When it comes to machining processes, one machine stands out as a true essential: the lathe machine. But what exactly makes the lathe machine so important? In this article, we’re going to explore the ins and outs of how the lathe machine plays a crucial role in the world of manufacturing. So, if you’ve ever wondered how this powerful tool shapes the things we use every day, keep reading!

You may be wondering, “What exactly is a lathe machine?” Well, think of it as a master of transformation. The lathe machine takes raw materials, like metal or wood, and carves them into precise, complex shapes. It’s like a sculptor, but instead of working with clay or stone, it works with spinning objects and cutting tools. The result? Intricate parts, perfect for everything from engines to furniture.

So, why is the lathe machine so important? It boils down to its versatility and precision. Whether it’s creating symmetrical designs or adding threads to a bolt, the lathe machine does it all. With its ability to spin, cut, drill, and shape, it’s a powerful tool that manufacturers rely on to bring their ideas to life. So, next time you see a perfectly formed metal or wooden object, remember that it’s likely the work of a lathe machine in action. ”

How Lathe Machine is Important for the Machining Process

Lathe machines are essential tools in the field of manufacturing and machining. These versatile machines play a crucial role in shaping and cutting various materials, making them indispensable in industries such as automotive, aerospace, and construction. In this article, we will explore the significance of lathe machines in the machining process and understand their various applications.

The Basics of Lathe Machines

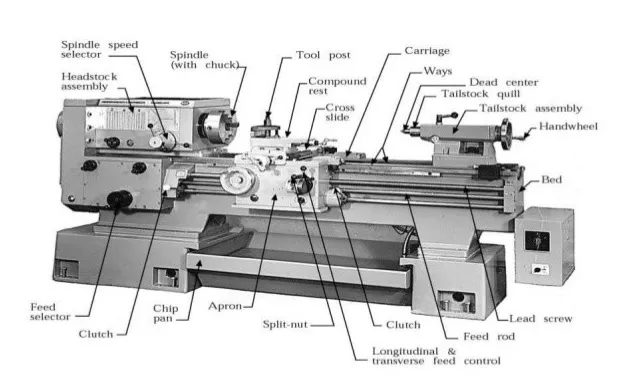

A lathe machine is a powerful tool used to rotate a workpiece on its axis to perform various operations such as cutting, drilling, facing, threading, and turning. The primary component of a lathe machine is the spindle, which holds and rotates the workpiece. The cutting tool is mounted on a toolpost that can move horizontally and vertically, allowing precise shaping and machining of the workpiece.

One of the key advantages of lathe machines is their versatility. They can work with a wide range of materials, including metal, wood, and plastic, making them suitable for various applications. Whether it’s creating intricate metal parts or turning wooden furniture components, lathe machines provide precision and accuracy in the machining process.

The Importance of Lathe Machines in Manufacturing

1. Shaping and Turning: Lathe machines excel in turning operations, which involve shaping cylindrical workpieces to a desired diameter and length. This is crucial in the manufacturing of components such as shafts, pins, and crankshafts used in various industries. The ability to create smooth and symmetrical surfaces ensures proper functionality and structural integrity of the final products.

2. Thread Cutting: Lathe machines are widely used for cutting threads on bolts, screws, and other fasteners. This process, known as threading, requires precision and accuracy to ensure proper fit and functionality of the threaded components. Lathe machines offer various methods for thread cutting, including single-point threading, which creates precise threads with consistent pitch and diameter.

3. Facing and Taper Turning: The machining process often requires creating flat surfaces, known as facing, and creating tapered shapes, known as taper turning. Lathe machines can perform these operations smoothly and efficiently, ensuring proper fit and alignment of mating components. From engine cylinders to furniture legs, lathe machines provide the necessary precision for creating perfect facing and tapering.

The Applications of Lathe Machines

1. Automotive Industry: Lathe machines are extensively used in the automotive industry for manufacturing various components such as engine parts, brake discs, crankshafts, and camshafts. The ability to shape and turn metal with precision ensures the efficient operation of vehicles.

2. Aerospace Industry: In the aerospace industry, where precision and reliability are critical, lathe machines are used to manufacture components such as landing gear parts, turbine blades, and fuel nozzles. The ability to create complex shapes and maintain tight tolerances is indispensable in this industry.

3. Woodworking Industry: Lathe machines are also popular in the woodworking industry for turning wooden objects such as furniture components, decorative items, and artistic pieces. The ability to create intricate designs and smooth finishes makes lathe machines invaluable to woodworkers.

4. Prototyping and Small-Scale Production: Lathe machines are commonly used for prototyping and small-scale production. They offer the flexibility to produce a limited number of customized parts, allowing manufacturers to refine their designs and test their functionality before full-scale production.

5. Repair and Maintenance: Lathe machines are essential in repair and maintenance workshops, where they are used to restore worn-out or damaged components. By machining and reshaping the parts, lathe machines extend the lifespan of various machinery and equipment, saving time and money.

In conclusion, lathe machines are of utmost importance in the machining process. Their versatility, precision, and ability to work with various materials make them indispensable in industries ranging from automotive and aerospace to woodworking. With their significant applications and contributions in manufacturing, lathe machines continue to play a vital role in shaping the world around us.

Key Takeaways – How Lathe Machine is Important for Machining Process?

- A lathe machine is a crucial tool for shaping and machining various materials.

- It helps to create cylindrical shapes, threads, and intricate designs with precision.

- Lathe machines enable the production of parts for industries like automotive and aerospace.

- They aid in the repair and maintenance of equipment by fabricating replacement components.

- With the use of different attachments, lathe machines can perform various operations like turning, drilling, and milling.

Frequently Asked Questions

When it comes to the machining process, the lathe machine plays a crucial role. Here are some common questions about the importance of the lathe machine:

1. Why is a lathe machine important in the machining process?

A lathe machine is important in the machining process because it allows for the shaping and cutting of various materials. With its rotating workpiece, a lathe machine can perform operations such as turning, facing, tapering, and threading. This versatility makes it an essential tool in industries such as manufacturing, automotive, and construction. The lathe machine enables precision and accuracy for creating complex and intricate components.

Additionally, the lathe machine allows for the efficient removal of material, reducing waste and saving time in the machining process. Its ability to work on different types of materials, including metal, wood, and plastics, makes it a valuable asset in a wide range of industries.

2. What are the advantages of using a lathe machine in machining?

Using a lathe machine in machining brings several advantages. Firstly, it enables the production of precise and symmetrical components with tight tolerances. The lathe machine’s accuracy allows for the creation of intricate shapes and threads.

Secondly, the lathe machine increases productivity by enabling the simultaneous machining of multiple workpieces. This leads to faster production cycles and reduced turnaround times. Additionally, the lathe machine’s versatility allows for the creation of both simple and complex parts, catering to a wide range of machining needs. Finally, the lathe machine’s durability and longevity make it a cost-effective investment for businesses in the long run.

3. Can a lathe machine be used for both small-scale and large-scale production?

Yes, a lathe machine can be used for both small-scale and large-scale production. Whether you need to manufacture a single prototype or produce thousands of components, the lathe machine can accommodate various production volumes. Its versatility allows for both manual and automated operations, making it suitable for different production scales.

For small-scale production, the lathe machine provides precision and flexibility, allowing for the creation of intricate components. It is an ideal choice for custom-made or low-volume parts. On the other hand, for large-scale production, the lathe machine’s speed and efficiency make it an invaluable asset. It can handle high-volume manufacturing while maintaining quality and consistency.

4. How does a lathe machine contribute to cost savings in the machining process?

A lathe machine contributes to cost savings in the machining process in several ways. Firstly, its precision and accuracy minimize material wastage, reducing material costs. The lathe machine allows for efficient removal of material, optimizing resource utilization.

Secondly, the lathe machine’s versatility eliminates the need for multiple machines for different operations, reducing equipment costs. Its ability to perform various machining tasks, such as turning, drilling, and threading, streamlines the production process and eliminates the need for additional specialized equipment.

Lastly, the lathe machine’s durability and longevity reduce maintenance and replacement costs. With proper care and maintenance, a lathe machine can have a long lifespan, providing a cost-effective solution for machining needs.

5. Is it necessary to have a skilled operator to operate a lathe machine?

While having a skilled operator is beneficial, it is not always necessary to operate a lathe machine. Modern lathe machines are designed to be user-friendly and come with intuitive controls. Basic training and familiarization with the machine’s operation can enable operators to perform routine tasks efficiently.

However, for complex operations and achieving the highest level of precision, having a skilled operator is recommended. Skilled operators can leverage the lathe machine’s capabilities to its fullest potential, ensuring optimal performance and quality. They can also troubleshoot any issues that may arise during operation, minimizing downtime. Investing in training programs and continuous skill development for operators can enhance the overall efficiency and productivity of the lathe machine.

Summary

The lathe machine is really important in the machining process. It helps shape and cut materials like wood and metal. By rotating the material against a cutting tool, it creates precise shapes and smooth finishes. With this machine, we can make things like furniture, parts for cars, and even parts for machines. It is a versatile tool that is used in various industries and is essential for creating many of the things we use every day.