Are you wondering how many RPM (revolutions per minute) a table saw should have? Well, you’re in luck because we’re here to answer that question for you! Table saws are a popular tool used for woodworking, and understanding the right RPM is crucial for achieving optimal performance and safety. So, let’s dive in and discover the ideal RPM for your table saw!

When it comes to the RPM for a table saw, there isn’t a one-size-fits-all answer. The speed of a table saw’s blade depends on various factors, such as the type of material being cut and the diameter of the blade itself. Different blades have different recommended RPM ranges, which are typically indicated on the blade’s packaging or the table saw’s manual. It’s essential to match the blade’s recommended RPM range with the table saw’s motor speed to ensure smooth and efficient cutting.

Safety is a top priority when it comes to using a table saw. Operating a table saw with the correct RPM ensures that the blade cuts smoothly through the material without causing kickback or other potential hazards. So, understanding the recommended RPM for your specific table saw and blade combination is vital for both achieving accurate cuts and ensuring your safety. Now, let’s explore some general guidelines for RPM based on common table saw blade sizes.

Understanding the Optimal RPM for Table Saws

Table saws are versatile tools that are commonly used in woodworking projects. The speed at which the saw blade rotates, measured in revolutions per minute (RPM), plays a crucial role in the performance and safety of the tool. Understanding the optimal RPM for a table saw is essential for achieving accurate cuts and getting the best results from your woodworking projects.

The Importance of RPM in Table Saws

When it comes to table saws, RPM refers to the number of times the saw blade rotates in one minute. The speed at which the blade spins impacts the quality of the cut, the type of material that can be cut, and the overall efficiency of the tool. It is important to choose the right RPM based on the blade size and the material you are working with to ensure optimal performance.

The Relationship Between Blade Diameter and RPM

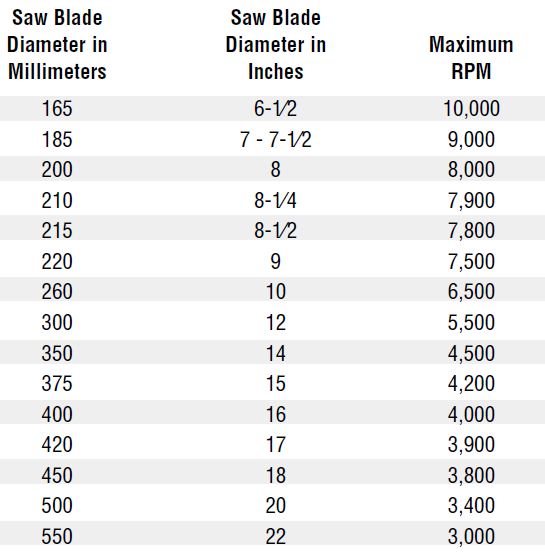

The blade diameter and RPM have a direct relationship. As the diameter of the blade increases, the RPM should decrease to maintain a consistent cutting speed. This is because the peripheral speed of the blade, the distance traveled by a tooth in one revolution, remains constant regardless of the blade size. If the RPM is not adjusted accordingly, the blade will become less efficient, resulting in poor cuts and potential safety hazards.

Most table saws come with adjustable RPM settings or offer different speed options depending on the blade size. It is crucial to consult the manufacturer’s guidelines or the saw’s manual to determine the recommended RPM range for each blade size.

For example, a 10-inch table saw blade typically requires an RPM of around 3,450. If you are using a smaller blade, such as a 7.25-inch blade commonly found in circular saws, the recommended RPM may be higher, around 5,000 to 6,500. Always refer to the manufacturer’s recommendations to ensure you are using the appropriate RPM for your specific blade size.

The Impact of Material on RPM Selection

The type of material being cut also influences the choice of RPM. Softer materials like wood can usually be cut at higher RPMs. However, when working with denser materials like metal, it is important to reduce the RPM to prevent damage to the blade and ensure clean and accurate cuts.

Consult the manufacturer’s guidelines or the blade packaging to understand the recommended RPM range for specific materials. If you are unsure, it is always best to start at a lower RPM and gradually increase it until you achieve the desired cutting performance.

Benefits of Using the Correct RPM

Using the correct RPM for your table saw comes with several benefits. First and foremost, it ensures the safety of the operator. Operating a table saw at the wrong speed can lead to blade damage, kickback, and even accidents. Additionally, using the appropriate RPM maximizes the cutting efficiency and extends the lifespan of the blade, resulting in cleaner cuts and fewer trips to the sharpening shop.

Moreover, achieving the ideal RPM for your table saw improves the overall quality of your woodworking projects. By selecting the right speed for the blade and the material, you will experience fewer instances of burning or tearing, resulting in smoother and more professional-looking cuts.

Tips for Setting the Correct RPM

Here are some tips to help you set the correct RPM for your table saw:

- Refer to the manufacturer’s guidelines or the saw’s manual for recommended RPM settings for different blade sizes and materials.

- Start at a low RPM and gradually increase the speed until you achieve the desired cutting performance.

- Consider the type of material you are working with and adjust the RPM accordingly. Softer materials can generally be cut at higher speeds, while denser materials require lower speeds.

- Regularly check the RPM of your table saw using a tachometer or a reliable speed indicator to ensure it is within the recommended range.

- Keep your blades clean and sharp to optimize cutting performance and reduce the need for excessive RPM.

- Follow proper safety protocols when adjusting and operating your table saw to minimize the risk of accidents.

Understanding the Relationship Between RPM and Blade Size

The RPM of a table saw and the size of the blade have a direct and important relationship. It is crucial to select the appropriate RPM based on the blade size to ensure optimal performance and safety while working.

The Ideal RPM for Different Blade Sizes

The ideal RPM for a table saw blade is determined by its size. Different blade sizes require different speeds to maintain consistent cutting performance and maximize safety.

The Impact of RPM on Cutting Performance

The RPM setting on a table saw has a significant impact on the cutting performance. It determines the speed at which the blade rotates and affects the smoothness, accuracy, and quality of the cuts made.

Key Takeaways – How Many RPM for Table Saw?

- The recommended RPM (Revolutions Per Minute) for a table saw ranges from 3000 to 5000 RPM.

- Higher RPM allows for smoother and faster cuts, especially for harder materials.

- Lower RPM means more torque, which is useful for cutting thicker materials.

- It’s important to match the blade speed with the type and thickness of the material you’re cutting.

- Always refer to the manufacturer’s guidelines for the specific RPM range for your table saw.

Frequently Asked Questions

Welcome to our FAQ section on table saw RPMs! Here, we’ll answer some common questions related to the RPM (revolutions per minute) settings for table saws. Keep reading to learn more!

1. What do RPMs mean and why are they important for a table saw?

RPM stands for “revolutions per minute” and it refers to how many times the saw blade on a table saw rotates in one minute. The RPM setting is important for a table saw because it determines the speed at which the blade cuts through the material being worked on. Higher RPMs typically result in smoother and faster cuts, while lower RPMs are better for cutting denser or thicker materials.

Having control over the RPMs on a table saw allows you to adapt the cutting speed to suit different materials and cutting techniques. It helps ensure clean and accurate cuts while reducing the risk of kickback or damage to the material.

2. What is the ideal RPM range for a table saw?

The ideal RPM range for a table saw depends on various factors, such as the type of material being cut and the diameter of the saw blade. As a general guideline, most table saws have an RPM range of 3,000 to 5,000. However, the specific requirements may vary depending on the manufacturer and the type of blade being used.

It is important to consult the user manual or guidelines provided by the manufacturer of your table saw to determine the ideal RPM range for your specific model. Following the manufacturer’s recommendations will help you achieve optimal cutting performance and ensure safe operation.

3. Can I adjust the RPM settings on a table saw?

Yes, in most cases, you can adjust the RPM settings on a table saw. Some table saw models offer multiple speed settings that allow you to choose the RPM range that best suits your cutting needs. These models typically have a speed control knob or switch that enables you to adjust the RPMs accordingly.

However, it’s important to note that not all table saws have adjustable RPMs. Some may have a fixed speed that cannot be changed. If you require flexibility in RPM settings, make sure to check the specifications or consult the manufacturer before purchasing a table saw.

4. Are higher RPMs always better for cutting on a table saw?

While higher RPMs can often result in smoother and faster cuts, they may not always be better for every cutting scenario. Higher RPMs are generally more suitable for cutting softer or less dense materials, as they can cause more friction and heat when cutting denser or harder materials.

It’s essential to consider the type of material and the desired cutting outcome when selecting the RPM setting. If you’re unsure, it’s recommended to start with a lower RPM and gradually increase it until you achieve the desired result. Testing on scrap material can also help you determine the optimal RPM setting before working on your actual project.

5. Are there any safety precautions to keep in mind when adjusting table saw RPM?

When adjusting table saw RPM settings, it’s crucial to follow safety precautions to prevent accidents or injuries. Here are a few key considerations:

1. Always turn off the table saw and make sure the blade has come to a complete stop before adjusting the RPM settings.

2. Wear appropriate safety gear, such as safety glasses and hearing protection, to protect yourself from flying debris and noise.

3. Consult the user manual or guidelines provided by the manufacturer for specific instructions on adjusting RPMs, as different table saw models may have different mechanisms.

4. Take your time when making RPM adjustments and double-check that the blade is securely fastened before turning on the saw.

5. If you’re unsure about adjusting the RPM settings or any other aspect of operating the table saw, seek guidance from a professional or an experienced user.

Good Tips With Table Saws

Summary

Here’s what you need to know about how many RPM (rotations per minute) for a table saw:

A higher RPM helps make smoother cuts, but it can also be more dangerous if you’re not careful. Different types of blades require different RPMs for optimal performance. It’s important to check the manufacturer’s recommendations for your specific blade. Remember to always wear safety gear and follow proper woodworking techniques to stay safe.

In conclusion, understanding the right RPM for your table saw is crucial for both safety and quality cuts. Be sure to follow the manufacturer’s guidelines and take safety precautions to make your woodworking projects a success.