If you’ve ever used a circular saw, you must have wondered, “How many cuts can a circular saw blade handle?” Well, my young friend, you’ve come to the right place! Today, we’re going to dive into the fascinating world of circular saw blades and find out just how long they can last before they need to be replaced.

Now, imagine you’re in the midst of a big woodworking project, creating masterpieces with your trusty circular saw. You want to make sure your saw blade is up to the task, right? That’s where our question comes in: How many cuts is a circular saw blade good for? It’s a crucial piece of information every young carpenter should know.

Don’t worry, my curious reader, we’re here to demystify the life of a circular saw blade and reveal the secrets behind its endurance. Grab your safety goggles, fasten your tool belt, and let’s embark on this captivating journey together!

How Many Cuts is a Circular Saw Blade Good For?

A circular saw is an essential tool for any woodworking enthusiast or professional tradesperson. It allows for precise and efficient cutting of various materials, including wood, metal, and plastic. However, one common question that arises when using a circular saw is, “How many cuts is a circular saw blade good for?” In this article, we will explore this topic in detail to provide you with the information you need to know about the lifespan of a circular saw blade.

Understanding Circular Saw Blades

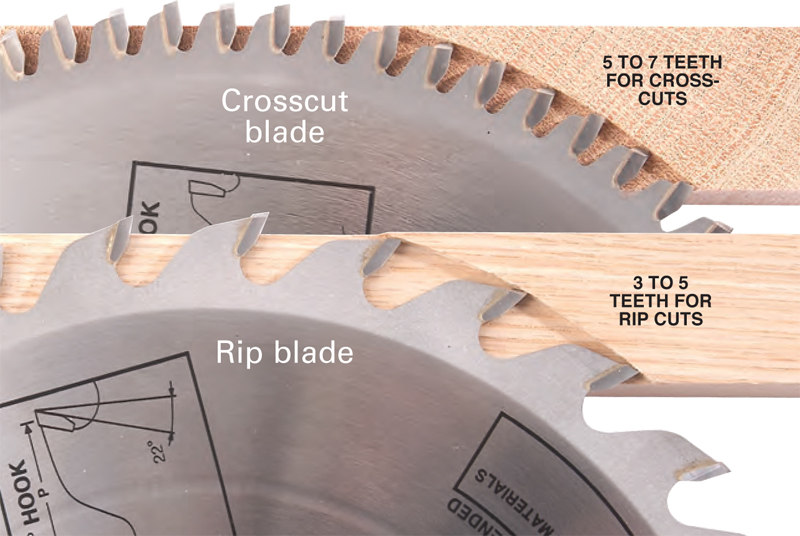

Circular saw blades are designed with various tooth configurations, materials, and sizes to suit different cutting applications. The number of teeth on a blade, combined with the material it is made from, greatly influences its performance and durability. Generally, the higher the tooth count, the smoother the cut, but the blade may wear out faster.

Typically, a circular saw blade can last for a long time, depending on several factors. These factors include the type of material being cut, the quality of the blade, the cutting technique employed, and the frequency of use. Understanding these factors will help you determine how many cuts you can expect from a circular saw blade.

If you primarily cut softwoods like pine or plywood, you can expect a circular saw blade to last longer compared to cutting hardwoods like oak or maple. Softwoods are generally less abrasive and less dense, causing less wear on the blade’s teeth.

Factors Affecting the Lifespan of Circular Saw Blades

1. Material Being Cut: The type of material being cut plays a significant role in determining the lifespan of a circular saw blade. As mentioned earlier, softwoods are less abrasive and less dense than hardwoods, resulting in less wear on the blade. Similarly, cutting non-ferrous metals like aluminum will also wear out the blade faster due to their abrasive nature.

2. Blade Quality: The quality of the circular saw blade is crucial in determining its longevity. Higher quality blades are made from carbide or high-speed steel, which are known for their durability and resistance to wear. Investing in a good quality blade will result in more cuts before requiring replacement.

3. Cutting Technique: The way you use a circular saw also affects the lifespan of the blade. For example, applying excessive force or cutting at an incorrect angle can cause the blade to wear out faster. It’s essential to use the appropriate technique, allowing the blade to cut efficiently without putting unnecessary strain on its teeth.

Extending the Lifespan of a Circular Saw Blade

While the lifespan of a circular saw blade will ultimately depend on various factors, there are steps you can take to extend its longevity:

- Proper Maintenance: Regularly clean the blade and remove any debris or resin buildup. This reduces friction during cutting and prevents premature wear.

- Use the Right Blade for the Material: Different blades are designed for specific materials. Make sure to use the appropriate blade for each cutting task to minimize wear and tear.

- Adjust the Cutting Depth: Set the cutting depth of the blade to the thickness of the material being cut. Cutting too deep can cause unnecessary strain on the blade.

- Allow the Blade to Cool: During prolonged cutting sessions, pause periodically to allow the blade to cool down. This helps prevent overheating, which can lead to blade warping and premature wear.

- Store the Blade Properly: When not in use, store the circular saw blade in a dry place, away from moisture, and protect it from any physical damage.

In Summary

The number of cuts a circular saw blade can handle before needing replacement can vary depending on several factors, including the material being cut, the quality of the blade, the cutting technique employed, and the frequency of use. Softwoods generally result in less wear on the blade compared to hardwoods or metals.

By understanding the factors that affect the lifespan of a circular saw blade and implementing proper maintenance and cutting techniques, you can extend the blade’s longevity and optimize its performance. Remember to choose the right blade for the job, adjust the cutting depth, and allow the blade to cool during prolonged use.

Key Takeaways: How Many Cuts is a Circular Saw Blade Good For?

- A circular saw blade is typically good for around 200-500 cuts, depending on various factors.

- The quality and type of the circular saw blade can affect its lifespan.

- Using the correct cutting technique and proper maintenance can extend the life of a circular saw blade.

- Factors such as the material being cut and the blade’s diameter also impact its longevity.

- Regular blade inspections and replacing worn-out blades are essential for safety and optimal performance.

Frequently Asked Questions

Are you wondering how long a circular saw blade lasts? We’ve got you covered! Check out these commonly asked questions about the lifespan of circular saw blades and their overall durability.

1. How many cuts can I expect from a circular saw blade?

While the exact number of cuts a circular saw blade can handle varies depending on various factors such as the blade quality, material being cut, and how well it has been maintained, most circular saw blades can last for hundreds to thousands of cuts. With proper care and regular maintenance, you can maximize the lifespan of your blade.

It’s worth mentioning that different types of cuts, such as ripping or crosscutting, can affect the longevity of the blade. Ripping wood fibers can be more demanding on the blade than crosscutting, so it’s essential to choose a blade suitable for your specific cutting needs.

2. How do I know when it’s time to replace a circular saw blade?

There are a few signs that indicate it’s time to replace your circular saw blade. One of the most obvious signs is when the cuts become noticeably rough or uneven. If the blade starts to leave burn marks on the material or produces excessive heat while cutting, it’s a good indicator that it’s time to replace it.

Another clue to look out for is a significant decrease in cutting speed. If you notice that it’s taking much longer to complete cuts compared to when the blade was new, it may be time to invest in a new one. Remember, a dull blade not only compromises the quality of your work but can also pose safety risks.

3. What can I do to extend the lifespan of my circular saw blade?

To prolong the lifespan of your circular saw blade, there are a few key things you can do. First and foremost, always use the appropriate blade for the material you’re cutting. Using a blade designed for wood on metal, for example, will wear it out faster.

Proper maintenance is also crucial. Keep the blade clean by removing any sawdust or debris that accumulates on it. Lubricating the blade with a blade-specific lubricant also helps reduce friction and heat, extending its life. Lastly, always handle the blade with care, avoiding any rough handling or misuse that could damage its teeth or core.

4. Can a circular saw blade be sharpened or resharpened?

Yes, many circular saw blades can be sharpened or resharpened to maximize their lifespan and cutting performance. However, not all blades are suitable for this process, so it’s essential to check the manufacturer’s guidelines.

Typically, carbide-tipped blades are more suitable for sharpening or resharpening compared to high-speed steel blades. There are professional sharpening services available that can restore the sharpness of your blades, ensuring they perform like new.

5. What are some indicators that a circular saw blade is damaged beyond repair?

In some cases, a circular saw blade may become damaged beyond repair, making it necessary to replace it. Signs of irreparable damage can include missing or chipped teeth, cracks or warping on the blade body, or an overall loss of structural integrity.

If you notice any of these signs, it’s best to err on the side of caution and invest in a new blade. Continuing to use a damaged blade can compromise both the quality of your cuts and your safety.

Cutting Steel with Circular Saws | Metal Cutting vs. Standard Sidewinder

Summary

So, here’s what you need to know about how many cuts a circular saw blade is good for. First, it depends on the type of blade and what material you’re cutting. Second, you should pay attention to signs of wear, like dullness or chipping. Finally, proper maintenance and cleaning can help extend the lifespan of your blade. Remember, always prioritize safety and consult the manufacturer’s recommendations for the specific blade you’re using. Happy cutting!