Have you ever wondered how a bandsaw is measured? Well, wonder no more! In this article, we’ll explore the fascinating world of bandsaw measurements and unravel the mystery behind this powerful tool. So, if you’re curious and ready to dive in, let’s get started!

When it comes to measuring a bandsaw, there are a few key factors to consider. First off, the blade length plays a crucial role. It determines the size of the material you can cut and ultimately affects the versatility of the bandsaw. Additionally, the throat depth is another important measurement that determines the width of the material you can feed through the bandsaw.

But wait, there’s more to it! Bandsaw measurements also include the table size, which affects the stability and support of your workpieces. And let’s not forget about the horsepower and speed options, which impact the cutting efficiency and performance of the bandsaw. With all these factors in mind, understanding how a bandsaw is measured will empower you to make an informed decision when purchasing or using one.

So, get ready to embark on a bandsaw-measuring adventure! By the end of this article, you’ll be equipped with the knowledge to confidently navigate the world of bandsaws and unleash your woodworking skills. Let’s dive in and discover the ins and outs of measuring a bandsaw!

How is a Bandsaw Measured?

A bandsaw is a versatile and powerful tool used in woodworking and metalworking. It consists of a continuous bandsaw blade that is stretched around two or more wheels and used to make cuts in various materials. To ensure the bandsaw fits your specific needs, it is important to understand how it is measured. This article will provide detailed information on the different measurements used to describe a bandsaw, including blade length, throat capacity, and cutting depth.

Blade Length

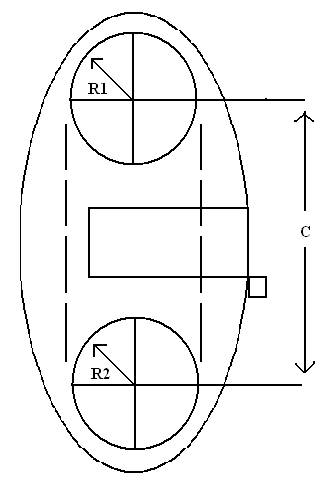

The blade length of a bandsaw refers to the distance around the bandsaw blade when it is fully extended and wrapped around the wheels. It is an essential measurement to determine the compatibility of a bandsaw blade with a particular machine. To find the appropriate blade length for your bandsaw, you can refer to the bandsaw’s user manual or measure it yourself. To measure the blade length, start at the point where the blade emerges from the upper wheel, follow its path around both wheels, and return to the point where it enters the lower wheel. Make sure to take the measurement along the blade’s teeth, not the back edge.

Once you have the blade length, you can choose the appropriate replacement blade for your bandsaw. It is important to select a blade with the correct length to ensure optimal performance and avoid any damage to the bandsaw or the workpiece. Using a blade that is too short can result in inadequate tension and poor cutting accuracy, while a blade that is too long may not fit properly or cause unnecessary strain on the bandsaw’s motor.

When purchasing a new bandsaw blade, you can consult the manufacturer’s guidelines or seek advice from experts to ensure you get the right length for your specific bandsaw model.

Throat Capacity

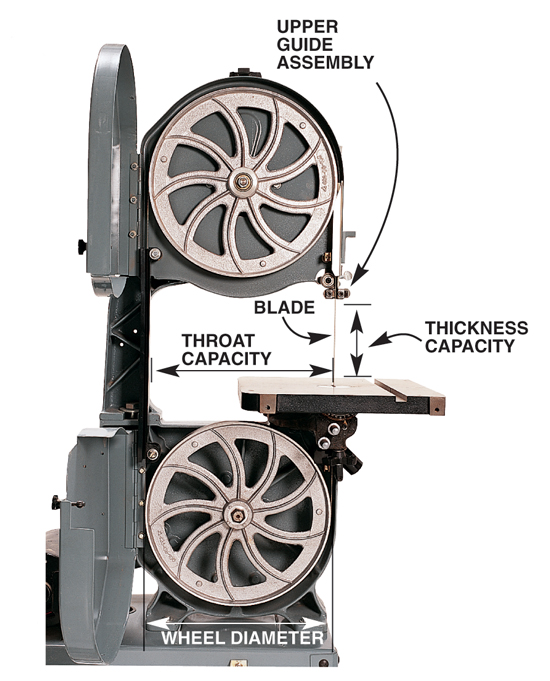

The throat capacity of a bandsaw refers to the distance between the vertical frame of the bandsaw and the blade. It is a crucial measurement that determines the maximum width of cut the bandsaw can make. The throat capacity is typically measured in inches and can range from as small as 8 inches for portable bandsaws to over 36 inches for larger industrial models.

When measuring the throat capacity of a bandsaw, you need to start from the inner edge of the blade and measure straight back to the vertical frame. This measurement determines the maximum width of a workpiece that the bandsaw can comfortably accommodate. For example, a bandsaw with a throat capacity of 14 inches can cut a workpiece up to 14 inches wide without any restrictions.

It is important to consider the throat capacity of a bandsaw when choosing a model, as it directly impacts the types and sizes of materials you can work with. If you frequently work with larger pieces of wood or metal, you may need a bandsaw with a larger throat capacity to accommodate your projects.

Cutting Depth

The cutting depth of a bandsaw refers to the maximum height that the bandsaw blade can cut through a workpiece. It is an important measurement to consider when selecting a bandsaw, as it determines the thickness of material you can effectively cut.

Measuring the cutting depth of a bandsaw is straightforward. It involves measuring the distance between the table (or work surface) and the upper blade guide assembly. This measurement indicates the maximum thickness of material that the bandsaw can cut. For example, a bandsaw with a cutting depth of 12 inches can make cuts up to 12 inches thick.

When choosing a bandsaw, it is important to select a model with a cutting depth that suits your specific needs. Consider the types of materials you will be working with and their thicknesses to ensure the bandsaw can handle your projects effectively.

Bandsaw Blade Tension

Before we dive into the measurements used to describe a bandsaw, it is important to understand the significance of proper blade tension. Blade tension refers to the tightness or stretch applied to the bandsaw blade, ensuring it remains in place during cutting without slipping or deflecting. Adequate blade tension is crucial for precise and efficient cutting operations.

Tensioning System

Bandsaws come with different tensioning systems, including manual and automatic systems. Manual tensioning systems require the user to adjust the tension by hand using a tension knob, while automatic systems use a mechanism that automatically adjusts the tension to the optimal level.

The tensioning system of a bandsaw ensures that the blade is properly stretched and secured around the wheels. It is important to follow the manufacturer’s guidelines for the recommended tension and make adjustments when necessary. Improper blade tension can result in poor cuts, excessive blade wear, or even blade breakage.

Regular maintenance and checks of the tensioning system are essential to ensure the smooth operation of the bandsaw and to preserve the longevity of the blade. It is recommended to periodically check the tension and make any necessary adjustments to guarantee optimal performance.

Tensioning Tips

When tensioning a bandsaw blade, there are a few important considerations to keep in mind:

- Always consult the manufacturer’s instructions or user manual for specific guidance on tensioning the blade for your bandsaw model.

- Ensure the bandsaw is turned off and unplugged before making any adjustments to the blade tension.

- Use a proper tension gauge to measure the tension accurately. This will help you achieve consistent and reliable results.

- Avoid over-tensioning the blade, as this can lead to premature wear and decreased cutting performance. Similarly, under-tensioning the blade can result in poor cutting quality and blade deflection.

- Regularly inspect the bandsaw blade for signs of wear, such as missing teeth or excessive wear on the gullets. Replace the blade if necessary to maintain optimal cutting performance.

Choosing the Right Bandsaw for Your Needs

Now that you understand how a bandsaw is measured and the importance of blade tension, it’s time to consider the factors to keep in mind when choosing the right bandsaw for your needs. Here are a few key considerations:

Bandsaw Type

There are several types of bandsaws available, including benchtop, floor-standing, and portable models. The type you choose will depend on your workspace, the materials you work with, and your specific cutting requirements. Benchtop bandsaws are suitable for smaller projects and limited space, while floor-standing models offer increased power and capacity. Portable bandsaws are ideal for on-site work or when mobility is a priority.

Cutting Capacity

Consider the maximum width and thickness of the materials you typically work with and ensure the bandsaw you choose can accommodate those dimensions. This will ensure you can make precise cuts without any constraints.

Motor Power

Check the motor power of the bandsaw to ensure it is sufficient for your cutting requirements. Higher-powered motors offer more cutting capacity and the ability to cut through denser or harder materials without straining the machine.

Blade Guides and Adjustments

Inspect the blade guides and adjustments available on the bandsaw. Look for features such as quick-release blade tensioning mechanisms, easy blade tracking adjustments, and reliable blade guides that provide stability and accuracy during cutting operations.

Maintaining Your Bandsaw

To ensure your bandsaw remains in optimal condition and performs at its best, regular maintenance is essential. Here are a few maintenance tips:

Cleaning and Lubrication

Regularly clean your bandsaw by removing any debris or sawdust that may accumulate. Lubricate the moving parts and guide mechanisms to ensure smooth operation and prevent premature wear.

Blade Inspection and Replacement

Periodically inspect your bandsaw blade for signs of wear, damage, or dullness. Replace the blade as needed to maintain optimal cutting performance. Keep spare blades on hand for quick replacements when necessary.

Tension and Tracking Checks

Regularly check the blade tension using a tension gauge and make adjustments as needed. Ensure the blade remains properly aligned and centered on the wheels to prevent tracking issues and maximize cutting accuracy.

Conclusion

Understanding how a bandsaw is measured is essential for selecting the right tool and achieving accurate and efficient cutting results. By considering factors such as blade length, throat capacity, cutting depth, and blade tension, you can choose a bandsaw that suits your specific needs. Regular maintenance and proper usage will ensure the longevity and optimal performance of your bandsaw. So, put this knowledge into practice and enjoy the benefits of a well-measured and well-maintained bandsaw in your woodworking or metalworking endeavors.

Key Takeaways: How is a Bandsaw Measured?

- A bandsaw’s size is determined by the throat size, which is the distance between the blade and the frame.

- The bandsaw’s cutting capacity is measured by its resaw height, which is the maximum thickness it can cut.

- Blade length is another important measurement, as it determines the size of material that can be fed into the bandsaw.

- When measuring a bandsaw, consider its overall dimensions, including height, width, and depth.

- It’s also important to check the motor size and power of the bandsaw, as it impacts its cutting performance.

Frequently Asked Questions

In this section, we will answer some common questions about how bandsaws are measured.

How does the size of a bandsaw blade impact its performance?

The size of a bandsaw blade, specifically its length and width, directly affects its performance. The length of the blade determines the maximum size of stock that can be cut. A longer blade allows for cutting larger pieces, while a shorter blade is ideal for smaller projects. On the other hand, the width of the blade affects the accuracy and stability of the cut. Wider blades are more stable and less prone to bending, making them suitable for straight cuts, while narrower blades allow for tighter-radius curves and intricate cuts.

Additionally, the thickness of the blade, known as the blade gauge, impacts the bandsaw’s ability to handle different materials. Thicker blades can handle more tension and are better suited for cutting denser materials like hardwoods, while thinner blades are more suitable for softer materials or intricate scrollwork.

What does the throat capacity of a bandsaw refer to?

The throat capacity of a bandsaw refers to the distance between the blade and the vertical frame of the bandsaw. It determines the maximum width of stock that can be cut on the bandsaw. For example, if a bandsaw has a throat capacity of 12 inches, it means that the blade can cut a maximum width of 12 inches from the edge of the board to the blade.

It is important to choose a bandsaw with an adequate throat capacity that matches the size of the projects you typically work on. If you often work with larger pieces of material, you will require a bandsaw with a larger throat capacity to accommodate the width of the stock you work with.

What is the blade speed and why is it important?

The blade speed refers to the rate at which the bandsaw blade moves while cutting. The speed is measured in feet per minute (FPM) and can be adjusted on most bandsaws. The blade speed is an essential factor in achieving smooth and accurate cuts. Different materials and cutting tasks require different blade speeds.

For example, cutting thick hardwoods requires a slower speed to prevent overheating, while cutting thin metals would require a higher speed for efficient cutting. It is important to consult the manufacturer’s recommendations to determine the appropriate blade speed for the specific material you are working with. Using the correct blade speed not only ensures clean cuts but also prolongs the life of the blade.

What is the cutting capacity of a bandsaw?

The cutting capacity of a bandsaw refers to the maximum thickness of the material that the bandsaw can cut. It is determined by the distance between the table surface and the upper blade guides, also known as the maximum cutting height. For example, a bandsaw with a cutting capacity of 6 inches can cut through a maximum thickness of 6 inches.

When choosing a bandsaw, consider the types of projects you typically work on and ensure the cutting capacity is sufficient for your needs. If you frequently work with thicker stock, you may need a bandsaw with a higher cutting capacity.

What is the difference between a 14-inch or 16-inch bandsaw?

The terms “14-inch” or “16-inch” bandsaw refer to the nominal size of the bandsaw’s wheel diameter. It does not represent the cutting capacity or the maximum width of the stock that can be cut. The wheel diameter primarily affects the speed and power of the bandsaw.

A larger wheel diameter, such as 16 inches, allows for higher blade speeds and more power in the motor. This is beneficial for cutting thicker or denser materials. However, a 14-inch bandsaw is typically sufficient for most woodworking tasks and offers more affordability and versatility. It is important to consider your specific needs and the types of projects you plan to work on when deciding between a 14-inch or 16-inch bandsaw.

Summary

So, to measure a bandsaw, you need to know its blade length, throat depth, and table size. The blade length tells you how big of a cut the bandsaw can make. The throat depth is the distance from the blade to the frame, determining the width of the material you can cut. The table size indicates the amount of workspace available. Remember these measurements next time you’re shopping for a bandsaw!