Curious about the weight of a Boxford lathe? Well, you’ve come to the right place! If you’ve been wondering how much this popular lathe model weighs, you’re in for a treat. In this article, we’ll dive into the world of lathe weights, focusing specifically on the Boxford lathe. So, let’s not waste any more time and get straight to it!

When it comes to the weight of a Boxford lathe, it’s important to consider the specific model you have in mind. Different Boxford lathe models can vary in weight, depending on their size and configuration. So, whether you’re interested in a smaller benchtop lathe or a larger industrial-sized one, we’ll cover it all.

So, how much does a Boxford lathe weigh? Stay tuned as we reveal some of the common weight ranges for Boxford lathes, allowing you to find the perfect fit for your needs. Whether you’re a hobbyist or a professional, understanding the weight of a lathe is crucial for transportation, setup, and overall stability. Let’s dive into the fascinating world of Boxford lathe weights together!

How Much Does a Boxford Lathe Weigh?

Boxford lathes are known for their quality and durability, making them popular among both hobbyists and professional machinists. If you are considering purchasing a Boxford lathe, one important factor to consider is its weight. Knowing the weight of the lathe is essential for transportation purposes and ensuring that it is suitable for your workspace. In this article, we will discuss in detail how much a Boxford lathe typically weighs and why this information is important for prospective buyers.

The Weight of Boxford Lathes

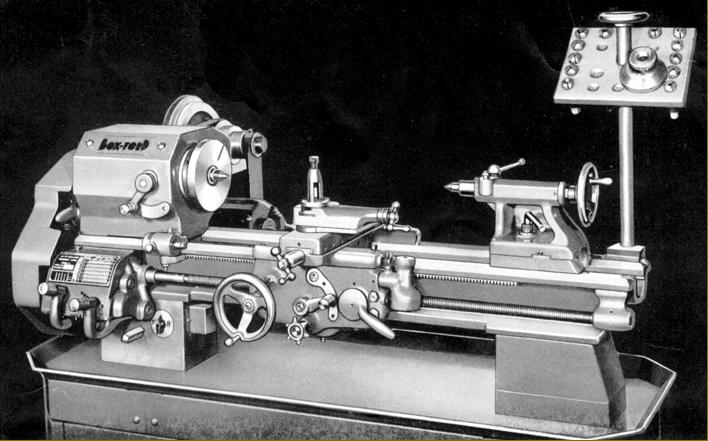

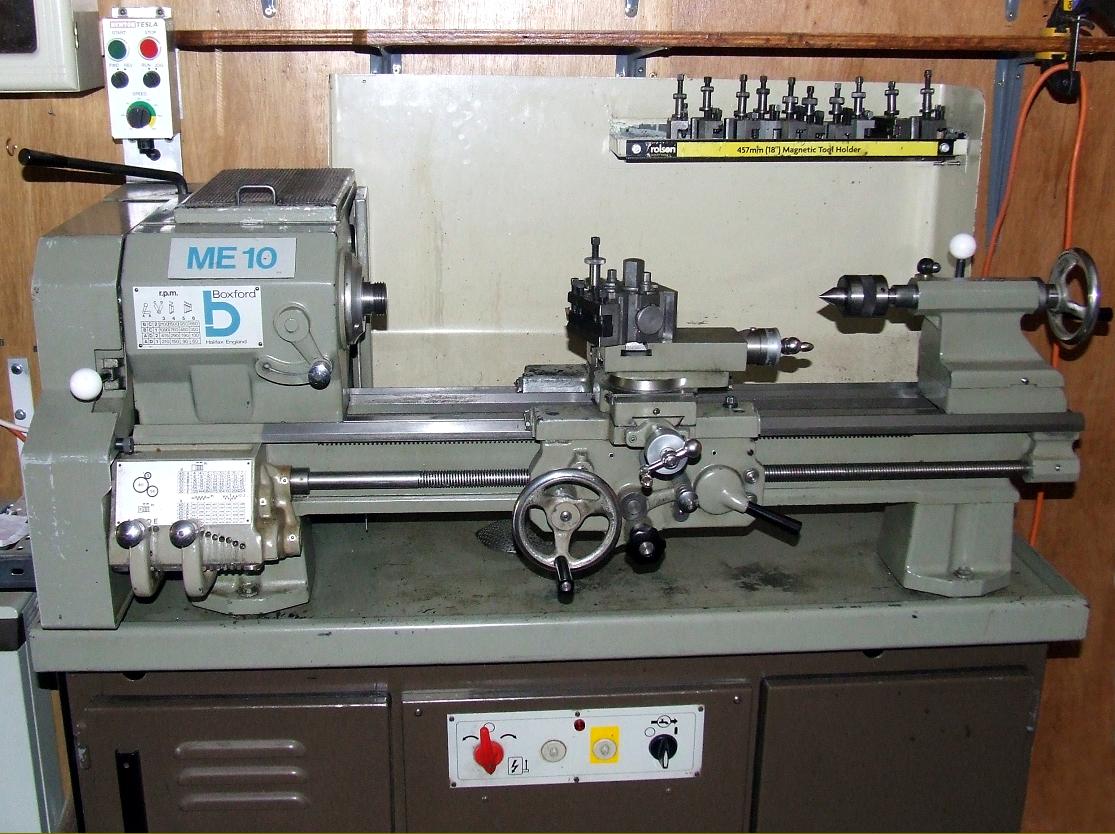

Boxford lathes come in various models and sizes, each with its own weight specifications. While the weight can vary depending on the specific model, on average, a Boxford lathe weighs between 500 pounds (226.8 kg) to 1500 pounds (680.4 kg). This weight range includes both the lathe bed and the associated components. It is important to note that the weight may increase if additional accessories or attachments are added to the lathe.

The weight of a Boxford lathe is primarily influenced by the materials used in its construction. These lathes are typically made from heavy-duty cast iron or steel, which ensures stability and minimizes vibrations during operation. The robust construction also contributes to the overall weight of the lathe, making it a sturdy and reliable machine for precision machining tasks.

It is important to consider the weight of the Boxford lathe when planning its installation and transportation. The weight can affect the logistics of moving the lathe into your workspace and may require special equipment or assistance. Additionally, the weight will also dictate the requirements for a sturdy and stable workbench or stand to support the lathe during operation.

Factors Affecting the Weight of a Boxford Lathe

Several factors influence the weight of a Boxford lathe. Understanding these factors can help you make an informed decision when selecting a lathe model that best suits your needs.

Size and Capacity:

Generally, larger Boxford lathes with higher weight capacities will weigh more than smaller models. This is because larger lathes require more materials, including heavier-duty components, to support the increased size and workload.

Accessories and Attachments:

Add-ons such as chucks, tool rests, and tailstocks can add to the overall weight of the lathe. The more accessories and attachments you choose to use, the heavier the lathe will become.

Bed Length:

The length of the lathe bed can also impact its weight. Longer beds require more material, resulting in increased weight. However, it is essential to consider the bed length based on your machining needs and available workspace, as longer beds may be necessary for certain projects.

Transportation and Installation Considerations

Transporting a Boxford lathe, especially the heavier models, requires careful planning and consideration of safety measures. The weight of the lathe often necessitates the use of specialized equipment, such as forklifts or cranes, to lift and move it. It is crucial to follow proper lifting and handling procedures to avoid injuries and prevent damage to both the lathe and the surrounding environment.

When installing the lathe in your workspace, it is important to ensure the foundation or workbench is sturdy enough to support the weight of the lathe. A solid and stable base will reduce vibrations during operation and contribute to better machining results. Professionals recommend bolting the lathe securely to the workbench to further enhance stability and reduce any movement.

Considering the weight of a Boxford lathe and its transportation and installation requirements is essential for a smooth and successful setup in your workshop. By understanding the factors influencing the weight, you can confidently select the appropriate lathe size and ensure that your workspace is adequately prepared to accommodate the machine’s weight and size.

Factors to Consider When Choosing a Boxford Lathe

When purchasing a Boxford lathe, there are several factors to consider to ensure that you make the right choice for your machining needs. Here are three important factors to keep in mind:

1. Size and Capacity

One of the first considerations when choosing a Boxford lathe is the size and capacity that will meet your machining requirements. Determine the maximum diameter and length of the workpieces you anticipate working on. Choose a lathe with a swing over bed and distance between centers that comfortably accommodates your desired projects.

Consider the weight capacity of the lathe as well. This is important if you plan on working with heavier or larger workpieces. Opt for a lathe with a weight capacity that exceeds your heaviest anticipated workpiece to ensure stability and prevent strain on the machine.

Take into account the available space in your workshop as well. Ensure the selected lathe can fit comfortably in your workspace without compromising safety or hinder your ability to move around the machine.

2. Bed Construction and Stability

The construction of the lathe bed influences its stability and precision during machining. Boxford lathes are known for their robust and durable cast iron or steel beds. These materials provide superior stability, reduce vibrations, and ensure accurate machining results.

Consider the length of the lathe bed based on the projects you intend to undertake. Longer beds are beneficial for working on larger projects or creating longer turning profiles. However, if you mainly work on smaller pieces, a shorter bed may suffice and save space in your workshop.

Look for features such as dovetail or boxway construction, which enhance the stability and rigidity of the lathe. These features minimize backlash and improve the overall accuracy of your machining operations.

3. Available Accessories and Attachments

Boxford lathes offer a range of optional accessories and attachments that can enhance your machining capabilities. Consider the availability and compatibility of these accessories when choosing a lathe model.

Common accessories include chucks, steady rests, follow rests, and faceplates. These attachments expand the range of workpieces you can handle and allow for more versatile turning operations. Ensure that the lathe you select has compatibility with the specific accessories you may require.

Additionally, consider the ease of installation and removal of these accessories. Some lathes may require tools or additional setup time to attach or detach certain accessories, while others may offer quick-change systems for efficient and seamless transitions between different machining setups.

Conclusion

When considering purchasing a Boxford lathe, understanding the weight of the machine is crucial for transportation, workspace planning, and ensuring that it aligns with your machining needs. Boxford lathes are known for their high-quality construction and durability, which contribute to their weight. By considering the factors impacting the weight and carefully planning for transportation and installation, you can make an informed decision and set up your Boxford lathe for success in your workshop.

Key Takeaways: How Much Does a Boxford Lathe Weigh?

1. The weight of a Boxford lathe can vary depending on the model and specifications.

2. On average, a Boxford lathe can weigh anywhere from 500 to 1500 kilograms.

3. It’s important to consider the weight of a Boxford lathe when planning for transportation or installation.

4. The weight of a Boxford lathe can impact its stability and performance, so it’s essential to ensure that the lathe is properly supported.

5. When purchasing a Boxford lathe, it’s helpful to check the weight specifications provided by the manufacturer to determine the appropriate handling and setup requirements.

Frequently Asked Questions

Hello! Welcome to our FAQ section on the weight of a Boxford lathe. Here, we will answer some common questions related to the weight of a Boxford lathe, providing you with the information you need. Let’s get started!

1. Why is it important to know the weight of a Boxford lathe?

Knowing the weight of a Boxford lathe is important for a few reasons. Firstly, it helps with transportation and logistics, especially if you need to move or transport the lathe from one location to another. By understanding its weight, you can ensure that the proper equipment and resources are used for safe and successful transportation.

Secondly, knowing the weight of the lathe is vital for determining the load-bearing capacity of a floor or workbench where the lathe will be placed. This helps to prevent any structural damage or accidents due to an inadequate support system. Overall, understanding the weight of a Boxford lathe is essential for practical and safety reasons.

2. What factors contribute to the weight of a Boxford lathe?

The weight of a Boxford lathe is determined by various factors. The primary component influencing its weight is the size or model of the lathe. Different Boxford lathe models may have varying dimensions, additional features, or components, which can impact the overall weight. Generally, larger models with more robust constructions tend to weigh more.

In addition to size and model, the materials used in the construction of a Boxford lathe can contribute to its weight. Lathes made from denser materials, such as cast iron or steel, will generally weigh more than those made from lighter materials. The presence of additional accessories or attachments can also add to the overall weight of the lathe.

3. How can I determine the weight of a specific Boxford lathe model?

To determine the weight of a specific Boxford lathe model, it is best to consult the manufacturer’s specifications or documentation. Most manufacturers provide detailed information about their products, including the weight. These specifications can often be found on the manufacturer’s website, in product brochures, or through customer support channels.

If you are unable to find the weight information from official sources, you can also reach out to authorized dealers or distributors who work with Boxford lathes. They may have access to the necessary details or be able to provide an estimate based on their experience with the lathe models they sell.

4. Can I estimate the weight of a Boxford lathe based on its dimensions?

While it can be challenging to accurately estimate the weight of a Boxford lathe based solely on its dimensions, you can get a rough idea by considering the lathe’s overall size and construction. Typically, larger lathes with solid constructions will weigh more than smaller or lighter-duty models.

However, keep in mind that factors such as the specific materials used, additional accessories, and the design of the lathe can significantly influence its weight. For a precise weight measurement, it is always best to refer to the manufacturer’s information or consult with experts familiar with Boxford lathes.

5. Are there any safety precautions when handling a Boxford lathe due to its weight?

Yes, there are some safety precautions to consider when handling a Boxford lathe due to its weight. Firstly, ensure that you have an appropriate setup in terms of floor or workbench strength, capable of safely supporting the lathe’s weight. This helps prevent any accidents or structural damage.

When moving or transporting the lathe, use suitable lifting equipment and techniques to avoid strain or injury. If possible, enlist the help of others for assistance. It is crucial to follow proper lifting guidelines to protect yourself and the lathe from any potential damage during the process. Always prioritize safety when dealing with heavy machinery like a Boxford lathe.

Summary

So, how much does a Boxford lathe weigh? Well, it depends on the model and size. Boxford lathes can range from around 200 kilograms to over 900 kilograms. It’s important to know the weight to ensure safe handling and transportation.

If you’re thinking of getting a Boxford lathe, it’s crucial to consider the weight and make necessary arrangements for lifting and moving it. Remember, these lathes are heavy machines that require proper handling to avoid any accidents or damage. So, plan ahead and be prepared to handle the weight of a Boxford lathe properly.