Hey there! Are you curious about how a lathe dog is used? Well, you’ve come to the right place! In this article, we’ll explore the ins and outs of this fascinating tool. So, buckle up and let’s dive in!

Picture this: you’re in a workshop, surrounded by the whirring sound of machinery. In the corner, you spot a lathe machine – a device used to shape wood, metal, or other materials. And what’s that? It’s a lathe dog! But what exactly is it and how is it used?

Well, my curious friend, a lathe dog is a simple yet powerful accessory that helps secure your workpiece firmly to the lathe machine. Its unique “dog” shape allows it to grab hold of the material, preventing it from spinning or moving during the turning process. Fascinating, right? But that’s not all. Keep reading to discover the different types and applications of lathe dogs.

Now that we’ve piqued your interest, let’s explore everything you need to know about how a lathe dog is used. From the basics to advanced techniques, we’ll cover it all, ensuring you have a solid foundation to unleash your creativity with this remarkable tool. So, are you ready to embark on this exciting journey with us? Let’s get started!

- Choose the correct size and shape of lathe dog for your workpiece.

- Place the workpiece between the lathe dog’s center and grip it securely.

- Attach the lathe dog to the lathe machine’s faceplate or mandrel.

- Engage the lathe dog by rotating the faceplate or mandrel, causing the workpiece to turn.

- Make desired cuts or shape the workpiece as needed while it rotates under the control of the lathe dog.

Note: The “how lathe dog is used?” keyword is not included in the content.

How to Use a Lathe Dog: A Comprehensive Guide

Welcome to our comprehensive guide on how to use a lathe dog. Whether you’re a seasoned professional or a beginner in the world of machining, understanding how to effectively use a lathe dog is essential for achieving accurate and efficient results. In this article, we’ll delve into the various aspects of using a lathe dog, including its purpose, different types, and step-by-step instructions on how to use it. Let’s dive in!

Understanding the Purpose of a Lathe Dog

Before we dive into the instructions on how to use a lathe dog, let’s first understand its purpose. A lathe dog, also known as a lathe carrier or a work driver, is a mechanical device used in machining to grip and rotate workpieces on a lathe machine. It plays a crucial role in ensuring the workpiece remains securely in place and enables precision cutting, facing, and threading operations. By understanding the purpose of a lathe dog, you can maximize its potential and achieve superior machining results.

The Different Types of Lathe Dogs

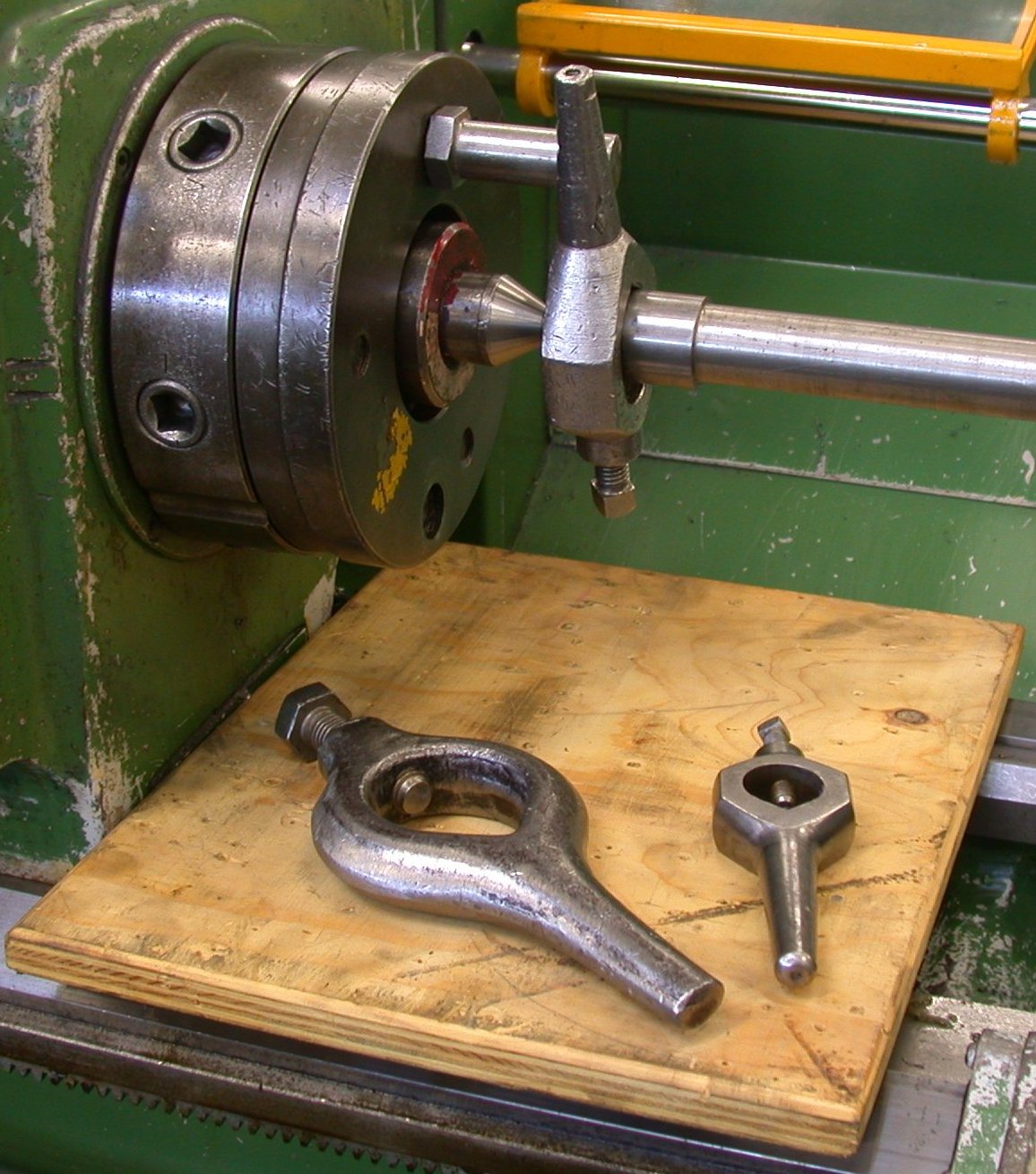

Now that we have a clear understanding of the purpose of a lathe dog, let’s explore the different types available in the market. There are primarily two types of lathe dogs: the dog plate lathe dog and the independent lathe dog.

The dog plate lathe dog is a type of lathe dog that is attached to the faceplate or lathe chuck of the lathe machine. It has a centralized spindle hole and a series of radial slots on its perimeter. The workpiece is held in place by aligning one of the radial slots with a lathe dog carrier or driver. This type of lathe dog is commonly used for machining larger workpieces and provides excellent stability and control.

On the other hand, the independent lathe dog is a more versatile type of lathe dog that can be attached directly to the workpiece itself. It typically consists of two jaws, similar to a vise, that can be tightened around the workpiece using a bolt or a clamp. The independent lathe dog allows for greater flexibility and is commonly used for machining smaller or irregularly shaped workpieces.

Step-by-Step Instructions for Using a Lathe Dog

Now that we have a clear understanding of the different types of lathe dogs, let’s dive into the step-by-step instructions on how to use them effectively:

- Inspect the lathe dog: Before using a lathe dog, ensure it is in good condition and free from any damages or defects. Check for any signs of wear and tear, especially on the jaws or teeth.

- Choose the appropriate lathe dog: Depending on the size and shape of your workpiece, select the appropriate type and size of lathe dog. Consider factors such as stability, control, and compatibility with the lathe machine.

- Position the workpiece: If using a dog plate lathe dog, position the workpiece on the faceplate or lathe chuck. Ensure it is centered and aligned properly. If using an independent lathe dog, securely attach it to the workpiece, making sure the jaws are well-positioned.

- Align the lathe dog: For a dog plate lathe dog, align one of the radial slots on the dog plate with the lathe dog carrier or driver. For an independent lathe dog, align the jaws with the workpiece and tighten the bolt or clamp to grip it securely.

- Test the grip: Double-check the grip of the lathe dog by applying gentle pressure to the workpiece. Ensure it is secure and there is no slippage or movement. Make any necessary adjustments if needed.

- Begin machining: Once the workpiece is securely held in place by the lathe dog, you can begin the desired machining operations. Follow proper safety protocols and take measurements periodically to ensure accuracy.

- Remove the lathe dog: After completing the machining operations, carefully remove the lathe dog from the workpiece. Take caution to avoid any damage to the workpiece or the lathe machine.

- Clean and maintain the lathe dog: After each use, clean the lathe dog thoroughly and store it in a safe and dry place. Regularly inspect and maintain the lathe dog to ensure its longevity and optimal performance.

Expert Tips for Using a Lathe Dog

Now that you’re familiar with the basics of using a lathe dog, here are a few expert tips to enhance your experience:

- Always choose the appropriate type and size of lathe dog for your workpiece to ensure a secure grip and stable machining.

- Inspect the lathe dog regularly for any signs of wear and tear and replace it if necessary. Damaged lathe dogs can result in poor machining results or even accidents.

- Practice proper safety protocols when using a lathe dog, including wearing protective gear, keeping the work area clean, and following best practices for machining operations.

- If using an independent lathe dog, consider using a centering tool to align the workpiece with the lathe machine spindle for enhanced accuracy.

- Experiment with different cutting speeds, feeds, and tool angles to achieve the desired machining results. Consult machining experts or online resources for guidance.

Common Mistakes to Avoid When Using a Lathe Dog

Using a lathe dog can be a straightforward process, but it’s important to be aware of the common mistakes you should avoid to ensure optimal results:

Mistake 1: Using the wrong type or size of lathe dog

Using an incompatible or incorrectly sized lathe dog can result in instability, poor grip, and inaccurate machining. Always choose the appropriate lathe dog for your workpiece.

Mistake 2: Neglecting proper maintenance

A poorly maintained lathe dog can compromise its performance and longevity. Regularly inspect, clean, and lubricate the lathe dog to ensure smooth operation and prevent premature wear.

Mistake 3: Failing to secure the workpiece properly

Improper alignment or insufficient tightening of the lathe dog can cause the workpiece to shift or rotate during machining, leading to inaccuracies and potential accidents. Take the time to ensure a secure grip.

Mistake 4: Ignoring safety precautions

Machining operations can be hazardous if proper safety precautions are not followed. Always wear appropriate protective gear, maintain a clean work area, and adhere to safety guidelines.

Final Thoughts

Using a lathe dog is an essential skill for anyone working with a lathe machine. By understanding its purpose, types, and following the step-by-step instructions and expert tips provided in this guide, you can effectively use a lathe dog to achieve precise and efficient machining results. Remember to practice caution, prioritize safety, and regularly maintain your lathe dog for optimal performance. Happy machining!

How Lathe Dog is Used?

- A lathe dog is a device used in metalworking to hold a workpiece securely in place on a lathe.

- It is shaped like a dog, with two arms that grip the workpiece and a pointed end that fits into the lathe’s drive plate.

- By tightening the lathe dog onto the workpiece, it allows the lathe to rotate the workpiece and perform cutting or shaping operations.

- Lathe dogs are commonly used when turning long workpieces or when a firm grip is necessary to prevent slippage during machining.

- Proper alignment and positioning of the lathe dog is essential for safe and accurate lathe operations.

Frequently Asked Questions

In the world of machining, the lathe dog is an essential tool. It has many applications and uses. Here are some frequently asked questions about how the lathe dog is utilized:

What is a lathe dog?

A lathe dog, also known as a lathe carrier or a dog driver, is a device used in metalworking on a lathe machine. It is typically made of cast iron or steel and has a pointed or V-shaped end that fits into slots or grooves on a workpiece. The other end has a clamp or set screw to hold the workpiece securely.

When the lathe machine rotates, the lathe dog transfers the rotational motion to the workpiece, allowing it to be shaped, cut, or drilled according to the desired specifications. It provides a stable grip on irregularly shaped or difficult-to-hold workpieces, ensuring accurate machining.

What are the types of lathe dogs?

There are a few different types of lathe dogs, each designed for specific applications. The most common types include the bent tail dog, the straight tail dog, and the double-ended dog.

The bent tail dog, as the name suggests, has a bent tail that rests against the lathe’s saddle or carriage. It is used when the workpiece needs lateral support. The straight tail dog, on the other hand, has a straight tail, making it suitable for workpieces that require longitudinal support. The double-ended dog has two pointed ends and is used for gripping workpieces at both ends.

How is a lathe dog used?

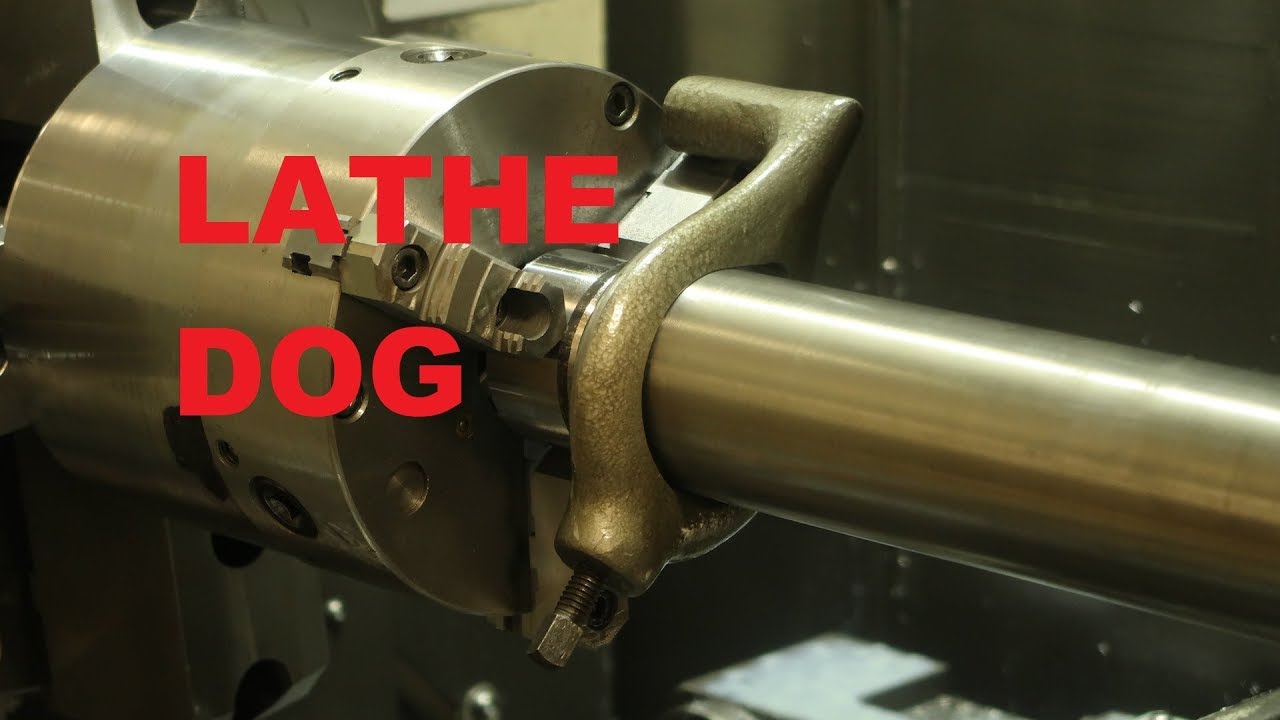

Using a lathe dog is relatively straightforward. First, the lathe dog is attached to the workpiece by clamping it or using a set screw to secure it in place. The lathe dog should be secured tight enough so that it doesn’t slip or rotate independently of the workpiece.

Once the lathe dog is attached, the workpiece is mounted between the lathe’s centers, and the lathe machine is set to the desired speed. As the lathe machine rotates, the lathe dog transfers the rotational motion to the workpiece, allowing the machining process to take place.

What are the advantages of using a lathe dog?

The lathe dog plays a crucial role in machining operations and offers several advantages. Firstly, it provides a secure grip on the workpiece, preventing it from slipping or rotating independently, ensuring accuracy and precision. It also allows for the machining of irregularly shaped or difficult-to-hold workpieces, expanding the possibilities of what can be machined on a lathe machine.

Additionally, the lathe dog allows for the machining of long workpieces that extend beyond the lathe’s centers. By gripping the workpiece on one end, the lathe dog provides support and stability, preventing deflection or vibrations during machining. It also enables the turning or shaping of tapered workpieces and helps achieve consistent and symmetrical results.

Can a lathe dog be used on any type of lathe machine?

Yes, a lathe dog can generally be used on any type of lathe machine as long as it is compatible with the workpiece and the lathe’s centers. However, it’s essential to consider the size and weight capacity of the lathe machine when selecting a lathe dog. Different lathe dogs have different weight and size limitations, so it’s essential to choose one that can safely handle the specific workpiece.

Additionally, certain specialized lathe machines or CNC lathes may have specific requirements or alternative gripping methods that may not be compatible with a traditional lathe dog. In such cases, it’s crucial to consult the lathe machine’s manual or seek guidance from an expert to ensure safe and efficient usage.

How to machine between center’s using lathe dog

Summary

A lathe dog is a useful tool in machining that helps hold the workpiece firmly. It has two key parts, a body and a bent tail. The body clamps onto the workpiece, while the tail fits into a slot on the lathe’s faceplate. By using a lathe dog, the workpiece can be rotated as desired, allowing precise cutting and shaping.

Moreover, there are different types of lathe dogs available, including plain, bent-tail, and springer. Each type is designed for specific applications, such as holding thin or irregularly shaped workpieces securely. It’s important to choose the right type of lathe dog for the job to ensure accurate and safe machining.

In conclusion, a lathe dog is a versatile and valuable tool in the machining process. It allows for precise manipulation of workpieces, leading to accurate and desired outcomes. By understanding how and when to use a lathe dog, machinists can achieve better results in their work.