So, you’re curious about how a bandsaw blade is measured? Well, you’ve come to the right place! In this article, we’re going to break down the process of measuring a bandsaw blade into easy-to-understand steps. Whether you’re a woodworking enthusiast or just someone looking to expand their knowledge, we’ve got you covered. Let’s dive in and demystify the world of bandsaw blade measurements!

Now, you might be wondering why it’s important to know how to measure a bandsaw blade. Well, having a clear understanding of the dimensions of your blade is crucial for a few reasons. Firstly, it ensures that the blade you’re using is compatible with your bandsaw. Secondly, it allows you to make accurate cuts and achieve the desired results. So, let’s not waste any more time and get straight into the nitty-gritty of measuring a bandsaw blade!

When it comes to measuring a bandsaw blade, there are two key dimensions that you need to consider: the length and the width. The length is pretty straightforward – it’s the total distance around the blade in a circle. On the other hand, the width refers to the height of the blade from the base to the tip. By knowing these two measurements, you’ll be able to find the perfect bandsaw blade for your specific needs. So, let’s explore these measurements in more detail and equip you with the knowledge you need to measure a bandsaw blade accurately.

And there you have it! As you can see, measuring a bandsaw blade isn’t as complicated as it may seem. By understanding the length and width of the blade, you’ll be able to find the right fit for your bandsaw and achieve precise cuts. So, whether you’re a seasoned woodworker or just starting out, remember to measure your bandsaw blade correctly for optimal performance. Get ready to tackle your next woodworking project with confidence!

How is a Bandsaw Blade Measured?

In the world of woodworking and metalworking, bandsaws are essential tools for cutting precise and intricate shapes. But have you ever wondered how a bandsaw blade is measured? Understanding the measurements of a bandsaw blade is crucial for ensuring proper fit and optimal performance. In this article, we will delve into the details of how bandsaw blades are measured and explore some key factors to consider when choosing the right blade for your needs.

The Anatomy of a Bandsaw Blade

Before we dive into the measurements, let’s take a moment to understand the different parts of a bandsaw blade. A bandsaw blade consists of a continuous loop of sharpened teeth that are welded or brazed together to form a strong and durable cutting edge. The blade is made up of several important components, including the teeth, gullet, back, and width. Each of these components plays a crucial role in the cutting process and contributes to the overall performance of the blade.

Width

One of the primary measurements of a bandsaw blade is its width. The width refers to the distance between the bandsaw blade’s two edges. It typically ranges from ¼ inch to 2 inches, depending on the application. The width of the blade determines the maximum thickness of the material that can be cut. For example, a wider blade is suitable for resawing thick stock, while a narrower blade is ideal for making intricate cuts in thinner materials.

When choosing the width of a bandsaw blade, it’s important to consider the thickness of the material you plan to cut. You should select a blade width that is slightly wider than the material to ensure efficient cutting and minimize the risk of blade drift. Keep in mind that using a blade that is too wide for the material can lead to excessive heat generation and premature blade wear.

Tooth Pitch

The tooth pitch of a bandsaw blade refers to the distance between the tips of two adjacent teeth. It is measured in teeth per inch (TPI) or millimeters per tooth (mm/Tooth). The tooth pitch determines the aggressiveness and speed of the cut. Blades with a high tooth pitch (fewer teeth per inch) are suitable for cutting thick and dense materials, while blades with a low tooth pitch (more teeth per inch) are better for cutting thinner materials and producing smoother finishes.

When choosing the tooth pitch of a bandsaw blade, consider the type of material you will be cutting and the desired finish. For general-purpose cuts in wood, a blade with 4-6 TPI is a good starting point. For resawing thicker stock or making faster rip cuts, a coarser blade with 2-3 TPI is more suitable. On the other hand, for fine cuts and smoother finishes, a blade with 10-12 TPI is recommended.

Length

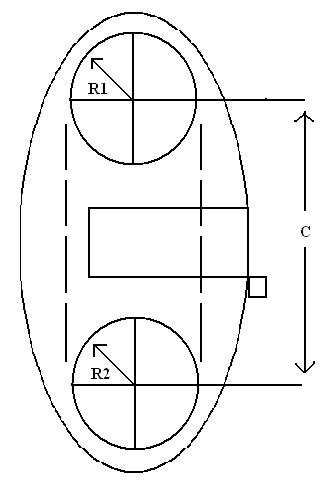

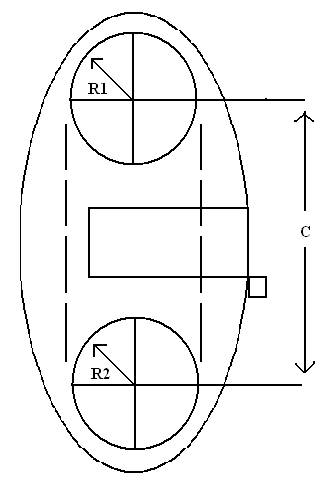

The length of a bandsaw blade refers to the distance between the tips of the blade when it is fully extended and stretched out. It is typically measured in inches or millimeters. The length of the blade is determined by the circumference of the bandsaw’s wheels or pulleys. To determine the correct length for your bandsaw, you need to know the diameter of the wheels and the distance between them.

When measuring the length of a bandsaw blade, it’s important to account for the thickness of the material you will be cutting and the necessary blade tension. It is recommended to refer to the bandsaw manufacturer’s guidelines or consult a bandsaw blade sizing chart to ensure accurate measurement and proper fit.

Choosing the Right Bandsaw Blade

Now that you have a good understanding of how bandsaw blades are measured, let’s explore some key factors to consider when choosing the right blade for your needs:

- Material: Different materials require different blade types. For example, woodcutting blades have coarser teeth, while metalcutting blades have finer teeth.

- Application: Consider the type of cuts you will be making. If you will be making straight cuts, a standard blade will suffice. But if you will be making intricate curved cuts, a blade with a thinner width and higher TPI is recommended.

- Blade Lifespan: The quality and durability of the blade are important considerations. Look for high-quality blades made from premium materials to ensure longevity and consistent cutting performance.

- Compatibility: Ensure that the blade you choose is compatible with your bandsaw model and size. Refer to the manufacturer’s guidelines or consult an expert if you are unsure.

- Maintenance: Consider the ease of blade maintenance and the availability of replacement blades. Blades that can be easily sharpened or replaced are more convenient in the long run.

Common Bandsaw Blade FAQs

Now that we have covered the basics of how bandsaw blades are measured, let’s address some common questions that arise when working with bandsaw blades:

Q: How often should I change my bandsaw blade?

A: The frequency of blade changes depends on several factors, including the type of material being cut, the intensity of use, and the quality of the blade. As a general rule of thumb, it is recommended to change the blade when it becomes dull or shows signs of wear. Regular inspection of the blade and prompt replacement when necessary will ensure optimal cutting performance.

Q: How do I sharpen a bandsaw blade?

A: Sharpening a bandsaw blade can be a complex process that requires specialized tools and expertise. It is generally more cost-effective and efficient to replace a dull or damaged blade with a new one. However, if you have the necessary skills and equipment, it is possible to sharpen a bandsaw blade using a sharpening tool or fixture designed for that purpose.

Q: Can I use a bandsaw blade for cutting metal and wood?

A: While it is possible to use a bandsaw blade for cutting both metal and wood, it is generally recommended to use specialized blades for each material. Metalcutting blades are designed to withstand the higher heat generated when cutting metal and have finer teeth to produce smoother finishes. Woodcutting blades, on the other hand, have coarser teeth to efficiently clear wood chips and are optimized for cutting through various wood densities.

Tips for Maximizing Bandsaw Blade Performance

Here are some tips to help you get the most out of your bandsaw blade:

- Keep the blade clean and free from debris to prevent heat buildup and premature wear.

- Properly tension the blade to ensure accurate cuts and minimize the risk of blade drift.

- Use lubricants or cutting fluids when cutting metal to reduce friction and prolong blade life.

- Feed the material at an appropriate rate to avoid overloading the blade.

- Regularly inspect the blade for signs of wear or damage and replace as needed.

By following these tips and understanding how bandsaw blades are measured, you can maximize the performance and longevity of your bandsaw blade and achieve professional-quality results in your woodworking or metalworking projects.

#Wrap-Up:

In summary, understanding how bandsaw blades are measured is crucial for selecting the right blade for your cutting needs. The width, tooth pitch, and length of the blade are the key measurements to consider. By choosing the appropriate blade measurements and taking into account factors such as material, application, and compatibility, you can optimize the performance of your bandsaw and achieve precise and efficient cuts. Regular maintenance and proper blade handling will also ensure the longevity and reliability of your bandsaw blade. So, whether you’re a woodworking enthusiast or a professional metalworker, now you have the knowledge to confidently choose and work with bandsaw blades.

Key Takeaways: How is a Bandsaw Blade Measured?

- A bandsaw blade is measured by its length, width, and thickness.

- The length of a bandsaw blade is measured by running a tape measure along the edge of the blade from tip to tip.

- The width of a bandsaw blade is measured by the distance between the two sides of the blade.

- The thickness of a bandsaw blade is measured by using a micrometer or caliper to determine the thickness of the blade.

- It is important to measure the bandsaw blade accurately to ensure proper fit and tension for optimal performance.

Frequently Asked Questions

Welcome to our FAQ page on how bandsaw blades are measured. Below, you’ll find answers to commonly asked questions about the measurement process. Read on to learn more!

1. What are the different measurements used for bandsaw blades?

When it comes to bandsaw blades, there are two primary measurements: length and width. Length refers to the distance around the blade in a complete circle, while width measures the distance between the blade’s two edges.

Blade length is typically expressed in inches, while width is given in terms of the blade’s thickness, often in fractions of an inch. These measurements are crucial in ensuring the proper fit and performance of the blade on your bandsaw machine.

2. How do I measure the length of a bandsaw blade?

Measuring the length of a bandsaw blade is a straightforward process. Start by removing the blade from your machine and laying it flat on a surface. Then, take a measuring tape and place it at one end of the blade.

Next, extend the tape measure along the blade until you reach the opposite end. Be sure to follow the path of the blade, including any loops or twists. The resulting measurement is the length of your bandsaw blade, which you can then use to find a replacement or select the right size for your machine.

3. How is the width of a bandsaw blade determined?

The width of a bandsaw blade is determined by measuring the distance between the blade’s edges. To do this, simply take a caliper or a ruler and place it across the blade perpendicular to its length.

Ensure that the measuring instrument is touching both edges of the blade. Read the measurement from the instrument, and this will give you the width of your bandsaw blade. Note that the width refers to the thickness of the blade, not the distance between the teeth.

4. Can bandsaw blades be cut to fit a specific length?

Generally, bandsaw blades are manufactured in standard lengths to fit common bandsaw machines. However, some suppliers may offer the option to custom cut blades to a specific length.

If you require a bandsaw blade that is not a standard length, it’s best to check with the supplier to see if they offer custom cutting services. Keep in mind that custom-cut blades may have additional costs or lead times compared to off-the-shelf options.

5. Are there any other factors to consider when measuring a bandsaw blade?

While length and width are the primary measurements for bandsaw blades, there are a few other factors to consider. One important consideration is the blade’s TPI (teeth per inch), which affects its cutting capabilities.

Additionally, the number of teeth, tooth configuration, and blade material are all aspects that can influence the blade’s performance. It’s also crucial to select a blade that matches the material and thickness you’ll be cutting to ensure optimal results.

Summary

So, to measure a bandsaw blade, you need to look at two important things: the length and the width. The length is measured by wrapping a tape measure around the blade, counting the number of inches or centimeters. The width is determined by looking at the distance between the teeth on the blade. Remember, it’s important to choose the right size blade for your bandsaw to ensure smooth and accurate cuts.

Now that you know how to measure a bandsaw blade, you can confidently shop for and replace blades as needed. Just remember to measure the length and width, and you’ll be on your way to a successful woodworking project. Happy sawing!