So, you’re curious about lathes and their weight? Well, you’ve come to the right place! Lathes are fascinating machines used in woodworking, metalworking, and other crafts. But let’s get to the question burning in your mind: how much do lathes actually weigh?

Picture this: you’re in a workshop, surrounded by tools and materials. And there, in the corner, stands a majestic lathe. You might be wondering if this beast is heavy enough to require a forklift to move. Well, it depends on the size and type of lathe you’re dealing with.

Whether you’re a young aspiring craftsman or just a curious mind, stick around to uncover the weighty secrets of lathes! So, are you ready to delve into the world of machining and unravel the mystery of how much lathes weigh? Let’s go!

How Much Do Lathes Weigh? Exploring the Weight of a Vital Tool

When it comes to woodworking or metalworking, lathes are essential tools that allow craftsmen to shape and manipulate materials with precision. But have you ever wondered, “How much do lathes weigh?” Understanding the weight of a lathe is crucial for transportation, stability, and ensuring workspace compatibility. In this article, we will delve into the factors that influence the weight of lathes, explore different types of lathes, and provide insights to help you choose the right lathe for your needs.

The Influence of Size and Type on Lathe Weight

The weight of a lathe can vary significantly depending on its size and type. Larger lathes designed for industrial or heavy-duty applications tend to be heavier due to their robust construction and components. For instance, a large woodturning lathe used in professional workshops can weigh anywhere between 500 pounds (227 kg) to over 2,000 pounds (907 kg).

On the other hand, smaller lathes designed for hobbyists or light-duty tasks are generally lighter in weight. Mini or benchtop lathes, which are perfect for beginners or those with limited workspace, weigh around 50 pounds (23 kg) to 150 pounds (68 kg). These lathes are often made from lighter materials but still maintain the necessary stability and functionality for their intended purposes.

It’s important to note that the weight of a lathe can also be influenced by its specific type. For example, metal lathes are typically heavier than wood lathes due to the stronger materials and components required to withstand the forces involved in metalworking. The weight of a lathe may also vary based on additional features such as motor power, bed length, and spindle size, which all contribute to the overall weight of the machine.

The Weight of Common Lathe Types

Now let’s take a closer look at the weights of some common types of lathes:

1. Wood Lathes:

Wood lathes come in various sizes, from small hobbyist models to large professional machines. Here are some common examples and their average weights:

- Benchtop Wood Lathe: 50 pounds (23 kg) to 150 pounds (68 kg)

- Standard Wood Lathe: 200 pounds (91 kg) to 500 pounds (227 kg)

- Large Woodturning Lathe: 500 pounds (227 kg) to over 2,000 pounds (907 kg)

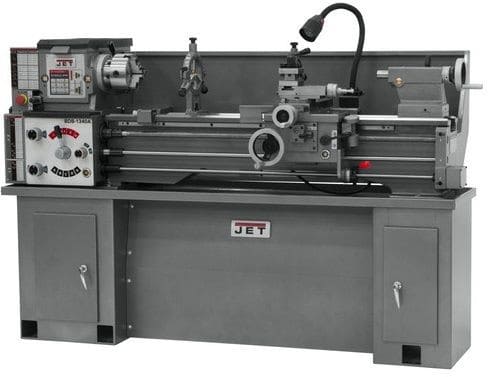

2. Metal Lathes:

Metal lathes are generally more robust and heavier than wood lathes. Here are some examples of common metal lathe types and their average weights:

- Benchtop Metal Lathe: 150 pounds (68 kg) to 400 pounds (181 kg)

- Standard Metal Lathe: 500 pounds (227 kg) to 1,000 pounds (454 kg)

- Industrial Metal Lathe: 1,000 pounds (454 kg) to over 5,000 pounds (2,268 kg)

3. CNC Lathes:

CNC (Computer Numerical Control) lathes are automated machines designed for precision and efficiency. Due to their complex components and advanced technology, they tend to be heavier. Here are some examples:

- Benchtop CNC Lathe: 200 pounds (91 kg) to 500 pounds (227 kg)

- Standard CNC Lathe: 1,000 pounds (454 kg) to 3,000 pounds (1,361 kg)

- Industrial CNC Lathe: 3,000 pounds (1,361 kg) to over 10,000 pounds (4,536 kg)

These weights are approximate averages and can vary depending on the manufacturer, specific model, and additional features.

Key Takeaways: How Much Do Lathes Weigh?

- Lathes can vary in weight depending on their size and type.

- Small benchtop lathes typically weigh around 100 to 200 pounds.

- Medium-sized lathes can weigh between 500 and 2,000 pounds.

- Industrial-sized lathes can weigh several tons.

- It’s important to consider the weight of a lathe when purchasing or transporting one.

Frequently Asked Questions

Curious about the weight of lathes? Here are some common questions and answers to satisfy your curiosity.

1. How heavy are lathes?

Lathes can vary in weight depending on their size and design. Mini-lathes, often used for hobbies and small-scale projects, typically weigh around 50 to 150 pounds. Medium-sized lathes, suitable for professional workshops, can weigh anywhere from 400 to 1,200 pounds. Heavy-duty industrial lathes, designed for large-scale projects, can weigh well over 10,000 pounds. So, the weight of a lathe depends on its intended purpose and specifications.

It’s worth noting that lathes are usually built to be sturdy and stable, as they need to withstand the forces exerted during machining operations. The weight of a lathe is not only necessary for stability but also indicates the machine’s durability and capability to handle heavy workloads.

2. How can I determine the weight of a lathe?

While it’s difficult to estimate the exact weight of a lathe without knowing its specific make and model, there are a few general methods to get an idea. First, you can check the manufacturer’s specifications, which often include the weight of the lathe. If that information is not readily available, you can try searching online forums or communities where lathe owners discuss their machines. Many owners share details about the weight of their lathes to help others.

If all else fails, you can try contacting the manufacturer directly. They should be able to provide you with the accurate weight of the lathe model you are interested in. It’s best to have the serial number or specific details of the lathe ready when contacting the manufacturer, as this will help them identify the exact model and provide an accurate weight estimate.

3. Does the weight of a lathe affect its performance?

The weight of a lathe does have some impact on its performance. Heavier lathes tend to be more stable, which is crucial for achieving precise and accurate machining results. The increased weight helps absorb vibrations and reduces chatter, making the lathe more reliable and efficient. It also contributes to the overall rigidity of the machine, allowing for better handling of heavier workpieces and more demanding machining tasks.

However, the weight of a lathe is just one factor to consider when evaluating its performance. Other aspects such as motor power, spindle speed, and overall construction quality also play significant roles. It’s important to find the right balance between weight and other features to ensure optimal performance for your specific needs.

4. Can I move a heavy lathe by myself?

Moving a heavy lathe by yourself can be challenging and potentially dangerous. It’s generally recommended to seek assistance from others or use appropriate equipment when relocating a heavy lathe. The weight and size of the machine make it difficult to handle alone.

Professional riggers or machinery movers with experience in handling heavy equipment are better equipped to safely move lathes. They have the necessary tools and expertise to disassemble, transport, and reassemble lathes without causing damage or injuries. If you need to move a heavy lathe, it’s advisable to consult experts who specialize in machinery relocation to ensure a smooth and safe process.

5. Are there any portable or lightweight alternatives to heavy lathes?

Absolutely! If you’re looking for a more portable or lightweight alternative to a heavy lathe, there are options available. Mini-lathes, also known as benchtop or hobby lathes, are designed to be compact and lightweight. These lathes are suitable for smaller projects and can easily be transported or stored when not in use. While they may not have the same capabilities as larger industrial lathes, they still provide opportunities for woodworking or metalworking enthusiasts to pursue their hobbies.

Keep in mind that portable or lightweight lathes may have certain limitations in terms of the size of the workpieces they can handle or the types of machining operations they can perform. However, they offer versatility and convenience for those who prioritize mobility and have space constraints in their workshops or garages.

Summary

Lathes are heavy machines used to shape wood or metal. The weight of a lathe depends on its size and features. Generally, smaller lathes weigh around 500 pounds, while larger industrial lathes can weigh several tons. It’s important to consider weight when moving or installing a lathe.

If you’re planning to purchase a lathe, make sure to check its weight specifications and ensure that your workspace can handle the weight. Remember to use proper lifting equipment and ask for help when moving a heavy lathe. Understanding the weight of a lathe will help you make informed decisions and keep yourself safe.