So you want to know how a jig saw works? Well, you’re in luck because I’m here to break it down for you in a way that’s easy to understand.

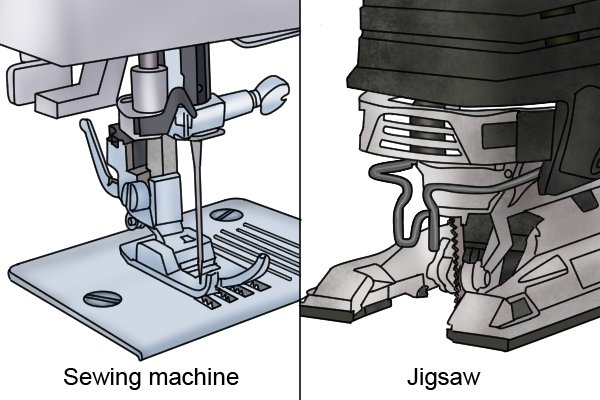

Imagine you have a puzzle, and you need to put all the pieces together to see the big picture. A jig saw works in a similar way. It’s a power tool that helps you cut different materials, like wood or plastic, into intricate shapes and curves.

The secret to its cutting magic lies in its blade, which moves up and down really fast. This up-and-down motion, combined with your careful guidance, allows you to create smooth and precise cuts. So, let’s dive deeper into the inner workings of this mighty tool!

How a Jig Saw Works: The Ultimate Guide

Jig saws are versatile and powerful tools that are essential for any woodworking enthusiast or DIY enthusiast. Whether you’re cutting intricate shapes or making straight cuts, a jig saw can get the job done with precision. But have you ever wondered how these remarkable machines work? In this article, we will delve into the inner workings of a jig saw, exploring the components, mechanisms, and operation that make it such a valuable tool in any workshop.

The Anatomy of a Jig Saw

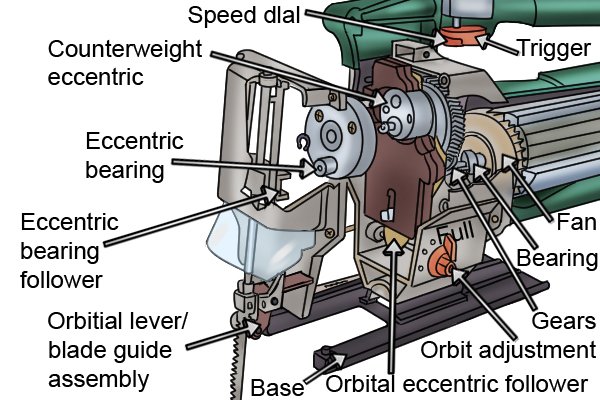

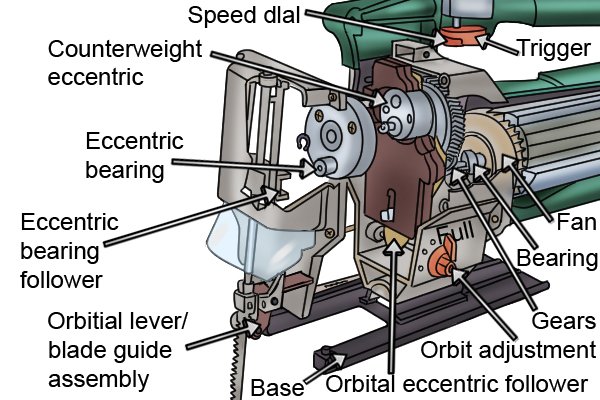

Before we dive into how a jig saw works, let’s take a closer look at its anatomy. A typical jig saw consists of several key components that work together to achieve precise and controlled cutting. Understanding these parts will help you grasp the inner workings of the tool and how they contribute to its functionality.

The Motor

The motor is the heart of the jig saw, providing the power required to drive the blade. Most modern jig saws are equipped with electric motors, which can be either corded or cordless. Corded jig saws are powered directly from an electrical outlet, while cordless options rely on rechargeable batteries. The motor’s power and speed can vary depending on the model, with higher-end jig saws offering more control and cutting power.

Inside the motor, there are a set of rotating magnets that create a magnetic field. When electricity flows through the motor’s coils, it interacts with the magnetic field, causing the motor shaft to rotate. This rotational motion is what drives the jig saw’s blade, allowing it to cut through various materials.

The motor is typically located near the grip of the jig saw, ensuring a comfortable and balanced feel during operation. Some jig saws also feature variable speed control, allowing users to adjust the blade’s cutting speed to match the material being cut.

The Blade Mechanism

The blade mechanism is responsible for securing the blade in place and providing the necessary movement for cutting. In a jig saw, the blade is held by a blade clamp, which can be tightened to prevent any movement during operation. Different jig saw models use various types of blade clamps, including tool-less clamps that allow for quick and easy blade changes.

Once the blade is secured, it moves up and down in a reciprocating motion. This movement is achieved through a combination of an eccentric shaft and a linkage system. The eccentric shaft converts the rotary motion of the motor into a back-and-forth motion, while the linkage system transfers this motion to the blade. Some jig saws also offer orbital action, which adds a slight elliptical movement to the blade, enhancing cutting efficiency.

A guide roller or shoe is also attached to the blade mechanism, ensuring stability and preventing the blade from wandering off course during cutting. The guide roller or shoe can be adjusted to achieve different cutting angles or depths, depending on the user’s needs.

The Base Plate

The base plate, also known as the shoe, provides a stable surface for the jig saw to rest on while cutting. It is usually made of metal or plastic and features a flat or curved shape to accommodate different cutting angles. The base plate is essential for maintaining the stability and accuracy of the cuts, allowing users to achieve precise results.

Some jig saws also have a beveling capability, allowing the base plate to tilt at an angle. This feature is particularly useful when making beveled cuts or cutting curves. The beveling angle can usually be adjusted by loosening a locking lever or knob located on the base plate.

The Dust Extraction System

Woodworking can generate a significant amount of dust and debris, which can hinder visibility and affect cutting accuracy. To combat this, many jig saws come equipped with a dust extraction system. This system typically consists of a dust port or nozzle that can be connected to a vacuum cleaner or dust extraction device.

When the jig saw is in use, the dust extraction system sucks up the generated dust and particles, preventing them from obstructing the view of the cutting line. This not only improves visibility but also helps keep the work area clean.

Some jig saws may feature a built-in dust collection bag instead of a dust extraction system. The bag collects the dust and debris as you cut, reducing the need for external vacuuming.

Power Source and Controls

…

The Benefits of Using a Jig Saw

Precision Cutting

…

Versatility

…

Efficient Curved Cutting

…

Control and Maneuverability

…

Easy Blade Changes

…

Ability to Cut Various Materials

…

Less Noise and Vibration

…

Portability and Convenience

…

Enhanced Safety Features

…

Tips for Using a Jig Saw

Choose the Right Blade

…

Secure the Workpiece

…

Start Slow and Steady

…

Follow the Cutting Line

…

Practice on Scrap Material

…

Jig Saw vs. Other Power Saws

Jig Saw vs. Circular Saw

…

Jig Saw vs. Scroll Saw

…

Jig Saw vs. Band Saw

…

Jig Saw vs. Reciprocating Saw

…

Maintenance and Care for Your Jig Saw

…

Choosing the Right Jig Saw for You

…

Common Jig Saw Techniques

…

Frequently Asked Questions About Jig Saws

…

Conclusion

In conclusion, a jig saw is a versatile and powerful tool that can make precise cuts and handle various materials. By understanding its anatomy and operation, you can unleash the full potential of this tool. Remember to choose the right blade for the job, secure your workpiece, and practice proper technique for the best results. Whether you’re a woodworking enthusiast or a DIY hobbyist, a jig saw should be a staple in your toolbox.

Key Takeaways: How Jigsaw Works

- Jigsaw is a power tool used for cutting curves or irregular shapes in various materials.

- It consists of a motor that moves a small, thin blade up and down at high speed.

- When cutting, the blade moves in a reciprocating motion, making it easier to maneuver in tight spaces.

- The blade is guided by a shoe or a base plate, which helps keep the cut straight and accurate.

- Jigsaw blades can be selected based on the material being cut, such as wood, metal, or plastic.

Frequently Asked Questions

Are you curious about how a jig saw works? We’ve got you covered! Check out these common questions and their answers to learn more about this versatile tool.

1. What is a jig saw used for?

A jig saw is a powerful handheld tool used for cutting various materials, such as wood, metal, and plastic. Its primary purpose is to cut intricate shapes or curves that other saws, like a circular saw or a table saw, cannot easily accomplish. With the right blade, a jig saw can make cuts in tight corners, create beveled edges, and even perform plunge cuts.

The beauty of a jig saw lies in its versatility. It is a go-to tool for DIY enthusiasts, craftsmen, and professionals in woodworking, metalworking, and construction industries. Whether you need to make a curved cut in a piece of furniture or create a custom design in a wooden sign, a jig saw is the perfect tool for the job.

2. How does a jig saw work?

A jig saw operates by using a reciprocating motion to move the saw blade up and down rapidly. The blade attaches to a motor that drives this motion using an eccentric mechanism. As the blade moves up and down, it cuts through the material placed underneath it.

The user controls the speed and direction of the blade’s movement by gripping the tool’s handle and guiding it along the desired cutting path. Jig saws often have variable speed settings, allowing users to adjust the cutting speed according to the material being cut and the desired level of precision.

3. What types of blades can I use with a jig saw?

Jig saws accept a wide variety of blades, each designed for specific materials and cutting applications. The most common types of blades include those for cutting wood, metal, plastic, laminate, and fiberglass. Additionally, there are specialized blades for tasks like making curved cuts, straight cuts, or beveled cuts.

When selecting a blade, it’s essential to consider the material you’ll be cutting and the type of cut you want to achieve. Using the appropriate blade for the job not only ensures clean and precise cuts but also prolongs the life of the blade and the efficiency of your jig saw.

4. Can I make straight cuts with a jig saw?

Yes, you can make straight cuts with a jig saw. While a jig saw is primarily known for its ability to create curved and intricate cuts, it can also make straight cuts. To achieve a straight cut, you can use a guide or a straightedge placed alongside the cutting line to provide support and maintain a straight path for the saw’s base plate.

It’s important to note that achieving perfectly straight cuts with a jig saw requires proper technique and practice. Keeping a steady hand, using a guide, and maintaining a consistent forward motion are key elements in obtaining clean and accurate straight cuts with a jig saw.

5. Are there any safety precautions I should take when using a jig saw?

While a jig saw is a versatile and useful tool, it’s crucial to prioritize safety when operating one. Here are a few important safety precautions to follow:

1. Wear appropriate safety gear: Always wear safety goggles or glasses to protect your eyes from flying debris, as well as ear protection and a dust mask if necessary.

2. Secure the material: Ensure the material you are cutting is firmly secured to prevent movement or slipping during the cutting process.

3. Use the right blade: Select a blade suitable for the material you’ll be cutting. Using the wrong blade can result in decreased cutting performance and potential accidents.

4. Follow the manufacturer’s instructions: Familiarize yourself with the tool’s user manual to understand its specific features, recommended operating procedures, and any safety warnings.

By following these safety precautions and using your jig saw responsibly, you can enjoy its benefits while minimizing the risk of accidents or injuries.

Summary

A jigsaw is a cool tool that helps cut different shapes in materials like wood or metal. It has a blade that moves up and down very fast to slice through the material. You can change the blade depending on what you’re cutting. Just be careful and follow safety guidelines!

It’s important to choose the right blade, adjust the speed, and hold the jigsaw securely. Practice makes perfect! Happy jigsawing!