Are you curious about how much CFM you need for a table saw? Well, you’ve come to the right place! Figuring out the right CFM, or cubic feet per minute, is crucial for ensuring optimal performance and safety while using a table saw. So let’s dive in and explore the factors that come into play!

Now, you might be wondering, “Why is CFM important for a table saw?” Great question! CFM determines how effectively dust and debris are removed from the saw’s work area, keeping it clean and reducing the risk of health hazards. With the right CFM, you can achieve better visibility, prolong the lifespan of your saw, and even enhance its cutting accuracy.

But here’s the thing: determining the ideal CFM for your table saw isn’t as straightforward as it may seem. It depends on various factors like the size and type of the table saw, the projects you’ll be working on, and your personal preference. So, let’s take a closer look at these factors and help you find the right CFM for your table saw!

How Much CFM Do I Need for a Table Saw?

When it comes to using a table saw, one of the key factors to consider is the amount of CFM (cubic feet per minute) needed for proper dust collection. CFM refers to the volume of air that can be moved by a ventilation system in one minute and plays a crucial role in maintaining a clean and safe work environment. In this article, we will explore the various factors that determine the required CFM for a table saw and provide helpful tips to ensure efficient dust collection.

The Importance of CFM for Dust Collection

Proper dust collection is essential not only for keeping your workspace clean but also for your health and safety. Fine dust particles generated by table saws and other power tools can pose serious health risks when inhaled. These particles can lead to respiratory problems, lung diseases, and even cancer. By investing in effective dust collection, you can minimize the amount of airborne dust and create a healthier workplace.

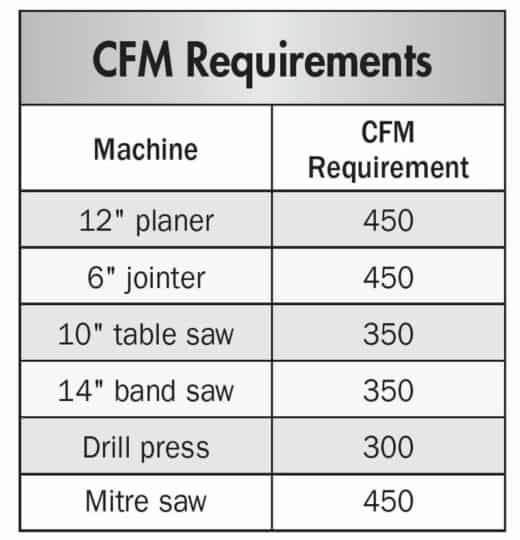

To achieve efficient dust collection, you need to ensure that the CFM requirements of your table saw are met. The CFM needed depends on various factors, including the type and size of the table saw, the diameter and length of the dust collection hose, and the airflow restrictions within the system. By understanding these factors and calculating the required CFM, you can choose the right dust collection equipment and protect yourself from the harmful effects of dust.

Factors Influencing CFM Requirements

Several factors come into play when determining the CFM needed for a table saw. These factors include the size and power of the table saw, the nature of the work being performed, and the dust collection system setup. Let’s explore each of these factors in detail:

1. Size and Power of the Table Saw

The size and power of the table saw directly affect the amount of dust generated during operation. Larger and more powerful table saws tend to produce a greater volume of dust and debris, requiring a higher CFM to effectively collect it. Additionally, if you frequently use the table saw for heavy-duty cutting tasks, the CFM requirement will increase accordingly.

It’s crucial to check the specifications of your table saw to determine the size and power ratings, as this will help you estimate the CFM needed for efficient dust collection. In general, larger and more powerful table saws will require a higher CFM rating on your dust collection system.

2. Nature of Work

The specific woodworking tasks you perform on your table saw can also influence the CFM requirements. For example, cutting dense hardwoods or continuously making deep cuts will generate more dust compared to lighter tasks. Tasks that involve ripping, cross-cutting, and mitering also contribute to the amount of dust produced. Consider these factors and the frequency of such tasks when calculating the necessary CFM for dust collection.

3. Dust Collection Setup

The configuration and setup of your dust collection system greatly impact its ability to collect dust efficiently. This includes factors like the length and diameter of the dust collection hose, the presence of any bends or turns in the system, the type and quality of the filtration system, and the power and capacity of the dust collector or vacuum.

Longer hoses or hoses with smaller diameters tend to cause greater air resistance, leading to a reduction in CFM. Adding bends or turns to the system can also disrupt the airflow and decrease the efficiency of dust collection. It’s important to choose appropriate hose sizes, minimize bends, and select a high-quality dust collection system with the required CFM capacity and filtration capabilities.

Calculating the Required CFM

To determine the specific CFM requirements for your table saw, you can use a simple formula:

- Measure the length and diameter of your dust collection hose in inches.

- Convert the length and diameter measurements to feet by dividing by 12.

- Calculate the square footage of the hood opening (the area where dust is extracted from the table saw).

- Multiply the hose length (in feet) by 100.

- Multiply the diameter of the hose (in feet) by 100.

- Multiply the square footage of the hood opening by 4.

- Add the results of steps 4, 5, and 6 together.

- Divide the total by 8.

The resulting value is the minimum CFM required for your table saw. However, keep in mind that it’s always recommended to choose a dust collection system with a higher CFM rating to account for any potential variations or future upgrades to your setup.

Choosing the Right Dust Collection System

Now that you have a better understanding of the CFM requirements for your table saw, it’s crucial to select an appropriate dust collection system that can meet those demands. Here are a few tips to help you make the right choice:

1. Consider the CFM Rating

When shopping for a dust collector or vacuum, pay close attention to the CFM rating. Ensure that the system you choose can handle the minimum CFM requirements calculated for your table saw. It’s always better to go for a higher CFM rating to maintain optimum dust collection efficiency.

2. Evaluate the Filtration System

The quality of the filtration system in your dust collection system is crucial for effective dust control. Look for systems with high-quality filters that can capture even the finest dust particles. HEPA (High-Efficiency Particulate Air) filters are highly recommended for efficient dust collection and improved air quality in your workspace.

3. Check for Portability and Versatility

If you work in different locations or have multiple tools that require dust collection, consider a portable and versatile system. Look for features like wheels, compact designs, and easy tool attachments to make your dust collection setup more convenient and flexible.

Regular Maintenance and Best Practices

Proper maintenance and adherence to best practices are essential for ensuring the effectiveness and longevity of your dust collection system. Here are a few tips to keep in mind:

1. Clean the System Regularly

Regularly clean and empty the collection bag or canister of your dust collector or vacuum. This prevents clogging, maintains airflow, and maximizes dust collection efficiency.

2. Check for Air Leaks

Inspect your dust collection system for any air leaks that may reduce CFM. Ensure that all connections, joints, and fittings are secure and airtight to prevent any loss of suction power.

3. Use Appropriate Dust Collection Accessories

Invest in accessories such as dust collection hoods, splitter kits, and zero-clearance inserts that are designed to enhance dust collection efficiency and keep your workspace cleaner.

4. Wear Proper Personal Protective Equipment (PPE)

While dust collection systems play a crucial role in minimizing airborne dust, it’s important to supplement their effectiveness with proper PPE. Wear a dust mask, safety glasses, and hearing protection to further protect yourself from any potential health hazards.

By following these maintenance tips and adopting best practices, you can ensure that your dust collection system continues to function optimally and provides a safe and clean working environment.

In conclusion, determining the required CFM for a table saw is crucial for efficient dust collection and maintaining a healthy workspace. Consider the size and power of your table saw, the nature of your work, and the setup of your dust collection system to calculate the necessary CFM. Choose a dust collection system with an appropriate CFM rating, evaluate the filtration system, and consider portability when making your purchase. Regular maintenance and following best practices are also vital for keeping your system in optimal condition. By prioritizing dust collection and the necessary CFM, you can create a safer and cleaner work environment for your woodworking projects.

Key Takeaways: How Much CFM Do I Need for a Table Saw?

- To choose the right CFM (cubic feet per minute) for your table saw, consider the size and power of the saw.

- For smaller table saws, a CFM rating of around 350-400 is sufficient.

- Larger table saws with more power may require a higher CFM rating of 500-600 or more.

- Consider the dust collection system you’re using alongside your table saw and ensure the CFM rating is compatible.

- Don’t forget to factor in the length and configuration of the ducting system when determining the CFM needed.

Frequently Asked Questions

When it comes to operating a table saw, having the right amount of CFM (cubic feet per minute) is crucial for optimal performance. Here are some common questions and answers related to determining how much CFM you need for a table saw.

1. How does CFM affect the performance of a table saw?

The CFM rating of a table saw directly impacts its ability to effectively collect dust and debris. When you have a sufficient CFM, the saw’s dust collection system can efficiently remove particles, keeping the work area clean and improving overall safety. Without enough CFM, dust can accumulate, affecting visibility and potentially causing health hazards.

Furthermore, an inadequate CFM may lead to poor ventilation, increasing the risk of overheating the motor. Proper air circulation helps cool the motor and prolong its lifespan, ensuring smooth operation and preventing damage.

2. How do I calculate the CFM requirement for my table saw?

The CFM requirement for a table saw depends on a few factors, such as the size of the saw, the type of work you do, and the thickness of the materials you typically cut. While there isn’t a set formula, you can make an estimation based on the saw’s blade diameter and motor power.

As a general guideline, aim for a minimum of 350 CFM per inch of blade diameter. For example, for a 10-inch blade, you’d want a dust collection system that delivers at least 3,500 CFM. However, it’s always a good idea to consult the manufacturer’s recommendations for your specific table saw model.

3. Can I use a vacuum cleaner instead of a dedicated dust collection system for my table saw?

While it’s possible to use a vacuum cleaner for dust collection on a table saw, it may not provide sufficient CFM for optimal performance. Vacuum cleaners are designed for smaller tasks and may struggle to keep up with the debris produced by a table saw.

Using a vacuum cleaner also poses a risk of clogging due to the larger particles and sawdust generated during cutting. Additionally, a vacuum cleaner may not have the necessary filtration system to capture fine dust, which can be a health hazard. Investing in a dedicated dust collection system with the appropriate CFM is recommended for a table saw.

4. What are the benefits of having a higher CFM for a table saw?

Having a higher CFM for your table saw offers several benefits, including improved dust collection efficiency, cleaner work environment, and enhanced safety. A higher CFM ensures that more dust and debris are effectively captured, preventing them from settling on surfaces and reducing the need for manual clean-up.

In terms of safety, a higher CFM helps maintain good air quality in the workshop, reducing the risk of respiratory issues caused by inhalation of fine dust particles. It also helps dissipate heat generated by the motor, preventing overheating and potential damage. Overall, a higher CFM contributes to a more efficient and comfortable working environment.

5. Are there any other factors to consider besides CFM when choosing a dust collection system for a table saw?

While CFM is a crucial factor to consider when choosing a dust collection system for a table saw, there are a few other factors to keep in mind. The size of the dust collection bag or bin is important, as it determines how often you will need to empty it. Look for a system with a capacity that suits your needs and frequency of use.

You should also consider the filtration system of the dust collector. Look for models with efficient filters that can capture fine particles. A system with a HEPA filter is highly recommended for optimal dust collection. Additionally, consider noise levels, portability, and ease of maintenance when selecting a dust collection system for your table saw.

Summary

So, how much CFM do you need for a table saw? It depends on the size of your table saw and the type of cutting you typically do. Smaller table saws generally require around 350-400 CFM, while larger ones may need 800-1000 CFM. It’s important to choose a dust collection system that is powerful enough to effectively remove sawdust and protect your lungs.

Remember, it’s not just about the horsepower but also the efficiency of the system. A properly designed dust collection system with appropriate CFM will help keep your workspace clean and ensure you have a healthier working environment. So, do your research, consider the size of your table saw, and make an informed decision to keep the sawdust at bay!