Welcome! Have you ever wondered how a lathe chuck works? Well, you’ve come to the right place! In this article, we’re going to delve into the fascinating world of lathe chucks and uncover the secrets behind their functionality.

Picture this: you have a piece of wood or metal that you want to shape into something amazing. A lathe chuck is an essential tool that holds your workpiece securely in place while it rotates. This rotation allows you to shape, cut, drill, or perform various operations on the material.

The way a lathe chuck works is quite ingenious. It consists of jaws that grip the workpiece tightly, securing it in position. As the lathe rotates, the chuck holds the workpiece firmly, ensuring that you have precise control over your cutting or shaping movements.

Now that we have a general idea, let’s dive deeper into the inner workings of a lathe chuck and explore its different types and applications. Get ready to discover how this remarkable tool can bring your woodworking or metalworking projects to life!

Are you curious about how a lathe chuck works? Let’s dive in!

Step 1: Start by selecting the appropriate chuck based on your project.

Step 2: Install the chuck onto the lathe spindle, ensuring it’s securely tightened.

Step 3: Insert the workpiece into the chuck jaws and tighten them using the chuck key.

Step 4: Turn on the lathe and adjust the speed as needed.

Step 5: Engage the lathe tool and begin shaping or cutting your workpiece.

With these steps, you’ll have a good understanding of how a lathe chuck works! Happy woodworking!

How Lathe Chuck Works: Exploring the Mechanics

Understanding Lathe Chucks

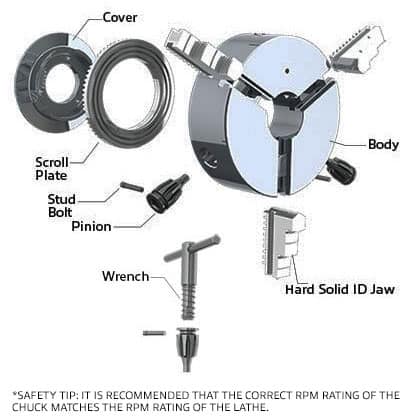

Lathe chucks are essential components of lathes, machines used for shaping and cutting workpieces. They are responsible for securely holding the workpiece in place while it rotates at high speeds. A lathe chuck consists of jaws, a spindle, and a chuck key. The jaws are the primary gripping mechanism, which can be adjusted to accommodate different sizes of workpieces. The spindle, connected to the lathe machine, rotates the chuck and the workpiece. The chuck key is used to tighten or loosen the jaws. This article will delve into the intricate workings of a lathe chuck and explain how it functions.

When a lathe chuck is mounted on the lathe machine and the workpiece is firmly held in place, the chuck begins to rotate as the machine is powered on. As the chuck rotates, the jaws move inwards or outwards, depending on the adjustments made using the chuck key. This movement allows for the secure gripping of the workpiece. The gripping force is crucial to prevent any slippage or movement of the workpiece during machining, ensuring precise and accurate cuts.

Lathe chucks come in various designs and configurations, including three-jaw chucks, four-jaw chucks, and six-jaw chucks. Each design has its own advantages and is suitable for different types of turning projects. The three-jaw chuck is the most common and provides self-centering capabilities, making it ideal for symmetrical workpieces. Four-jaw chucks allow for greater flexibility in gripping irregularly shaped or non-symmetrical workpieces. Six-jaw chucks offer even more gripping power and are often used for heavy-duty applications. Understanding the specific type of chuck and its configuration is essential for efficient and accurate machining.

The Mechanics of Lathe Chuck Operation

Lathe chuck operation involves the precise movement of the jaws to grip and release the workpiece. The chuck key is used to engage the jaws and control their position. To tighten or loosen the jaws, the chuck key is inserted into the slots on the periphery of the chuck and turned clockwise or counterclockwise, respectively. As the key is turned, it engages with a gear mechanism inside the chuck that translates the rotational motion into linear motion. This causes the jaws to move towards the center or away from it.

In a three-jaw chuck, each jaw is moved simultaneously to ensure that the workpiece remains centered. This self-centering feature is especially useful in applications where concentricity is critical. By contrast, in a four-jaw or six-jaw chuck, each jaw can be adjusted independently. This allows for greater flexibility in gripping non-symmetrical workpieces and compensating for any irregularities or inconsistencies.

It is important to note that when operating a lathe chuck, one should always follow proper safety precautions. Ensuring that the chuck key is securely fitted and that the jaws are properly aligned and tightened is crucial to prevent accidents. Additionally, regular maintenance and inspection of the chuck are essential to maintain its accuracy and prevent any wear and tear that may affect its gripping ability.

Benefits of Using a Lathe Chuck

Using a lathe chuck offers several advantages, making it an indispensable tool in the machining industry. One of the main benefits is its ability to securely hold the workpiece, allowing for precise and accurate machining. The grip provided by the chuck minimizes any slippage or movement, ensuring that the desired shape and dimensions are achieved.

Another advantage of using a lathe chuck is its versatility. With the ability to adjust the jaws, different sizes and shapes of workpieces can be accommodated, expanding the range of possible machining projects. The self-centering feature of three-jaw chucks also simplifies the setup process, saving time and effort in aligning the workpiece.

Moreover, lathe chucks are designed to withstand high-speed rotations, ensuring stability and reducing vibrations. This enhances the overall quality of the machining process and contributes to the longevity of the lathe chuck itself. The durability and reliability of lathe chucks make them a worthwhile investment for professional machinists and hobbyists alike.

Caring for a Lathe Chuck

To ensure the longevity of a lathe chuck and maintain its optimal performance, proper care and maintenance are essential. One crucial aspect of caring for a lathe chuck is regular cleaning and lubrication. Removing any accumulated dirt, dust, or debris from the chuck and applying lubrication to the moving parts helps prevent friction and corrosion.

Inspecting the chuck for any signs of wear or damage is also important. If the jaws or spindle are worn out or damaged, they should be replaced promptly to avoid compromising the gripping ability of the chuck. Regular tightening of the chuck jaws is necessary to prevent slippage during operation.

Additionally, it is advisable to store the chuck in a clean and dry environment when it is not in use. This helps protect it from potential damage and ensures that it remains in optimal condition. Following these care and maintenance practices will significantly extend the lifespan of the lathe chuck and ensure consistent performance.

Choosing the Right Lathe Chuck for Your Needs

Considerations for Selecting a Lathe Chuck

Choosing the right lathe chuck is essential for achieving the desired results in your machining projects. There are several factors to consider when selecting a lathe chuck:

- Workpiece Size: Evaluate the range of workpiece sizes you will be working with and ensure that the chuck you choose can accommodate them.

- Type of Workpiece: Consider the shape, weight, and material of the workpiece, as different chuck designs are better suited for specific types of workpieces.

- Machining Precision: If high precision is a requirement, opt for a chuck with self-centering capabilities and greater accuracy.

- Application: Determine the specific applications you plan to use the chuck for, such as general turning, turning between centers, or heavy-duty machining.

- Budget: Set a budget and look for a lathe chuck that offers the best value for your investment.

Different Types of Lathe Chucks

There are various types of lathe chucks available, each with its own advantages and limitations:

1. Three-Jaw Chucks

Three-jaw chucks are the most common and widely used type of lathe chuck. They provide self-centering capabilities, allowing for quick and easy setup. Three-jaw chucks are ideal for symmetrical workpieces and offer simplicity and convenience in gripping and turning operations.

2. Four-Jaw Chucks

Four-jaw chucks provide greater flexibility in gripping non-symmetrical or irregularly shaped workpieces. With independent adjustment of each jaw, four-jaw chucks allow for precise centering and enhanced versatility.

3. Six-Jaw Chucks

Six-jaw chucks offer even more gripping power and stability compared to their three and four-jaw counterparts. They are commonly used for heavy-duty machining applications and workpieces that require maximum security and rigidity.

4. Scroll Chucks

Scroll chucks are operated by a scroll plate mechanism, which moves the jaws simultaneously in a self-centering manner. They are suitable for a wide range of workpiece sizes and are typically used in applications where quick adjustments and repeated setups are required.

5. Independent Jaw Chucks

Independent jaw chucks allow for individual adjustment of each jaw, providing precise control over the gripping force and accommodating irregularly shaped workpieces. They are commonly used in applications that require fine-tuning and increased gripping accuracy.

Tips for Proper Usage of a Lathe Chuck

- Always ensure that the chuck key is securely fitted before operating the lathe.

- Regularly inspect the chuck jaws for any signs of wear or damage, and replace them when necessary.

- Clean the chuck after each use and apply lubrication to the moving parts to prevent friction and corrosion.

- Properly align and tighten the chuck jaws to avoid slippage during operation.

- Store the chuck in a clean and dry place when not in use to protect it from potential damage.

Common Lathe Chuck vs. Collet Chuck: Which is Right for You?

Comparing Lathe Chucks and Collet Chucks

When it comes to gripping and holding workpieces in a lathe, there are two main options: lathe chucks and collet chucks. While both serve the same purpose, they have distinct differences:

Lathe Chucks

Lathe chucks are versatile and can accommodate a wide range of workpiece sizes and shapes. They provide a secure grip and allow for easy adjustments. Lathe chucks are suitable for most turning operations, including general turning, facing, and threading.

Collet Chucks

Collet chucks are specialized clamping devices that utilize collets to grip the workpiece. These chucks are preferred when high precision and concentricity are crucial, as collets provide excellent gripping accuracy. Collet chucks are commonly used for delicate and precise machining operations, such as milling, grinding, and drilling.

Choosing between a Lathe Chuck and a Collet Chuck

When deciding between a lathe chuck and a collet chuck, consider the following factors:

- Workpiece Size: Lathe chucks are better suited for larger workpieces, while collet chucks excel at gripping small and delicate parts.

- Application: Identify the specific machining operations you will be performing. Lathe chucks are generally more versatile and suitable for a wide range of turning applications, while collet chucks are ideal for precise and delicate operations.

- Precision and Accuracy: If high precision and concentricity are paramount, a collet chuck is the preferred choice.

- Cost: Lathe chucks are typically more affordable compared to collet chucks, making them a practical option for those on a budget.

Maintaining and Troubleshooting Your Lathe Chuck

Maintenance Tips for Your Lathe Chuck

To ensure the longevity and optimal performance of your lathe chuck, follow these maintenance tips:

- Regularly clean the chuck to remove any debris or dirt that may affect its gripping ability.

- Inspect the jaws for wear or damage, and replace them if necessary.

- Lubricate the moving parts of the chuck to prevent friction and corrosion.

- Check the chuck key for any signs of wear or damage, and replace it if needed.

- Store the chuck in a clean and dry environment when not in use to protect it from potential damage.

Troubleshooting Common Issues with Your Lathe Chuck

If you encounter any issues with your lathe chuck, consider the following troubleshooting steps:

- If the chuck jaws are not gripping the workpiece securely, check that they are aligned and tightened properly. If necessary, clean the jaws and the workpiece for better grip.

- If the chuck jaws are stuck and not moving, ensure that the chuck key is inserted correctly and engage the gear mechanism properly.

- If the chuck is making unusual noises, inspect the moving parts for signs of damage or wear. Apply lubrication if necessary.

- If the chuck is not rotating smoothly, check the spindle and bearings for any issues, and inspect the chuck mounting for proper alignment.

- If you are still experiencing problems, consult the manufacturer’s instructions or seek professional assistance to diagnose and resolve the issue.

Conclusion

Understanding how a lathe chuck works is essential for anyone involved in machining operations. From its gripping mechanism to the precise movement of its jaws, a lathe chuck plays a crucial role in ensuring accurate and efficient turning processes. By selecting the right type of chuck, following proper maintenance practices, and troubleshooting any issues that may arise, you can maximize the performance and lifespan of your lathe chuck. Whether you are a professional machinist or a hobbyist, a well-maintained and well-utilized lathe chuck will contribute to the quality and success of your machining projects.

Key Takeaways – How Lathe Chuck Works?

- A lathe chuck is a device used to hold and secure workpieces in a lathe machine.

- It consists of jaws that can move inwards or outwards to grip or release the workpiece.

- The chuck is typically operated using a chuck key or a lever, allowing easy adjustment of the jaws.

- It enables the rotation of the workpiece, allowing the lathe to perform various operations like cutting, drilling, and shaping.

- The design of the chuck ensures a secure and stable grip on the workpiece, preventing slippage during machining.

Frequently Asked Questions

Welcome to our FAQ section, where we will answer some of the most common questions related to how a lathe chuck works. If you’re new to lathes or simply curious about how this important component operates, you’ve come to the right place. Read on to learn more!

How does a lathe chuck hold the workpiece securely?

A lathe chuck uses jaws to grip and hold the workpiece securely in place. The jaws are adjusted to fit the diameter of the workpiece and then tightened. This creates a strong grip that prevents the workpiece from moving during machining. Some chucks have three jaws, while others have four jaws, allowing for different types of workpieces to be held.

When the lathe spindle rotates, the chuck rotates along with it, ensuring that the workpiece also spins. This rotation allows for precise machining operations to be performed on the workpiece without it slipping or shifting position, resulting in accurate and consistent results.

Can a lathe chuck be used to hold different types of workpieces?

Yes, a lathe chuck can hold a wide variety of workpieces, ranging from cylindrical shapes to irregularly shaped objects. The jaws of the chuck can be adjusted and tightened to accommodate different diameters, allowing for a secure grip. This versatility makes the lathe chuck a valuable tool in various machining applications.

Additionally, some lathe chucks have reversible jaws or interchangeable top jaws, further expanding their capabilities. By changing the jaws, the chuck can securely hold different types of workpieces, providing flexibility and efficiency in the machining process.

What are the different types of lathe chucks available?

There are several types of lathe chucks available, each with its specific features and applications. The most common types include three-jaw chucks, four-jaw chucks, and collet chucks.

Three-jaw chucks are commonly used when working with cylindrical workpieces as they provide a stable grip and are quick to adjust. Four-jaw chucks, on the other hand, are preferred for irregularly shaped workpieces as they allow for better centering and balancing. Collet chucks are used when precise concentricity is required, such as in high-precision machining.

How do you change the jaws on a lathe chuck?

To change the jaws on a lathe chuck, follow these simple steps:

1. Ensure the chuck is securely mounted on the lathe spindle and the lathe is turned off.

2. Loosen the jaw retaining screws or other locking mechanisms.

3. Gently remove the existing jaws, taking care not to damage them.

4. Place the new jaws in the chuck, aligning them properly with the jaw slots.

5. Tighten the jaw retaining screws or locking mechanisms evenly on all jaws.

6. Double-check that the jaws are properly seated and securely tightened before using the chuck.

Remember, always consult your specific lathe chuck’s manual for detailed instructions and safety precautions.

What are some safety tips when using a lathe chuck?

When working with a lathe chuck, it’s crucial to prioritize safety. Here are some important tips to keep in mind:

1. Always wear appropriate personal protective equipment (PPE), including safety glasses or goggles and protective gloves.

2. Ensure the lathe is properly set up and secured before operating the chuck.

3. When changing the jaws or adjusting the chuck, make sure the lathe is turned off and unplugged to prevent accidental starting.

4. Never reach into the chuck while it is rotating or attempt to adjust the jaws while the lathe is running.

5. Avoid wearing loose clothing or jewelry that can get caught in the rotating chuck.

6. Regularly inspect the chuck for any signs of wear or damage, and replace it if necessary to maintain safe operation.

By following these safety guidelines, you can minimize the risk of accidents and ensure a safe working environment when using a lathe chuck.

I disassembled a Lathe Chuck🧐🧐and here’s what I found…!😇😇| Lathe Chuck Working Animation..! 🤩🤩

Summary

So, to sum it up, a lathe chuck is a device used to hold and rotate an object while it is being worked on. It has jaws that can be adjusted to grip different sizes of objects. The chuck is attached to the spindle of the lathe and can be tightened or loosened to secure the object in place. When the lathe is turned on, the chuck spins the object, allowing for precise shaping and cutting.

In conclusion, a lathe chuck is an important tool in machining and woodworking. It provides a secure grip on the workpiece, allowing for accurate and efficient cutting and shaping. Understanding how the chuck works helps to ensure safe and effective use of the lathe, enabling users to create beautiful and precise pieces.