Are you curious about the lifespan of carbide lathe tools? Well, you’ve come to the right place! In this article, we’ll uncover the answer to the burning question: “How long do carbide lathe tools last?”

Let’s dive right in. Carbide lathe tools are known for their durability and long-lasting performance. Thanks to their composition of tungsten carbide, a tough and wear-resistant material, these tools can withstand the demands of heavy-duty machining tasks.

But just how long can you expect your carbide lathe tools to last? It depends on various factors, such as the intensity of use, the type of material being machined, and the maintenance routine.

So, if you’re eager to learn more about the lifespan of carbide lathe tools and gain some valuable insights, keep reading! You’ll discover practical tips on maximizing their longevity and get the most out of your machining projects. Let’s get started!

Carbide lathe tools can last significantly longer than traditional high-speed steel tools. Thanks to their high hardness and wear resistance, carbide tools can withstand heavy usage and maintain their cutting edge. On average, carbide lathe tools can last 10 to 20 times longer than high-speed steel tools. However, the lifespan of carbide tools varies depending on several factors such as the material being machined, the cutting conditions, and the quality of the tool. Regular maintenance and proper usage can extend the life of carbide lathe tools even further.

How Long Do Carbide Lathe Tools Last?

Carbide lathe tools are an essential component of any woodworking or metalworking workshop. They offer durability and precision, allowing for clean and efficient cuts. However, like any tool, the lifespan of carbide lathe tools is not indefinite. In this article, we will explore the factors that influence the longevity of carbide lathe tools and provide tips for maximizing their lifespan.

The Quality of the Carbide

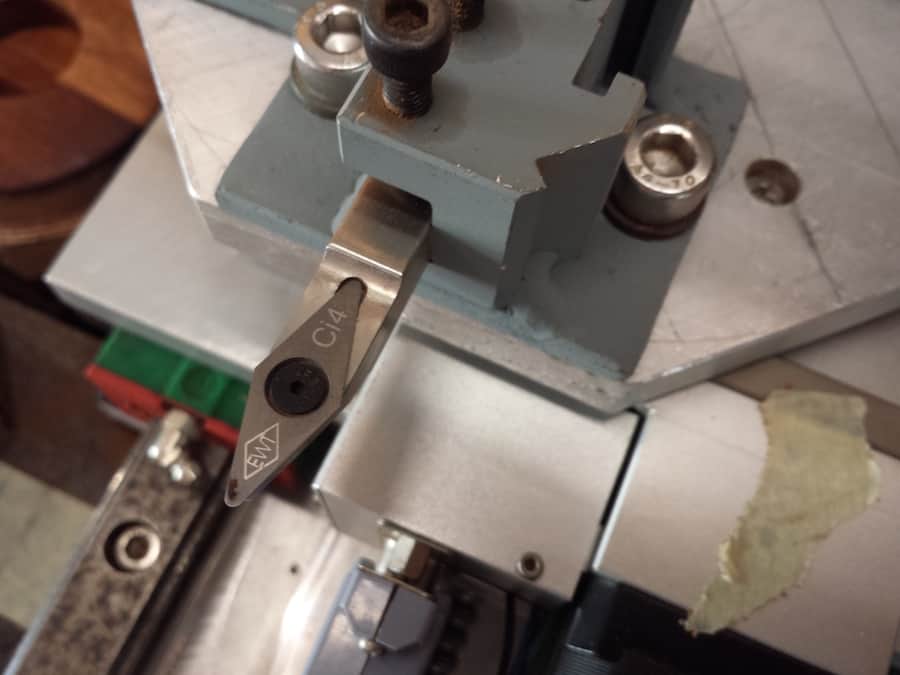

The quality of the carbide used in the lathe tools plays a significant role in determining how long they will last. Carbide comes in various grades, and higher-grade carbide tends to be more durable and resistant to wear. When purchasing carbide lathe tools, it is crucial to opt for tools made from high-quality carbide. While these tools may be more expensive initially, they will last longer and provide better performance in the long run.

Furthermore, the manufacturing process used to create the carbide tools can also impact their lifespan. Tools that are precision-ground and heat-treated tend to be more durable and capable of withstanding the rigors of heavy use. It is worth investing in well-manufactured carbide lathe tools to maximize their lifespan and ensure optimal performance.

Lastly, the design of the carbide lathe tools can also affect their longevity. Tools that are designed with reinforced cutting edges and proper chip breakers are less prone to chipping, dulling, or breaking. When choosing carbide lathe tools, consider their design features and how they contribute to the overall durability of the tools.

Maintenance and Care

Proper maintenance and care are essential for prolonging the lifespan of carbide lathe tools. Here are some tips to keep in mind:

- Regularly inspect your carbide lathe tools for any signs of wear, such as chipped edges or dullness. Replace any tools that are beyond repair.

- Keep your lathe tools clean and free from debris. After each use, remove any residue or buildup by wiping the tools with a clean cloth.

- Store your carbide lathe tools in a dry and temperature-controlled environment to prevent rust or corrosion.

- Sharpen your lathe tools regularly to maintain their cutting performance. Use a sharpening stone or a dedicated sharpening system designed for carbide tools.

- Use cutting lubricants or coolant when working with your lathe tools to minimize heat buildup and reduce tool wear.

By following these maintenance practices, you can significantly extend the lifespan of your carbide lathe tools and ensure their consistent performance over time.

Frequency and Intensity of Use

The frequency and intensity of use will naturally affect how long carbide lathe tools last. Heavy and constant use will lead to faster wear and dulling of the cutting edges. On the other hand, occasional and lighter use will result in a longer lifespan for the tools.

If you frequently work with your lathe tools or undertake demanding projects, it is important to monitor their condition regularly and address any signs of wear promptly. By doing so, you can prevent further damage and maintain the tools in optimal working condition for as long as possible.

Additionally, it is worth noting that different materials and cutting applications can also impact how long carbide lathe tools last. Harder materials and more abrasive cutting tasks will naturally wear down the tools faster compared to softer materials and lighter cutting tasks. When working on challenging projects, consider using specialty carbide tools designed specifically for those applications.

Cost-Effective Choice

When it comes to evaluating the lifespan of carbide lathe tools, it is essential to consider the cost-effectiveness of the investment. While higher-quality carbide tools may be more expensive initially, they offer a longer lifespan and superior performance compared to lower-quality alternatives.

By opting for durable, well-manufactured carbide tools and providing proper maintenance and care, you can maximize the lifespan of your lathe tools and minimize the need for frequent replacements. Ultimately, this leads to cost savings and ensures that you can continue to enjoy the benefits of precise and efficient cutting with your lathe.

Choosing the Right Carbide Lathe Tools

The type of carbide lathe tools you choose can significantly impact their lifespan. Different tools are designed for specific applications, so it is important to select the right tool for your needs. Consider factors such as tool geometry, cutting edge design, and coating options.

When choosing carbide lathe tools, reputable manufacturers are a reliable choice as their products are often manufactured to high standards. Additionally, reading customer reviews and seeking recommendations from experienced woodworkers or metalworkers can provide valuable insights into the longevity and performance of specific carbide lathe tools.

Remember, the longevity of carbide lathe tools is a combination of factors, including the quality of the carbide, maintenance and care, frequency and intensity of use, and selecting the right tools for the job. By considering these factors and implementing best practices, you can ensure that your carbide lathe tools last as long as possible, allowing you to achieve precise and exceptional results in your woodworking or metalworking projects.

Key Factors Affecting the Lifespan of Carbide Lathe Tools

While we have discussed several factors that influence the longevity of carbide lathe tools in the previous sections, it is important to highlight the key factors that have the most significant impact. By understanding these factors, you can make informed decisions when purchasing and using carbide lathe tools.

Quality of the Carbide

The quality of the carbide used in the tools is crucial. Higher-grade carbide is more durable and resistant to wear, leading to a longer tool lifespan.

Maintenance and Care

Regular maintenance and proper care, including cleaning, sharpening, and storage, can significantly prolong the lifespan of carbide lathe tools.

Frequency and Intensity of Use

The more frequently and intensively the tools are used, the faster they will wear down. Monitoring tool condition and addressing wear promptly is essential.

Material and Cutting Applications

Harder materials and more abrasive cutting tasks will wear down carbide tools faster. Specialty carbide tools for specific applications can be beneficial.

Maximizing the Lifespan of Carbide Lathe Tools

In addition to the factors discussed above, there are further steps you can take to maximize the lifespan of your carbide lathe tools. By following these tips, you can ensure that your tools last as long as possible.

Proper Cutting Technique

Using the right cutting technique can minimize wear and tear on your tools. It is important to maintain a steady and consistent feed rate and avoid unnecessary pressure that can cause chipping or breaking of the tool.

Tool Rotation

Rotating your carbide lathe tools regularly can distribute the wear more evenly and extend their overall lifespan. By using different sections of the cutting edge, you can avoid excessive wear on specific points.

Using Cutting Lubricants and Coolant

Using cutting lubricants, such as oils or coolants, can reduce friction and heat buildup during cutting. This helps to minimize tool wear and prolong the lifespan of your carbide lathe tools.

Conclusion

Carbide lathe tools, when properly maintained and used, can last for a significant period. By considering the quality of the carbide, implementing effective maintenance practices, and being mindful of the frequency and intensity of use, you can maximize the lifespan of your tools. Ultimately, investing in high-quality carbide lathe tools and providing proper care will ensure that you can achieve precise and exceptional results in your woodworking or metalworking projects for years to come.

How Long Do Carbide Lathe Tools Last? – Key Takeaways

- Carbide lathe tools can last up to 20 times longer than regular high-speed steel tools.

- The lifespan of carbide lathe tools largely depends on usage and cutting conditions.

- Proper tool maintenance, such as sharpening and cleaning, can extend the lifespan of carbide lathe tools.

- Carbide tool wear is gradual, and tools can be used until they become ineffective or damaged.

- Using proper cutting speeds and feeds, as well as coolant and lubrication, can enhance the lifespan of carbide lathe tools.

Frequently Asked Questions

Carbide lathe tools are known for their durability and long lifespan. If you’re curious about how long these tools typically last, we’ve got you covered. Check out these commonly asked questions and their answers to learn more.

How often do I need to replace carbide lathe tools?

Carbide lathe tools are known for their longevity, and can often outlast traditional high-speed steel tools. The exact lifespan of carbide tools can vary depending on factors such as usage frequency, material being cut, and the quality of the tool itself. With proper maintenance and care, carbide lathe tools can last anywhere from several months to several years.

It’s important to regularly inspect your carbide tools for signs of wear, such as dullness or chipping. When the cutting edge starts to become dull, it may be time to rotate or replace the insert. Properly sharpening and maintaining the tools can also help extend their lifespan.

Are there any factors that can shorten the lifespan of carbide lathe tools?

While carbide tools are known for their durability, certain factors can potentially shorten their lifespan. One such factor is running the tools at excessive speeds or feeds, which can cause the cutting edge to wear down more quickly. Using coolant or lubricant during cutting can help reduce the heat generated and extend the tool’s lifespan.

Another factor to consider is the type of material being cut. Cutting abrasive materials, such as cast iron or stainless steel, can cause carbide tools to wear down faster compared to cutting softer materials like aluminum or wood. It’s also important to use the correct tool for the job and avoid excessive tool overhang, as this can put extra strain on the tool and reduce its lifespan.

How can I extend the lifespan of my carbide lathe tools?

To extend the lifespan of your carbide lathe tools, there are a few key steps you can take. First and foremost, make sure you’re using the correct tool for the specific cutting operation you’re performing. Using the wrong tool can lead to premature wear and damage.

Proper maintenance is crucial. Regularly inspect your tools for signs of wear and damage, and rotate or replace inserts as needed. Keep the tools clean and free from debris, and consider using coolant or lubricant during cutting to reduce heat and friction. Finally, always use the appropriate cutting speeds and feeds recommended for the material you’re working with.

Can I sharpen carbide lathe tools?

Contrary to popular belief, carbide lathe tools cannot be sharpened in the traditional sense, as carbide is an extremely hard and brittle material. However, carbide inserts can be rotated or replaced when the cutting edge becomes dull. This allows you to continue using the tool with a fresh cutting edge.

It’s important to follow the manufacturer’s instructions for inserts and properly secure them in the tool holder. If an insert becomes chipped or damaged, it should be replaced to ensure optimal performance. By regularly rotating or replacing inserts, you can effectively prolong the lifespan of your carbide lathe tools.

Are there any signs that indicate it’s time to replace carbide lathe tools?

There are several signs that can indicate it’s time to replace your carbide lathe tools. If you notice a significant decrease in cutting performance, such as difficulty in achieving clean or accurate cuts, it may be a sign that the tool is nearing the end of its lifespan.

Inspect the cutting edge of the tool for signs of wear, such as dullness, chipping, or visible damage. If the tool has reached a point where it cannot be effectively sharpened or rotated, it’s likely time to replace it. Trust your instincts and if you feel like the tool is no longer performing at its best, consider investing in a new one to ensure optimal results.

Summary

Carbide lathe tools can last a long time if used properly and cared for. Keeping them clean and sharp is essential for their longevity.

Regular maintenance, such as sharpening the cutting edges, can significantly extend the tools’ lifespan. It is crucial to avoid overheating the carbide tips, as excessive heat can cause them to wear out faster.

Additionally, using the correct cutting speed and lubricant can help prevent premature wear and ensure the tools last as long as possible.

In conclusion, by taking good care of carbide lathe tools, they can last a long time and provide efficient performance for all your lathe projects.