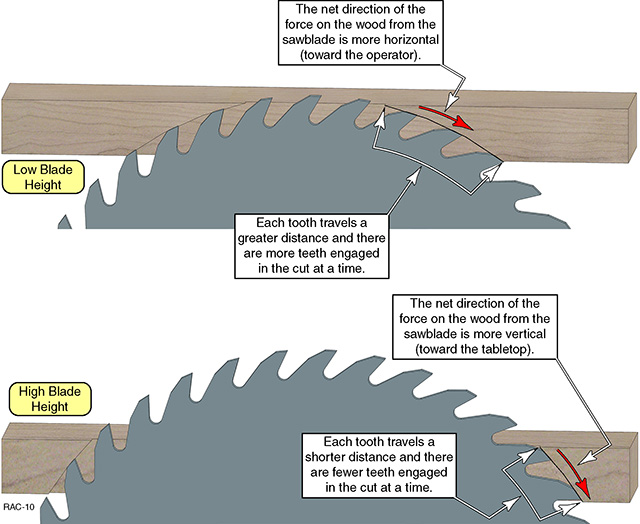

It is crucial to adjust the height of the table saw blade to match the material you are cutting. As a general rule, the blade should protrude slightly above the material being cut, with the gullet (the curve of the blade tooth) clearing the material. By adjusting the blade height appropriately, you can achieve clean, accurate cuts.

2. What factors should I consider when determining the height of the table saw blade?

When determining the height of the table saw blade, there are a few factors to take into account. Firstly, consider the type of material you are cutting. Different materials may require different blade heights to achieve optimal results.

Secondly, consider the type and size of the blade itself. Some blades have specific cutting depths recommended by the manufacturer, so be sure to check their guidelines. Lastly, think about the type of cut you want to achieve. For delicate, precise cuts, you may need to adjust the blade height differently compared to rougher, faster cuts.

3. Should I adjust the height of the table saw blade while the machine is running?

No, it is not recommended to adjust the height of the table saw blade while the machine is running. Doing so can be extremely dangerous and may result in serious injuries. Always ensure the machine is turned off and unplugged before making any adjustments to the blade height.

Before adjusting the blade height, make sure the saw has come to a complete stop and the blade has fully retracted beneath the table. Safety should always be the top priority when working with power tools like table saws.

4. Is there a standard height for a table saw blade?

There is no universal standard height for a table saw blade, as it depends on various factors such as the material being cut and the type of cut you want to achieve. As mentioned earlier, it’s essential to consider these factors and make adjustments accordingly.

However, as a general guideline, the blade should typically be set so that it protrudes 1/8 to 1/4 of an inch above the material being cut. It’s best to refer to the manufacturer’s guidelines or the specific recommendations for the blade you are using.

5. Are there any safety precautions I should take when adjusting the height of the table saw blade?

Absolutely! When adjusting the height of the table saw blade, there are several safety precautions you should follow. Always ensure the saw is turned off and unplugged before making any adjustments.

Wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from debris and possible accidents. Take your time and make incremental adjustments, checking the height after each adjustment. Lastly, always follow the manufacturer’s instructions and recommendations for safe operation of your specific table saw model.

ENOUGH BS! Here’s how high your table saw blade should be.

Summary

So, to sum it all up, when it comes to how high the table saw blade should be, it’s important to consider the thickness of the material you’re cutting. For thinner materials, a lower blade height is usually best. But for thicker materials, you’ll want to raise the blade. Just make sure to follow the recommendations in the user manual and take safety precautions.

Remember, safety should always come first when using power tools like table saws. Always wear protective gear, keep your hands away from the blade, and never force the material through. With the right blade height and careful attention, you can create accurate and clean cuts with your table saw.