Lathes – those versatile machines used to shape and carve various materials. But have you ever wondered, “How much do lathes weigh?” Well, my friend, you’ve come to the right place! In this article, we’ll dive into the fascinating world of lathe weights and uncover the answer to that burning question.

Now, you might be thinking, “Why does the weight of a lathe even matter?” Well, hold on tight, because here’s where things get interesting! The weight of a lathe can give us valuable insights into its stability, durability, and overall performance. A heavier lathe is generally more stable, reducing vibrations and ensuring smoother and more accurate cuts.

So, how much does a lathe usually weigh? Buckle up, because it varies! Lathes come in all shapes and sizes, from compact benchtop models to massive industrial giants. The weight of a lathe can range anywhere from a few hundred pounds to several tons, depending on its size, construction, and intended use. So, whether you’re a curious hobbyist or a savvy machinist, understanding lathe weights is key to finding the perfect machine for your needs.

Now that we’ve gotten you hooked on the weighty world of lathes, get ready to explore even more intriguing details about their construction, features, and benefits. So, grab a cup of your favorite beverage, make yourself comfortable, and let’s embark on this exciting journey through the world of lathe weights!

How Much Do Lathes Weigh? A Comprehensive Guide

Introduction: Lathes are essential tools in various industries and workshops. They are used for shaping and cutting materials like wood, metal, and plastic. One common question that arises when considering buying or using a lathe is, “How much do lathes weigh?” The weight of a lathe can affect its portability, stability, and suitability for different tasks. In this article, we will explore the factors influencing a lathe’s weight and the different weight ranges of lathes available in the market.

The Factors Influencing a Lathe’s Weight

Several factors contribute to the weight of a lathe. First and foremost is the size of the lathe. Larger lathes that have a higher swing capacity and can accommodate longer workpieces tend to be heavier. The bed length, headstock, tailstock, and other structural components also play a role in determining the weight of the lathe.

The material used to construct the lathe is another determining factor. Cast iron is a common material used in lathe construction due to its durability and ability to absorb vibrations. However, cast iron is quite heavy, which can significantly increase the overall weight of the lathe. In contrast, lathes made from aluminum or polymer composites are lighter but may sacrifice some stability and vibration absorption capabilities.

Additionally, the accessories and features of the lathe can contribute to its weight. For example, a lathe equipped with a large chuck, steady rest, and other accessories will weigh more than a basic model. Advanced features like variable speed control mechanisms, digital readouts, and automatic tool changers can also add to the overall weight of the lathe.

The Weight Ranges of Lathes

Lathes come in a wide range of sizes and weights to cater to different user needs and applications. Let’s explore the various weight ranges of lathes:

1. Mini Lathes: Mini lathes are compact and lightweight, making them suitable for hobbyists, small-scale projects, and portable use. They typically weigh around 40 to 150 pounds (18 to 68 kilograms), depending on their size and construction materials.

2. Benchtop Lathes: Benchtop lathes are larger than mini lathes and offer more versatility and power. They are designed to be placed on a workbench or sturdy stand. The weight of benchtop lathes ranges from 150 to 500 pounds (68 to 227 kilograms), depending on the model and features.

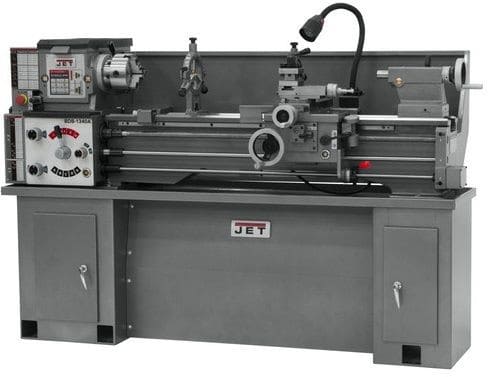

3. Floor Lathes: Floor lathes are heavy-duty machines designed for professional workshops and industrial applications. They are larger and more robust than mini and benchtop lathes and are typically mounted on the floor. The weight of floor lathes can range from 500 pounds (227 kilograms) up to several thousand pounds.

Choosing the Right Lathe Weight for Your Needs

When selecting a lathe, it’s essential to consider your specific needs and requirements. Here are some factors to keep in mind:

1. Portability: If you plan on moving your lathe frequently or need it for portable use, a lighter option like a mini lathe or benchtop lathe may be more suitable. Ensure that the lathe is lightweight enough for you to handle comfortably.

2. Stability: For heavy-duty projects and precision work, a heavier lathe, such as a floor lathe, is recommended. The weight and sturdy construction contribute to stability, reducing vibrations and ensuring accurate results.

3. Available Space: Consider the dimensions and weight capacity of your workshop or workspace. Ensure that the lathe can be accommodated and that the floor or table can support its weight.

4. Project Requirements: Evaluate the size and type of projects you plan to undertake. Larger lathes with higher weight capacities are suitable for handling larger workpieces and more significant tasks, while smaller lathes are ideal for intricate and smaller-scale projects.

By considering these factors and understanding the weight ranges of lathes, you can make an informed decision and select the right lathe that meets your specific needs.

Additional Considerations for Lathe Weight

1. Stability Factor: A heavier lathe tends to offer better stability and reduced vibrations. This is particularly important when working with delicate materials or intricate designs that require precision and accuracy.

2. Maneuverability: While heavier lathes may offer better stability, they can be challenging to move around. Consider the layout and accessibility of your workspace, as well as any requirements for portability.

3. Weight Capacity: Ensure that the weight capacity of the lathe aligns with the type and size of projects you intend to undertake. Exceeding the weight capacity can lead to decreased performance, reduced accuracy, and potential damage to the lathe.

Conclusion

When considering purchasing or using a lathe, understanding its weight is crucial. The weight of a lathe is influenced by factors such as size, material, and features. Different weight ranges cater to various needs, from lightweight and portable options to heavy-duty industrial machines. By considering your specific requirements and project needs, you can select a lathe with the appropriate weight and features to achieve the desired results. Whether you’re a hobbyist or a professional, choosing the right lathe weight is essential for successful woodworking, metalworking, and other machining projects.

Key Takeaways: How Much Do Lathes Weigh?

- Lathes come in different sizes and weights depending on their capacity and purpose.

- Mini lathes typically weigh around 80 to 200 pounds, making them easily portable.

- Medium-sized lathes can weigh between 500 and 2,000 pounds, requiring proper setup and stability.

- Large industrial lathes can weigh over 10,000 pounds and may require professional installation.

- Knowing the weight of a lathe is important for transportation, setup, and ensuring safety during operation.

Frequently Asked Questions

Are you curious about the weight of lathes? Find answers to your questions below!

1. Is the weight of a lathe important?

The weight of a lathe is indeed crucial. The weight directly impacts the stability and accuracy of the machine. A heavier lathe will have reduced vibrations, resulting in smoother and more precise cutting operations. It provides a steady base for the workpiece, minimizing the chances of errors and ensuring consistent results.

Furthermore, a heavier lathe will be more durable and sturdy, with better resistance to wear and tear. This means it will have a longer lifespan and require fewer repairs, ultimately saving you time and money in the long run. So, yes, the weight of a lathe is an important factor to consider when making a purchase.

2. How much does a small benchtop lathe weigh?

The weight of a small benchtop lathe can vary depending on the specific model and brand. On average, a small benchtop lathe may weigh between 100 to 250 pounds (45 to 113 kilograms). However, it’s important to note that this is just an estimate, and the weight can vary significantly based on the features, materials, and construction of the lathe.

When considering a small benchtop lathe, it’s always a good idea to check the product specifications provided by the manufacturer. These specifications will give you the most accurate information regarding the weight of the lathe you are interested in.

3. What is the weight range of a mid-sized floor-standing lathe?

A mid-sized floor-standing lathe can range in weight from approximately 500 to 1,500 pounds (227 to 680 kilograms). This is a general weight range and can vary depending on the specific model and design of the lathe. Some mid-sized floor-standing lathes may be lighter, while others may be heavier, depending on factors such as the bed length, motor size, and overall construction.

If you are interested in purchasing a mid-sized floor-standing lathe, it’s best to consult the manufacturer’s specifications for the exact weight of the lathe model you are considering. This will ensure that you have the most accurate information and can make an informed decision.

4. How heavy are large industrial lathes?

Large industrial lathes can weigh a considerable amount due to their size, power, and heavy-duty construction. The weight of these machines can range anywhere from 2,000 to 50,000 pounds (907 to 22,680 kilograms) or even more. The weight will depend on various factors, such as the maximum swing capacity, bed length, spindle horsepower, and additional features.

Due to their substantial weight, large industrial lathes often require special equipment and expertise for installation. It’s important to consult the manufacturer or a professional to ensure the proper handling and setup of these heavy machines.

5. How can the weight of a lathe affect transportation and mobility?

The weight of a lathe plays a significant role in transportation and mobility. In smaller lathes, a lighter weight makes them more portable and easier to transport to different locations. This can be advantageous for professionals who need to carry out projects on-site or for hobbyists who prefer the flexibility of a portable lathe.

On the other hand, larger lathes can be more challenging to transport due to their heavy weight. Specialized equipment, such as cranes or forklifts, may be required to move and position these machines. Additionally, the weight of a lathe should be taken into account when selecting a suitable workspace, considering factors such as floor load capacity and accessibility.

Summary

Lathes come in different sizes, so their weights can vary a lot. Smaller lathes weigh around 100 pounds, while larger ones can weigh thousands of pounds.

The weight of a lathe depends on its size, material, and additional features. If you’re planning to buy or move a lathe, make sure to check its weight specifications to ensure it’s manageable for you.