If you’re wondering how many CFM (cubic feet per minute) you need for an orbital sander, you’ve come to the right place! Whether you’re a woodworking enthusiast or a DIY enthusiast, having the right equipment is essential. And finding the right CFM for your orbital sander can make a big difference in its performance. So stick around as we dive into this topic and give you all the answers you need.

Okay, let’s start with the basics. CFM is a measure of the airflow that a tool or machine requires to operate effectively. And when it comes to an orbital sander, the CFM rating determines how well it can remove debris, dust, and other particles. It’s all about keeping your workspace clean and achieving that smooth finish on your projects.

So, you might be wondering, “How many CFM do I need for an orbital sander?” Well, the answer depends on a few factors, such as the size of your sander and the type of work you’ll be doing. Don’t worry, though! We’ll break it down for you and help you figure out the best CFM rating for your orbital sander needs. Let’s dive in!

How Many CFM for Orbital Sander: A Comprehensive Guide

Orbital sanders are essential tools for any woodworking or DIY enthusiast. They make the task of smoothing and finishing surfaces much easier and more efficient. If you’re new to using an orbital sander, you might be wondering how many CFM (cubic feet per minute) you need for effective operation. In this article, we’ll delve into the world of CFM and provide you with all the information you need to select the appropriate CFM for your orbital sander. So, let’s get started!

Understanding CFM: The Basics

To understand how many CFM you need for an orbital sander, it’s important to grasp the concept of CFM first. CFM is a unit of measurement that indicates the volume of air that a tool requires to function optimally. In the case of orbital sanders, CFM refers to the amount of air needed to effectively carry away dust and debris created during the sanding process.

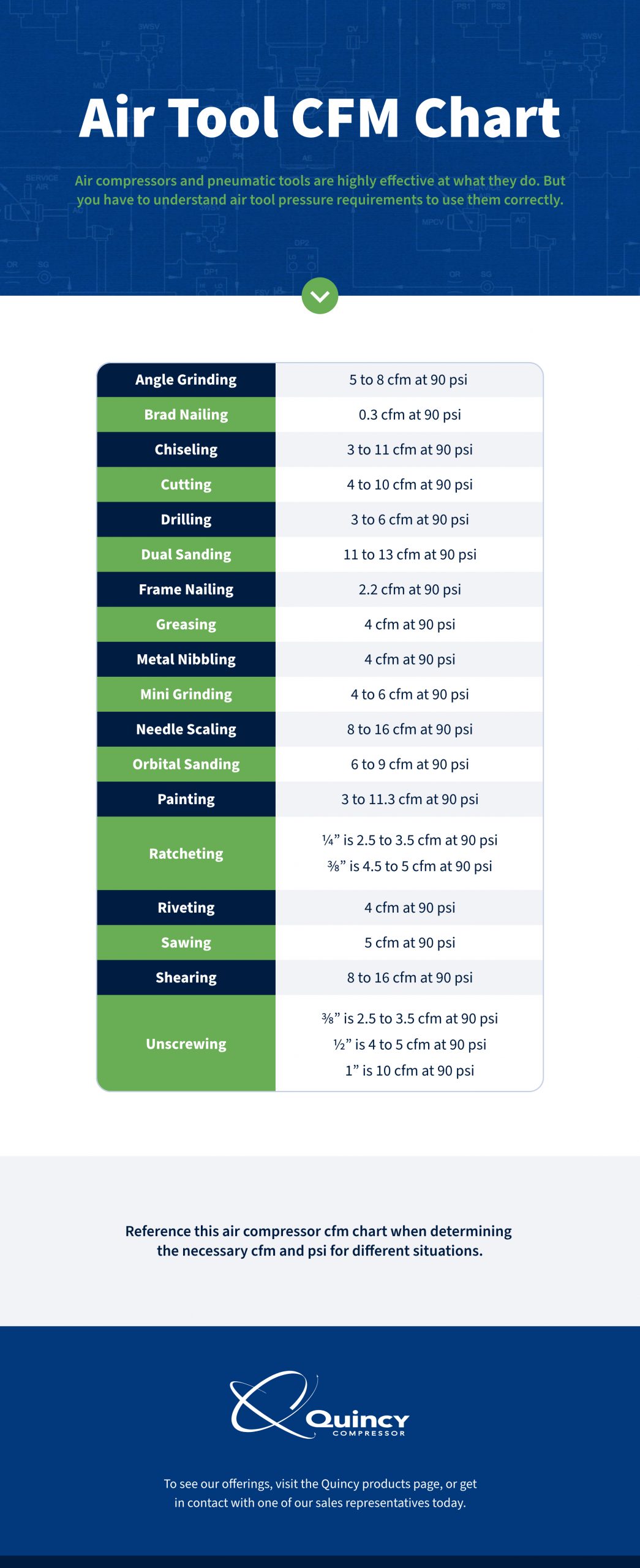

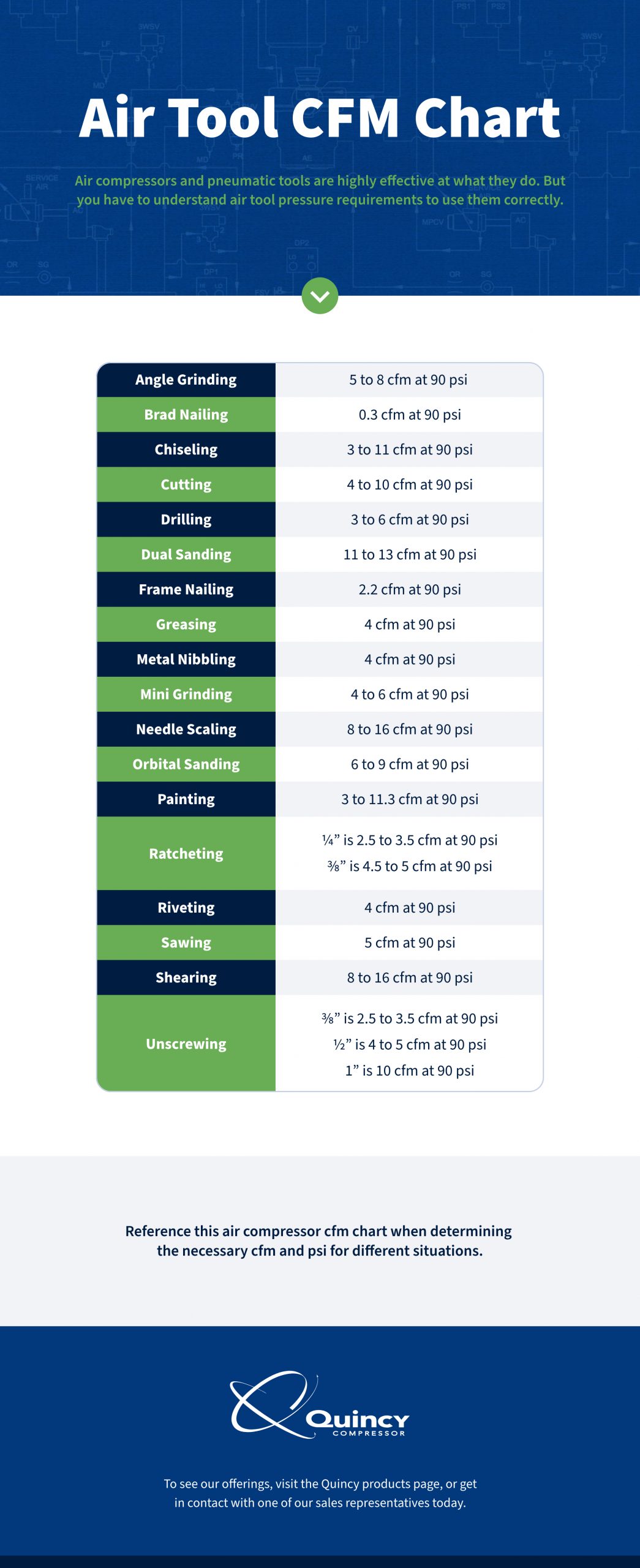

The CFM requirement for an orbital sander can vary depending on the model, the depth of the sanding, and the type of material being sanded. As a general rule of thumb, orbital sanders typically require a CFM range of 3 to 6 CFM. However, it’s important to note that this is merely a guideline and not an absolute rule. Some sanders may require more or less CFM based on their specific design and intended use.

The Benefits of Choosing the Right CFM

Selecting the appropriate CFM for your orbital sander is crucial for several reasons. Firstly, using the right CFM ensures efficient dust collection, which helps maintain a clean working environment. This is especially important when working with materials that produce a significant amount of dust, such as wood or drywall.

Secondly, using the correct CFM for your orbital sander will result in better sanding performance. The proper CFM ensures that the sander operates at its optimal speed, providing smooth and even sanding results. It also helps prevent clogging or overheating of the sanding pad, extending its lifespan and reducing the need for frequent replacements.

Lastly, selecting the right CFM contributes to the overall safety and comfort of the user. Proper dust collection reduces the risk of respiratory issues caused by inhaling airborne particles. It also minimizes the mess created during the sanding process, making cleanup quicker and easier.

Factors Affecting CFM Requirements

Now that we have a basic understanding of CFM and its importance, let’s explore the factors that can affect the CFM requirements for your orbital sander.

Type of Material Being Sanded

The type of material being sanded plays a significant role in determining the CFM requirements. Softer materials like pine or cedar typically produce less dust and require a lower CFM. On the other hand, harder materials such as oak or metal may generate more dust, necessitating a higher CFM to effectively remove it.

Depth of Sanding

The depth of sanding, or the amount of material being removed, can impact CFM requirements. Sanding surfaces with a higher depth may create more dust and debris, necessitating a higher CFM for efficient collection.

Sanding Speed

The speed at which you operate the orbital sander can affect the CFM requirements. Sanding at a faster speed may generate more dust, requiring a higher CFM for effective collection. Conversely, sanding at a slower speed may produce less dust and allow for lower CFM usage.

How to Determine the Ideal CFM for Your Orbital Sander

Determining the ideal CFM for your orbital sander involves considering various factors, such as the type of work you’re doing and the specific sander you’re using. Here are some helpful tips to guide you in selecting the right CFM:

1. Consult the Manufacturer’s Specifications

Start by checking the manufacturer’s specifications for your orbital sander. They often provide recommended CFM ranges for different types of sanding tasks. It’s crucial to follow these guidelines to ensure optimal performance and avoid damaging the tool.

2. Assess the Dust Collection System

Evaluate the dust collection system of your orbital sander. A highly efficient and well-designed system will require lower CFM as it can effectively capture dust and debris. In contrast, a less effective system may require a higher CFM to compensate for its limitations.

3. Consider the Frequency of Use

If you plan to use your orbital sander frequently or for long periods, it’s advisable to invest in a sander with a higher CFM rating. This will ensure that the tool can handle prolonged operation without experiencing issues related to dust collection or performance.

4. Personal Comfort and Safety

While CFM requirements are essential, it’s also important to consider your personal comfort and safety. If you find that a specific CFM range doesn’t provide adequate dust collection or leaves you surrounded by debris, consider opting for a higher CFM to ensure a cleaner and safer working environment.

The Impact of CFM on Sanding Efficiency: Tips and Tricks

Now that you understand the significance of CFM for orbital sanders, let’s explore some tips and tricks to maximize sanding efficiency:

1. Use a Dust Collection System

Invest in a quality dust collection system for your orbital sander. This will not only improve the efficiency of dust removal but also help maintain a cleaner workspace.

2. Use Proper Sanding Techniques

Adopting proper sanding techniques can minimize the amount of dust and debris generated. Apply consistent pressure, move the sander in a smooth and controlled motion, and avoid excessive sanding in one spot.

3. Use the Right Abrasive Grit

Selecting the appropriate abrasive grit for your specific sanding task can help reduce the amount of material being removed and, consequently, the amount of dust generated. Start with a coarser grit and gradually move to finer grits for smoother results.

Conclusion

Finding the right CFM for your orbital sander is crucial for optimal performance, effective dust collection, and a safer working environment. Consider the type of material being sanded, the depth of sanding, and the sanding speed to determine the ideal CFM range. Always consult the manufacturer’s specifications and invest in a reliable dust collection system. By following these guidelines and implementing the tips and tricks provided, you can ensure efficient and hassle-free sanding with your orbital sander.

Key Takeaways: How Many CFM for Orbital Sander?

- An orbital sander typically requires an air compressor with a minimum CFM (cubic feet per minute) rating of 3 to 4.

- The CFM requirement may vary depending on the size and type of the orbital sander.

- Having a higher CFM rating ensures optimal performance and prevents the sander from stalling or overheating.

- It’s important to check the manufacturer’s recommendations for the specific CFM requirements of your orbital sander.

- Consider investing in an air compressor with a higher CFM rating to accommodate for future tool upgrades or heavier sanding tasks.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer common queries about orbital sanders and their CFM requirements. Find all the information you need to know about how many CFM (cubic feet per minute) is appropriate for an orbital sander.

What is CFM and why is it important for an orbital sander?

CFM stands for cubic feet per minute and is a unit of measurement used to quantify the volume of air that a tool requires to operate effectively. In the case of an orbital sander, CFM represents the amount of air needed to power the sander and provide efficient sanding action. It is crucial because insufficient CFM may lead to poor performance, decreased sanding efficiency, and potential damage to the sander.

Having the correct CFM rating for your orbital sander ensures that the tool receives enough airflow to function optimally, resulting in smoother sanding, better dust collection, and extended tool lifespan.

How do I determine the appropriate CFM for my orbital sander?

The appropriate CFM for your orbital sander depends on its size and the type of sanding tasks you’ll be performing. Generally, orbital sanders have CFM ratings ranging from 3 to 6. To determine the suitable CFM for your sander, consider the following factors:

1. Size of the sander: Larger orbital sanders typically require higher CFM ratings, while smaller ones may work efficiently with lower CFM.

2. Sanding tasks: Heavy-duty sanding tasks, like removing paint or refinishing floors, typically require orbital sanders with higher CFM ratings. Lighter tasks, such as surface preparation or light sanding, can be handled well with lower CFM ratings.

By assessing the size of your sander and the type of sanding tasks you’ll be undertaking, you can determine the appropriate CFM range that suits your needs.

What are the consequences of using a higher CFM than recommended for my orbital sander?

Using a higher CFM than recommended for your orbital sander can have adverse effects on its performance and longevity. When the tool receives more airflow than it is designed to handle, it can cause excessive sanding speed, which results in less control over the sander. This can lead to over-sanding, uneven surfaces, and potential damage to the workpiece.

Additionally, using a higher CFM might cause more dust and debris to be thrown into the air, reducing the effectiveness of dust collection systems and potentially creating a mess in your work area. It may also put unnecessary strain on the motor of the sander, leading to premature wear and tear.

Can I use a lower CFM-rated compressor with my orbital sander?

While it is generally not recommended, you can use a lower CFM-rated compressor with your orbital sander, but there are a few things to consider. Using a compressor with lower CFM than the recommended rating may result in reduced sanding performance and slower sanding speeds.

The airflow provided by the compressor may not be adequate to maintain optimal sanding action, causing the sander to struggle and potentially leave behind rough surfaces. Additionally, a lower CFM compressor may lead to less effective dust collection, resulting in more dust in the air and on your work area.

If you choose to use a lower CFM-rated compressor, it’s essential to pay attention to the performance and adjust your sanding technique accordingly to achieve the desired results.

Are there any other factors to consider when using an orbital sander with a specific CFM rating?

Yes, there are a few additional factors to consider when using an orbital sander with a specific CFM rating. First, ensure that the air hoses and connectors you use are compatible with the CFM requirements of your sander and compressor. Using mismatched hoses or connectors can restrict airflow and negatively affect performance.

It’s also crucial to maintain good airflow by keeping the air intake vent on your sander clear of dust and debris. Regularly clean or replace the air filter in your compressor to ensure optimal airflow and prevent any obstruction that could compromise sanding efficiency.

Lastly, always use appropriate eye and respiratory protection when using an orbital sander, regardless of the CFM rating. Dust and debris from sanding can be harmful if inhaled or come into contact with your eyes.

Summary

So, to summarize, when it comes to choosing the right CFM for an orbital sander:

First, consider the size of the sander and the type of projects you’ll be working on. Smaller sanders typically require around 6-8 CFM, while larger ones may need 10 CFM or more.

Next, think about the power source of the sander. If you have a compressor, make sure it has enough CFM to meet the sander’s requirements. If you’re using a battery-powered sander, check the manufacturer’s recommendations for CFM or airflow needed.

Lastly, keep in mind that having a higher CFM than needed won’t harm the sander, but having a lower CFM can lead to poor performance. So, choose a sander with an appropriate CFM based on your needs and the tools you have available.