If you’ve ever wondered how long a drill bit lasts, you’re in luck! Today, we’re diving into the fascinating world of drill bits and uncovering the secrets behind their lifespan. So buckle up and get ready to learn all about this essential tool and how to make it last.

Drill bits are like the unsung heroes of the toolbox – they work hard, but often go unnoticed. But have you ever wondered how long they can keep drilling before they start losing their edge? Well, my friend, you’re about to find out.

Whether you’re a DIY enthusiast or a professional contractor, understanding the lifespan of your drill bits is key to efficient and successful projects. So let’s answer the burning question: how long do drill bits last? Join me as we embark on this informative journey. Let’s go!

Drill bits can last anywhere from 6 months to several years, depending on various factors. The lifespan is influenced by the type of material being drilled, the frequency of use, and the quality of the drill bits. Regular maintenance, such as cleaning and sharpening, can also extend their longevity. To ensure your drill bits last longer, always use the appropriate drilling speed and apply consistent pressure. Keeping them stored in a dry and well-organized manner can prevent damage and corrosion.

How Long Do Drill Bits Last?: A Comprehensive Guide

Drill bits are essential tools for any DIY enthusiast or professional. Whether you’re drilling through wood, metal, or concrete, the longevity of your drill bits plays a crucial role in achieving efficient and precise results. So, how long do drill bits last? In this comprehensive guide, we will explore the factors that affect the lifespan of drill bits and provide practical tips to extend their durability.

The Importance of Quality Drill Bits

Investing in high-quality drill bits is essential for both safety and longevity. Cheap, low-quality drill bits may compromise the integrity of your projects and wear out quickly. Opting for reputable brands ensures that you get durable drill bits made from top-quality materials, such as high-speed steel (HSS) or carbide. These materials have exceptional hardness and heat resistance, allowing them to withstand the rigors of drilling.

Factors Affecting the Lifespan of Drill Bits

The lifespan of drill bits depends on several factors. Let’s delve into each of these factors to gain a better understanding of how long drill bits can last:

1. Material Being Drilled: Different materials pose varying levels of resistance, leading to varying levels of wear on drill bits. Hard materials like metal or concrete will wear out drill bits faster than soft materials like wood.

2. Drill Speed and Pressure: Using the correct drill speed and applying the appropriate amount of pressure during drilling are crucial. Excessive speed or pressure can cause heat buildup, leading to premature wear and even breakage of drill bits.

3. Drill Bit Quality: As mentioned earlier, the quality of the drill bit itself plays a significant role in its longevity. Cheap, low-quality bits are more likely to break or wear out quickly compared to high-quality bits made from superior materials.

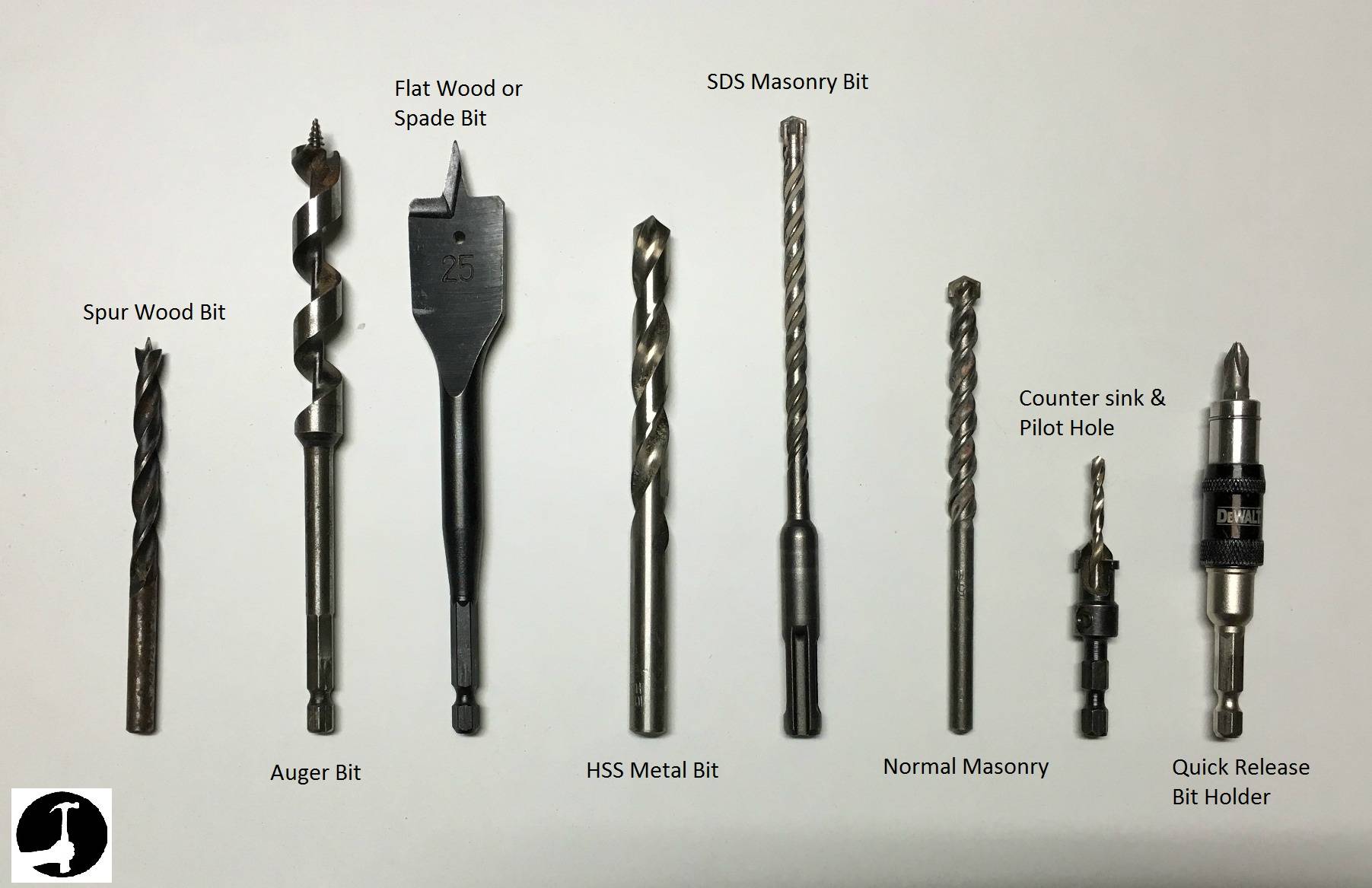

4. Bit Size and Type: The size and type of drill bit also impact its lifespan. Larger bits experience more torque and heat, leading to faster wear. Additionally, specialized bits like masonry or tile bits may have different durability properties.

5. Cooling and Lubrication: Proper cooling and lubrication can greatly extend the lifespan of drill bits. Using cutting fluids or coolants when drilling metal can prevent excessive heat buildup, reducing wear on the bits. In the case of wood drilling, drilling at a slower speed can generate less heat.

6. Maintenance and Storage: Regular maintenance and proper storage are crucial for prolonging the life of drill bits. Keeping the bits clean, sharpened, and stored in a dry and organized manner will prevent premature wear and damage.

Tips for Extending Drill Bit Lifespan

Now that we understand the factors that affect the lifespan of drill bits, let’s explore some practical tips to extend their durability:

1. Use the right drill bit for the job. Choosing the correct bit size and type will minimize strain and wear on the bit.

2. Drill at the appropriate speed. Different materials require different speeds, so refer to the manufacturer’s guidelines or drilling charts for optimal speeds.

3. Apply consistent and moderate pressure. Too much pressure can lead to overheating, while too little can reduce drilling efficiency.

4. Keep the drill bit and work area clean. Accumulated debris and dust can hinder the drilling process and cause increased heat buildup.

5. Use cutting fluids or lubricants when drilling metals. These products reduce friction, heat, and wear on the drill bit.

6. Allow the drill bit to cool down during prolonged drilling sessions. This will prevent excessive heat buildup and extend the bit’s lifespan.

7. Sharpen or replace dull drill bits promptly. Dull bits not only decrease efficiency but also exert more pressure on the workpiece, leading to faster wear.

8. Store drill bits in a dry and organized manner to prevent rust and damage. Consider using a drill bit case or drawer organizer for easy access and protection.

9. Perform regular maintenance on your drill bits, such as sharpening and cleaning, to keep them in optimal condition.

Conclusion

In conclusion, the lifespan of drill bits depends on various factors, including the material being drilled, drill speed and pressure, bit quality, cooling and lubrication, and maintenance. By investing in high-quality drill bits, using them correctly, and following maintenance best practices, you can significantly extend their durability. So, next time you embark on a drilling project, remember these tips to maximize the lifespan of your drill bits and ensure precise and efficient results.

Key Takeaways: How Long Do Drill Bits Last?

- Drill bits can last a long time if used properly.

- Factors like material, usage intensity, and maintenance affect the lifespan of drill bits.

- On average, high-quality drill bits can last for hundreds or even thousands of holes.

- Regular inspection and sharpening can prolong the life of drill bits.

- Replacing worn or damaged drill bits is essential for efficient and safe drilling.

Frequently Asked Questions

When it comes to drill bits, understanding their lifespan is crucial for efficient and safe drilling. Here are answers to common questions about how long drill bits last.

1. Why is the lifespan of drill bits important?

The lifespan of drill bits is important because it affects the quality of your work and your safety. A dull or worn-out drill bit can lead to inefficient drilling, damaged materials, and potential accidents. By knowing how long drill bits typically last, you can plan your projects accordingly and ensure optimal drilling performance.

Additionally, being aware of the lifespan of drill bits helps you determine when it’s time to replace them. Regularly using old or worn drill bits can lead to poor drilling results, increased drilling time, and potential damage to your drill and materials.

2. What factors affect the lifespan of drill bits?

The lifespan of drill bits can be influenced by several factors. One primary factor is the type of material being drilled. Drill bits designed for specific materials, such as wood, metal, or concrete, have different levels of durability and can last longer when used correctly.

Another factor is the drilling technique used. Applying excessive force, using incorrect speeds, or drilling at the wrong angle can shorten the lifespan of drill bits. Additionally, maintaining the drill bits properly, such as keeping them clean and sharp, can contribute to their longevity.

3. How long do drill bits typically last?

The lifespan of drill bits can vary depending on several factors. On average, high-quality drill bits used for general drilling purposes can last anywhere from 200 to 400 holes. However, this estimate can change based on the type of material being drilled, the drilling technique used, and the overall quality of the drill bits.

It’s important to note that drill bits will gradually wear down with each use, resulting in decreased performance. By regularly inspecting your drill bits and assessing their condition, you can determine when it’s time to replace them and ensure efficient and safe drilling.

4. How can I extend the lifespan of my drill bits?

To extend the lifespan of your drill bits, there are a few key practices to follow. Firstly, always use the correct drill bit for the specific material you are drilling. This ensures that the drill bit is designed to handle the material, reducing wear and tear.

Additionally, maintaining proper drilling technique is crucial. Avoid applying excessive force, use appropriate drilling speeds, and ensure the drill is at the correct angle. This helps prevent unnecessary stress on the drill bit and prolongs its lifespan.

5. How can I tell if my drill bits need to be replaced?

There are a few signs that indicate it may be time to replace your drill bits. One obvious sign is if they are visibly worn down, with dull or chipped cutting edges. Such damage can affect the drilling performance, leading to inefficient and unsafe drilling.

Experiencing increased drilling time or difficulty in penetrating materials can also be a sign that your drill bits need replacement. If you notice a decrease in drilling speed or the formation of a lot of heat while drilling, it’s likely time to invest in new drill bits. Regularly inspecting your drill bits and assessing their condition is key to ensuring optimal drilling performance.

How to Make Drill Bits Last Longer – Quick Tip

Summary:

How long drill bits last depends on the material being drilled and how they are used. Harder materials like metal can wear out drill bits faster. Regular maintenance and proper use can extend their lifespan. Sharpening or replacing dull bits can also help them last longer. It’s important to keep an eye on signs of wear and tear to ensure safe and effective drilling.

In conclusion, taking good care of drill bits and using them correctly can help them last longer, saving you money and time in the long run. Regular maintenance, like sharpening and checking for damage, is key. Remember, different materials and drilling techniques will affect the lifespan.