So, you’re curious about how long magnetic drill bits last? Well, you’ve come to the right place! When it comes to durability and longevity, mag drill bits are known for their impressive performance. But just how long can you expect these powerful tools to last? Let’s dive in and find out!

When you invest in magnetic drill bits, you want to ensure they hold up under pressure, right? Well, you’ll be pleased to know that these bits are designed to withstand the toughest drilling tasks. Whether you’re working with metal, wood, or other materials, mag drill bits are built to last, thanks to their high-quality construction and sturdy materials.

So, what’s the typical lifespan of mag drill bits? While it ultimately depends on various factors like usage, maintenance, and the types of materials you’re drilling into, you can generally expect these bad boys to stick around for a good while. With proper care and regular inspections, you can potentially extend their lifespan and enjoy reliable drilling performance for longer. Now, let’s dive deeper into the factors that can affect the longevity of your mag drill bits.

Mag drill bits can last for a considerable amount of time with proper care and usage. The longevity of these drill bits depends on various factors like the material being drilled, the speed of drilling, and the maintenance routine. On average, mag drill bits can last between 100 to 300 holes, but this can vary. To maximize the lifespan of your mag drill bits, make sure to keep them clean, use lubrication, and avoid excessive heat buildup. Regularly inspecting and replacing worn-out bits is also essential to ensure optimal performance.

How Long Do Mag Drill Bits Last? Exploring the Lifespan of Magnetic Drill Bits

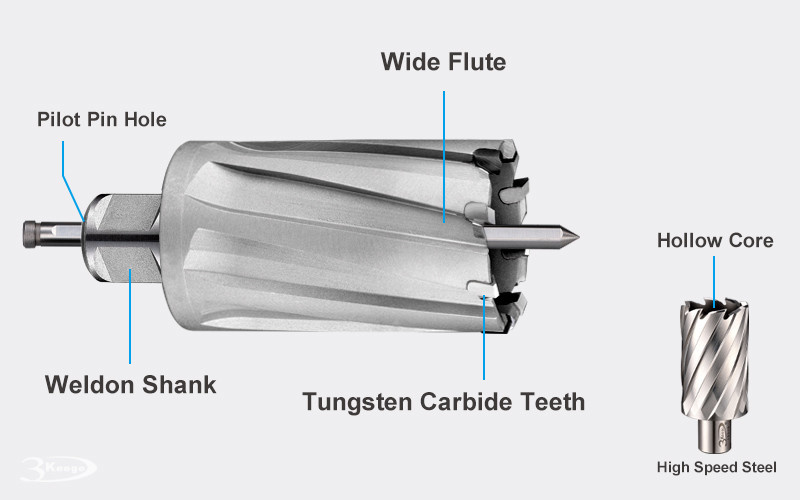

Mag drill bits, also known as magnetic drill bits, are essential tools for drilling precise holes in metal surfaces. However, like any other tool, they have a limited lifespan. The longevity of mag drill bits depends on various factors, including the type of material being drilled, the quality of the bit itself, and the conditions in which it is used. In this article, we will delve into the world of mag drill bits and uncover how long they typically last, along with some tips to prolong their lifespan.

Factors Affecting the Lifespan of Mag Drill Bits

1.

Material Being Drilled

The material being drilled plays a significant role in determining the lifespan of mag drill bits. Different metals have varying levels of hardness and abrasiveness. Hard metals, such as stainless steel, require more force and effort to drill through, leading to faster wear and tear on the drill bits. Softer metals, like aluminum, tend to be less demanding on the bits and can prolong their lifespan.

2.

Quality of the Bit

The quality of the mag drill bit itself is crucial in determining its lifespan. Higher-quality bits are made from materials like cobalt or carbide, which are more durable and resist heat buildup during drilling. These premium materials also tend to have better cutting edges, allowing them to maintain their sharpness for longer periods. On the other hand, lower-quality bits made from standard high-speed steel (HSS) may wear out more quickly, especially when used on tougher materials.

3.

Usage Conditions

The conditions in which mag drill bits are used can significantly impact their lifespan. Factors like drilling speed, feed rate, and coolant usage can affect the wear and tear on the bits. Using the correct drilling speed for the material being drilled and maintaining a consistent feed rate can prevent unnecessary strain on the bits. Additionally, using coolants or lubricants during drilling can reduce friction and heat buildup, preserving the sharpness and longevity of the bits.

Estimating the Lifespan of Mag Drill Bits

While it is challenging to provide an exact lifespan for mag drill bits due to the variables involved, a general estimate can still be made. On average, a high-quality mag drill bit can last between 300 and 500 holes when drilling through mild steel. However, drilling through harder materials, like stainless steel, may reduce the lifespan to around 200 to 300 holes. It’s important to note that these numbers can vary depending on the quality of the bit and the drilling conditions.

To maximize the lifespan of your mag drill bits, consider following these tips:

1. Choose high-quality bits made from cobalt or carbide for increased durability.

2. Use the appropriate drilling speed and feed rate for the material being drilled.

3. Ensure proper cooling and lubrication by using coolant or lubricant during drilling.

4. Regularly inspect the bits for signs of wear and replace them when necessary.

5. Store the bits properly to prevent damage or contamination.

Remember, proper maintenance and careful usage can go a long way in extending the lifespan of your mag drill bits, saving you time and money in the long run.

Mag Drill Bits vs. Traditional Drill Bits: A Comparison

When it comes to drilling through metal, mag drill bits and traditional drill bits differ in many ways. Let’s compare these two types of drill bits and explore their strengths and weaknesses.

Mag Drill Bits

Mag drill bits, designed specifically for magnetic drills, offer several advantages over traditional drill bits:

1. Improved Stability: Mag drill bits are designed to be used with magnetic drilling machines, ensuring a stable drilling experience. The strong magnetic base holds the drill securely in place, preventing slippage and enhancing precision.

2. Efficient Operation: Mag drill bits are optimized for drilling through metal, allowing for faster and more efficient drilling. Their design reduces the risk of overheating and enhances chip evacuation, resulting in smoother and cleaner holes.

3. Longevity: Mag drill bits, especially those made from high-quality materials like cobalt or carbide, tend to have a longer lifespan compared to traditional drill bits. They are built to withstand the demands of drilling through tough metals and can provide consistent performance over time.

Traditional Drill Bits

While mag drill bits excel in metal drilling applications, traditional drill bits still have their place for certain tasks. Here are a few advantages of traditional drill bits:

1. Versatility: Traditional drill bits can be used with a wide range of drilling machines, including handheld drills, making them more versatile than mag drill bits. They can handle various materials, including wood, plastic, and lighter metals.

2. Cost-Effectiveness: Traditional drill bits tend to be more affordable than mag drill bits, especially when considering the need for specialized magnetic drilling machines. If your drilling needs are not predominantly focused on metal, traditional drill bits can be a more cost-effective option.

3. Accessibility: Traditional drill bits are readily available in most hardware stores and online retailers, making them easily accessible for DIY enthusiasts and professionals alike.

In conclusion, mag drill bits offer superior stability, efficiency, and longevity when drilling through metal surfaces. However, traditional drill bits still have their advantages in terms of versatility, cost, and accessibility. Consider your specific drilling needs and materials before deciding which type of drill bit is most suitable for your situation.

How to Choose the Right Mag Drill Bit for Your Needs

Choosing the right mag drill bit is crucial for achieving optimal drilling results. With various options available in the market, it can be overwhelming to make the right choice. Here are some factors to consider when selecting a mag drill bit for your needs:

1. Material Compatibility

Different mag drill bits are designed to drill through specific materials. Ensure that the bit you choose is compatible with the material you intend to drill. This compatibility will ensure efficient drilling and prolong the lifespan of the bit.

2. Bit Size

Consider the desired hole diameter when selecting a mag drill bit. The bit size should match the diameter of the hole you wish to create. Additionally, ensure that the bit is compatible with your magnetic drilling machine, taking into account any size restrictions.

3. Bit Coating

Some mag drill bits come with coatings that improve performance and durability. For example, TiN (Titanium Nitride) coatings reduce friction and increase the lifespan of the bit. Consider whether a coated or uncoated bit is more suitable for your drilling needs.

4. Quality and Brand Reputation

Invest in high-quality mag drill bits from reputable brands. These bits are typically made from premium materials and undergo rigorous testing to ensure consistent performance and longevity. Research customer reviews and seek recommendations to find brands known for producing reliable drill bits.

5. Budget

Consider your budget when selecting a mag drill bit. While it’s essential to invest in quality bits, there is a range of options available at different price points. Determine how frequently you will be using the bit and balance your budget with the expected lifespan and performance of the chosen bit.

By considering these factors and making an informed decision, you can choose the right mag drill bit that meets your specific needs, ensuring efficient and precise drilling operations.

Tips for Extending the Lifespan of Mag Drill Bits

To get the most out of your mag drill bits and maximize their lifespan, here are some tips to follow:

1. Use the appropriate drilling speed and feed rate for the material being drilled. Too much speed or pressure can cause excessive wear on the bit.

2. Utilize coolants or lubricants during drilling to reduce friction and heat buildup. This helps preserve the sharpness of the bit and prevents premature wear.

3. Regularly inspect the mag drill bits for signs of wear or damage. Replace any worn-out or damaged bits promptly to avoid compromising drilling performance or causing accidents.

4. Clean the bits after each use to remove debris and maintain their cutting edges. Use a brush or compressed air to remove chips and keep the bits in good condition.

5. Store the mag drill bits properly in a designated container or case to prevent damage, contamination, or loss. Ensure they are protected from moisture and extreme temperatures.

By implementing these tips and adopting proper maintenance practices, you can extend the lifespan of your mag drill bits, resulting in cost savings and improved drilling performance.

To summarize, the lifespan of mag drill bits depends on various factors such as the material being drilled, the quality of the bit, and the usage conditions. By understanding these factors and following best practices, you can prolong the lifespan of your mag drill bits and ensure optimal drilling results. Remember to choose the right drill bit for your needs, make informed decisions, and prioritize maintenance to get the most out of your investment in mag drill bits.

Key Takeaways: How Long Do Mag Drill Bits Last?

- Mag drill bits can have varying lifespans depending on multiple factors.

- Quality and material composition of the drill bit play a significant role in its durability.

- Usage frequency and workload impact the lifespan of mag drill bits.

- Proper maintenance, including regular sharpening and cleaning, can extend the life of drill bits.

- On average, mag drill bits can last anywhere from several months to a couple of years.

Frequently Asked Questions

When it comes to the longevity of mag drill bits, there are several factors to consider. Here are some common questions related to how long these drill bits last and their maintenance.

1. Why do mag drill bits wear out over time?

Mag drill bits are subject to wear and tear due to the tremendous amount of force and friction they undergo during drilling operations. The materials being drilled, such as steel or other metals, can be quite abrasive, leading to gradual erosion of the bit’s cutting edge. Additionally, the heat generated from drilling can cause the bit’s hardness to decrease, further reducing its lifespan.

Proper maintenance, such as sharpening, can help prolong the life of mag drill bits, but eventually, they will reach a point where they no longer produce accurate and efficient results. Regular inspections and replacements are crucial to ensure optimal performance and safety.

2. What factors influence the lifespan of mag drill bits?

The lifespan of mag drill bits can vary depending on several factors. The type and quality of the drill bit itself play a significant role. High-quality bits made from durable materials tend to last longer compared to cheaper alternatives. The hardness and toughness of the materials being drilled also affect the bit’s lifespan, with harder materials wearing down bits more quickly.

Another critical factor is the drilling technique and maintenance practices. Incorrect drilling techniques, such as excessive pressure or improper alignment, can accelerate wear on the mag drill bit. Regular cleaning, lubrication, and periodic sharpening can help extend the lifespan of the drill bit.

3. How frequently should mag drill bits be replaced?

There is no definitive answer to this question as the lifespan of mag drill bits varies based on usage and the factors mentioned earlier. However, as a general guideline, it’s recommended to inspect the drill bits regularly for signs of wear and damage. If you notice significant dullness, chipping, or other visible signs of wear, it’s time to replace the bit.

For heavy-duty drilling projects or continuous use, it may be necessary to replace mag drill bits more frequently compared to occasional use. As a best practice, consider having spare drill bits on hand to avoid interruptions in your drilling operations.

4. Can mag drill bits be sharpened or resharpened?

Yes, mag drill bits can be sharpened or resharpened to restore their cutting performance and extend their lifespan. However, it’s important to note that not all types of mag drill bits can be sharpened. Some bits, especially those with specialized coatings or intricate designs, may not be suitable for sharpening.

For drill bits that can be sharpened, it’s recommended to use a proper sharpening tool or seek professional assistance. Attempting to sharpen the bit manually without the right tools can lead to improper sharpening, affecting the bit’s overall performance. When in doubt, consult the manufacturer’s guidelines or reach out to a professional sharpening service.

5. How can I maximize the lifespan of my mag drill bits?

To maximize the lifespan of your mag drill bits, there are some key steps you can take. First, always choose high-quality bits made from durable materials, as they tend to last longer and provide better performance. Secondly, ensure proper drilling technique, maintaining proper alignment and avoiding excessive pressure.

Regular maintenance is crucial. Clean the bits after each use, removing any debris or metal shavings that may have accumulated. Apply lubrication to reduce friction and heat buildup. Consider investing in a drill bit sharpener or utilizing professional sharpening services when needed. Finally, store your mag drill bits properly, protecting them from moisture and keeping them in a secure and organized manner, to avoid unnecessary damage.

Summary

Mag drill bits can last a long time with proper maintenance. Keeping them clean and sharp is key. Using lubrication and avoiding excessive heat will extend their lifespan. In general, how frequently you use them and the materials you work with will affect their durability.

It’s important to regularly inspect your mag drill bits for signs of wear and damage. When a bit becomes dull or chipped, it needs to be replaced to ensure safe and effective drilling. By taking good care of your mag drill bits, you can make them last and save money in the long run.