Looking to find out how many TPI (teeth per inch) your bandsaw blade should have? Well, you’ve come to the right place! Whether you’re a beginner or a seasoned woodworker, understanding the right TPI for your bandsaw blade is essential for achieving clean and precise cuts.

But don’t worry, we’re here to break it down for you in simple terms. In this guide, we’ll explain what TPI is, how it affects your cuts, and provide some tips to help you choose the right TPI for your specific woodworking projects.

So, let’s dive in and unravel the mystery of how many TPI bandsaw blade you need for your cutting needs!

How Many TPI Bandsaw Blade: A Comprehensive Guide

Bandsaws are versatile tools used for various cutting tasks, and choosing the right blade for your bandsaw is crucial for achieving optimal results. One important factor to consider is the number of teeth per inch (TPI) on the blade. In this article, we will delve into the world of TPI bandsaw blades, exploring their significance, different TPI options, and how to choose the right blade for your specific needs.

Understanding TPI: The Basics

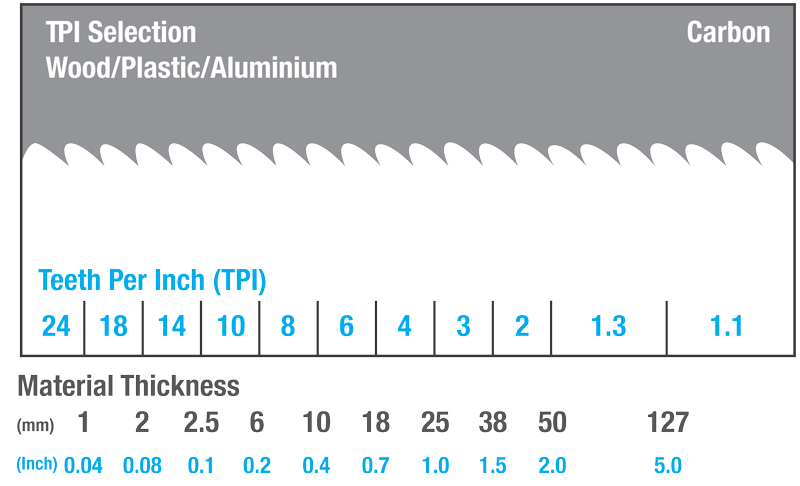

When it comes to bandsaw blades, TPI refers to the number of teeth present on one inch of the blade. The TPI directly impacts the cutting speed, quality, and versatility of the bandsaw. In general, a higher TPI means more teeth per inch, providing a smoother, finer cut, while a lower TPI offers a faster but rougher cut. The choice of TPI depends on the material being cut and the desired outcome.

For example, a low TPI blade, such as 3-6 TPI, is suitable for ripping large pieces of wood or making quick cuts in thicker materials. On the other hand, a high TPI blade, like 18-24 TPI, excels at intricate work, such as cutting metal, thin plastics, or veneer.

It is essential to consider the TPI carefully to achieve the desired finish and prevent damage to the material or the blade. Let’s explore the different TPI options available and when to use each one.

Low TPI Blades: Versatility and Speed

Low TPI blades, ranging from 3-8 TPI, are known for their versatility and speed. These blades are commonly used for resawing thick stock and making rough cuts in larger pieces of wood. They are ideal for tasks that require fast cutting speed and do not require a smooth finish.

Additionally, low TPI blades are suitable for cutting softer materials, such as non-ferrous metals, plastic, and foam. They provide faster cutting action, but the finish may be rougher compared to higher TPI blades. It is important to note that the low TPI blades are not suitable for cutting thin materials or making intricate and detailed cuts.

While low TPI blades offer optimal cutting speed, it is important to select the appropriate blade width and material to prevent blade deflection, which can result in inaccurate cuts or even breakage. Consider the material thickness and type when choosing a low TPI blade to ensure efficient and safe cutting.

Medium TPI Blades: Balance of Speed and Finish

Medium TPI blades, ranging from 10-14 TPI, strike a balance between cutting speed and finish. These blades are versatile options that can handle a variety of materials and tasks. They are ideal for general-purpose cutting where a balance of speed and precision is required.

Medium TPI blades are commonly used for cutting solid wood, plywood, plastics, and similar materials. They allow for relatively fast cutting while providing a smoother finish compared to low TPI blades. These blades are suitable for making straight cuts, contours, and curves with ease.

When selecting a medium TPI blade, consider the material thickness and desired finish. Thicker materials may require a slightly lower TPI for optimal performance, while thinner materials can benefit from a slightly higher TPI blade for a smoother finish. Experimentation with different TPI options can help you determine the best blade for your specific needs.

High TPI Blades: Fine Finishes and Intricate Cuts

High TPI blades, ranging from 18-24 TPI, are designed for fine finishes and intricate cuts. These blades have numerous teeth per inch, resulting in smoother cuts and minimal material waste. They are commonly used for delicate work and tasks that require precision, such as cutting thin metals, veneer, or detailed scrollwork.

High TPI blades offer excellent control and precision, allowing for intricate curves and tight radius cuts. They excel at producing clean edges and minimal sanding or finishing work. However, it is crucial to match the blade thickness and width to the material thickness to avoid blade deflection or breakage.

When working with high TPI blades, it is important to apply consistent pressure and feed rate to ensure the blades do not overheat or become dull prematurely. These blades require delicate handling and should be used with caution for optimal results.

Choosing the Right TPI for Your Bandsaw Blade

Now that you have a better understanding of the different TPI options and their applications, selecting the right TPI for your specific bandsaw blade becomes more manageable. Here are some key factors to consider when making your decision:

- Material: Determine the type and thickness of the material you will be cutting.

- Cutting Speed: Assess whether speed or finish is your priority for the specific task.

- Blade Width and Thickness: Consider the appropriate blade width and thickness for the TPI you choose to prevent deflection and maximize efficiency.

- Experimentation: Don’t be afraid to experiment with different TPI options to find the best match for your needs.

Benefits of Using the Right TPI Bandsaw Blade

Using the right TPI bandsaw blade offers several benefits:

- Improved Cutting Efficiency: Choosing the appropriate TPI ensures optimal cutting performance, increasing efficiency and reducing the time required to complete a task.

- Enhanced Finish: The right TPI blade delivers the desired finish, minimizing the need for additional sanding or finishing work.

- Extended Blade Life: Using the correct TPI blade for the task prevents premature blade wear, increasing the lifespan of your bandsaw blade.

- Accurate Cuts: Matching the TPI to the material and task at hand results in accurate cuts and reduces the likelihood of mistakes or material damage.

Common Mistakes to Avoid When Choosing a Bandsaw Blade TPI

While selecting the right TPI bandsaw blade is essential, it is equally important to avoid common mistakes that can result in subpar performance. Here are some mistakes to avoid:

Mistake 1: Using the Wrong TPI for the Material

Using the wrong TPI blade for the material can lead to inefficient cutting, rough finishes, and potential damage to the material or the blade. Always consider the material type and thickness when selecting the TPI.

Mistake 2: Neglecting Blade Width and Thickness

Blade width and thickness must be considered in conjunction with the TPI to ensure optimal performance. Using a blade that is too thick or too thin for the chosen TPI can result in blade deflection, inaccurate cuts, or even breakage.

Mistake 3: Overlooking Experimentation

Every bandsaw and cutting task may have unique requirements. It is important to experiment with different TPI options to determine the best combination of blade and TPI for your specific needs. Don’t be afraid to try different combinations and evaluate the results.

Tips for Ensuring Optimal Performance with Your Bandsaw Blade

To make the most out of your bandsaw blade and achieve optimal performance, consider the following tips:

Tip 1: Maintain Your Blade

Regularly inspect and clean your bandsaw blade to remove debris, pitch, and sawdust that can affect its performance. Keep the blade sharp and properly tensioned for optimal cutting action.

Tip 2: Use Proper Feeding Techniques

Apply consistent pressure and feed rate when using your bandsaw to ensure smooth and accurate cuts. Avoid forcing the material into the blade or pushing too quickly, as this can cause overheating and premature blade wear.

Tip 3: Choose the Right Blade for Each Task

Consider the material, thickness, and desired outcome for each cutting task, and select the appropriate blade and TPI combination accordingly. Using the right blade for the job ensures the best results and prolongs the life of your bandsaw blade.

In conclusion, the number of teeth per inch (TPI) on a bandsaw blade plays a crucial role in achieving the desired cutting speed, quality, and finish. Understanding the different TPI options and their applications allows you to choose the right blade for your specific needs. By avoiding common mistakes and following the tips provided, you can ensure optimal performance with your bandsaw blade and achieve exceptional results in your cutting projects.

Key Takeaways: How Many TPI Bandsaw Blade?

- The term TPI stands for “teeth per inch” and refers to the number of teeth on a bandsaw blade.

- The ideal TPI for a bandsaw blade depends on the type of material you are cutting. Higher TPI is suitable for thinner materials, while lower TPI is better for thicker materials.

- For general-purpose cutting, a TPI between 4 and 6 is often recommended.

- When cutting curves or intricate shapes, a higher TPI blade, such as 10 to 14, is preferred for better control and precision.

- It’s important to choose the right TPI for your bandsaw blade to ensure clean cuts and prolong blade life.

Frequently Asked Questions

Welcome to our FAQs section where we answer some common questions about bandsaw blades and their TPI (Teeth Per Inch). If you’re wondering about the best TPI for a bandsaw blade or how to determine the right TPI for your specific needs, you’ve come to the right place. Read on to find the answers.

1. What is the importance of TPI in a bandsaw blade?

Teeth Per Inch (TPI) is a crucial factor when selecting a bandsaw blade. The TPI determines the number of teeth on the blade that will come into contact with the material being cut. Higher TPI blades are ideal for making smoother cuts on thinner materials, while lower TPI blades are better suited for rougher cuts on thicker materials. The right TPI ensures optimal cutting performance and helps prevent blade damage.

It’s important to note that different materials and cutting applications require different TPI. So, understanding the importance of TPI in a bandsaw blade helps you make the right choice for your specific cutting needs and ensures efficient and effective results.

2. How do I determine the right TPI for my bandsaw blade?

Determining the right TPI for your bandsaw blade involves considering several factors. First, you need to assess the thickness and hardness of the material you’ll be cutting. Thicker and harder materials typically require lower TPI blades, while thinner and softer materials can be cut more effectively with higher TPI blades.

Additionally, you should consider the type of cut you want to achieve. For intricate and precise cuts, a higher TPI blade is recommended. On the other hand, rougher and faster cuts may require a lower TPI blade. Lastly, take into account the speed at which you’ll be running your bandsaw. Higher speeds typically require lower TPI blades, while slower speeds work better with higher TPI blades. By analyzing these factors, you can determine the right TPI for your specific bandsaw blade needs.

3. Can I use the same TPI for all types of materials?

No, it’s not recommended to use the same TPI for all types of materials. Different materials have varying densities, hardness levels, and cutting requirements. Using the wrong TPI can lead to inefficient cutting, blade damage, and poor results. It’s essential to choose the appropriate TPI for each material to achieve the best cutting performance.

Before starting a cutting project, take the time to assess the material you’ll be working with and consult the manufacturer’s recommendations or industry guidelines. These resources can provide valuable information on the recommended TPI range for specific materials. By using the right TPI for each material, you can ensure cleaner cuts, longer blade life, and a smoother cutting experience.

4. What are the common TPI ranges for different applications?

The common TPI ranges for different applications depend on the thickness and type of material being cut. For general woodworking applications, TPI ranges between 3 and 6 are commonly used. For fine woodworking and intricate cuts, higher TPI ranges from 10 to 18 are preferred. On the other hand, heavier-duty cuts in thicker materials may require lower TPI ranges from 2 to 4.

It’s important to note that these are general guidelines, and specific projects or materials may deviate from these ranges. Always consider the material’s characteristics and your desired cutting outcome when selecting the appropriate TPI range.

5. Can I change the TPI on my bandsaw blade?

Yes, bandsaw blades can have their TPI changed according to specific cutting requirements. Most bandsaw blades are designed to be versatile and allow for different TPI settings. This flexibility enables users to switch between different TPI ranges to accommodate various materials and cutting applications.

To change the TPI on your bandsaw blade, you need to replace the blade with one that has the desired TPI. This can be done by selecting a compatible replacement blade with the desired TPI range and following the manufacturer’s instructions for blade installation. By having multiple bandsaw blades with different TPI options, you can adapt your bandsaw to different cutting tasks and achieve optimal results.

Summary

So, to sum it all up, choosing the right TPI bandsaw blade is important for your woodworking needs. The number of teeth per inch affects the cut quality and speed. More teeth make smoother and slower cuts, while fewer teeth make faster but rougher cuts. Consider the thickness of your material and the type of cuts you want to make when selecting the TPI. Don’t forget to match the TPI to your bandsaw’s capabilities for the best results.