Have you ever wondered how drill press size is measured? Well, you’re in the right place! In this article, we’ll explore the ins and outs of measuring drill press size, so you can better understand this essential tool for woodworking and metalworking projects. Buckle up and get ready to dive into the world of drill press measurements!

When it comes to drill presses, size matters. But how exactly is drill press size determined? Stay with me, and we’ll unveil the mystery for you. Whether you’re a beginner or a seasoned DIY enthusiast, understanding drill press size is crucial for selecting the right tool for your projects. So let’s break it down and uncover the secrets behind drill press measurement methods!

Are you ready to demystify the process of measuring drill press size? Get ready for a deep dive into the world of drill presses, where we’ll explore the different ways this versatile tool is measured. From spindle travel to throat depth, we’ll cover it all. So, let’s get started on our journey to unlock the secrets of drill press size measurement!

The measurement of drill press size is determined by the distance from the center of the chuck to the front of the column. To measure the size, follow these steps:

- Position the drill press with the chuck fully retracted.

- Measure from the center of the chuck to the front of the column.

- Record the measurement in inches or millimeters.

By following these steps, you can accurately determine the size of a drill press.

How is Drill Press Size Measured?

When it comes to drill presses, size matters. But how exactly is drill press size measured? In this comprehensive guide, we will delve into the various factors used to determine the size of a drill press. From discussing the types of measurements to exploring the different components that contribute to the overall size, we aim to provide you with a clear understanding of how drill press size is determined. So, let’s get started and unlock the mysteries of drill press sizing!

The Different Types of Drill Press Measurements

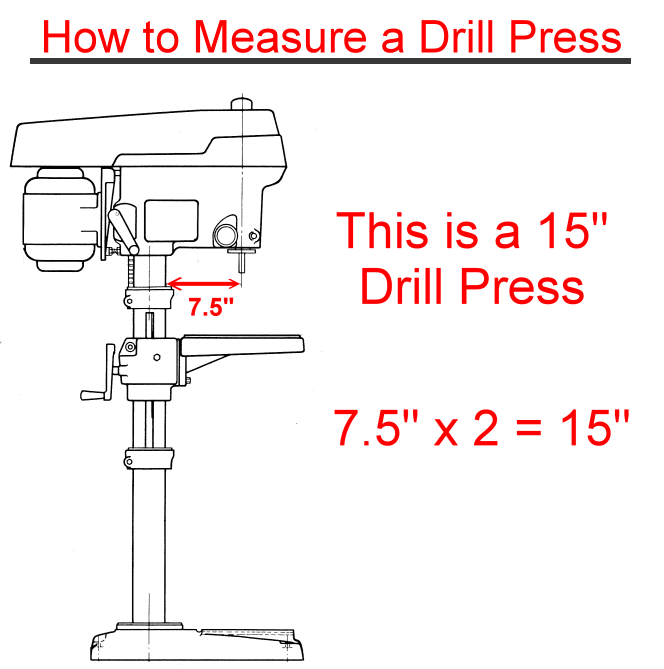

Measuring the size of a drill press involves several types of measurements. One of the most common ways to describe the size of a drill press is by referencing the swing, which determines the maximum diameter of the material that can be centered under the spindle. The swing is measured from the center of the spindle to the closest edge of the column, multiplied by two. Another important measurement is the spindle travel, which refers to the maximum depth that the spindle can travel vertically. Additionally, the distance between the spindle and the column, known as the throat depth, is another crucial measurement to consider when determining the size of a drill press.

It’s worth noting that drill press size can also be determined by the size of the motor, the height of the worktable, and the overall dimensions of the machine. All of these measurements contribute to the overall size of a drill press and should be taken into account when choosing the right one for your specific needs.

Factors Affecting Drill Press Size

The size of a drill press is influenced by several factors, including the purpose of the machine, the type of work it will be used for, and the available space in your workshop. Different industries and applications require different sizes of drill presses. For example, a small benchtop drill press with a compact size may be ideal for hobbyists or those with limited workspace, while a larger floor-standing drill press with a higher swing and throat depth may be more suitable for professional workshops or heavy-duty projects.

Consider the materials you will be working with as well. If you plan on drilling through thicker or harder materials, a larger drill press with more power and a greater spindle travel may be necessary. On the other hand, if you primarily work with smaller materials, a drill press with a smaller swing and throat depth may be more than sufficient.

Ultimately, the size of the drill press will depend on your specific needs and the demands of your projects. Assessing the various factors and considering the measurements mentioned earlier will help you determine the appropriate size for your drill press.

Swing: Determining the Size of a Drill Press

The swing of a drill press refers to the maximum diameter of material that can be centered under the spindle. It is one of the key measurements used to determine the size of a drill press. To find the swing, measure the distance from the center of the spindle to the closest edge of the column and multiply it by two. This will provide you with the swing measurement, which is typically expressed in inches.

The swing generally defines the overall capacity and versatility of a drill press. A larger swing means the drill press can handle larger materials and perform a wider range of drilling tasks. Keep in mind that the swing measurement refers to the distance between the spindle and the column, not the size of the worktable. Therefore, when considering the size of a drill press, it’s essential to take into account both the swing and the worktable dimensions to ensure compatibility with your projects.

Drill presses with larger swings are generally more versatile and can accommodate a wider range of materials. However, they are also typically larger and more expensive. It’s crucial to strike a balance between the size and features you require to meet your specific needs and preferences.

Spindle Travel: Exploring the Depth of a Drill Press

Another important measurement when it comes to drill press size is the spindle travel, which refers to the maximum depth that the spindle can travel vertically. The spindle is the rotating part of the drill press that holds and drives the drill bit. It moves up and down to penetrate the material being drilled.

Measuring the spindle travel is straightforward. It involves determining the distance between the top surface of the worktable and the bottom surface of the spindle when the spindle is fully raised. The spindle travel is generally expressed in inches and is an essential consideration, especially when drilling deep holes or working with materials that require a significant depth of penetration.

When choosing a drill press size based on the spindle travel, it’s important to consider the specific drilling tasks you will be performing. If you frequently work with materials that require deep drilling, a drill press with a larger spindle travel is necessary. On the other hand, if your projects involve primarily shallower holes, a drill press with a smaller spindle travel may suffice. It’s all about finding the right balance between the size and features that suit your drilling needs.

Throat Depth: Determining Reach and Flexibility

In addition to swing and spindle travel, throat depth is another essential measurement used to determine the size of a drill press. The throat depth is the distance between the spindle center and the column, measured horizontally. It determines the reach and flexibility of the drill press, especially when working with larger or irregularly shaped materials.

For most drill presses, the throat depth measurement is equal to half the swing measurement, as long as the worktable is centered on the column. However, some drill presses may have variations in throat depth due to design considerations or additional features.

The throat depth is particularly important when working with larger materials or performing tasks that require drilling holes near the edge. It determines how far you can position the workpiece away from the column while still maintaining stability and accuracy during drilling. If you often work with materials that require a larger throat depth, it’s essential to choose a drill press size that accommodates your specific needs.

Key Takeaways: How is Drill Press Size Measured?

- Drill press size is typically measured by the swing, which is the distance from the center of the chuck to the front support column.

- Another way to measure drill press size is by the throat depth, which is the distance from the front support column to the spindle center.

- Some drill press models also indicate their size by the maximum drilling capacity, which refers to the largest diameter hole it can drill.

- Understanding the drill press size is essential for choosing the right machine for your specific needs and projects.

- When considering drill press size, it is important to consider the space you have available in your workshop and the size of the materials you will be working with.

Frequently Asked Questions

Here are some commonly asked questions about how drill press size is measured:

1. What does the term “drill press size” refer to?

The term “drill press size” refers to the physical dimensions of a drill press, typically expressed as the distance between the center of the spindle and the column. This measurement determines the maximum size of workpiece that can be accommodated by the drill press.

Drill press size is an important consideration when choosing a drill press, as it determines the machine’s capabilities and the range of projects it can handle.

2. How is the drill press size measured?

Drill press size is measured by the distance between the center of the spindle and the column, known as the “throat depth.” This measurement is typically given in inches or millimeters.

To measure the throat depth of a drill press, you would measure from the center of the spindle to the closest point on the column. This measurement is often provided by the manufacturer or can be measured manually using a measuring tape or calipers.

3. What is the significance of drill press size?

The size of a drill press is significant because it determines the maximum size of workpiece that can be drilled or machined. A larger throat depth allows for drilling larger holes and working on larger workpieces.

When choosing a drill press, it’s important to consider the type and size of projects you plan to work on. If you frequently work with larger materials, you may need a drill press with a larger throat depth to accommodate those projects.

4. Are there different sizes of drill presses available?

Yes, there are drill presses available in a range of sizes to suit different needs. The size of a drill press can vary based on factors such as the throat depth and table size.

Smaller benchtop drill presses are compact and portable, making them suitable for smaller projects. Floor-standing drill presses, on the other hand, often have larger throat depths and more powerful motors, making them better suited for heavy-duty applications or larger workpieces.

5. Can the drill press size be adjusted?

The size of a drill press, specifically the throat depth, is typically fixed and cannot be adjusted. However, some drill presses may offer adjustable table heights, allowing for greater versatility in terms of the workpiece size that can be accommodated.

If you require a drill press with a larger throat depth, it would be necessary to choose a model with those specific dimensions rather than attempting to adjust the size of an existing drill press.

Summary

When it comes to measuring the size of a drill press, you need to consider two main factors: the swing and the throat depth. The swing is the maximum distance from the spindle center to the support column, while the throat depth is the distance from the support column to the spindle center. The bigger the swing and throat depth, the larger the workpieces you can handle with the drill press.

You should also remember that the size of a drill press is not determined by the length of the drill bit it can accommodate. The drill bit size that a specific drill press can handle depends on its chuck capacity. So, when choosing a drill press, focus on the swing and throat depth to ensure it can handle your project needs.