Is your curiosity piqued about how bandsaw size is measured? Well, you’ve come to the right place! Whether you’re an aspiring woodworker or simply looking to expand your knowledge, this article will unravel the mystery and provide you with easy-to-understand information. So, let’s dive right in and discover how bandsaw size is determined.

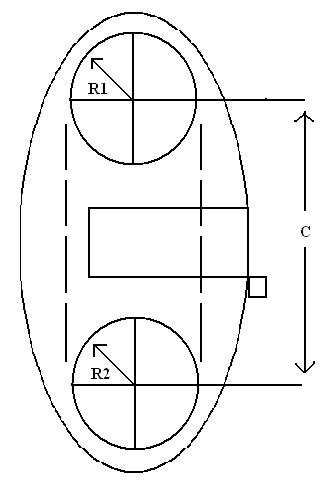

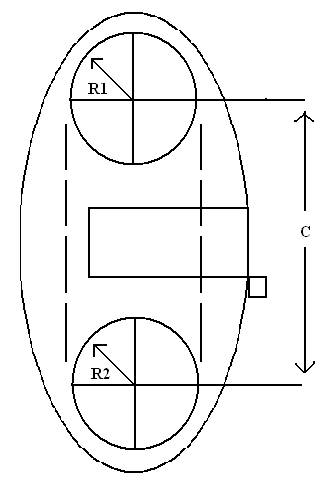

When it comes to measuring a bandsaw, we don’t whip out a regular ol’ tape measure! Instead, bandsaw size is determined by two key factors: the diameter of the wheels and the distance between them. These measurements play a crucial role in determining the size of the bandsaw, which can range from compact benchtop models to larger, more powerful models.

Now you might be wondering, why do these measurements matter? Well, the size of a bandsaw directly impacts its cutting capacity, meaning how wide and tall of a material it can handle. Understanding bandsaw size is essential for selecting the right tool that aligns with your woodworking needs. So, let’s roll up our sleeves and explore the fascinating world of bandsaw sizing in more detail!

How is Bandsaw Size Measured?

Bandsaws are versatile tools used in woodworking, metalworking, and other industries. When choosing a bandsaw, it’s crucial to understand how their size is measured. By understanding the measurements, you can ensure that the bandsaw you select will meet your needs. In this article, we will explore the different measurements used for bandsaws and how they impact their capabilities and performance.

1. Blade Length

The blade length is one of the essential measurements for a bandsaw. It refers to the total length of the bandsaw blade. To measure the blade length, start from the tip of one blade tooth, go around the bandsaw’s wheels, and end at the tip of the opposite tooth. This measurement determines the circumference of the bandsaw and affects the size of material it can cut.

A longer blade length allows for a larger cutting capacity, enabling you to work with wider and thicker materials. However, keep in mind that the blade length must match the bandsaw’s wheel diameter. It’s crucial to consult the bandsaw’s manual or manufacturer’s guidelines to ensure the correct blade length for your specific model.

2. Throat Capacity

The throat capacity of a bandsaw refers to the distance between the bandsaw blade and the vertical frame of the machine. It determines the maximum width of material that can pass through the bandsaw for cutting. Throat capacity is measured as the distance from the blade to the nearest edge of the frame.

For example, if a bandsaw has a throat capacity of 12 inches, it means you can cut materials that are up to 12 inches wide by moving them through the bandsaw’s throat. It’s important to note that the throat capacity also affects the maximum cutting height or depth of the bandsaw. A larger throat capacity generally allows for a larger cutting capacity and more versatility in the size of materials you can work with.

3. Cutting Capacity

The cutting capacity of a bandsaw refers to the maximum thickness of material that can be cut with the bandsaw. It is determined by the distance between the table or work surface and the upper blade guide, commonly referred to as the “resaw capacity” or “cutting height.”

A bandsaw’s cutting capacity is typically mentioned in terms of inches. For example, a bandsaw with a 12-inch cutting capacity can cut through materials up to 12 inches thick without any limitations. The cutting capacity is an important consideration when selecting a bandsaw, as it determines the size and thickness of materials you can work with.

4. Horsepower

The horsepower of a bandsaw refers to its motor power and determines the cutting performance and capabilities of the machine. Bandsaws with higher horsepower can handle more demanding tasks and cut through thicker and denser materials with ease. The horsepower rating indicates the maximum power output of the bandsaw’s motor.

When choosing a bandsaw, consider the type of materials you will be cutting and the level of intensity of your work. If you primarily work with softer woods or light materials, a lower horsepower bandsaw may suffice. However, if you frequently cut through hardwood or metal, a bandsaw with higher horsepower will provide smoother, more efficient cuts.

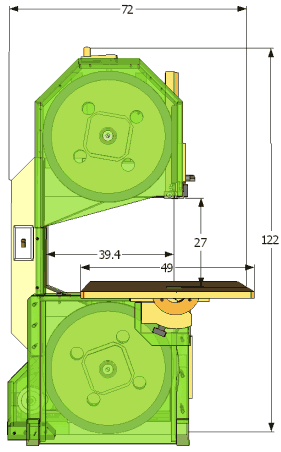

5. Table Size

The table size of a bandsaw refers to the dimensions of the surface on which the material rests during cutting. It is important to consider the table size when choosing a bandsaw, as it determines the amount of support and stability you have during the cutting process.

A larger table size provides more space for maneuvering and handling larger materials. It allows for better control and accuracy while cutting. Additionally, a larger table size can accommodate the use of auxiliary tools or guides for more intricate cuts and projects.

6. Weight and Portability

The weight of a bandsaw is an important consideration, especially if you need to move it frequently or have limited space in your workshop. Bandsaws can range in weight from portable benchtop models to heavy-duty industrial machines. Consider the weight of the bandsaw in relation to your needs and the accessibility of your workspace.

If you require a portable bandsaw, opt for a lighter model that can be easily transported. However, if stability and durability are crucial for your work, a heavier model with a robust frame and construction may be more suitable. Assess your specific requirements to determine the ideal weight and portability features for your bandsaw.

7. Additional Features

Apart from the fundamental measurements, bandsaws may come with additional features that can enhance their functionality and user experience. These features may include blade tensioning mechanisms, blade guides, dust collection systems, and miter gauges. Assess your specific needs and preferences to determine which additional features are essential for your work.

In conclusion, understanding how bandsaw size is measured is crucial for selecting the right tool for your woodworking or metalworking projects. By considering measurements such as blade length, throat capacity, cutting capacity, horsepower, table size, weight, and additional features, you can choose a bandsaw that will meet your performance requirements and offer optimal functionality in your workspace. Remember to consult the bandsaw’s manual or manufacturer’s guidelines for specific measurements and recommendations for your chosen model. Happy sawing!

Key Takeaways: How is Bandsaw Size Measured?

- 1. Bandsaw size is typically measured by the diameter of the wheels, which determines the cutting capacity and maximum stock thickness it can handle.

- 2. The bandsaw’s throat depth, measured from the blade to the vertical frame, determines the maximum width of material that can be cut.

- 3. Another important measurement is the distance between the blade and the table, known as the cutting height, which determines the thickness of material that can be cut.

- 4. Bandsaws can have different blade lengths, which affects the size of the workpiece that can be maneuvered around the blade.

- 5. It’s essential to consider the physical dimensions of a bandsaw, such as its height, width, and depth, to ensure it fits in your workshop space.

Frequently Asked Questions

Are you curious about how bandsaw size is measured? We’ve got you covered! Here are some common questions and answers that will help you understand how bandsaw size is determined.

1. What factors are considered when measuring bandsaw size?

When measuring the size of a bandsaw, there are a few key factors to consider. The two main measurements are the throat capacity and the size of the wheels. The throat capacity refers to the distance between the blade and the vertical frame of the bandsaw. It determines the maximum width of the material that can be cut. The size of the wheels, typically expressed in inches, indicates the diameter of the bandsaw’s wheels. The wheel size affects the blade length and the overall cutting capacity of the bandsaw.

Other factors to consider include the cutting height, which is the vertical distance between the table and the upper blade guides. The cutting height determines the maximum thickness of the material that can be cut. Additionally, the cutting depth, or the distance from the table to the rear blade guides, determines the maximum depth of a cut that a bandsaw can make.

2. How is the throat capacity of a bandsaw measured?

The throat capacity of a bandsaw is measured by determining the distance between the blade and the vertical frame of the bandsaw. This measurement is typically expressed in inches. It is important to note that the throat capacity is the maximum width of the material that can be cut on the bandsaw. For example, if a bandsaw has a throat capacity of 14 inches, it means it can cut materials up to 14 inches wide.

When measuring the throat capacity, it is essential to consider the resaw capacity as well. The resaw capacity is the maximum height of a workpiece that can be resawn on the bandsaw. This measurement is determined by the distance between the table and the upper blade guides. Understanding the throat capacity and resaw capacity will help you determine whether a bandsaw is suitable for your specific cutting needs.

3. How does the size of the wheels affect a bandsaw’s cutting capacity?

The size of the wheels on a bandsaw plays a significant role in determining its cutting capacity. The diameter of the wheels directly affects the length of the blade that can be installed on the bandsaw. Larger wheels allow for longer blades, which increases the cutting capacity of the bandsaw. On the other hand, smaller wheels restrict the length of the blade and, therefore, the maximum thickness of material that can be cut.

Additionally, the size of the wheels affects the blade tension. Larger wheels provide more tension, allowing the blade to stay in place and maintain its cutting accuracy. Smaller wheels may result in less tension, causing the blade to drift or veer off course during cutting. Therefore, it is essential to consider the size of the wheels when selecting a bandsaw, as it directly impacts the cutting capacity and overall performance of the machine.

4. What is the significance of cutting height in a bandsaw?

The cutting height in a bandsaw refers to the vertical distance between the table and the upper blade guides. It determines the maximum thickness of the material that can be cut on the bandsaw. Understanding the cutting height is crucial when choosing a bandsaw for specific cutting tasks, as it directly affects the types of materials you can work with.

A bandsaw with a larger cutting height will be able to handle thicker materials, allowing for greater versatility in your woodworking or metalworking projects. However, it’s important to remember that the cutting height is not the only factor that determines the maximum thickness of material that can be cut. The throat capacity and the resaw capacity are also crucial measurements to consider when determining the overall cutting capacity of a bandsaw.

5. How is cutting depth measured on a bandsaw?

The cutting depth on a bandsaw is measured by determining the distance from the table to the rear blade guides. This measurement is essential as it determines the maximum depth of a cut that a bandsaw can make. Similar to the cutting height, the cutting depth in a bandsaw is another important factor to consider when choosing the right machine for your needs.

The cutting depth is particularly important when working with thicker materials that require a deeper cut. If you often work with thick wood or metal pieces, you’ll want to select a bandsaw with a larger cutting depth to accommodate your projects. It’s also crucial to ensure that the cutting depth aligns with the throat capacity, resaw capacity, and other cutting specifications when making your decision.

Summary

Finding the right size bandsaw can be confusing, but it’s actually quite simple. When we talk about bandsaw size, we’re referring to the blade length. This measurement tells us how long the blade is from one end to the other. Smaller bandsaws have shorter blades, while larger ones have longer blades. So, if you need to cut larger materials, you’ll want a bandsaw with a longer blade. Just remember, bigger materials need a bigger bandsaw!

Also, it’s important to know that the blade length is not the only factor to consider when choosing a bandsaw. You’ll also want to think about the throat size, which determines the maximum width of the materials you can cut. Additionally, the horsepower of the motor plays a role in the bandsaw’s cutting ability. So, keep these factors in mind to find the perfect bandsaw size for all your cutting needs. Happy woodworking!