Have you ever wondered how long drill bits should last? Well, you’ve come to the right place! In this article, we’re going to dive into the world of drill bits and explore their lifespan. So, if you’re ready to learn more about this essential tool, let’s get started!

Drill bits are like the superheroes of the toolbox, helping us create holes in various materials. But have you ever wondered how long they can withstand the drilling action before needing to be replaced? Wonder no more! We’re here to uncover the truth behind the lifespan of drill bits.

Whether you’re a DIY enthusiast or a professional handyman, understanding the longevity of your drill bits is crucial. So stick around as we explore the factors that affect their lifespan and provide some tips on how to extend it. Let’s uncover the secrets of drill bits and make sure they last as long as possible!

1. Use the correct bit for the material

2. Avoid excessive heat buildup

3. Lubricate when necessary

4. Avoid excessive force

5. Store them properly. By following these steps, you can ensure your drill bits last longer and perform at their best.

How Long Should Drill Bits Last?

Drill bits are essential tools for any handyman or DIY enthusiast. They come in various shapes and sizes, designed for specific drilling tasks. But how long should drill bits last? This question plagues many users who want to ensure they are getting the most out of their investment. In this article, we will explore the factors that affect the lifespan of drill bits and provide tips on how to prolong their longevity.

Understanding Drill Bit Lifespan

Drill bits are made from different materials, each with its own durability and longevity. The most common types of drill bits are made from high-speed steel (HSS), cobalt steel, and carbide. HSS drill bits are the most affordable option and suitable for general drilling tasks. They can last for approximately 300 to 400 holes before they require resharpening or replacement.

On the other hand, cobalt steel drill bits are known for their durability and ability to withstand high temperatures. They are commonly used for drilling through hard materials such as stainless steel and cast iron. Cobalt steel drill bits can last up to five times longer than HSS bits, making them a worthwhile investment for heavy-duty drilling tasks.

Carbide drill bits are the most expensive but offer the longest lifespan. They are ideal for drilling into hard materials like concrete, masonry, and ceramics. Carbide drill bits can last up to 20 times longer than HSS bits. However, they are more brittle and can break if used improperly or subjected to excessive force.

Tips for Extending the Lifespan of Drill Bits

To maximize the lifespan of your drill bits, consider the following tips:

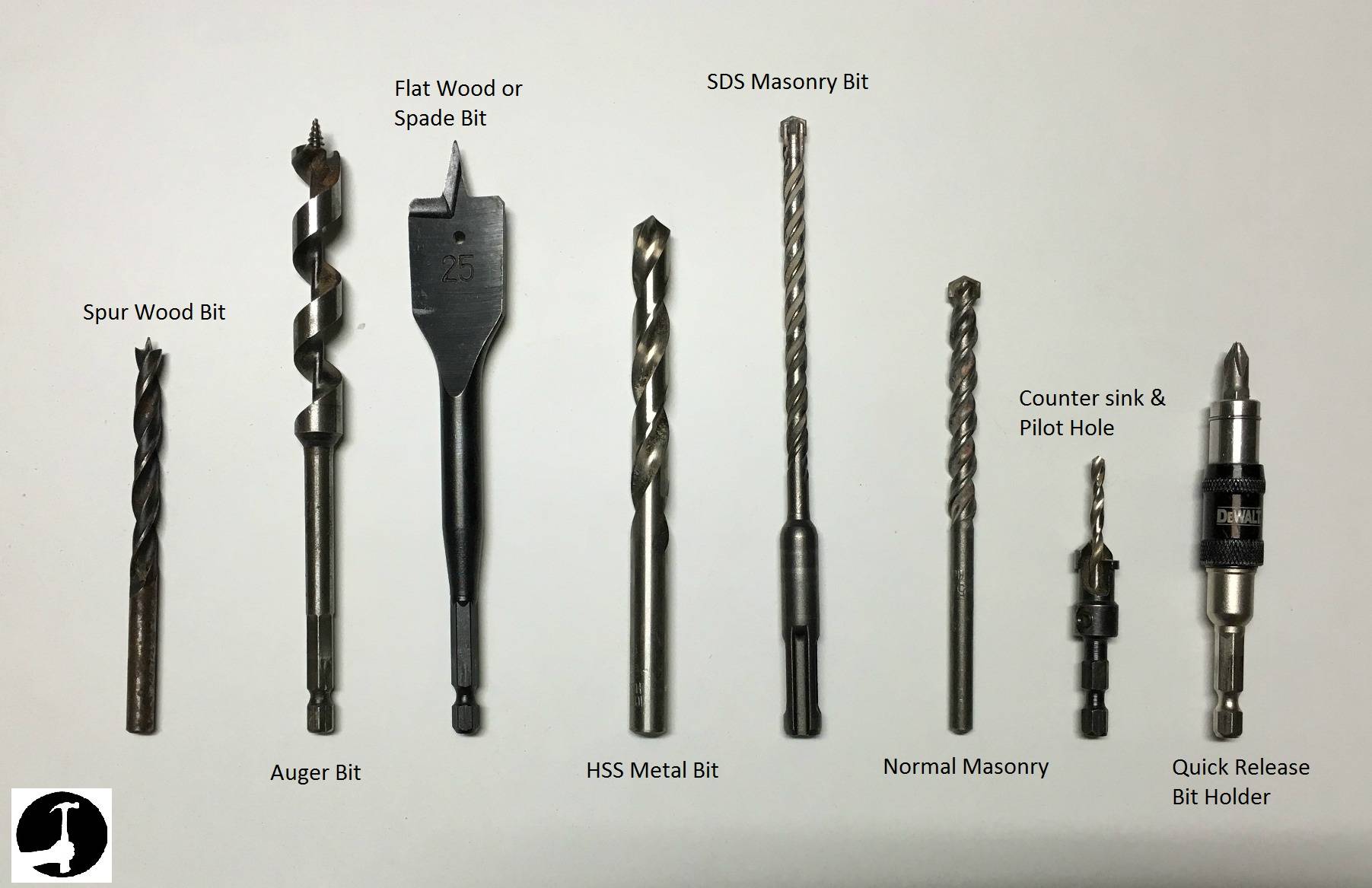

1. Use the right drill bit for the job: Using the wrong type of drill bit for a specific material can significantly reduce its lifespan. Match the drill bit material and design to the task at hand.

2. Apply the correct drilling technique: Improper drilling techniques, such as excessive speed, too much pressure, or inadequate cooling, can cause the drill bit to wear out prematurely. Follow the manufacturer’s recommendations for speed, pressure, and cooling.

3. Keep drill bits sharp: Dull drill bits require more force, increasing the chances of breaking or wearing them out faster. Regularly sharpen or replace drill bits to maintain optimal performance.

Factors Affecting Drill Bit Lifespan

Several factors can affect the lifespan of drill bits, regardless of the material they are made from. These factors include:

1. Material hardness: Harder materials, such as metals, concrete, or ceramics, can put more strain on the drill bit, causing it to wear out faster.

2. Speed and pressure: Excessive speed or pressure during drilling can generate heat, leading to premature wear or even breakage of the drill bit.

3. Coolant or lubrication: Using a coolant or lubricant while drilling can help reduce heat buildup, prolonging the lifespan of the drill bit.

4. Drill bit size and quality: Larger drill bits experience more stress during drilling, which can reduce their lifespan. Similarly, low-quality drill bits may wear out faster than those with superior craftsmanship.

5. Frequency of use: Drill bits used frequently will naturally wear out faster than those used infrequently.

Comparing Drill Bit Lifespans

Here is a comparison of the approximate lifespans for different types of drill bits:

| Drill Bit Material | Average Lifespan |

|---|---|

| High-Speed Steel (HSS) | 300-400 holes |

| Cobalt Steel | Up to 5 times longer than HSS |

| Carbide | Up to 20 times longer than HSS |

It’s important to note that these lifespans are approximate and can vary depending on various factors, as mentioned earlier. Additionally, proper maintenance and adherence to recommended drilling techniques can extend the lifespan of any drill bit.

Caring for Your Drill Bits

To ensure the longevity of your drill bits, follow these additional tips:

1. Clean drill bits after use: Removing any debris, dust, or shavings from the drill bits after each use can prevent them from becoming clogged or dull.

2. Store drill bits properly: Keep your drill bits in a designated container or case, organized and protected from moisture and damage.

3. Avoid excessive heat: Exposing drill bits to excessive heat, such as leaving them near a heat source, can impact their hardness and overall lifespan.

Remember, while drill bits do have a finite lifespan, proper care, maintenance, and adherence to recommended drilling techniques can significantly extend their usability and save you money in the long run.

Choosing the Right Drill Bit for Your Needs

In addition to considering the lifespan of drill bits, it’s essential to choose the right type for your specific drilling needs. Here are three key options to consider:

1. High-Speed Steel (HSS) Drill Bits

HSS drill bits are the most common and widely used type. They are suitable for drilling into wood, plastic, and mild steel. HSS bits are affordable, but their lifespan is shorter compared to other options.

2. Cobalt Steel Drill Bits

Cobalt steel drill bits are an excellent choice for drilling through hard materials such as stainless steel, cast iron, and other alloys. They are more durable and can withstand higher temperatures than HSS bits, making them ideal for heavy-duty applications.

3. Carbide Drill Bits

Carbide drill bits are the most expensive but offer superior performance when drilling into hard materials like concrete, masonry, and ceramics. They are highly durable and can withstand high heat and repetitive use.

Remember to select the right drill bit size and design for your specific drilling task to achieve the best results.

Troubleshooting Common Drill Bit Issues

Even with proper care and maintenance, drill bits can encounter issues that affect their performance. Here are a few common problems and their possible solutions:

1. Dull Drill Bits

If your drill bit becomes dull, it will require more force to drill into materials, putting unnecessary strain on the bit and potentially causing it to wear out faster. Sharpen or replace the drill bit to restore its cutting ability.

2. Chipped or Broken Drill Bits

Drill bits can chip or break, particularly if they are used incorrectly or subjected to excessive force. Replace the damaged bit with a new one to ensure effective and safe drilling.

3. Drilling Off-Center

If your drill bit tends to wander or drift off-center while drilling, it might indicate improper alignment or a worn-out drill bit. Check the alignment of the drill bit and replace it if necessary.

Remember, always prioritize your safety when using power tools and follow the manufacturer’s instructions and guidelines.

In Summary

The lifespan of drill bits depends on various factors, including the material they are made from, the drilling technique used, and the material being drilled into. High-speed steel (HSS) drill bits have the shortest lifespan, while cobalt steel and carbide drill bits offer greater durability and longevity. By following proper maintenance, using the correct drilling technique, and selecting the right drill bit for the job, you can extend the lifespan of your drill bits and achieve optimal drilling performance. Remember to assess your specific drilling needs and choose the appropriate drill bit material and design for the task at hand. With proper care and attention, your drill bits can last longer and continue to serve you well during your DIY projects and tasks.

Key Takeaways: How Long Should Drill Bits Last?

- Drill bits can last a long time if they are properly maintained and used correctly.

- The lifespan of a drill bit depends on various factors, such as the material being drilled and the speed and pressure applied during drilling.

- It’s important to keep drill bits clean and sharp to ensure optimal performance and longevity.

- Regularly inspect drill bits for any signs of wear or damage, and replace them if necessary.

- Investing in high-quality drill bits can often result in longer lifespans and better overall performance.

Frequently Asked Questions

When it comes to drill bits, longevity is an important factor. Here are some commonly asked questions about how long drill bits should last, along with their answers.

1. What factors can affect the lifespan of drill bits?

Several factors can impact how long a drill bit will last. Firstly, the material of the drill bit itself plays a role. Hardened steel bits tend to be more durable than softer materials. Secondly, the type of material being drilled into can also affect the lifespan of the drill bit. Drilling into softwood will generally be less taxing on the bit compared to drilling into hardened metal. Finally, the speed and pressure at which the drill is operated can also impact the life of the bit. Lower speeds and gentle pressure result in less wear and tear.

If you want your drill bits to last longer, it’s essential to choose the right drill bit for the material you’re working with and operate your drill in a controlled manner. Regular maintenance, such as cleaning and sharpening, can also help prolong the lifespan of your drill bits.

2. Can drill bits become dull over time?

Yes, drill bits can become dull over time. When a drill bit becomes dull, it no longer cuts through materials as efficiently as it should. Dull bits can cause excessive heat buildup, slower drilling, and reduced accuracy. This can be frustrating and may lead to a poor quality finish. However, the rate at which drill bits become dull can vary depending on factors such as the material being drilled, the drill bit quality, and the drilling technique used.

To ensure your drill bits last longer, it’s advisable to periodically inspect them for signs of dullness. Look for worn or chipped cutting edges. If you notice any signs of dullness, it may be time to replace or sharpen the bit. Regular sharpening can help restore the cutting edges and improve the performance and lifespan of your drill bits.

3. How often should I replace my drill bits?

The frequency at which you need to replace your drill bits can depend on various factors. If you frequently use your drill and work with tough materials, you may need to replace your drill bits more often. But as a general guideline, it is recommended to replace your drill bits when they become dull or damaged beyond repair.

Regular inspection of your drill bits is crucial. If you notice any signs of wear, such as chipped or worn-out cutting edges, it’s time to consider replacing the bit. Keeping spare drill bits on hand is also a good idea, especially if you have a project with a higher risk of damaging or dulling the bits.

4. Can I extend the lifespan of my drill bits?

Absolutely! There are several steps you can take to extend the lifespan of your drill bits. Firstly, proper usage and technique are essential. Always use the correct drill bit for the material you are working with and avoid applying excessive pressure. Operating your drill at the appropriate speed for the material can also help prevent premature wear. Additionally, regular cleaning after use and storing your drill bits in a dry, secure place can prevent rust and corrosion.

Furthermore, regular maintenance, such as sharpening the drill bits, can significantly extend their lifespan. By keeping the cutting edges sharp, you ensure that the drill bits can efficiently cut through materials. Investing in high-quality drill bits also pays off in the long run, as they tend to be more durable and hold their sharpness for a longer time.

5. Are there any warning signs that my drill bits need replacement?

Yes, there are a few warning signs that indicate your drill bits may need replacement. If you notice that the drill is not cutting as smoothly or cleanly as it used to, or if you experience increased resistance while drilling, it may be a sign that your drill bits are wearing out. Additionally, if you see visible signs of damage, such as chips or cracks in the cutting edges, it’s time to consider replacing the bits. Using worn or damaged drill bits can lead to less efficient drilling, poor results, and potential accidents.

It’s always good practice to periodically inspect your drill bits for signs of wear and assess their performance during drilling. By paying attention to these warning signs, you can replace your drill bits in a timely manner, ensuring smooth and efficient drilling operations.

How to Make Drill Bits Last Longer – Quick Tip

Summary

Drill bits can last a long time if you take care of them. Cleaning them after use and storing them properly will help them stay sharp. Consider the material you’re drilling into and choose the right type of bit for the job. Remember, quality matters, so invest in a good set of drill bits that are made to last. With the right maintenance and usage, your drill bits can serve you well for a long time.

In some cases, drill bits may become dull or damaged and need to be replaced. Signs of wear include decreased performance and difficulty in cutting. Pay attention to these signs and don’t try to force a dull bit. Remember, dull bits can cause accidents. So, be safe and replace your drill bits when necessary.